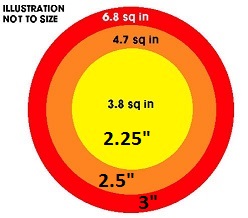

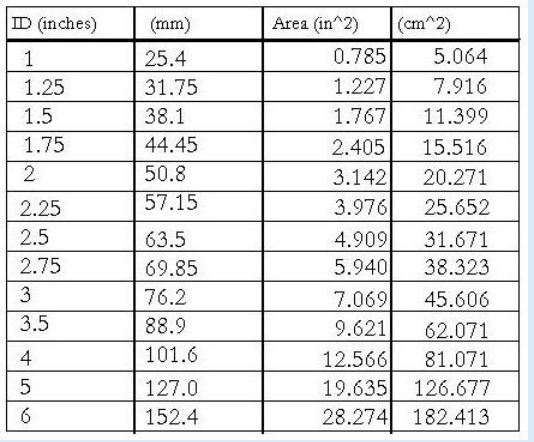

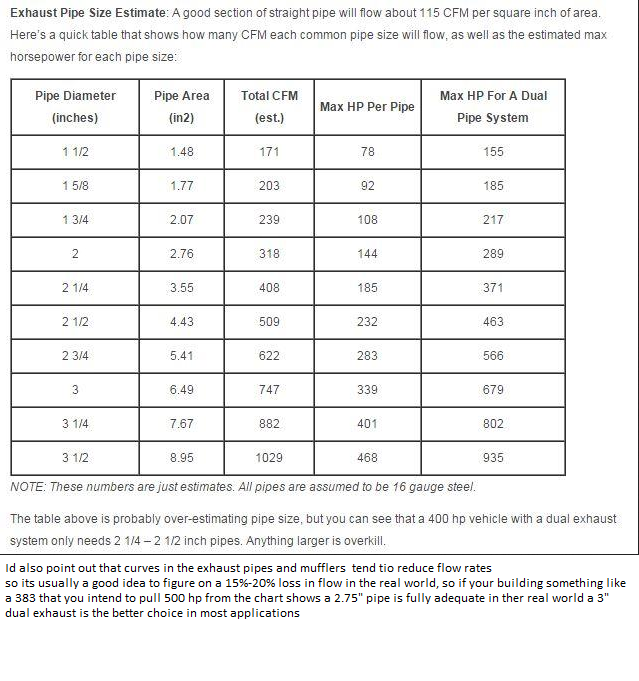

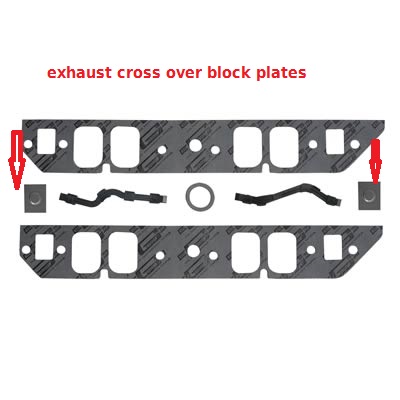

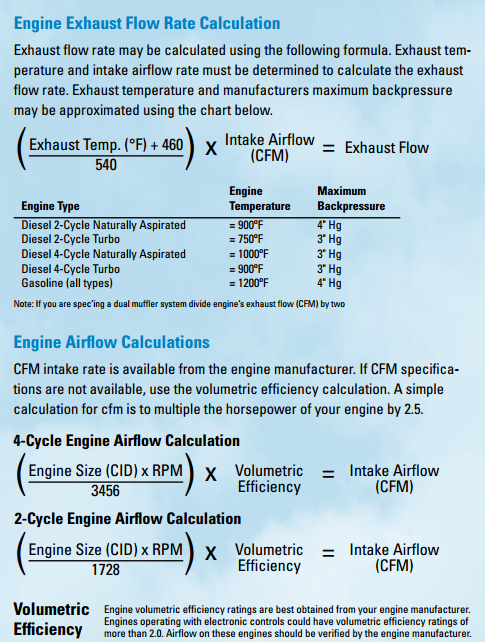

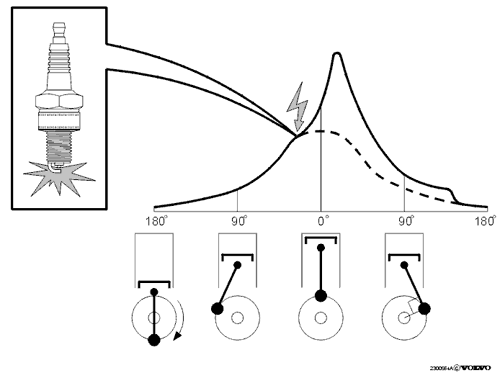

it helps a great deal to know what your working with ,ID suggest starting, by verifying TDC and having the correct timing tape on your damper then,start with 8 degrees btdc and verifying the full advance of 36 degrees total is all in at 3200rpm as a base line, once youve got that, as a standard you can tune and run the car and eventually try tweaks to the basic ignition curve if needed, once you have an ignition base line, move on to the carbs tuning, you also need to keep in mind that what goes in as a fuel /air mix needs to go out as a much expended volume of hot gases and a restrictive exhaust will effectively block most attempts to get more power from an engine, so measure exhaust back pressure. you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

you might be amazed at what a few tests with a fuel pressure gauge can tell you ILL point out a few factors a fuel/air ratio gauge is a big help as is an INFRARED TEMP GUN,

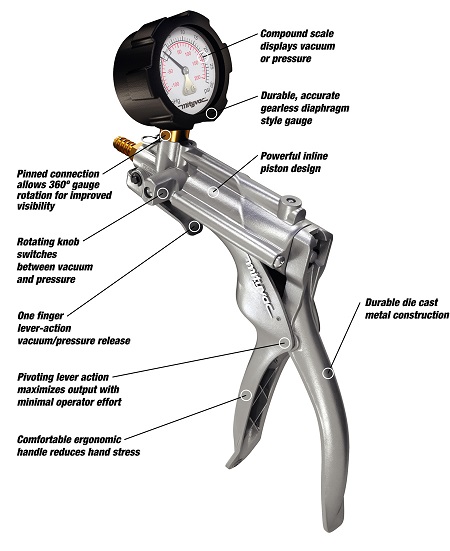

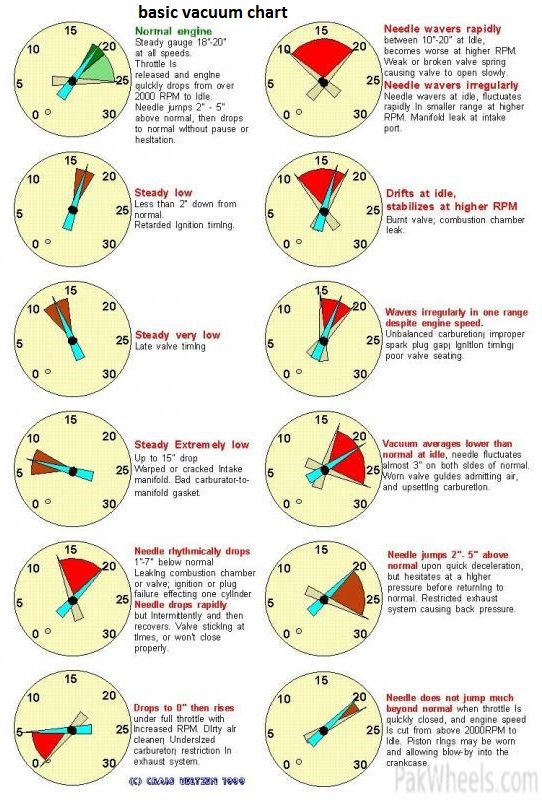

be very sure to verify the plenum vacuum and exhaust back pressure, as both vacuum leaks and clogged exhausts or clogged catalytic converters are a frequent source of problems

GET A FUEL PRESSURE GAUGE AND MEASURE DON,T GUESS

how can you possibly set up your fuel system unless you know the pressure and flow rates required and what currently exist's

RELATED INFO

A couple days of

reading the linked and sub-linked info

could save you a great deal of wasted time and money

and money spent on wrong or un-necessary parts

read the links and sub links below

a day or so spent doing reading and research,

(reading links and threads)

will frequently save you thousands of dollars and weeks of wasted work.

if you want a fast dependable car you will need to either do the research required to know exactly how and why things should work, or pay someone else to do the work that has taken that time and effort.

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.com/index.php?threads/how-big-a-fuel-pump-do-you-need.1939/

http://garage.grumpysperformance.co...ss-fuel-pressure-regulators.12776/#post-65998

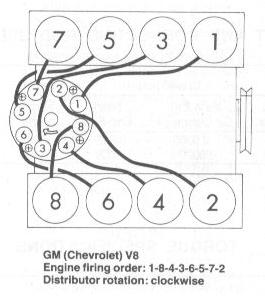

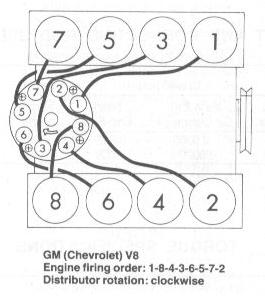

you might be amazed at the number of times "CARBURETOR PROBLEMS" are cured with getting the IGNITION, TIMING AND ADVANCE CURVE WORKING CORRECTLY, and check out the simply things your 100% sure you did correctly, because I can,t begin to tell you how many times I see guys who have the firing order on the ignition wrong, or guys that install a 4/7 swap cam and still use the standard ignition firing order or guys that never verify TDC and ignition advance curves.

get an IR temp gun and check for wild variations in exhaust temps, get a compression test done, do a logical check to verify each cylinder fires etc.

Ive found its a whole lot faster to use a quality IR temp gun, to locate a individual cylinder that's mis-firing as it tends to run significantly cooler than adjacent cylinders, or hotter if its a vacuum leak at times, as lean F/A mixes tend to run hotter

(Ive used this one for years)

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

many temp guns don,t read high enough or accurately enough

http://www.professionalequipment.com/ex ... ermometer/

that you can use on the engine to check ALL 8 exhaust temps, individually, this quickly locates plugged injectors or vacuum leaks ETC

Wide temperature range from -58 to 1832°F

when selecting an IR gun for automotive use, you really want to be able to read from 0 F deg-about 1400F deg. to cover most conditions you'll test for

READ THRU THESE RELATED LINKs YES I KNOW YOULL WANT TO SKIP OVER THEM< BUT YOULL MISS A GREAT DEAL OF INFO DOING SO!

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=5229

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1639

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1790

viewtopic.php?f=56&t=495&p=613#p613

download/file.php?id=1710

http://autospeed.com/cms/A_111456/article.html

http://www.innovatemotorsports.com/products/lm2.php

http://www.vintagemusclecarparts.com/pa ... seat1.html

http://www.holley.com/data/TechService/ ... 20Info.pdf

http://www.thecarburetorshop.com/Troubleshooting.htm

http://members.tccoa.com/392bird/tuning.htm

http://www.edelbrock.com/automotive_new ... vids.shtml

http://www.international-auto.com/fiat- ... gauges.cfm

http://www.summitracing.com/expertadviceandnews/calcsandtools/cfm-calculator

http://www.thecarburetorshop.com/Troubl ... rdstarthot

www.youtube.com

www.youtube.com

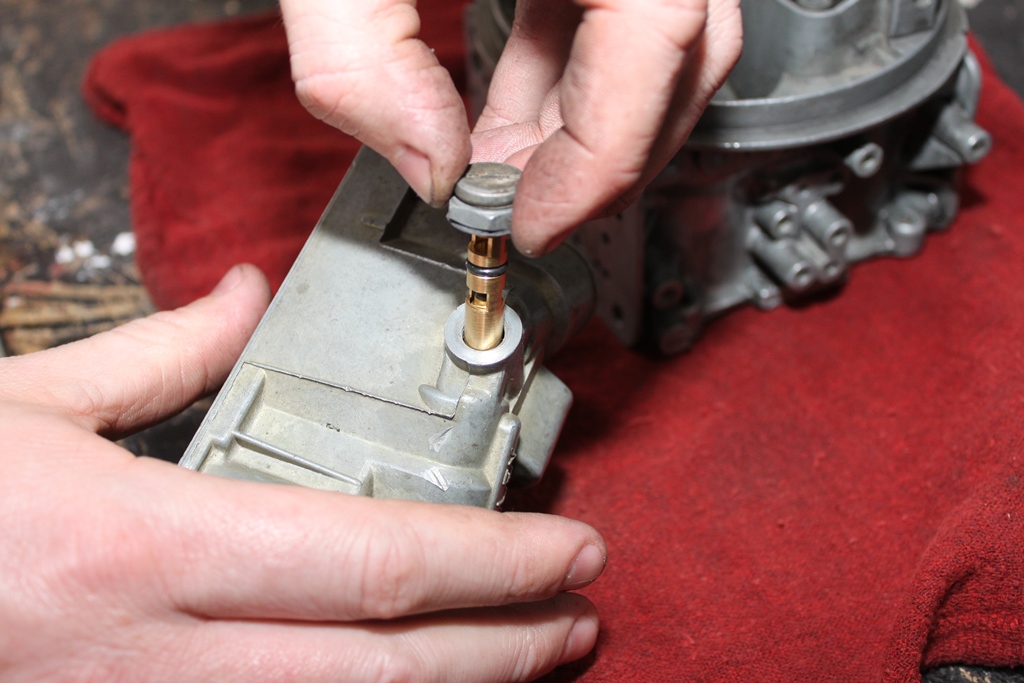

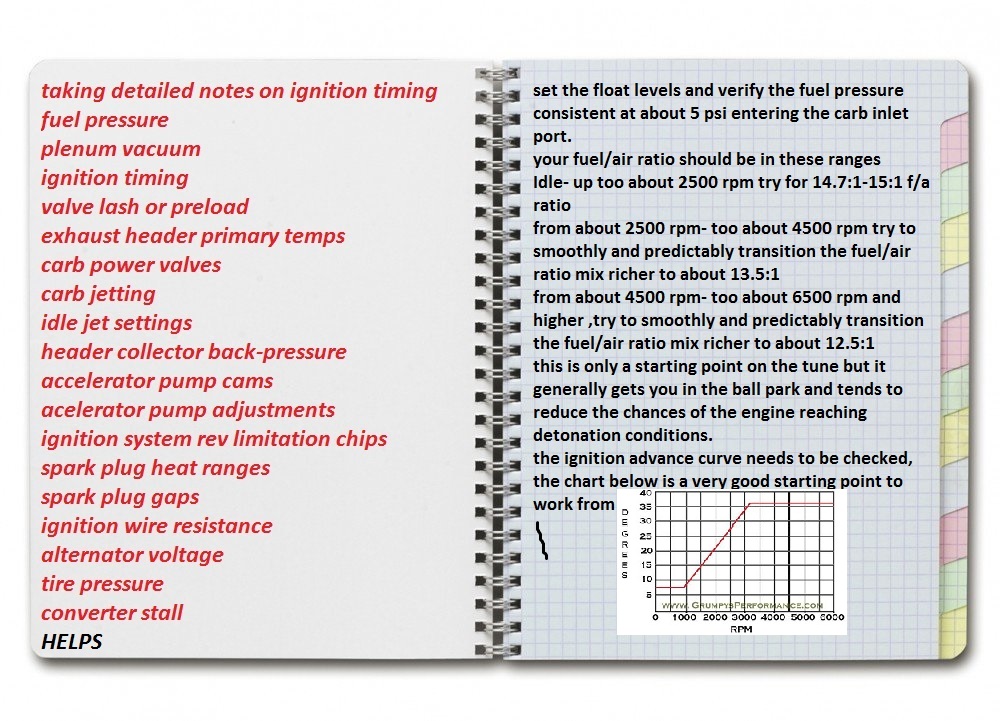

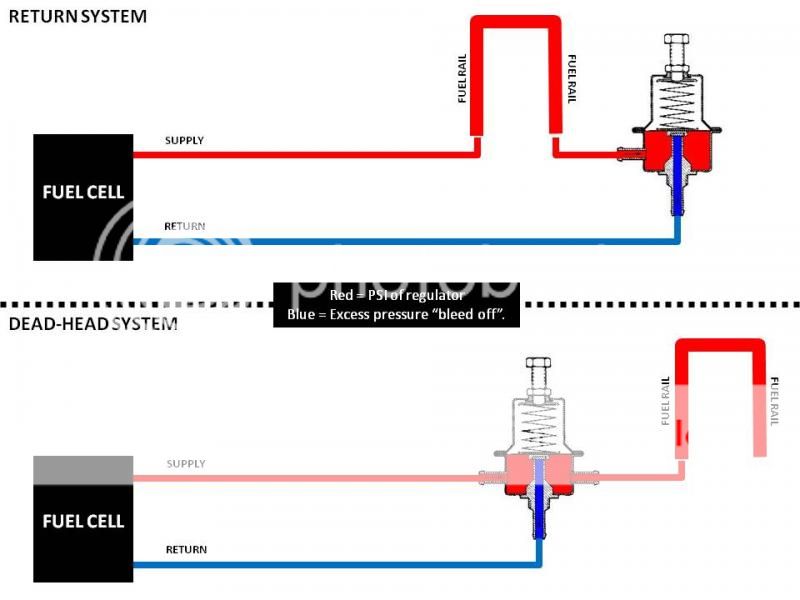

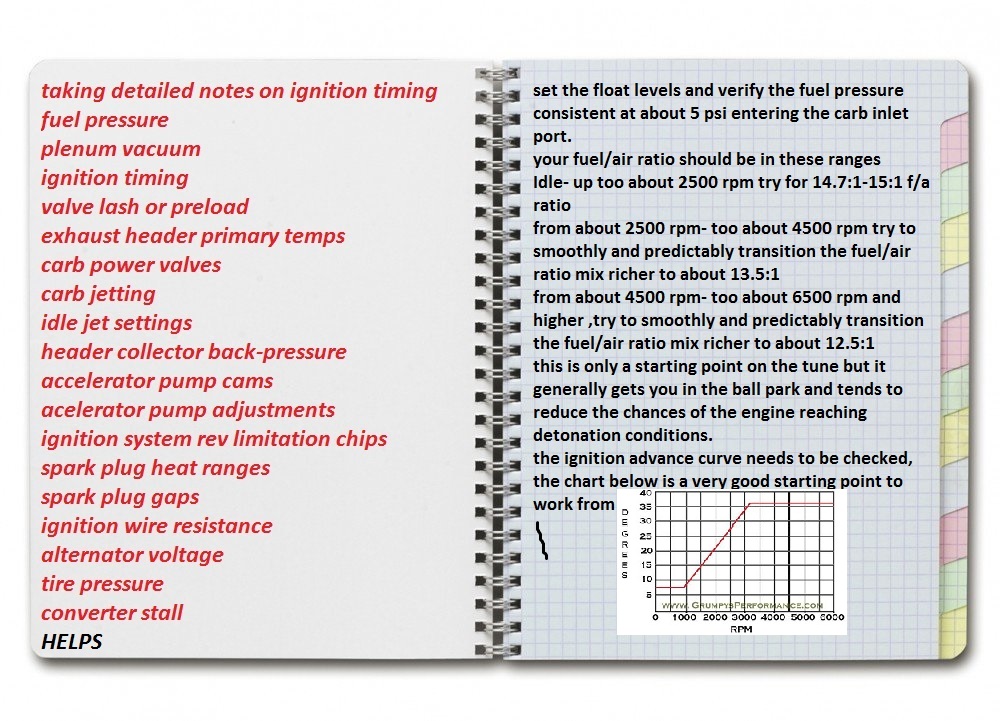

set the float levels and verify the fuel pressure consistent at about 5 psi entering the carb inlet port.

below you'll find a good base line starting point,

and Id suggest you monitor coolant and oil temps,

try hard to keep coolant temp under 200F and oil temp under 220F

verify your fuel delivery pressure is consistent over the whole rpm range

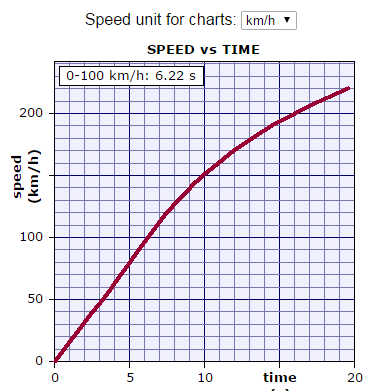

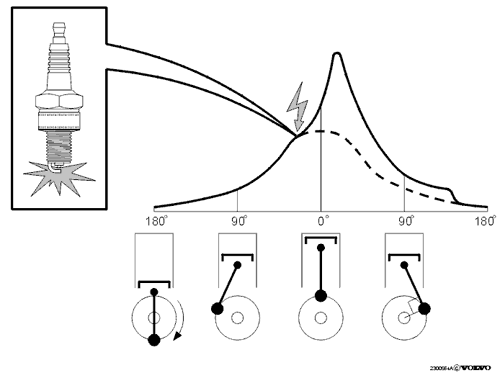

take the time to graph out and verify your ignition advance curve!

a good IR temp gun to use on the header primary tubes helps locate fuel/air ratio inconsistency's

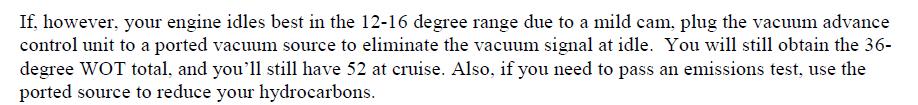

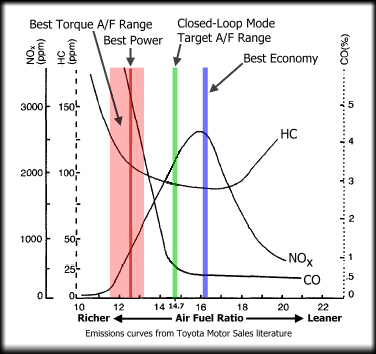

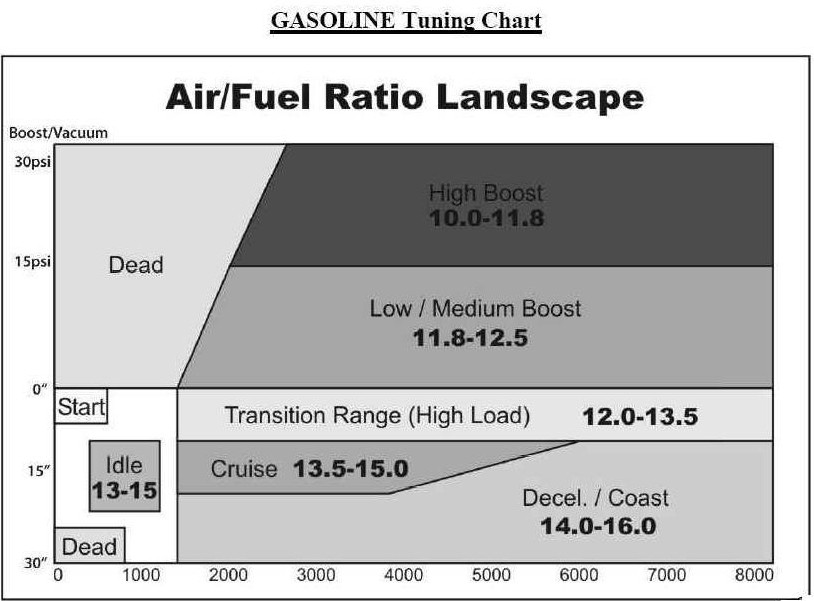

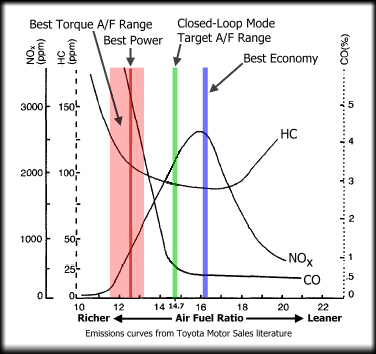

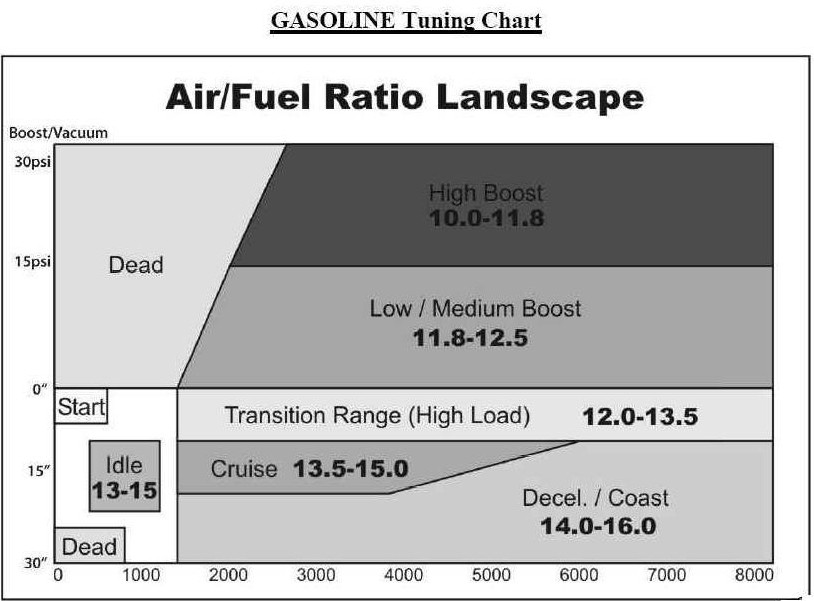

GENERALLY your fuel/air ratio should be in these ranges

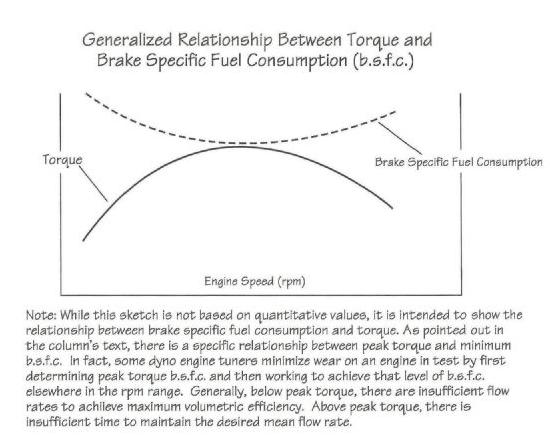

Idle- up too about 2500 rpm try for 14.7:1-15:1 f/a ratio,

too get max mileage and prevent spark plug fouling

from about 2500 rpm- too about 4500 rpm,

try to smoothly and predictably transition the fuel/air ratio mix richer to about 13.5:1

for good power and less chance of detonation

from about 4500 rpm- too about 6500 rpm and higher

,try to smoothly and predictably transition the fuel/air ratio mix richer to about 12.5:1,

for good peak power and less chance of detonation.

this is only a well proven starting point on the tune,

but it generally gets you in the ball park ,

and tends to reduce the chances of the engine reaching detonation conditions.

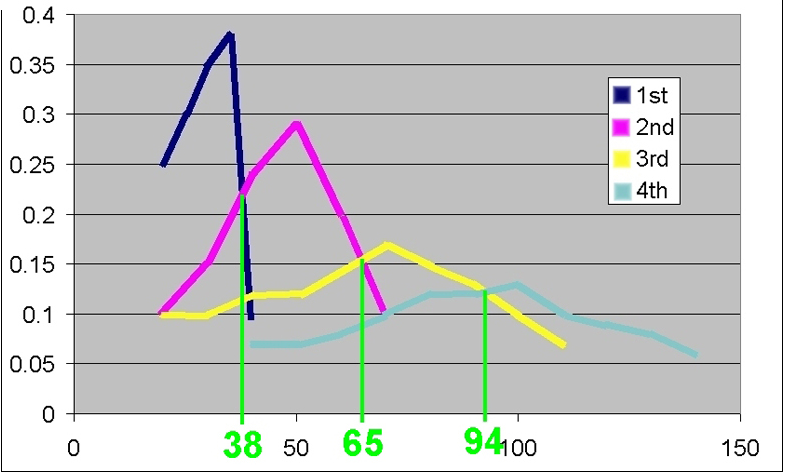

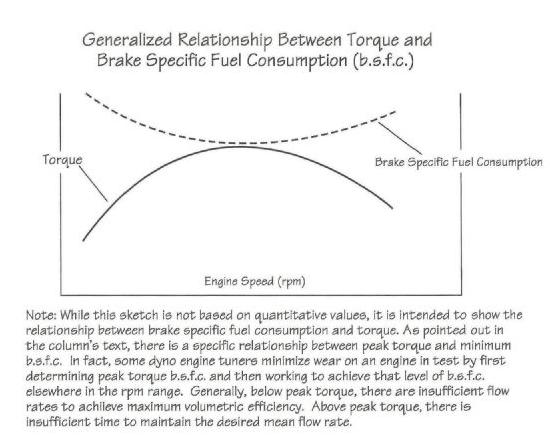

the ignition advance curve needs to be checked, the chart below is a very good starting point to work from, and USE OF A RICHER FUEL/AIR MIX, WILL AT TIMES BE REQUIRED IN THE OFF IDLE TO 3500 rpm range, but the idea here is to keep the lower rpm and lower stress operations running at efficient fuel/air ratios to reduce plug fouling and improve mileage as youll generally spend 90% of the cars operational life on the street at under 4500 rpm.

set the plug gaps at about .045, make sure the valves are adjusted correctly

WHEN TESTING<be sure the fuel pressure gauge reads correctly by comparing it to a second test gauge, these fuel pressure gauges are frequently defective

watch this

without testing you simply guessing

http://garage.grumpysperformance.com/index.php?threads/drop-back-to-basics.12943/#post-67323

http://garage.grumpysperformance.co...hink-logically-don-t-assume.12484/#post-62772

http://garage.grumpysperformance.co...-test-seems-to-be-a-forgotten-art-form.11838/

http://garage.grumpysperformance.com/index.php?threads/carb-tuning-info-and-links.109/

having a few basic meters,gauges etc.

IT sure helps too have basic tools, when isolating issues

MULTI METER

INFRARED TEMP GUN

TIMING LIGHT

COMPRESSION GAUGE

PRESSURE/VACUUM GAUGE

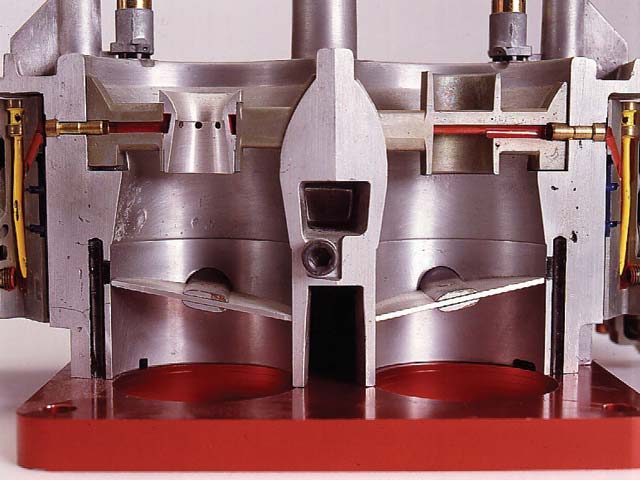

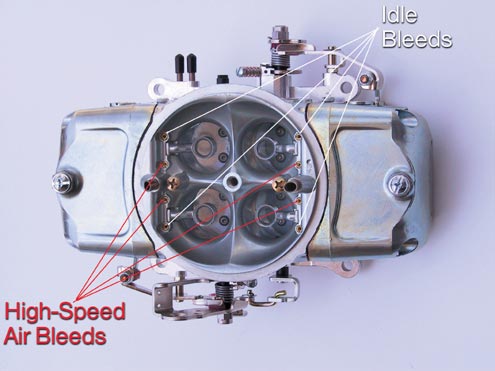

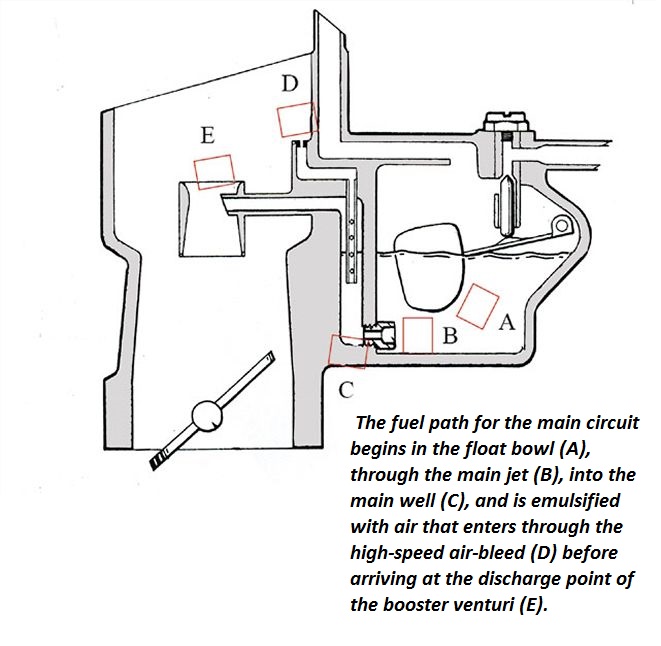

http://garage.grumpysperformance.com/index.php?threads/holley-annular-vs-down-leg-boosters.5229/

btw

before you get crazy chasing some problem your sure is an intermittent fuel delivery issue

(1) Do a compression test!

(2) verify your ignition advance curve, and verify the ignition systems working correctly , the spark plugs are new, properly gaped and the ignition wires in excellent condition visually and with an OHMS meter.

(3) adjust your valves, correctly

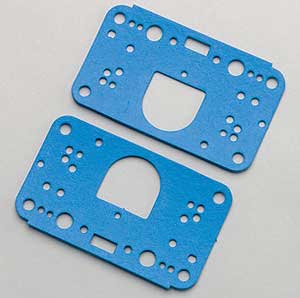

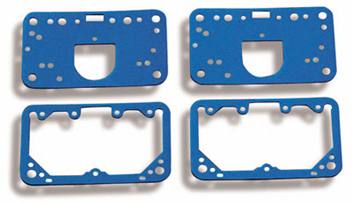

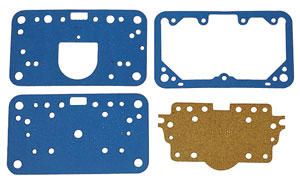

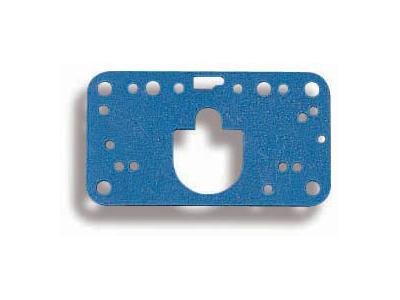

(4) carefully verify theres no vacuum leaks, in lines or gaskets

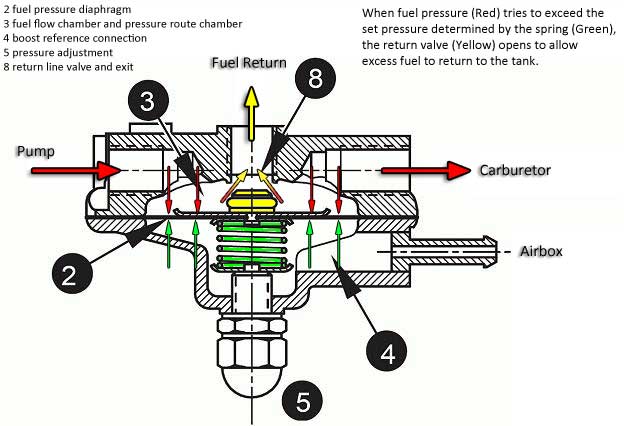

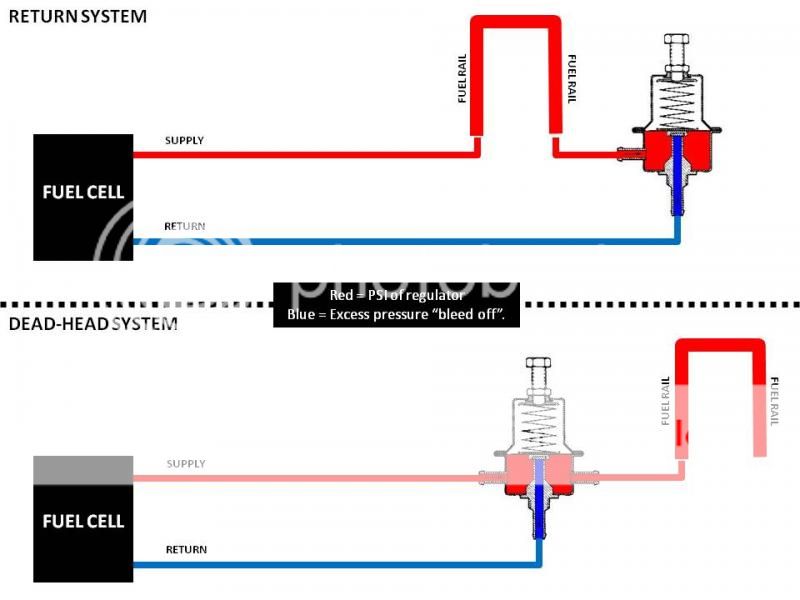

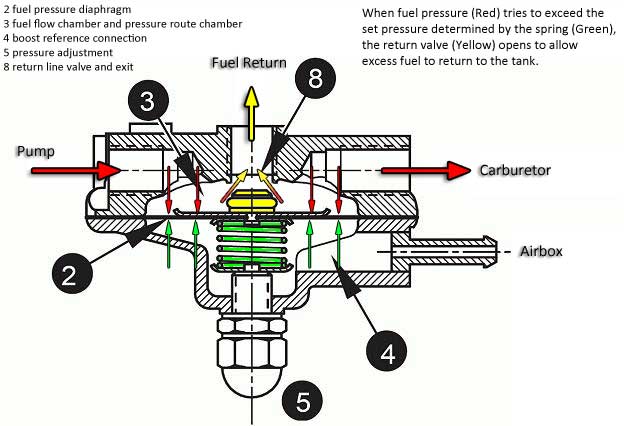

(5)Check the fuel delivery system, WITH A GAUGE, while the engines under real operational inertial loads to verify you have a consistent 5-6 psi at the carburetor inlet port

(6) change out the fuel and air filters, especially if over 3-4 months old

(7) actually check your exhaust back-pressure levels

(8) verify your return style fuel pressure regulator and fuel lines function as intended

(9)verify your using FRESH FUEL WITHOUT MOISTURE OR PARTICULAR CONTAMINANTS

(10) actually look for and read installation instructions and rated flow and pressure limitations on fuel pumps and filters

(11) If ALL of the above are normal, only then start looking at the carburetor, and tuning issues

READ THE LINK

viewtopic.php?f=50&t=268&p=18435#p18435

a few hours spent reading links and sub links should help

viewtopic.php?f=50&t=268&p=18434&hilit=wide+band#p18434

viewtopic.php?f=27&t=3096&p=18612&hilit=wide+band#p18612

viewtopic.php?f=32&t=6011&p=18597#p18597

viewtopic.php?f=57&t=4974&p=13868&hilit=infrared#p13868

read these links

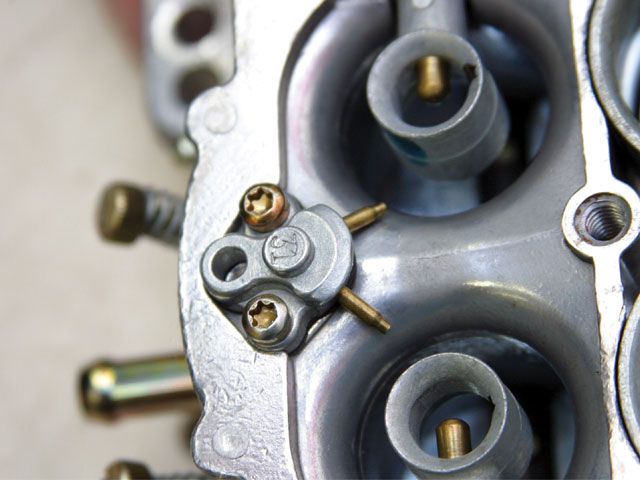

http://garage.grumpysperformance.com/index.php?threads/holley-air-bleed-jets-related.11859/

viewtopic.php?f=55&t=1790&p=4544#p4544

viewtopic.php?f=70&t=1809

viewtopic.php?f=55&t=11030

http://www.chevyhiperformance.com/techa ... 0_cfm.html

viewtopic.php?f=57&t=4701

http://www.corvettefever.com/techarticl ... ing_guide/

viewtopic.php?f=70&t=962

http://www.jetsrus.com/FAQs/FAQ_rejetti ... _carb.html

viewtopic.php?f=55&t=9326

viewtopic.php?f=55&t=8126&p=28205#p28205

http://www.ehow.com/how_7570346_calcula ... r-cfm.html

viewtopic.php?f=70&t=875

viewtopic.php?f=55&t=264&p=1301#p1301

http://www.carcraft.com/techarticles/cc ... ewall.html

viewtopic.php?f=44&t=5575&p=16927#p16927

viewtopic.php?f=55&t=10736&p=46872&hilit=4160#p46872

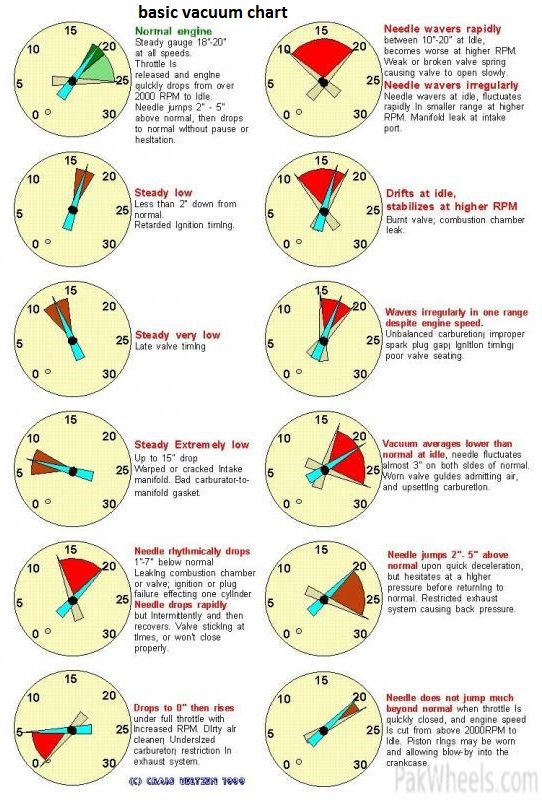

How to use a vacuum gauge to troubleshoot: http://www.secondchancegarage.com/public/186.cfm

viewtopic.php?f=55&t=2994&p=7857#p7857

many carb tuning issues are really basic fuel supply issues, if you can,t maintain a consistent flow at a constant pressure to the carbs feed the car will more than likely have tuning issues

viewtopic.php?f=55&t=10310

thats very useful info,

http://airdensityonline.com/free-calcs/

many guys fail to realize that only about 21% of the air content is oxygen thats physically useful in converting the fuels potential energy content into heat,

and rapidly expanding gases that produce the cylinder pressure that drives the piston down the cylinder, maintaining the ideal fuel to oxygen ratio will vary with altitude.

as a result the cost to run the car goes up and the cars power can go down.

another factor ignored is that not only does less dense air contain less oxygen it holds less MASS thus the inertia of the exhaust gasses exiting the headers has a bit less scavenging effect on the next incoming charge in the intake runner following it during overlap in cam timing

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

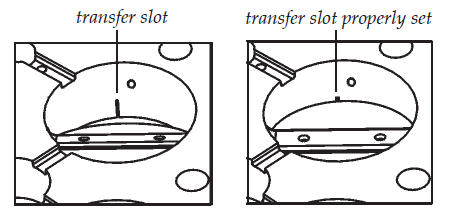

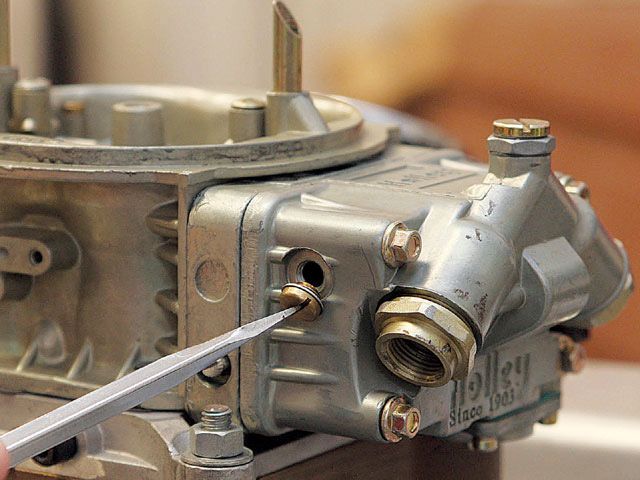

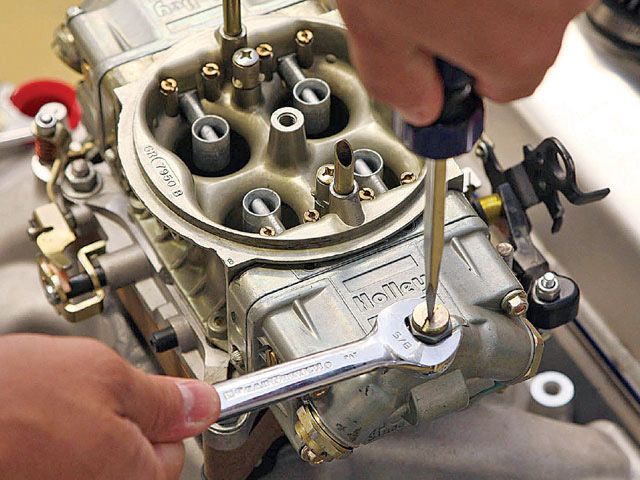

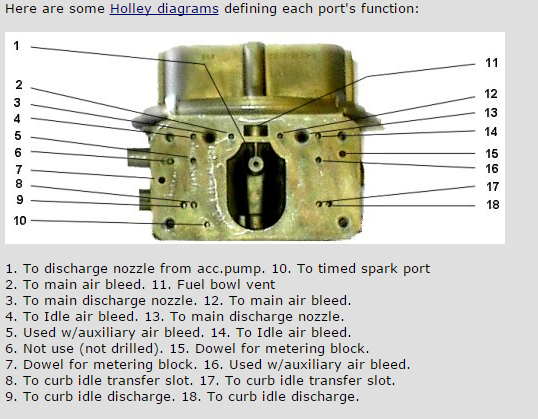

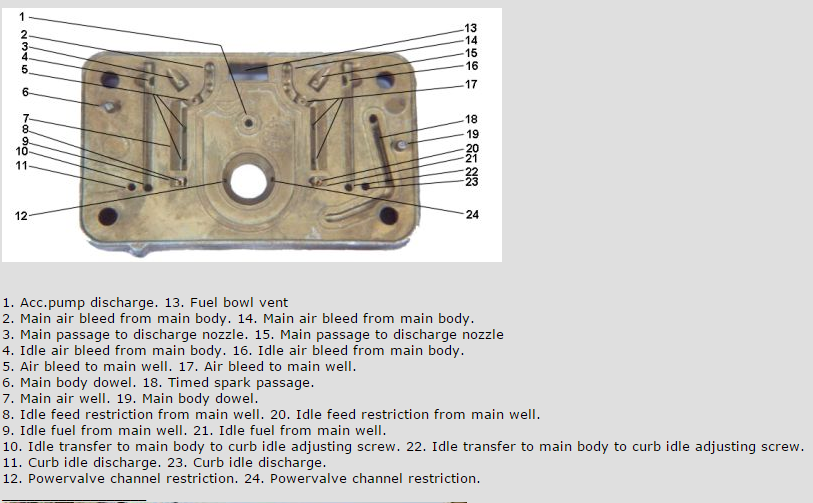

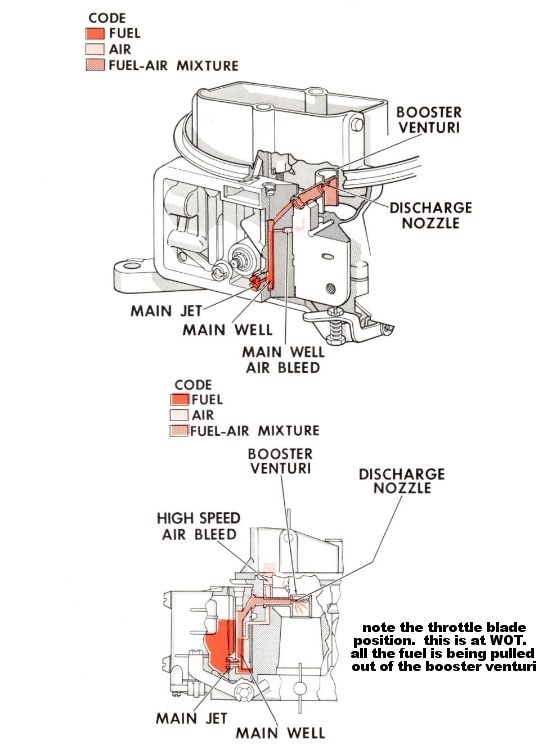

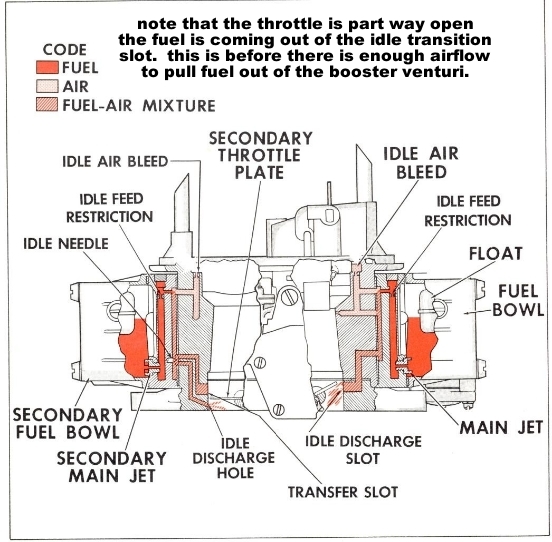

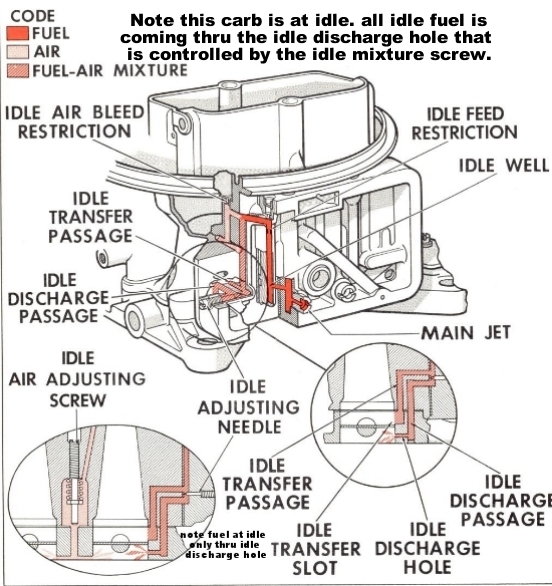

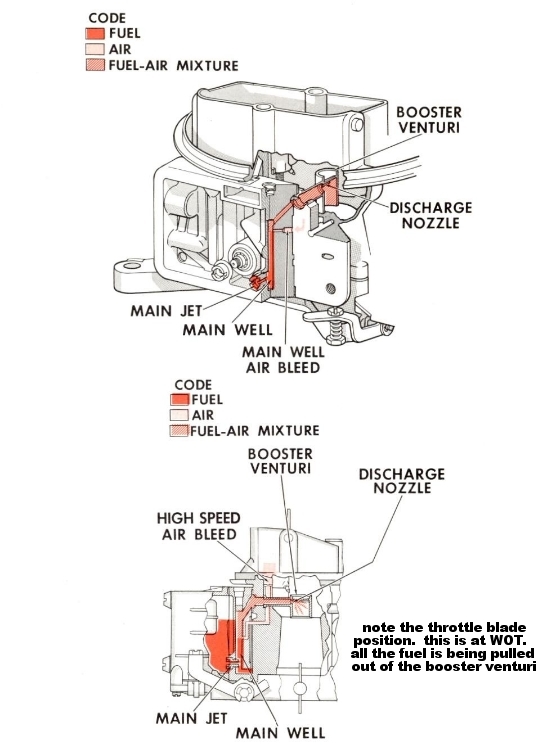

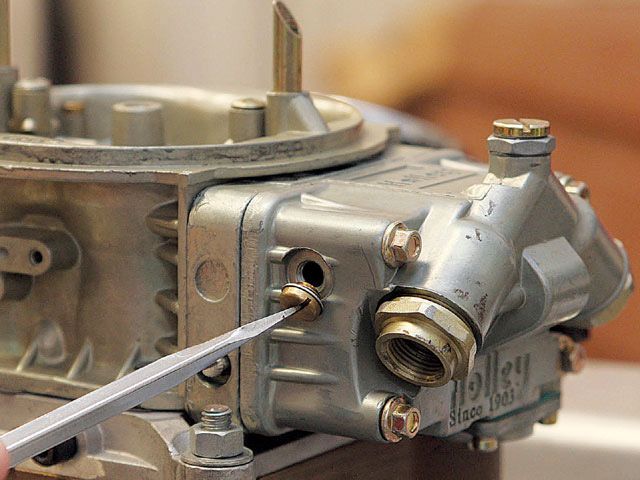

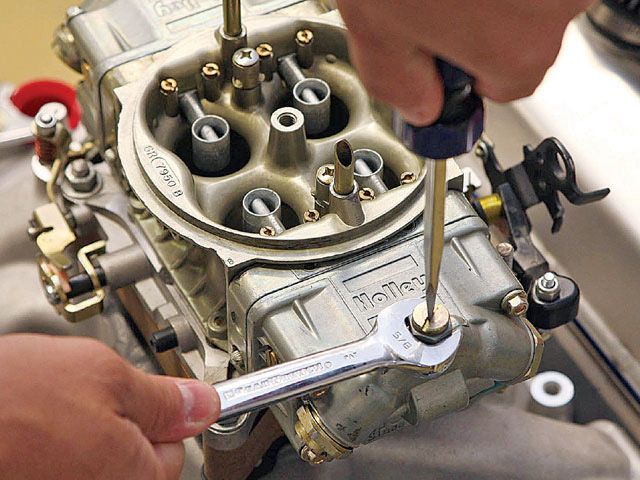

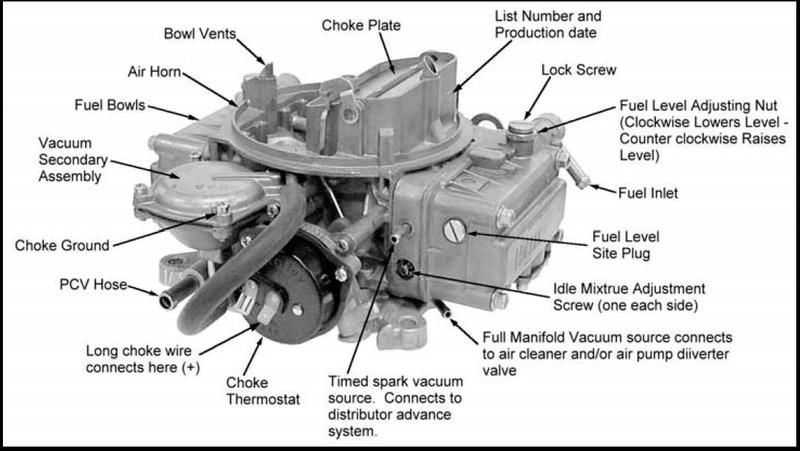

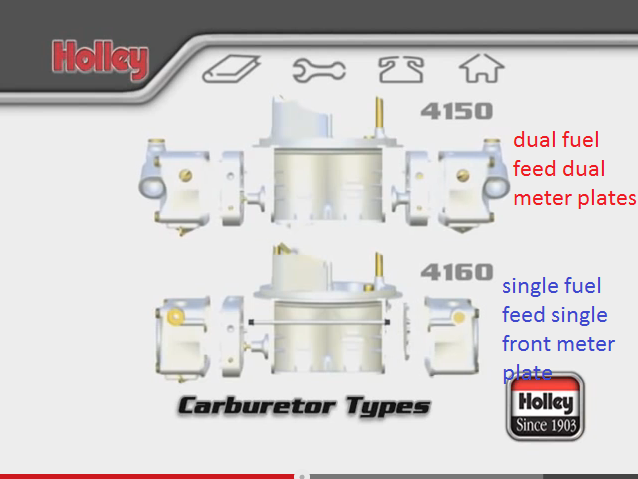

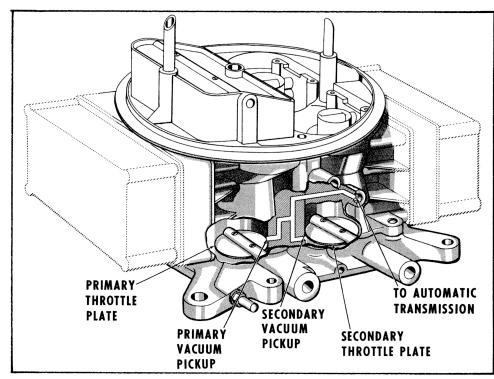

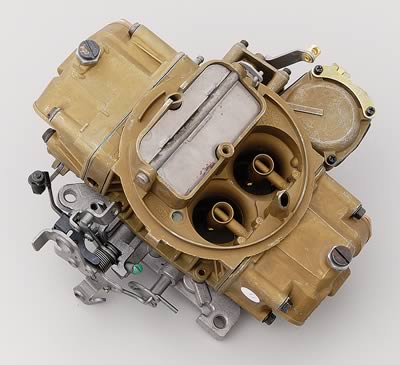

each carb has good and bad points, and most guys get into trouble by not following a logical step by step approach, where they verify the fuel pressure,is between 4.5 and 6psi, throttle linkage, fully opens, and youll want to know the carbs vacuum connections are correct, and what your vacuum gauge reads both at idle and at wide open throttle and youll need to verify the float levels are correctly set and verify theres no vacuum leaks on the intake or carb gaskets as a first step , youll want to verify the ignition works and the timings correct, it advances and that the valves are adjusted so you don,t spend time fighting a "CARBURETOR PROBLEM" that has NOTHING to do with the CARBURETOR!learning to read spark plugs and correctly using a timing light, correctly adjusting the valve train and use of a vacuum gauge will help a great deal, if you happen to own a infrared temp gun that's occasionally a big help in diagnosing problems

Id check the float level then change the accelerator pump diaphragm ,watch these

http://forums.holley.com/entry.php?428- ... or-Stumble

EDELBROCK

HOLLEY

viewtopic.php?f=55&t=1144&p=2310#p2310

as Im sure your aware the best torque will usually be with a ratio of about 12.5:1-13:1 and the most fuel efficient ratio will be closer to 14.7-15:1

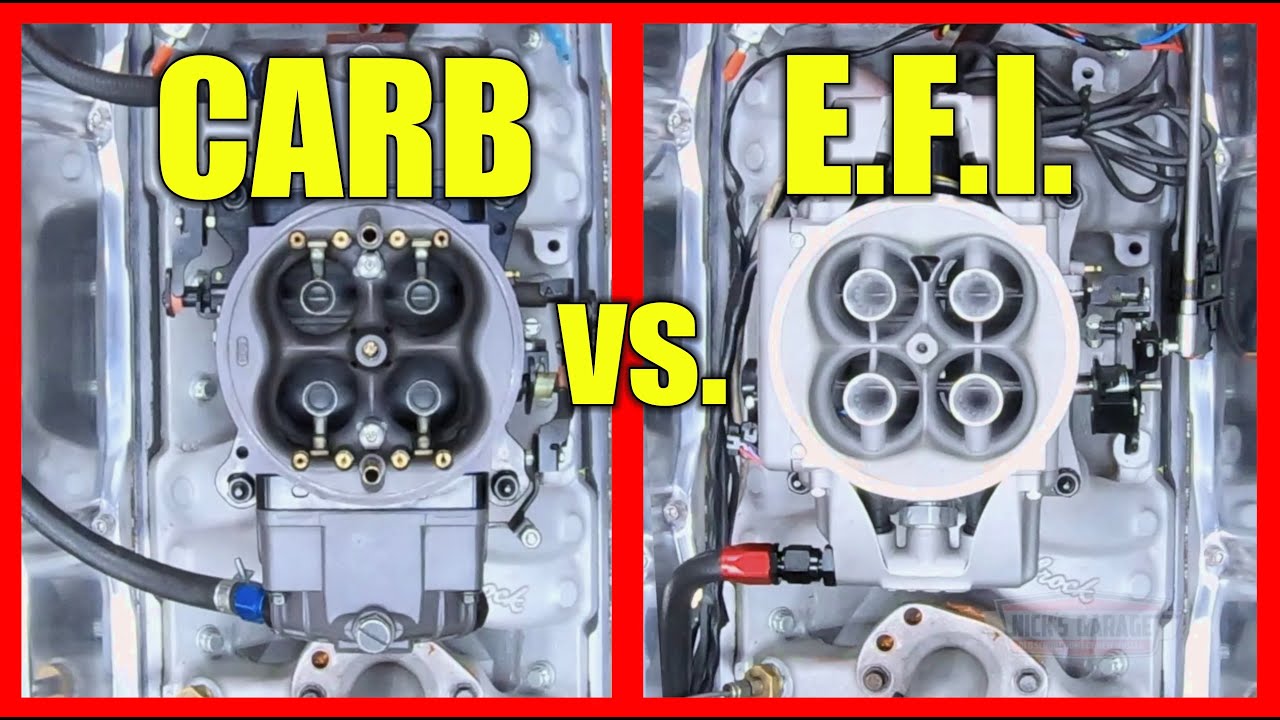

carbs react to CHANGES in air flow rates, to change the fuel feed rates so theres always a delayed reaction, EFI generally uses sensors to detect BOTH changes in AIR/FUEL RATIOS in the exhaust and changes in vacuum and airflow rates

carbs generally cover up sudden increases in air flow such as stomping on the throttle to WOT from idle with a long shot of fuel from the accelerator pump and power valves adding extra fuel, neither one is a precisely metered response.

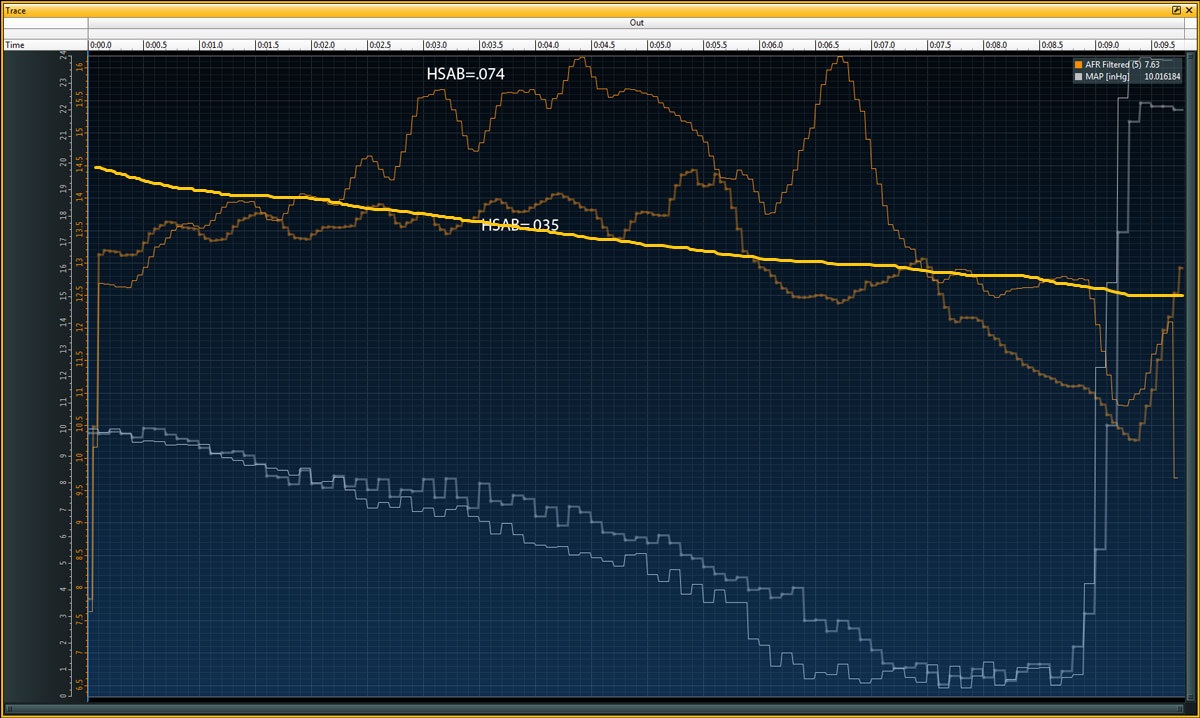

you can tell a good deal about the conditions in an engine if you know the vacuum readings (use a gauge), and know how to read spark plugs

now I use a vacuum gauge a timing light, and an IR temp gun on the headers along with the data from reading the plugs and the a/f ratio sensors, each adds to the indications of whats going on, yes you can achieve a 14.:1 ratio and get the engine to run decently, but in most cases it will tend to run better in the low 13:1 ratio range during transitions and about 14:1-14.7:1 during cruising simply because theres always a tendency to go lean during sudden transitions with most carbs.

Id keep in mind that going rich during rapid transitions is preferred over going lean and getting the a/f ratio stable and predictable at cruise and idle and during mild acceleration like on the freeway,where you'll spend 90% PLUS of your time is far more important than temp swings during throttle changes, or during WOT where running slightly richer, during high load high rpm conditions is preferred simply because it makes better power and has less tendency to run into detonation, especially since you'll spend far less time under those conditions

http://www.holley.com/TechService/Library.asp

BTW (lots of links and sub links on carb tuning, spark plug reading, etc.)

if you do some searching on the hybridz site,

but heres a bunch

http://www.goldrush.com/~rhuish/temp_data/carbtune.html

http://www.bob2000.com/carb.htm

carbs and tuning info, read all the links and sub links

http://www.secondchancegarage.com/public/186.cfm

https://www.centuryperformance.com/fuelish-tendencies.html

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1442

http://www.chevyhiperformance.com/howto ... index.html

http://www.chevyhiperformance.com/tech/ ... index.html

viewtopic.php?f=44&t=773

http://www.thecarburetorshop.com/Troubleshooting.htm

http://www.holley.com/TechService/Instr ... ry=&page=4

viewtopic.php?f=50&t=6174&p=20791#p20791

viewtopic.php?f=70&t=875

viewtopic.php?f=70&t=1015

http://www.youtube.com/watch?v=eiRIfcrc ... _embedded#

viewtopic.php?f=81&t=1189&p=2447#p2447

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=1961

viewtopic.php?f=55&t=2940

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=264

viewtopic.php?f=44&t=1788

viewtopic.php?f=44&t=579&p=743&hilit=infrared#p743

http://www.bgsoflex.com/holley.html

viewtopic.php?f=55&t=1961&p=5203#p5203

http://www.classictrucks.com/tech/0806c ... index.html

viewtopic.php?f=55&t=1442&p=5524#p5524

http://www.mortec.com/carbs.htm

http://www.mortec.com/carbtip1.htm

http://www.summitracing.com/parts/MOR-65222/?rtype=10

http://www.shockley.net/holley-jets.asp

http://www.chevyhiperformance.com/howto ... index.html

http://www.nastyz28.com/perftune.html#carb

http://www.digitalcorvettes.com/forums/showthread.php?t=77602

viewtopic.php?f=44&t=777&p=1127#p1127

(huge amount of linked info in this link)

BTW use a 190F T-stat and an extra electric fan that comes on at 200F to keep the engine coolant temp stable, try to keep the oil temp in the 215F-220F range if you can,to burn off moisture that can form acids over time in the oil, and the fuel pressure stable at about 5 PSI,, have no more than 1-1.5 psi of back pressure in the exhaust at WOT, it makes tuning far easier, make sure the ignition timing curve is smooth & consistent, and do a leak/down test and adjust the valves, do a vacuum leak test, check the oil pressure,and fuel filter, to make sure your not working with mechanical problems.

if your tuning an n/a engine and the IR gun shows header temps over 1250F or under about 1100f once its up to temp, you'll generally find vacuum leaks, ignition curve problems or a/f ratio problems

obviously you need to have a consistent base line advance curve to work with,

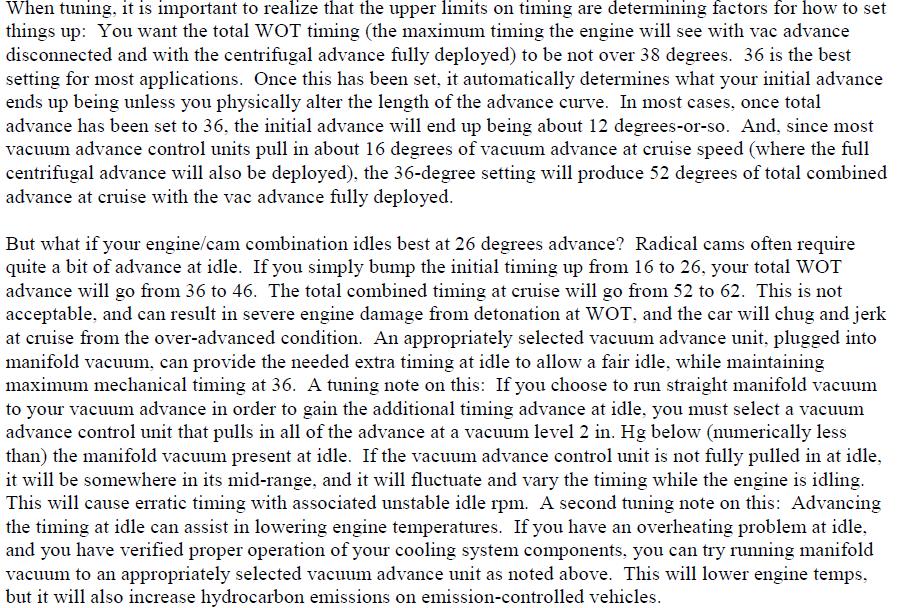

on most Chevy v8 engines that run cams designed for street/strip use Ive generally found a advance that goes from about 8 degrees at idle speed (800-900rpm in most cases) and smoothly advances the ignition to about 36 degrees or about 28 degrees advance from where it started at to reach 36 degrees at about 3200rpm , is generally a good place to start, or about 82 degrees advance per hundred rpm, you can then play with the engine and determine what changes MIGHT be required.

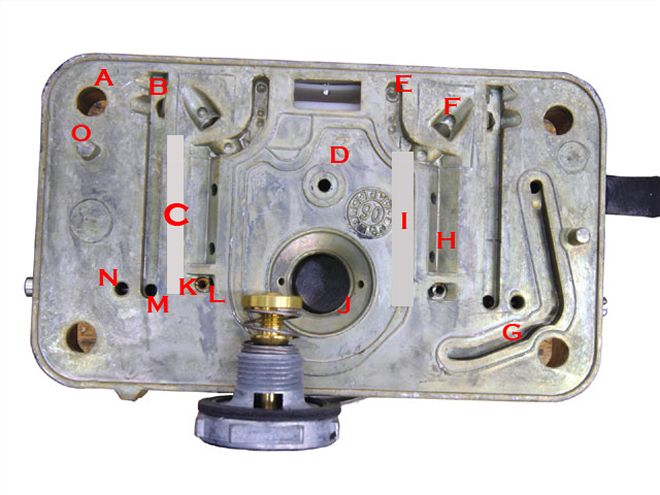

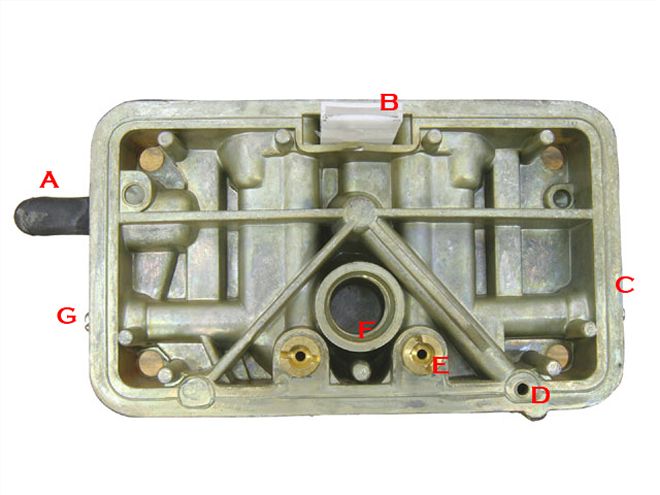

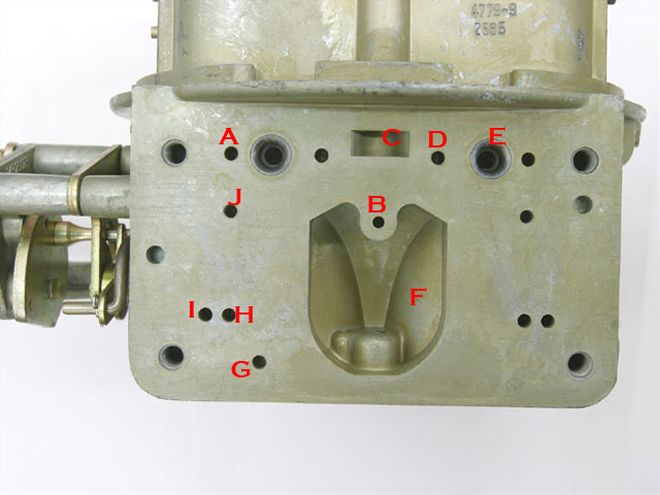

standard vacuum connections

http://www.secondchancegarage.com/public/186.cfm

manifold to power brake booster

manifold to distrib vacuum advance

pvc to carb or air cleaner assembly

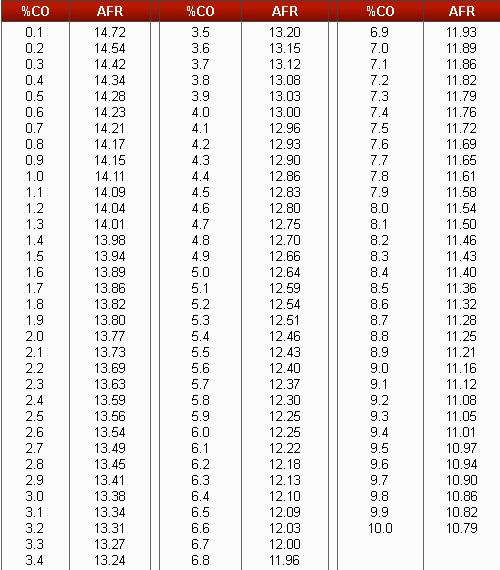

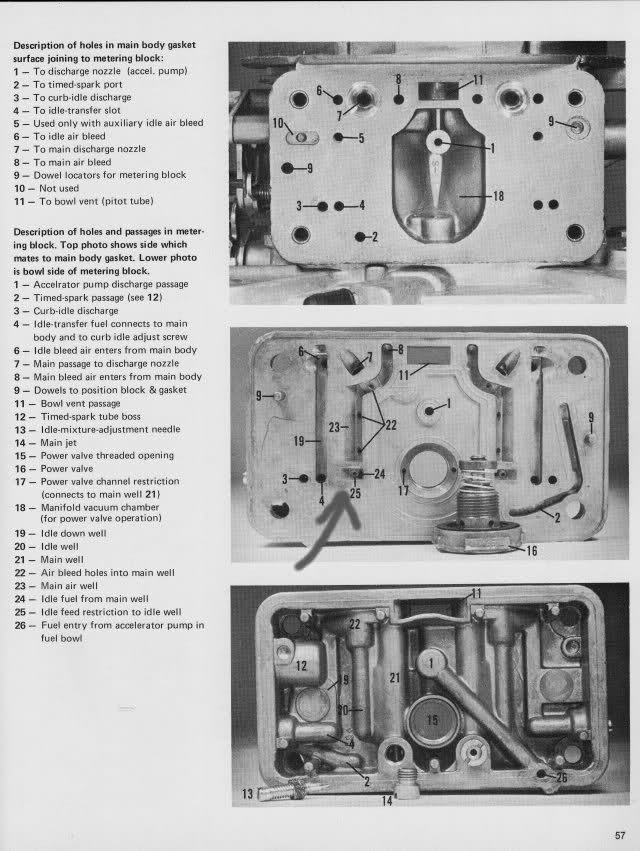

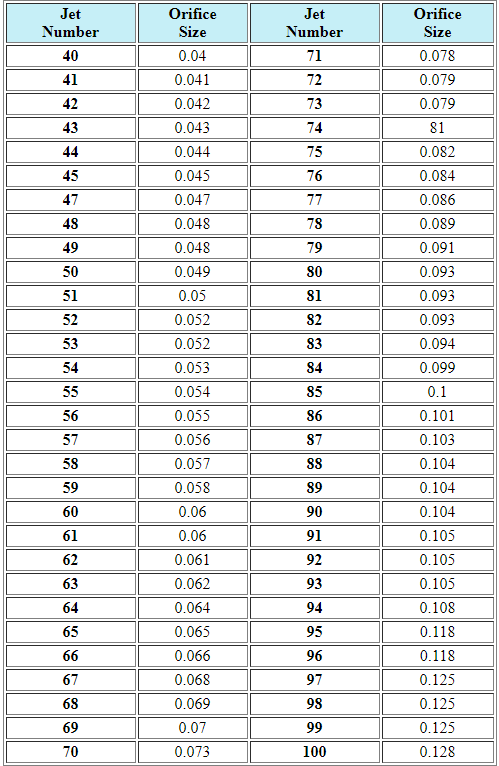

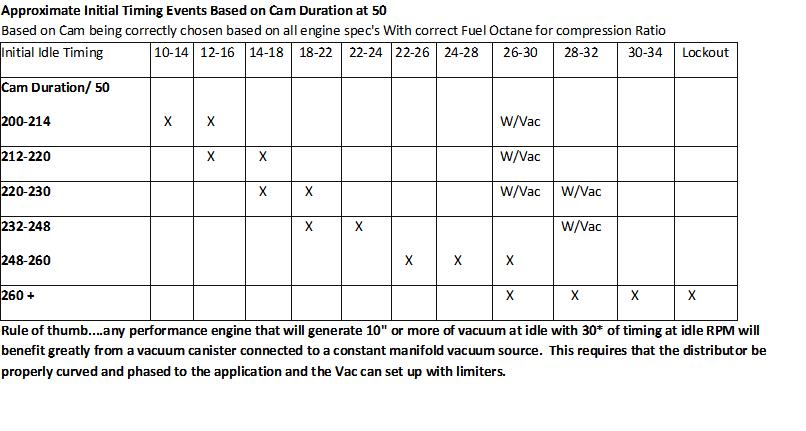

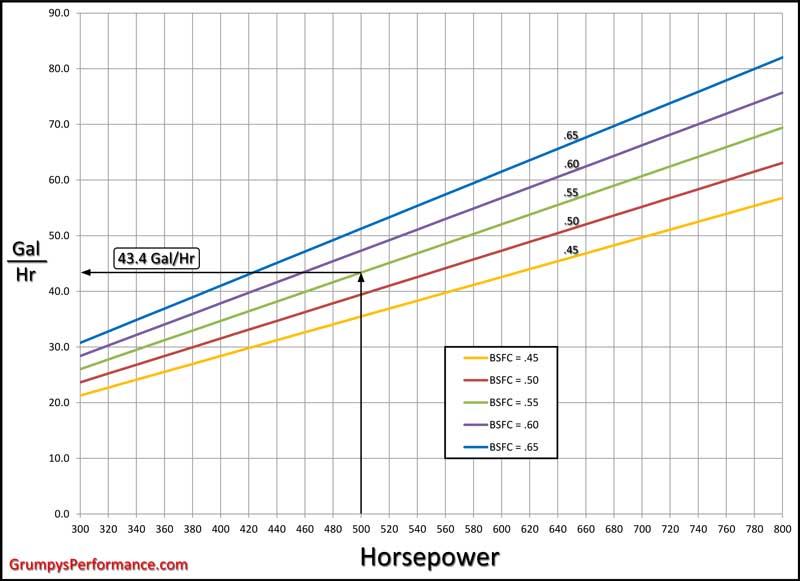

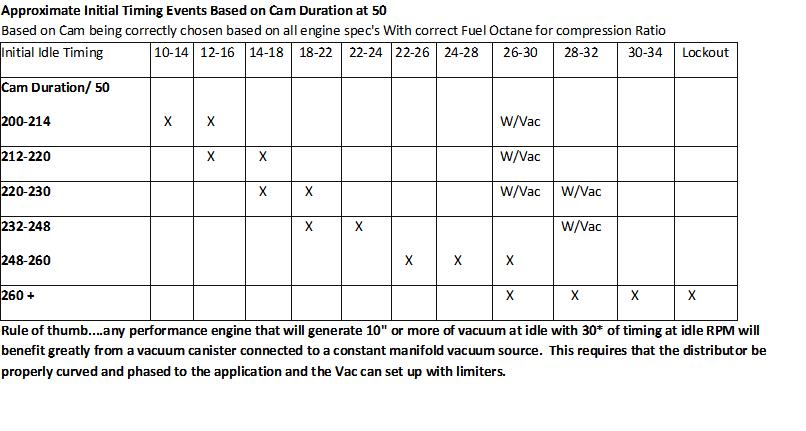

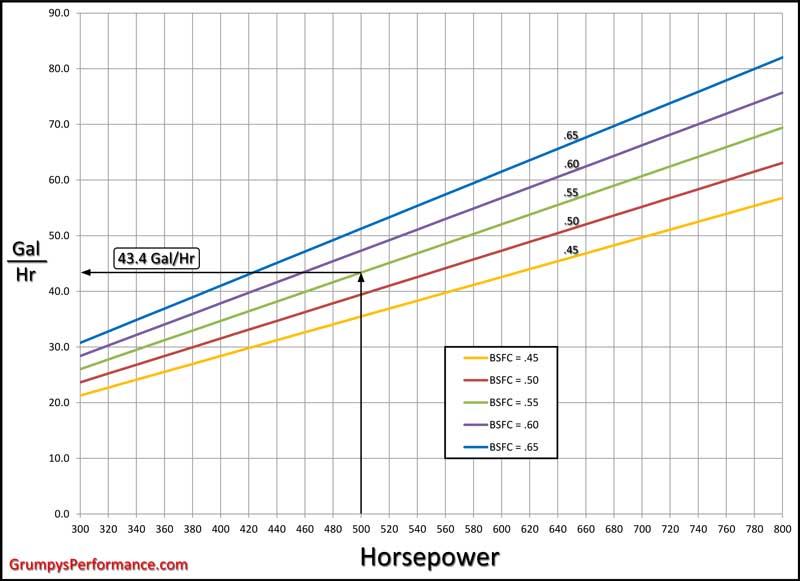

I ran ac-crossed this chart that might prove useful as a rough guide, and don,t forget this thread, and ITS sub-links

ILL point out a few factors a fuel/air ratio gauge is a big help as is an INFRARED TEMP GUN,

be very sure to verify the plenum vacuum and exhaust back pressure, as both vacuum leaks and clogged exhausts or clogged catalytic converters are a frequent source of problems

Ok Ive got one and have tested several of them.

viewtopic.php?f=4&t=1337&p=2921&hilit=+infrared#p2921

http://www.3barracing.com/product_3.htm

http://www.rbracing-rsr.com/rsrgauge.htm

http://www.scirocco.org/tech/misc/afgauge/af.html

http://www.innovatemotorsports.com/products/lm1.php

http://thedynoshop.net/prod01.htm

viewtopic.php?f=50&t=1853&p=4848#p4848

heres my take on them, short answer, they are a big help but a P.I.T.A. to set up and use if your not going to semi permanently install them on your car.

IVE come to use reading spark plug condition,

http://www.digitalcorvettes.com/forums/showthread.php?t=80783

http://www.digitalcorvettes.com/forums/showthread.php?t=85537&highlight=plugs

use of a good timing light and vacuum gauge , fuel pressure gauge and use of a GOOD HIGH TEMP INFRARED THERMOMETER (THIS ONE)

http://www.professionalequipment.co...hermometer-501-ds-42545/infrared-thermometer/

as a very quick to use and accurate set of tools.

OK WHY???

well your main concern when tuning an engine is to keep the all the cylinders running approximately the same ratio and at about 12.8:1 for max power up to about 14.7:1 for low emissions and good mileage,

so whats the advantage/disadvantages

a fuel air meter uses a o2 sensor, if you place it in the header collector it gives an AVERAGE of all the cylinders on that cylinder head,If theres an (X) installed close to the dual collectors reversion pulses can occasionally even give data from the other side of the engine, so in theory and in practice you can have two cylinders run lean and two rich and the AVERAGE tends to look RICH to the O2 sensor as it SEES unburnt fuel, if you place it in the individual primary header tubes you either need eight O2 sensors (VERY EXPENSIVE, and keeping the wires from burning or grounding outs a TOTAL P.I.T.A......IF you don,t succeed you destroy the O2 sensor and need to replace it.) or you need to be constantly swapping very hot and fragile O2 sensors and bung plugs constantly, but with the IR thermometer you can almost instantly see which cylinders are running hotter or cooler and adjust the jets or look for vacuum leaks, or other CAUSED for the TEMP DIFFERENCE, ETC, far faster too get all the cylinders running at approximately the same temp, indicating the same fuel air ratio, youll be amazed at how close the temp follows the fuel/air ratio, and you can confirm it with plug condition and the other test equipment. run any cylinder too lean and detonation can break rings or melt pistons, run it too rich and you can wash the oil off the cylinder walls and ruin rings/scuff pistons, you need to know whats going on in EACH CYLINDER not the AVERAGE of all cylinders.

SO, if your going to install a decent wide band fuel air ratio meter on your car thats fine, its going to be an asset to your tuning skills, if you install the indicator/gauge inside the car and weld in a couple extra bungs in the collectors for tuning and wide band O2 sensors which are a big help, but you will quickly find that its a P.I.T.A. to use it for tune ups on all your buddies cars with the welding collector bungs and installing plugs and O2 sensors while the IR thermometer route is fast and very simple and you can confirm with plug reading the condition of the engine.

YEAH! theres meters that you can stick in a tail pipe, but they read THE AVERAGE, not the individual cylinders ,

think about AVERAGEs

AS my old physics proffesor once said,

IF, I pour molten lead in your front slacks pockets and pack your butt in solid with DRY ICE,.... ON AVERAGE your comfortable

without a fuel pressure gauge and an adjustable return style fuel pressure regulator with a return line installed your basically restricted to guessing, and chances are very good youll have major problems, you need the engine timing set correctly and you need to learn how to tune carbs and correctly read spark plugs

step one is getting the fuel pressure rock steady at 5 psi, then get the carbs floats and jets set correctly, so you get plugs that look like this

good

too lean

too rich

its amazing what you can learn about engine combustion chamber conditions, air/fuel distribution and temps, from reading spark plugs

viewtopic.php?f=70&t=5428

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=211

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=202

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1015

you might be amazed at what a few tests with a fuel pressure gauge can tell you ILL point out a few factors a fuel/air ratio gauge is a big help as is an INFRARED TEMP GUN,

be very sure to verify the plenum vacuum and exhaust back pressure, as both vacuum leaks and clogged exhausts or clogged catalytic converters are a frequent source of problems

GET A FUEL PRESSURE GAUGE AND MEASURE DON,T GUESS

how can you possibly set up your fuel system unless you know the pressure and flow rates required and what currently exist's

RELATED INFO

A couple days of

reading the linked and sub-linked info

could save you a great deal of wasted time and money

and money spent on wrong or un-necessary parts

read the links and sub links below

a day or so spent doing reading and research,

(reading links and threads)

will frequently save you thousands of dollars and weeks of wasted work.

if you want a fast dependable car you will need to either do the research required to know exactly how and why things should work, or pay someone else to do the work that has taken that time and effort.

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.com/index.php?threads/how-big-a-fuel-pump-do-you-need.1939/

http://garage.grumpysperformance.co...ss-fuel-pressure-regulators.12776/#post-65998

you might be amazed at the number of times "CARBURETOR PROBLEMS" are cured with getting the IGNITION, TIMING AND ADVANCE CURVE WORKING CORRECTLY, and check out the simply things your 100% sure you did correctly, because I can,t begin to tell you how many times I see guys who have the firing order on the ignition wrong, or guys that install a 4/7 swap cam and still use the standard ignition firing order or guys that never verify TDC and ignition advance curves.

get an IR temp gun and check for wild variations in exhaust temps, get a compression test done, do a logical check to verify each cylinder fires etc.

Ive found its a whole lot faster to use a quality IR temp gun, to locate a individual cylinder that's mis-firing as it tends to run significantly cooler than adjacent cylinders, or hotter if its a vacuum leak at times, as lean F/A mixes tend to run hotter

(Ive used this one for years)

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

many temp guns don,t read high enough or accurately enough

http://www.professionalequipment.com/ex ... ermometer/

that you can use on the engine to check ALL 8 exhaust temps, individually, this quickly locates plugged injectors or vacuum leaks ETC

Wide temperature range from -58 to 1832°F

when selecting an IR gun for automotive use, you really want to be able to read from 0 F deg-about 1400F deg. to cover most conditions you'll test for

READ THRU THESE RELATED LINKs YES I KNOW YOULL WANT TO SKIP OVER THEM< BUT YOULL MISS A GREAT DEAL OF INFO DOING SO!

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=5229

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1639

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1790

viewtopic.php?f=56&t=495&p=613#p613

download/file.php?id=1710

http://autospeed.com/cms/A_111456/article.html

http://www.innovatemotorsports.com/products/lm2.php

http://www.vintagemusclecarparts.com/pa ... seat1.html

http://www.holley.com/data/TechService/ ... 20Info.pdf

http://www.thecarburetorshop.com/Troubleshooting.htm

http://members.tccoa.com/392bird/tuning.htm

http://www.edelbrock.com/automotive_new ... vids.shtml

http://www.international-auto.com/fiat- ... gauges.cfm

http://www.summitracing.com/expertadviceandnews/calcsandtools/cfm-calculator

http://www.thecarburetorshop.com/Troubl ... rdstarthot

Carburetor vs. E.F.I. on Small Block Chevy on the Dyno!

Nick's Garage Gear Shophttps://teespring.com/stores/nicks-garage-gear-------------------------------------------------------------------------Nick's Garage P...

set the float levels and verify the fuel pressure consistent at about 5 psi entering the carb inlet port.

below you'll find a good base line starting point,

and Id suggest you monitor coolant and oil temps,

try hard to keep coolant temp under 200F and oil temp under 220F

verify your fuel delivery pressure is consistent over the whole rpm range

take the time to graph out and verify your ignition advance curve!

a good IR temp gun to use on the header primary tubes helps locate fuel/air ratio inconsistency's

GENERALLY your fuel/air ratio should be in these ranges

Idle- up too about 2500 rpm try for 14.7:1-15:1 f/a ratio,

too get max mileage and prevent spark plug fouling

from about 2500 rpm- too about 4500 rpm,

try to smoothly and predictably transition the fuel/air ratio mix richer to about 13.5:1

for good power and less chance of detonation

from about 4500 rpm- too about 6500 rpm and higher

,try to smoothly and predictably transition the fuel/air ratio mix richer to about 12.5:1,

for good peak power and less chance of detonation.

this is only a well proven starting point on the tune,

but it generally gets you in the ball park ,

and tends to reduce the chances of the engine reaching detonation conditions.

the ignition advance curve needs to be checked, the chart below is a very good starting point to work from, and USE OF A RICHER FUEL/AIR MIX, WILL AT TIMES BE REQUIRED IN THE OFF IDLE TO 3500 rpm range, but the idea here is to keep the lower rpm and lower stress operations running at efficient fuel/air ratios to reduce plug fouling and improve mileage as youll generally spend 90% of the cars operational life on the street at under 4500 rpm.

set the plug gaps at about .045, make sure the valves are adjusted correctly

WHEN TESTING<be sure the fuel pressure gauge reads correctly by comparing it to a second test gauge, these fuel pressure gauges are frequently defective

watch this

without testing you simply guessing

http://garage.grumpysperformance.com/index.php?threads/drop-back-to-basics.12943/#post-67323

http://garage.grumpysperformance.co...hink-logically-don-t-assume.12484/#post-62772

http://garage.grumpysperformance.co...-test-seems-to-be-a-forgotten-art-form.11838/

http://garage.grumpysperformance.com/index.php?threads/carb-tuning-info-and-links.109/

having a few basic meters,gauges etc.

IT sure helps too have basic tools, when isolating issues

MULTI METER

INFRARED TEMP GUN

TIMING LIGHT

COMPRESSION GAUGE

PRESSURE/VACUUM GAUGE

http://garage.grumpysperformance.com/index.php?threads/holley-annular-vs-down-leg-boosters.5229/

btw

before you get crazy chasing some problem your sure is an intermittent fuel delivery issue

(1) Do a compression test!

(2) verify your ignition advance curve, and verify the ignition systems working correctly , the spark plugs are new, properly gaped and the ignition wires in excellent condition visually and with an OHMS meter.

(3) adjust your valves, correctly

(4) carefully verify theres no vacuum leaks, in lines or gaskets

(5)Check the fuel delivery system, WITH A GAUGE, while the engines under real operational inertial loads to verify you have a consistent 5-6 psi at the carburetor inlet port

(6) change out the fuel and air filters, especially if over 3-4 months old

(7) actually check your exhaust back-pressure levels

(8) verify your return style fuel pressure regulator and fuel lines function as intended

(9)verify your using FRESH FUEL WITHOUT MOISTURE OR PARTICULAR CONTAMINANTS

(10) actually look for and read installation instructions and rated flow and pressure limitations on fuel pumps and filters

(11) If ALL of the above are normal, only then start looking at the carburetor, and tuning issues

READ THE LINK

viewtopic.php?f=50&t=268&p=18435#p18435

a few hours spent reading links and sub links should help

viewtopic.php?f=50&t=268&p=18434&hilit=wide+band#p18434

viewtopic.php?f=27&t=3096&p=18612&hilit=wide+band#p18612

viewtopic.php?f=32&t=6011&p=18597#p18597

viewtopic.php?f=57&t=4974&p=13868&hilit=infrared#p13868

read these links

http://garage.grumpysperformance.com/index.php?threads/holley-air-bleed-jets-related.11859/

viewtopic.php?f=55&t=1790&p=4544#p4544

viewtopic.php?f=70&t=1809

viewtopic.php?f=55&t=11030

http://www.chevyhiperformance.com/techa ... 0_cfm.html

viewtopic.php?f=57&t=4701

http://www.corvettefever.com/techarticl ... ing_guide/

viewtopic.php?f=70&t=962

http://www.jetsrus.com/FAQs/FAQ_rejetti ... _carb.html

viewtopic.php?f=55&t=9326

viewtopic.php?f=55&t=8126&p=28205#p28205

http://www.ehow.com/how_7570346_calcula ... r-cfm.html

viewtopic.php?f=70&t=875

viewtopic.php?f=55&t=264&p=1301#p1301

http://www.carcraft.com/techarticles/cc ... ewall.html

viewtopic.php?f=44&t=5575&p=16927#p16927

viewtopic.php?f=55&t=10736&p=46872&hilit=4160#p46872

How to use a vacuum gauge to troubleshoot: http://www.secondchancegarage.com/public/186.cfm

viewtopic.php?f=55&t=2994&p=7857#p7857

many carb tuning issues are really basic fuel supply issues, if you can,t maintain a consistent flow at a constant pressure to the carbs feed the car will more than likely have tuning issues

viewtopic.php?f=55&t=10310

thats very useful info,

http://airdensityonline.com/free-calcs/

many guys fail to realize that only about 21% of the air content is oxygen thats physically useful in converting the fuels potential energy content into heat,

and rapidly expanding gases that produce the cylinder pressure that drives the piston down the cylinder, maintaining the ideal fuel to oxygen ratio will vary with altitude.

as a result the cost to run the car goes up and the cars power can go down.

another factor ignored is that not only does less dense air contain less oxygen it holds less MASS thus the inertia of the exhaust gasses exiting the headers has a bit less scavenging effect on the next incoming charge in the intake runner following it during overlap in cam timing

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

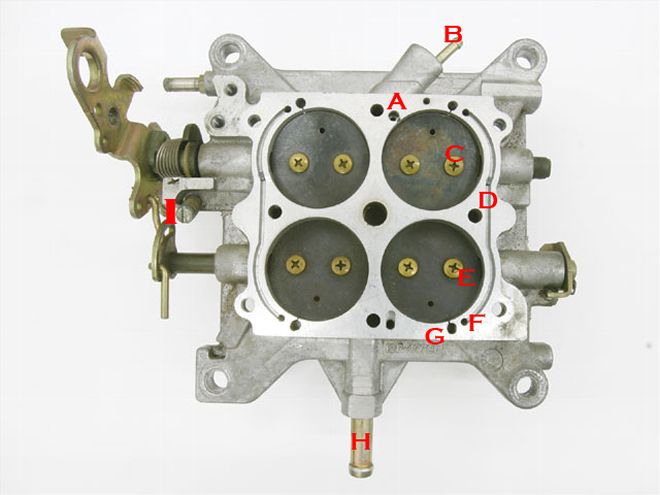

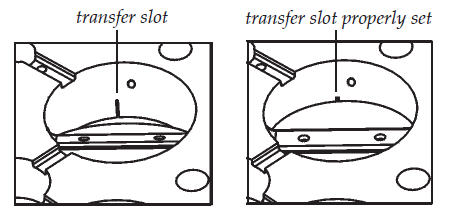

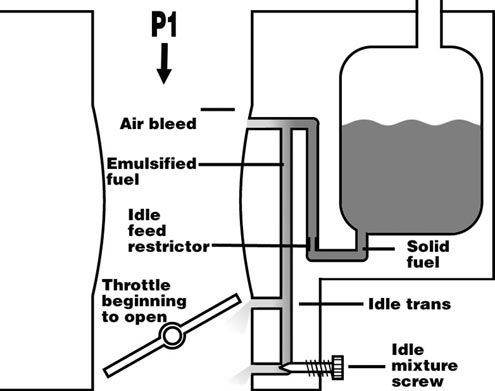

each carb has good and bad points, and most guys get into trouble by not following a logical step by step approach, where they verify the fuel pressure,is between 4.5 and 6psi, throttle linkage, fully opens, and youll want to know the carbs vacuum connections are correct, and what your vacuum gauge reads both at idle and at wide open throttle and youll need to verify the float levels are correctly set and verify theres no vacuum leaks on the intake or carb gaskets as a first step , youll want to verify the ignition works and the timings correct, it advances and that the valves are adjusted so you don,t spend time fighting a "CARBURETOR PROBLEM" that has NOTHING to do with the CARBURETOR!learning to read spark plugs and correctly using a timing light, correctly adjusting the valve train and use of a vacuum gauge will help a great deal, if you happen to own a infrared temp gun that's occasionally a big help in diagnosing problems

Id check the float level then change the accelerator pump diaphragm ,watch these

http://forums.holley.com/entry.php?428- ... or-Stumble

Off Idle Stumble - A Holley Carb Review said:I installed a GM crate engine in my 79 Vette a few months ago. The engine came with a 650 CFM Holley 4-barrel carb. During break-in, the engine seemed to run fine. I then had a less restrictive dual exhaust system installed on the vehicle. It was about that time that I noticed an off idle stumble, or flat spot, begin.

At first I began adjusting the easy and basic stuff - timing, carb float levels, fuel/air mixture, vacuum advance ports. When I still experienced a dead flat spot on full throttle from idle or low RPM's, I read technical articles on the Holley carburetor.

A dead spot from idle or part throttle to full throttle, especially if the flat spot is accompanied with a back fire through the carb is an indication of an overly lean fuel/air mixture or insufficient fuel delivery during wide open throttle, or "WOT".

A racing buddy suggested that the "squiters" were too small and not providing enough fuel during the transition from idle/part-throttle to WOT. He also noted that the secondary valves were not opening at any RPM. The Holley carb had .31 squirters so I bought the next size up (.35) and installed them in the carb. The engine bogged terribly so I put the .31 squirters back in.

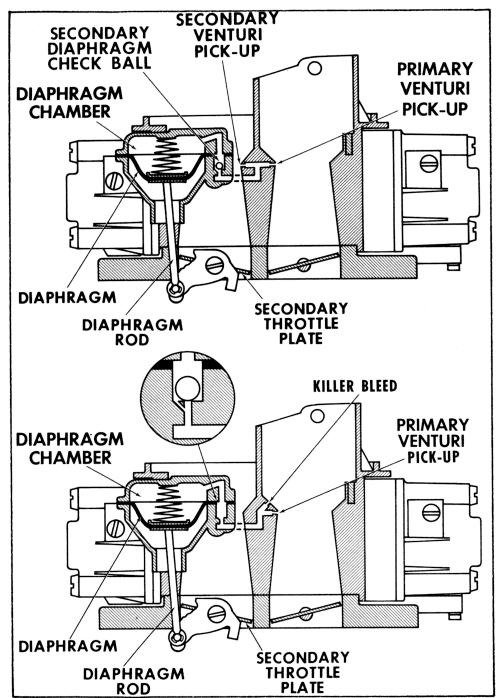

Next, I installed a "quick change" secondary vacuum valve/spring mechanism. The stock mechanism requires a fair amount of time to disassemble and replace the secondary vacuum springs with springs of different tension and operating ranges. I found the crate engine Holley carb came with the strongest spring available that never allowed the secondaries to fully open. If you want to have some inexpensive fun trying to improve your mid to top end response, I would recommend that you buy this quick change secondary vacuum kit and experiment with the 7 or 8 different springs that you can purchase in a separate kit. You really can dial in good performance in a matter of a couple of hours - if you have the quick change kit. Well, I ended up with a spring that was two steps lighter and faster responding, but this did nothing to help the dead spot off idle/part throttle.

My next step was to switch the vacuum hose from the distributor to every known vacuum port I could find. I thought that I may have a vacuum or timing problem so I spent hours switching the vacuum hose and taking test drives to measure the change in performance. No improvement in idle/part throttle response.

The next item I attacked was the adjustment bolt on the accelerator arm that presses against the power valve actuating arm on the left front side of the Holley carb. You can adjust the length of the bolt by tightening or loosening the adjustment nut. I tightened and loosened this darn nut/bolt set-up and sometimes it would help and other times it would be worse, but nothing corrected the backfiring through the carb and the flat spot response.

I then read an article that suggested a 50cc accelerator (power) valve would solve the off throttle flat spot. The kit cost $44 and basically is a larger reservoir of fuel to squirt into your carburetor when you transition from idle to running throttle. I hesitated installing this unit as the 30cc volume of the stock accelerator valve should be sufficient for the crate engine V-8. I decided to review other options.

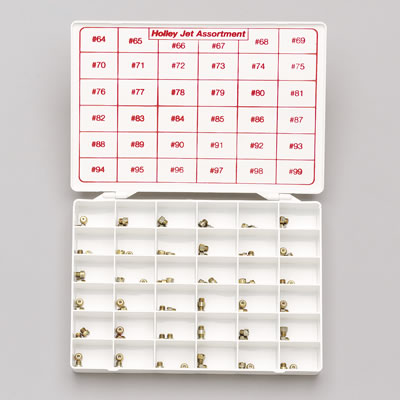

I read about the different profile plastic cams that Holley carbs use and thought I would experiment with these. I swear Holley makes more money on these various carb tuning kits and parts than they do on the carb itself. After removing the stock orange cam from the throttle linkage and examining it's profile, I discovered that it had two mounting holes marked "1" and "2". By the rub marks left on the cam from the actuator arm on the carb, it appeared that the cam could be reversed to have the steeper and more aggressive side of the cam actuate the arm that in turn presses the accelerator arm that presses the accelerator pump valve that squirts raw fuel into the primaries during the transition phase from idle to throttle. At the same time, I thought I would replace the #65 main jets with something a little less restrictive, so I installed a pair of #67's.

One last adjustment I made was to eliminate any gap or slack between the bolt on the throttle actuator arm and the accelerator pump actuator arm. I figured that if there was any "slop" or gap between these two pieces, the throttle would begin it's opening without making contact with the accelerator pump valve actuating arm ... this would cause a delay in delivering more fuel during the initial opening of the primary valves and this would produce a lean mixture, backfire and stumble.

After installing slightly larger main jets, adjusting the throttle cam to a more aggressive slope/timing and eliminating the slop between the throttle actuator arm/bolt and the accelerator valve pump arm ... the engine ran fantastic. NO stumble. No back fire through the carb. No hesitation in acceleration from idle/part throttle to WOT.

If any of you are having trouble with flat spots & backfiring with your Holley carb, you might try the simple adjustments that are easy to do and don't cost much. The main problems I had were an incorrect throttle cam and a poorly adjusted contact between the throttle arm and the accelerator pump (or "power valve")actuator arm on the Holley carb.

I returned the $44 50cc accelerator pump valve. The pair of main jets cost $6.44, but I probably didn't need those. The cam adjustment made the biggest improvement and that was free - just flip it over and use a different mounting hole. And finally, adjusting the actuating arm was very helpful and cost nothing.

So before you give up or spend allot of money chasing Holley carb problems like mine, try the simple and inexpensive adjustments before you invest in expensive upgrades. Hope this helps.

EDELBROCK

HOLLEY

viewtopic.php?f=55&t=1144&p=2310#p2310

as Im sure your aware the best torque will usually be with a ratio of about 12.5:1-13:1 and the most fuel efficient ratio will be closer to 14.7-15:1

carbs react to CHANGES in air flow rates, to change the fuel feed rates so theres always a delayed reaction, EFI generally uses sensors to detect BOTH changes in AIR/FUEL RATIOS in the exhaust and changes in vacuum and airflow rates

carbs generally cover up sudden increases in air flow such as stomping on the throttle to WOT from idle with a long shot of fuel from the accelerator pump and power valves adding extra fuel, neither one is a precisely metered response.

you can tell a good deal about the conditions in an engine if you know the vacuum readings (use a gauge), and know how to read spark plugs

now I use a vacuum gauge a timing light, and an IR temp gun on the headers along with the data from reading the plugs and the a/f ratio sensors, each adds to the indications of whats going on, yes you can achieve a 14.:1 ratio and get the engine to run decently, but in most cases it will tend to run better in the low 13:1 ratio range during transitions and about 14:1-14.7:1 during cruising simply because theres always a tendency to go lean during sudden transitions with most carbs.

Id keep in mind that going rich during rapid transitions is preferred over going lean and getting the a/f ratio stable and predictable at cruise and idle and during mild acceleration like on the freeway,where you'll spend 90% PLUS of your time is far more important than temp swings during throttle changes, or during WOT where running slightly richer, during high load high rpm conditions is preferred simply because it makes better power and has less tendency to run into detonation, especially since you'll spend far less time under those conditions

http://www.holley.com/TechService/Library.asp

BTW (lots of links and sub links on carb tuning, spark plug reading, etc.)

if you do some searching on the hybridz site,

but heres a bunch

http://www.goldrush.com/~rhuish/temp_data/carbtune.html

http://www.bob2000.com/carb.htm

carbs and tuning info, read all the links and sub links

http://www.secondchancegarage.com/public/186.cfm

https://www.centuryperformance.com/fuelish-tendencies.html

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1442

http://www.chevyhiperformance.com/howto ... index.html

http://www.chevyhiperformance.com/tech/ ... index.html

viewtopic.php?f=44&t=773

http://www.thecarburetorshop.com/Troubleshooting.htm

http://www.holley.com/TechService/Instr ... ry=&page=4

viewtopic.php?f=50&t=6174&p=20791#p20791

viewtopic.php?f=70&t=875

viewtopic.php?f=70&t=1015

http://www.youtube.com/watch?v=eiRIfcrc ... _embedded#

viewtopic.php?f=81&t=1189&p=2447#p2447

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=1961

viewtopic.php?f=55&t=2940

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=264

viewtopic.php?f=44&t=1788

viewtopic.php?f=44&t=579&p=743&hilit=infrared#p743

http://www.bgsoflex.com/holley.html

viewtopic.php?f=55&t=1961&p=5203#p5203

http://www.classictrucks.com/tech/0806c ... index.html

viewtopic.php?f=55&t=1442&p=5524#p5524

http://www.mortec.com/carbs.htm

http://www.mortec.com/carbtip1.htm

http://www.summitracing.com/parts/MOR-65222/?rtype=10

http://www.shockley.net/holley-jets.asp

http://www.chevyhiperformance.com/howto ... index.html

http://www.nastyz28.com/perftune.html#carb

http://www.digitalcorvettes.com/forums/showthread.php?t=77602

viewtopic.php?f=44&t=777&p=1127#p1127

(huge amount of linked info in this link)

BTW use a 190F T-stat and an extra electric fan that comes on at 200F to keep the engine coolant temp stable, try to keep the oil temp in the 215F-220F range if you can,to burn off moisture that can form acids over time in the oil, and the fuel pressure stable at about 5 PSI,, have no more than 1-1.5 psi of back pressure in the exhaust at WOT, it makes tuning far easier, make sure the ignition timing curve is smooth & consistent, and do a leak/down test and adjust the valves, do a vacuum leak test, check the oil pressure,and fuel filter, to make sure your not working with mechanical problems.

if your tuning an n/a engine and the IR gun shows header temps over 1250F or under about 1100f once its up to temp, you'll generally find vacuum leaks, ignition curve problems or a/f ratio problems

obviously you need to have a consistent base line advance curve to work with,

on most Chevy v8 engines that run cams designed for street/strip use Ive generally found a advance that goes from about 8 degrees at idle speed (800-900rpm in most cases) and smoothly advances the ignition to about 36 degrees or about 28 degrees advance from where it started at to reach 36 degrees at about 3200rpm , is generally a good place to start, or about 82 degrees advance per hundred rpm, you can then play with the engine and determine what changes MIGHT be required.

standard vacuum connections

http://www.secondchancegarage.com/public/186.cfm

manifold to power brake booster

manifold to distrib vacuum advance

pvc to carb or air cleaner assembly

I ran ac-crossed this chart that might prove useful as a rough guide, and don,t forget this thread, and ITS sub-links

ILL point out a few factors a fuel/air ratio gauge is a big help as is an INFRARED TEMP GUN,

be very sure to verify the plenum vacuum and exhaust back pressure, as both vacuum leaks and clogged exhausts or clogged catalytic converters are a frequent source of problems

Ok Ive got one and have tested several of them.

viewtopic.php?f=4&t=1337&p=2921&hilit=+infrared#p2921

http://www.3barracing.com/product_3.htm

http://www.rbracing-rsr.com/rsrgauge.htm

http://www.scirocco.org/tech/misc/afgauge/af.html

http://www.innovatemotorsports.com/products/lm1.php

http://thedynoshop.net/prod01.htm

viewtopic.php?f=50&t=1853&p=4848#p4848

heres my take on them, short answer, they are a big help but a P.I.T.A. to set up and use if your not going to semi permanently install them on your car.

IVE come to use reading spark plug condition,

http://www.digitalcorvettes.com/forums/showthread.php?t=80783

http://www.digitalcorvettes.com/forums/showthread.php?t=85537&highlight=plugs

use of a good timing light and vacuum gauge , fuel pressure gauge and use of a GOOD HIGH TEMP INFRARED THERMOMETER (THIS ONE)

http://www.professionalequipment.co...hermometer-501-ds-42545/infrared-thermometer/

as a very quick to use and accurate set of tools.

OK WHY???

well your main concern when tuning an engine is to keep the all the cylinders running approximately the same ratio and at about 12.8:1 for max power up to about 14.7:1 for low emissions and good mileage,

so whats the advantage/disadvantages

a fuel air meter uses a o2 sensor, if you place it in the header collector it gives an AVERAGE of all the cylinders on that cylinder head,If theres an (X) installed close to the dual collectors reversion pulses can occasionally even give data from the other side of the engine, so in theory and in practice you can have two cylinders run lean and two rich and the AVERAGE tends to look RICH to the O2 sensor as it SEES unburnt fuel, if you place it in the individual primary header tubes you either need eight O2 sensors (VERY EXPENSIVE, and keeping the wires from burning or grounding outs a TOTAL P.I.T.A......IF you don,t succeed you destroy the O2 sensor and need to replace it.) or you need to be constantly swapping very hot and fragile O2 sensors and bung plugs constantly, but with the IR thermometer you can almost instantly see which cylinders are running hotter or cooler and adjust the jets or look for vacuum leaks, or other CAUSED for the TEMP DIFFERENCE, ETC, far faster too get all the cylinders running at approximately the same temp, indicating the same fuel air ratio, youll be amazed at how close the temp follows the fuel/air ratio, and you can confirm it with plug condition and the other test equipment. run any cylinder too lean and detonation can break rings or melt pistons, run it too rich and you can wash the oil off the cylinder walls and ruin rings/scuff pistons, you need to know whats going on in EACH CYLINDER not the AVERAGE of all cylinders.

SO, if your going to install a decent wide band fuel air ratio meter on your car thats fine, its going to be an asset to your tuning skills, if you install the indicator/gauge inside the car and weld in a couple extra bungs in the collectors for tuning and wide band O2 sensors which are a big help, but you will quickly find that its a P.I.T.A. to use it for tune ups on all your buddies cars with the welding collector bungs and installing plugs and O2 sensors while the IR thermometer route is fast and very simple and you can confirm with plug reading the condition of the engine.

YEAH! theres meters that you can stick in a tail pipe, but they read THE AVERAGE, not the individual cylinders ,

think about AVERAGEs

AS my old physics proffesor once said,

IF, I pour molten lead in your front slacks pockets and pack your butt in solid with DRY ICE,.... ON AVERAGE your comfortable

without a fuel pressure gauge and an adjustable return style fuel pressure regulator with a return line installed your basically restricted to guessing, and chances are very good youll have major problems, you need the engine timing set correctly and you need to learn how to tune carbs and correctly read spark plugs

step one is getting the fuel pressure rock steady at 5 psi, then get the carbs floats and jets set correctly, so you get plugs that look like this

good

too lean

too rich

its amazing what you can learn about engine combustion chamber conditions, air/fuel distribution and temps, from reading spark plugs

viewtopic.php?f=70&t=5428

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=211

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=202

http://forum.grumpysperformance.com/viewtopic.php?f=70&t=1015

Last edited by a moderator: