Chad Speier

Active Member

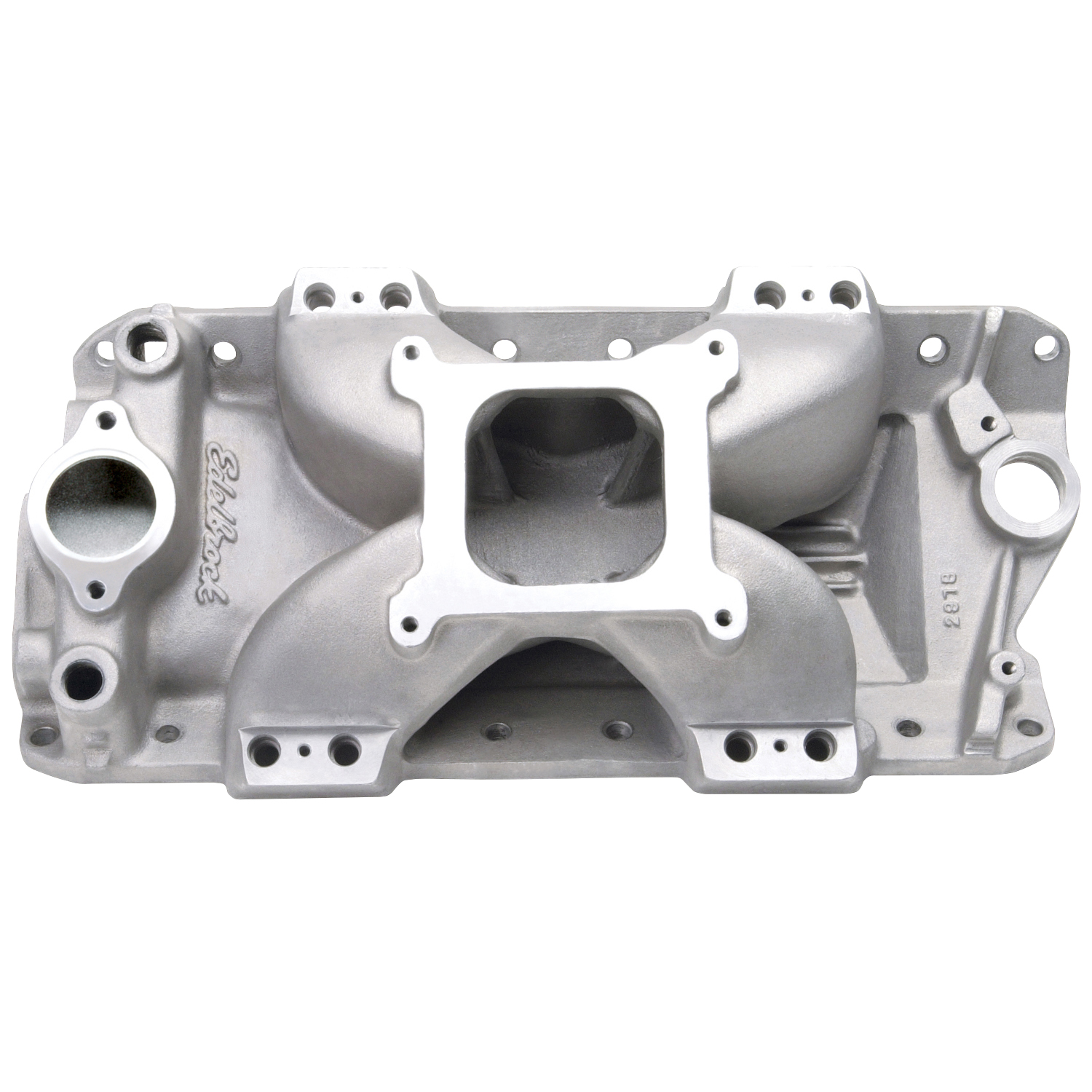

So look at this and it almost makes you forget you think something about port speed and localized velocities. I decided to go Super Stock racing. For the last 4 years I have been developing the legal Edelbrock casting with racer help and most importantly FJ Smith. I can talk about all this because it's MY engine.

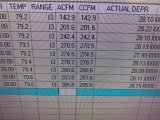

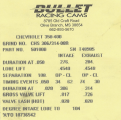

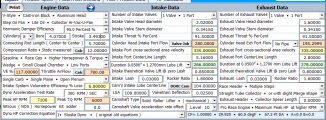

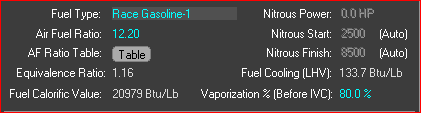

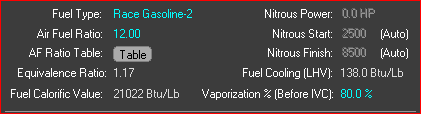

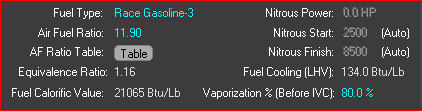

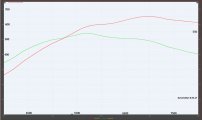

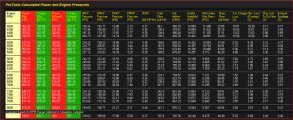

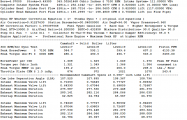

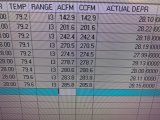

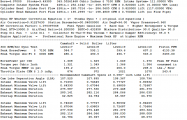

The engine is a 1970 LT1 combo. 350/360hp.. NHRA has it rated at 330. I get the angle plug head and 2.02/1.600. It has 11.5 compression. The heads flow sheet is posted. There IS NOT one area in the port under 400fps. The MIN CSA is 1.80in at the pushrod. The throat is 92%. I have attached the actual dyno sheet and the PipeMax simulation for the Stuska dyno. I'm getting ready to put it back on the dyno with changed.

The question, how does a cylinder head that has a 2.04 AVG CSA, and is 172cc, make the power and at 7100??

I have lots of data I can post up tomorrow.

The engine is a 1970 LT1 combo. 350/360hp.. NHRA has it rated at 330. I get the angle plug head and 2.02/1.600. It has 11.5 compression. The heads flow sheet is posted. There IS NOT one area in the port under 400fps. The MIN CSA is 1.80in at the pushrod. The throat is 92%. I have attached the actual dyno sheet and the PipeMax simulation for the Stuska dyno. I'm getting ready to put it back on the dyno with changed.

The question, how does a cylinder head that has a 2.04 AVG CSA, and is 172cc, make the power and at 7100??

I have lots of data I can post up tomorrow.

Last edited: