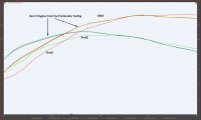

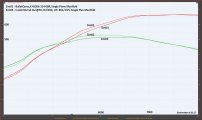

obviously the TIME spent in each section of the power bands

would have a large effect or influence on which intake provided the best compromise or better acceleration.

car weight, , converter stall speed, tire diameter and gearing would have an effect on acceleration

assuming a stall speed, and rear gear is selected for racing to maximize acceleration ,

the single plane should have a marginal edge in performance, as this is obviously not a street ,

performance application.

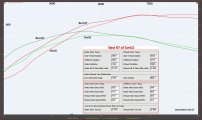

would have a large effect or influence on which intake provided the best compromise or better acceleration.

car weight, , converter stall speed, tire diameter and gearing would have an effect on acceleration

assuming a stall speed, and rear gear is selected for racing to maximize acceleration ,

the single plane should have a marginal edge in performance, as this is obviously not a street ,

performance application.