GRUMPYVETTE?

Can you seize a seized engine?

I,M thinking seriously of buying a 350 thats been sitting outside for a long period of time... the motor ran before it was taken out, according to the seller, but the idiot left the lifter valley open and been rained on for 4-8 months...MINIMUM, I have taken the heads off... but I cannot turn the motor in the slightest. I undid the main caps still nothing... anyone have any ideas?

http://garage.grumpysperformance.co...ge-yard-engine-just-some-info.3183/#post-9403

(1) step one!

IF IT WON,T EASILY SPIN OVER THERE'S A REASON!

ITS YOUR JOB TO LOCATE THAT REASON, IT MIGHT BE BENT VALVES OR A BENT CONNECTING ROD< IT MAY BE RUST ON THE RINGS , THINK IT THROUGH AND...

DON,T USE THE BIGGER HAMMER APPROACH!

Id darn sure check for water in the oil pan sump oil and pull the oil pan and valve covers to look for obvious signs of physical damage before trying to rotate the crank assembly,

it should go without even mention that all the spark plugs will need to be removed from the engine to preclude any potential for trapped water or liquid trapped above the piston, like any rain water from providing the potential for a hydraulic lock preventing the engine from rotating,OR DAMAGING THE ENGINE, make sure you leave the plugs all out until the engine spins with little effort.

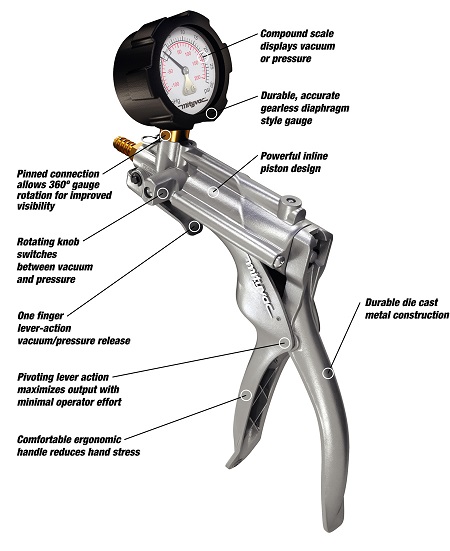

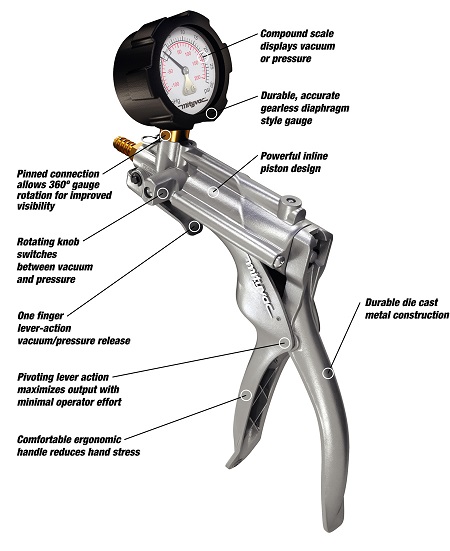

AND ITS ALSO A GOOD IDEA TO REMOVE THE ROCKER ARMS UNTILL THE ENGINE SPINS EASILY AND THAT THE ENGINE WILL REQUIRE A COMPLETE DIS-ASSEMBLY AND INSPECTION < THEN A GOOD CLEANING , POSSIBLY A CYLINDER HONE,OR RE-BORE TO GET THE CYLINDER WALLS REPAIRED, AND CAREFUL REASSEMBLY WITH NEW RINGS, BEARINGS, VALVE TRAIN COMPONENTS ETC. AND GASKETS BEFORE BEING RUN, the tools you use to bleed brakes can be useful in removing trapped fluids in a cylinder in a seized engine that was left outside in the rain, especially if the piston in the seized cylinder is well down the bore and there's considerable fluid trapped in the cylinder.

http://www.mityvac.com/pages/products_hvp.asp

http://www.aaawholesalecompany.com/bem-484410-pk.html

NOTICE THEY COME 12 to a carton and cost about $40 a dozen so get two buddies to split the cost

medical supplys can be useful in providing supplies for bleeding brakes, or removing fluids from cylinders without getting those fluids sucked into the tool providing the suction, one vinyl tube in the cylinder leading to the container and a second providing the negative or vacuum to the container

Use of a long reach air nozzle, and high pressure air can be very useful,and the nozzle pushed deep into the cylinder to provide a jet of 130 psi air to force out

any remaining trapped liquid in that cylinder is a mandatory check before you add any solvents or penetrating oils into the cylinder simply because oil floats on water so failure to remove the water will prevent the penetrating oil from reaching the rings

MY ANSWER HERE APPLIES TO THE GENERAL SUBJECT AS A GUIDE.....PEOPLE seldom pull running engines and throw them in the back yard if they think they can be rebuilt , so obviously the first logical step is close detailed inspection, that requires pulling the oil pan to check for busted parts in the lower engine rotating assembly,to determine if its just pistons locked in bores or something worse like a bent connecting rod as the cause, and pulling the heads and closely inspecting both the heads and the pistons and bores,, and Id HIGHLY advise complete dis-assembly to do that to determine its true condition RATHER than trying to free it up by physically forcing it to rotate.

if the engine was only out in the weather for a few days, or the engine had been stored properly, Id suggest lots of marvel mystery oil in the engines spark plug holes and a fresh oil and oil filter change, plus an oil change,after you get it running for 20 minutes or so, to flush out the loose crud. but sitting with rain water in the engine for 3 plus months or more in rain waters a totally different deal,

If he left it exposed that long theres an excellent chance its been sitting with significant amounts or water from rain, in the engine, bearings, rusting the crank, and valve train and rotating assembly, that easily over time destroys bearings, rings bore surfaces etc, first make sure the main caps are replaced and stamped so you know EXACTLY where they go and which direction they face, the lifters and cam are 99% sure to be trash as are the rings

keep in mind that any time you remove main caps or connecting rods you need to STAMP and NUMBER them , and the BLOCK showing location and direction the parts face, BEFORE dis-assembly, aluminum pistons with iron rings that have been sitting in rain water will be badly corroded in a few months time

viewtopic.php?f=50&t=1738&p=4333&hilit=stamp+number#p4333

(2)step two

no mater what you do the engine has seized that usually means the rings and/or pistons are locked in the bores so even if you were to free them up with oil theres an excellent chance the rings, pistons cam lobes and lifters and lifter bores are rusted, pitted and damaged, your best course of action is to take the block to a good local machine-shop for dis-assembly, cleaning and inspection, if your really lucky a good cleaning and hone of the lifter bores, main bearing surfaces and cylinders might result in reusable block, , possibly the crank and rods can be reused after careful cleaning but the cost/vs value of the parts involved usually means the block is the only salvageable part that should be saved and probably will need to be re-bored.

a machine shop has access to caustic solvents heat and vibration tools that can free up a seized engine but bearings and pistons are frequently trash after their use!

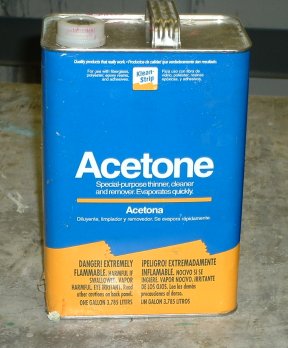

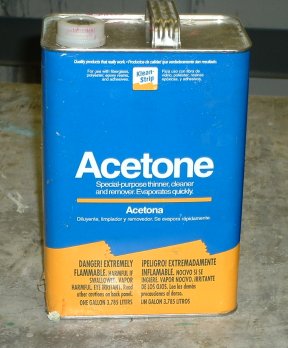

yes if the heads are still on the engine, you can squirt a mix of 30% MARVEL MYSTERY OIL, 30% acetone and 40% diesel fuel into the cylinder thru the spark plug holes and let it sit 24-36 hours, ITS THE MMO AND ACETONE MIX THAT DO THE WORK, THE DIESEL FUEL JUST ADD VOLUME,and provides a bit more fluid too loosen and penetrate, the rings and bearings clearances,and flush and hold in suspension micro trash..

the mix is thin enough in viscosity to penetrate into the micro cracks in piston ring, and piston grooves full of rust & corrosion, don,t forget to pour some of the mix on the valve train as its most likely rusted, or if your in a bit of a hurry squirt all the cylinder's as full as you can get them with that mixture then get out the threaded spark plug adapter hose from your compression test kit, use it on each cylinder connected to your air compressor,

and on one cylinder at a time apply 100 psi of DRY air pressure above the piston and let the pressure force the acetone thinned lubricant mix past the rings in each cylinder in turn for at least 30 minutes on each cylinder don,t get in a rush the mix lube works but usually takes 24-36 hours to soak into cracks and free rings in piston grooves, Id add more every 8-12 hours if you can,and don,t try to turn the engine, AND/or apply air pressure with the compression test adapter threaded into where spark plugs go into in the engine ,

and on one cylinder at a time apply 100 psi of DRY air pressure above the piston and let the pressure force the acetone thinned lubricant mix past the rings in each cylinder in turn for at least 30 minutes on each cylinder don,t get in a rush the mix lube works but usually takes 24-36 hours to soak into cracks and free rings in piston grooves, Id add more every 8-12 hours if you can,and don,t try to turn the engine, AND/or apply air pressure with the compression test adapter threaded into where spark plugs go into in the engine ,

then repeat,application of the acetone /MMO mix, as it is thin viscosity and penetrates very small fissures easily drawing more in with each repeated cycle

http://www.plews-edelmann.com/oil-cans-and-oilers/

remember to change your oil before running the engine as some of the lubricant mix will seep into the crank case past the rings , and theres also several types of penetrating oil, you could squirt into every opening and let it sit as it soaks into the cracks, for a few days then possibly free up the rotating assembly with a long breaker bar , or remove the heads and use a section of 4"x4" wood and a hammer to free up pistons, in really stubborn cases AFTER ITS SOAKED FOR SEVERAL DAYS IN LUBE, but its generally going to result in at least minor micro damaged the bores, surface and it could result in cracked pistons or broken rings, if its that well rusted ,rings or pistons are not designed to be hammered loose, and even if it works the engines unlikely to run without durability issues. your local machine shop should be able to give a good inspection and point to either its potential re-use or trashing the block.

(3)

step three

given that the cost of doing the cleanup and inspection work is very likely to exceed what the machine shop charges for a basic useable block I would rarely bother even looking into the cost if its a two bolt block. so in most cases its now either a good bare block after the machine-shop, dis-assembles , cleans and inspects it, or its junk, it would be RARE to find any part but the block, oil pan, and basic bare heads (that need rebuilding) timing cover, valve covers flywheel, water pump ,reusable after clean-up, the rotating assembly and valve train are very likely not TRASH, the crank MIGHT be salvageable but its not likely unless its journals are cut undersize

RELATED THREADS

keep in mind a properly stored engine won,t seize up even after,10-15 years in storage, if you first replace the old oil with clean oil, begin by backing off the rockers,making sure the batterys disconnected and coolants drained, and taking out the spark plugs and squirting marvel mystery oil in the cylinder then putting anti seize on the plug threads, before re-installing them, and placing the engine in a dry and reasonably warm enviroment for years

http://www.seized-engine.com/

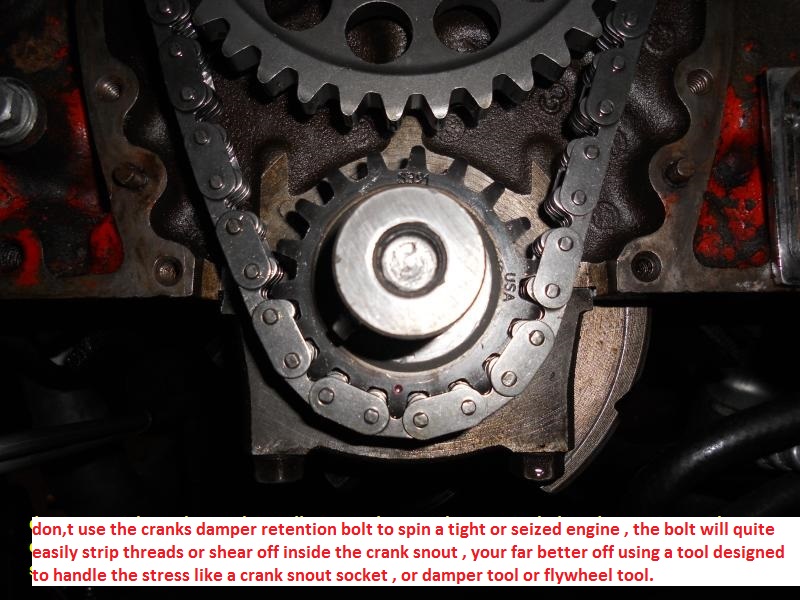

use of a starter to try and spin a seized engine or a breaker bar on the damper bolt is generally a very poor idea!

damper bolts twist off in cranks very easily and starters can easily bust piston rings or piston grooves

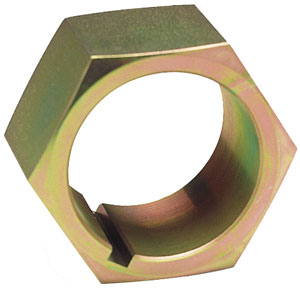

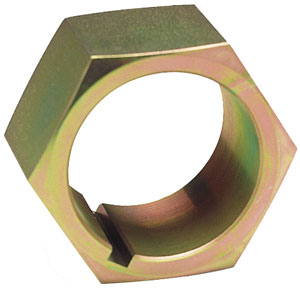

ways to turn over the engine WITHOUT the starter, and if you get the correct tool it hold the degree wheel properly also

http://www.summitracing.com/search/?key ... cket&dds=1

http://www.summitracing.com/parts/PRO-67492/

http://www.summitracing.com/parts/PRO-67491/

theres large bolts for your ballancer

theres crank sockets

Crankshaft Socket Tool For turning AND MOUNTING Degree Wheels

CRANK NUTS

crank rotators

flywheel turning tools

BTW I assume you gentlemen do know theres

even a correct and very inexpensive tool for spinning it from the flex-plate or flywheel,

once the cylinder heads are installed,

so your not stressing the damper retention bolt spinning the engine over manually,

https://www.summitracing.com/parts/wmr-w80510/overview/

https://www.summitracing.com/parts/sum-900178/overview/

viewtopic.php?f=50&t=611&p=812&hilit=+balancer+timing#p812

http://garage.grumpysperformance.co...ge-yard-engine-just-some-info.3183/#post-9403

Can you seize a seized engine?

I,M thinking seriously of buying a 350 thats been sitting outside for a long period of time... the motor ran before it was taken out, according to the seller, but the idiot left the lifter valley open and been rained on for 4-8 months...MINIMUM, I have taken the heads off... but I cannot turn the motor in the slightest. I undid the main caps still nothing... anyone have any ideas?

http://garage.grumpysperformance.co...ge-yard-engine-just-some-info.3183/#post-9403

(1) step one!

IF IT WON,T EASILY SPIN OVER THERE'S A REASON!

ITS YOUR JOB TO LOCATE THAT REASON, IT MIGHT BE BENT VALVES OR A BENT CONNECTING ROD< IT MAY BE RUST ON THE RINGS , THINK IT THROUGH AND...

DON,T USE THE BIGGER HAMMER APPROACH!

Id darn sure check for water in the oil pan sump oil and pull the oil pan and valve covers to look for obvious signs of physical damage before trying to rotate the crank assembly,

it should go without even mention that all the spark plugs will need to be removed from the engine to preclude any potential for trapped water or liquid trapped above the piston, like any rain water from providing the potential for a hydraulic lock preventing the engine from rotating,OR DAMAGING THE ENGINE, make sure you leave the plugs all out until the engine spins with little effort.

AND ITS ALSO A GOOD IDEA TO REMOVE THE ROCKER ARMS UNTILL THE ENGINE SPINS EASILY AND THAT THE ENGINE WILL REQUIRE A COMPLETE DIS-ASSEMBLY AND INSPECTION < THEN A GOOD CLEANING , POSSIBLY A CYLINDER HONE,OR RE-BORE TO GET THE CYLINDER WALLS REPAIRED, AND CAREFUL REASSEMBLY WITH NEW RINGS, BEARINGS, VALVE TRAIN COMPONENTS ETC. AND GASKETS BEFORE BEING RUN, the tools you use to bleed brakes can be useful in removing trapped fluids in a cylinder in a seized engine that was left outside in the rain, especially if the piston in the seized cylinder is well down the bore and there's considerable fluid trapped in the cylinder.

http://www.mityvac.com/pages/products_hvp.asp

http://www.aaawholesalecompany.com/bem-484410-pk.html

NOTICE THEY COME 12 to a carton and cost about $40 a dozen so get two buddies to split the cost

medical supplys can be useful in providing supplies for bleeding brakes, or removing fluids from cylinders without getting those fluids sucked into the tool providing the suction, one vinyl tube in the cylinder leading to the container and a second providing the negative or vacuum to the container

Use of a long reach air nozzle, and high pressure air can be very useful,and the nozzle pushed deep into the cylinder to provide a jet of 130 psi air to force out

any remaining trapped liquid in that cylinder is a mandatory check before you add any solvents or penetrating oils into the cylinder simply because oil floats on water so failure to remove the water will prevent the penetrating oil from reaching the rings

MY ANSWER HERE APPLIES TO THE GENERAL SUBJECT AS A GUIDE.....PEOPLE seldom pull running engines and throw them in the back yard if they think they can be rebuilt , so obviously the first logical step is close detailed inspection, that requires pulling the oil pan to check for busted parts in the lower engine rotating assembly,to determine if its just pistons locked in bores or something worse like a bent connecting rod as the cause, and pulling the heads and closely inspecting both the heads and the pistons and bores,, and Id HIGHLY advise complete dis-assembly to do that to determine its true condition RATHER than trying to free it up by physically forcing it to rotate.

if the engine was only out in the weather for a few days, or the engine had been stored properly, Id suggest lots of marvel mystery oil in the engines spark plug holes and a fresh oil and oil filter change, plus an oil change,after you get it running for 20 minutes or so, to flush out the loose crud. but sitting with rain water in the engine for 3 plus months or more in rain waters a totally different deal,

If he left it exposed that long theres an excellent chance its been sitting with significant amounts or water from rain, in the engine, bearings, rusting the crank, and valve train and rotating assembly, that easily over time destroys bearings, rings bore surfaces etc, first make sure the main caps are replaced and stamped so you know EXACTLY where they go and which direction they face, the lifters and cam are 99% sure to be trash as are the rings

keep in mind that any time you remove main caps or connecting rods you need to STAMP and NUMBER them , and the BLOCK showing location and direction the parts face, BEFORE dis-assembly, aluminum pistons with iron rings that have been sitting in rain water will be badly corroded in a few months time

viewtopic.php?f=50&t=1738&p=4333&hilit=stamp+number#p4333

(2)step two

no mater what you do the engine has seized that usually means the rings and/or pistons are locked in the bores so even if you were to free them up with oil theres an excellent chance the rings, pistons cam lobes and lifters and lifter bores are rusted, pitted and damaged, your best course of action is to take the block to a good local machine-shop for dis-assembly, cleaning and inspection, if your really lucky a good cleaning and hone of the lifter bores, main bearing surfaces and cylinders might result in reusable block, , possibly the crank and rods can be reused after careful cleaning but the cost/vs value of the parts involved usually means the block is the only salvageable part that should be saved and probably will need to be re-bored.

a machine shop has access to caustic solvents heat and vibration tools that can free up a seized engine but bearings and pistons are frequently trash after their use!

yes if the heads are still on the engine, you can squirt a mix of 30% MARVEL MYSTERY OIL, 30% acetone and 40% diesel fuel into the cylinder thru the spark plug holes and let it sit 24-36 hours, ITS THE MMO AND ACETONE MIX THAT DO THE WORK, THE DIESEL FUEL JUST ADD VOLUME,and provides a bit more fluid too loosen and penetrate, the rings and bearings clearances,and flush and hold in suspension micro trash..

the mix is thin enough in viscosity to penetrate into the micro cracks in piston ring, and piston grooves full of rust & corrosion, don,t forget to pour some of the mix on the valve train as its most likely rusted, or if your in a bit of a hurry squirt all the cylinder's as full as you can get them with that mixture then get out the threaded spark plug adapter hose from your compression test kit, use it on each cylinder connected to your air compressor,

then repeat,application of the acetone /MMO mix, as it is thin viscosity and penetrates very small fissures easily drawing more in with each repeated cycle

http://www.plews-edelmann.com/oil-cans-and-oilers/

remember to change your oil before running the engine as some of the lubricant mix will seep into the crank case past the rings , and theres also several types of penetrating oil, you could squirt into every opening and let it sit as it soaks into the cracks, for a few days then possibly free up the rotating assembly with a long breaker bar , or remove the heads and use a section of 4"x4" wood and a hammer to free up pistons, in really stubborn cases AFTER ITS SOAKED FOR SEVERAL DAYS IN LUBE, but its generally going to result in at least minor micro damaged the bores, surface and it could result in cracked pistons or broken rings, if its that well rusted ,rings or pistons are not designed to be hammered loose, and even if it works the engines unlikely to run without durability issues. your local machine shop should be able to give a good inspection and point to either its potential re-use or trashing the block.

(3)

step three

given that the cost of doing the cleanup and inspection work is very likely to exceed what the machine shop charges for a basic useable block I would rarely bother even looking into the cost if its a two bolt block. so in most cases its now either a good bare block after the machine-shop, dis-assembles , cleans and inspects it, or its junk, it would be RARE to find any part but the block, oil pan, and basic bare heads (that need rebuilding) timing cover, valve covers flywheel, water pump ,reusable after clean-up, the rotating assembly and valve train are very likely not TRASH, the crank MIGHT be salvageable but its not likely unless its journals are cut undersize

RELATED THREADS

keep in mind a properly stored engine won,t seize up even after,10-15 years in storage, if you first replace the old oil with clean oil, begin by backing off the rockers,making sure the batterys disconnected and coolants drained, and taking out the spark plugs and squirting marvel mystery oil in the cylinder then putting anti seize on the plug threads, before re-installing them, and placing the engine in a dry and reasonably warm enviroment for years

http://www.seized-engine.com/

use of a starter to try and spin a seized engine or a breaker bar on the damper bolt is generally a very poor idea!

damper bolts twist off in cranks very easily and starters can easily bust piston rings or piston grooves

ways to turn over the engine WITHOUT the starter, and if you get the correct tool it hold the degree wheel properly also

http://www.summitracing.com/search/?key ... cket&dds=1

http://www.summitracing.com/parts/PRO-67492/

http://www.summitracing.com/parts/PRO-67491/

theres large bolts for your ballancer

theres crank sockets

Crankshaft Socket Tool For turning AND MOUNTING Degree Wheels

CRANK NUTS

crank rotators

flywheel turning tools

BTW I assume you gentlemen do know theres

even a correct and very inexpensive tool for spinning it from the flex-plate or flywheel,

once the cylinder heads are installed,

so your not stressing the damper retention bolt spinning the engine over manually,

https://www.summitracing.com/parts/wmr-w80510/overview/

https://www.summitracing.com/parts/sum-900178/overview/

viewtopic.php?f=50&t=611&p=812&hilit=+balancer+timing#p812

http://garage.grumpysperformance.co...ge-yard-engine-just-some-info.3183/#post-9403

Last edited by a moderator: