I was recently asked if a block really needed to be decked after a neighbor blew a head gasket?

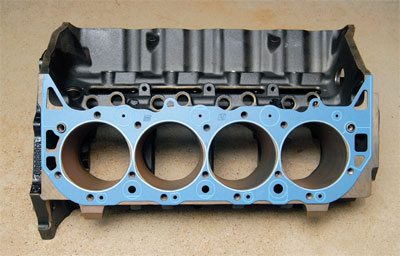

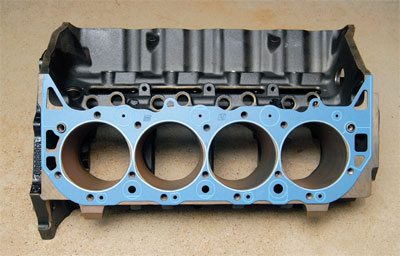

if you don,t know what that, decking the block means,

its basically re-surfacing , or removing a few thousands of material from the block surface where the cylinder heads bolt on,

the head gasket is sandwiched between the block deck and cylinder heads and compressed with the head bolt tension.

for the gasket to provide the proper seal it must be between two flat, smooth parallel surfaces that are measured from the crank centerline.

most factory blocks are about .020-.025 taller than the listed deck height,

to allow a deck trim/mill to straighten and make the head gasket sealing surface true,

without milling the engine deck height under the listed deck height.

having a used block deck milled .005 to true up the surface is rather common before a rebuild, obviously, with most factory cast blocks having about a .024 over the design specs in deck height, this can be done more than once in an engines life and head gaskets vary from about .015-.080 to allow you to get proper quench

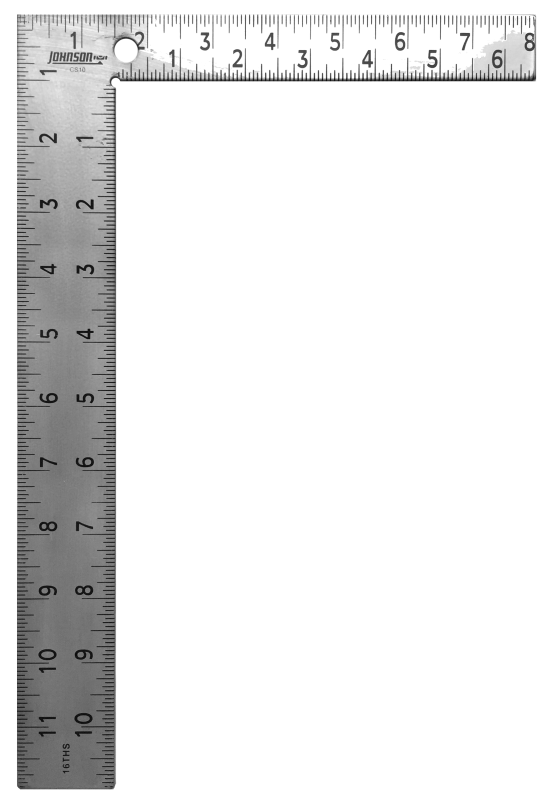

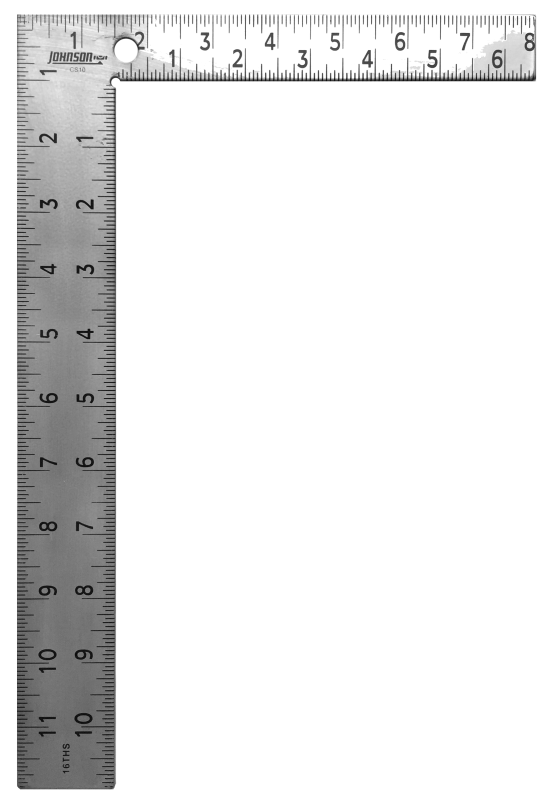

It might be a surprise to many guys but a $10,

METAL CARPENTERS SQUARE and feeler gauges, can be used ,

to verify a block thats is significantly warped on the deck surface.

on the deck surface.

now just because you blow a head gasket its not almost mandatory,

but it could be required ,that you might need the block deck re-machined,

....the hotter the engine got and the longer the engine ran,

with a defective head gasket ,

the more likely the block needs to be re-decked.

it should be obvious that careful inspection and accurate measurement is required,

and

if in doubt, bring it to a local trusted machine shop

for cleaning inspection and having the,

new cam bearings and new brass freeze plugs installed

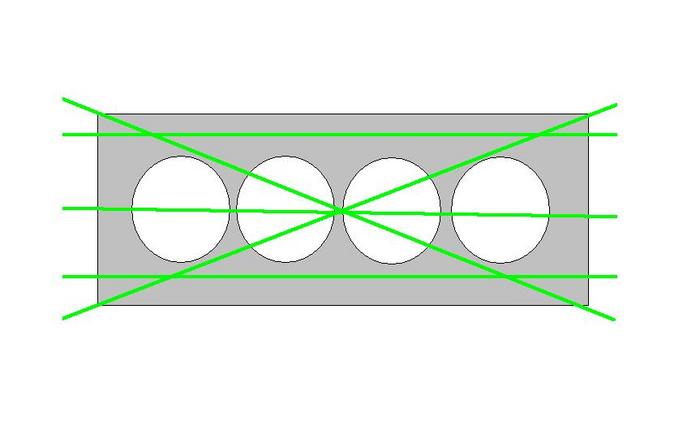

Here is a cutaway illustration of a piston at top dead center to show deck height in action.

hey measure the piston deck height after the machined block has the rotating assembly test fitted

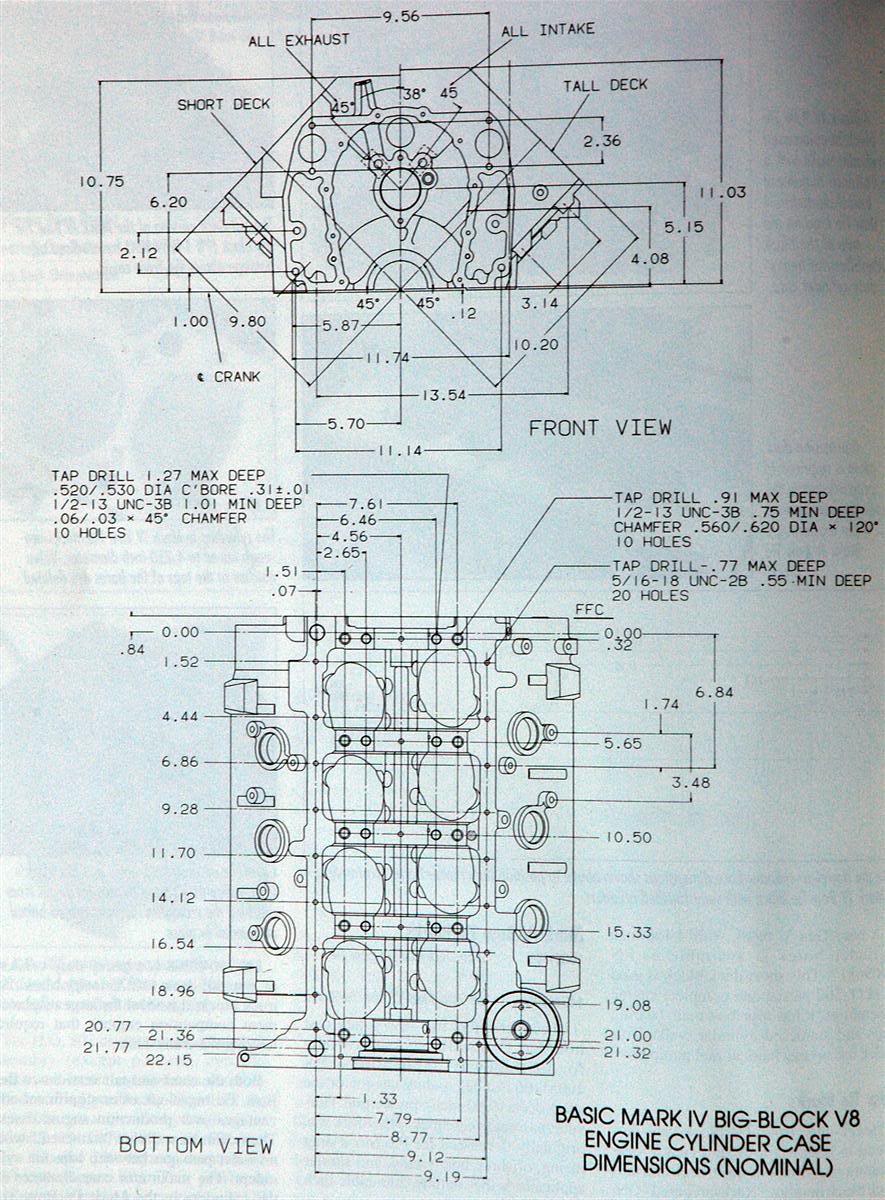

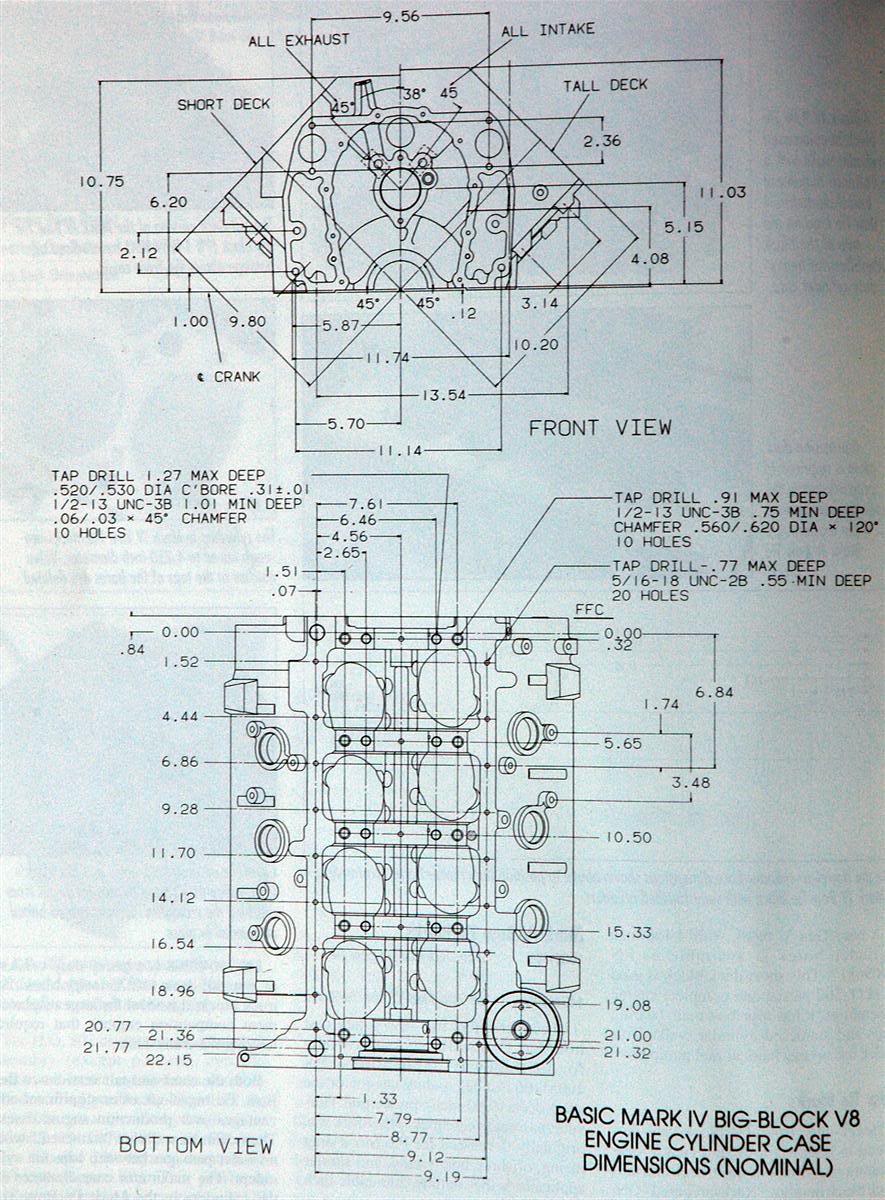

Deck Heights of Popular Domestic V8 Engines

Chevy

BlockDeck Height

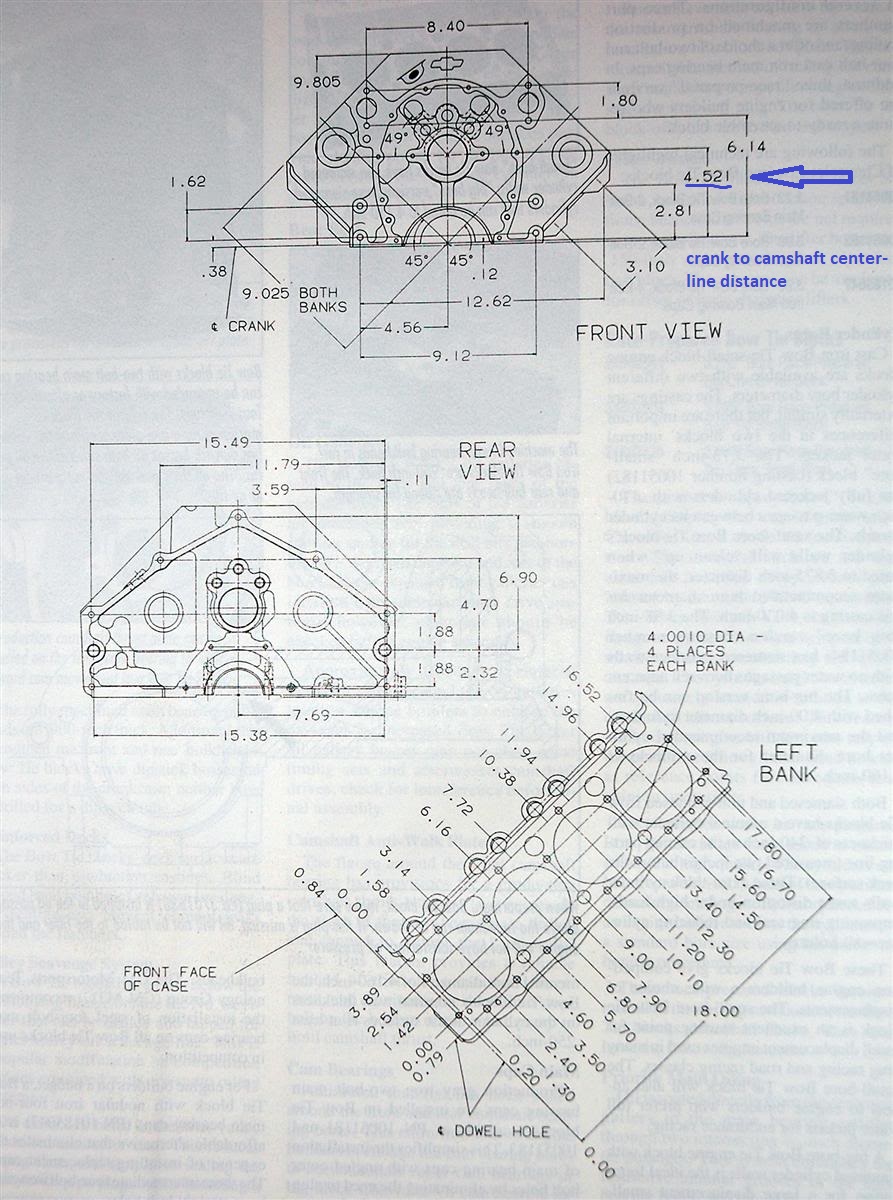

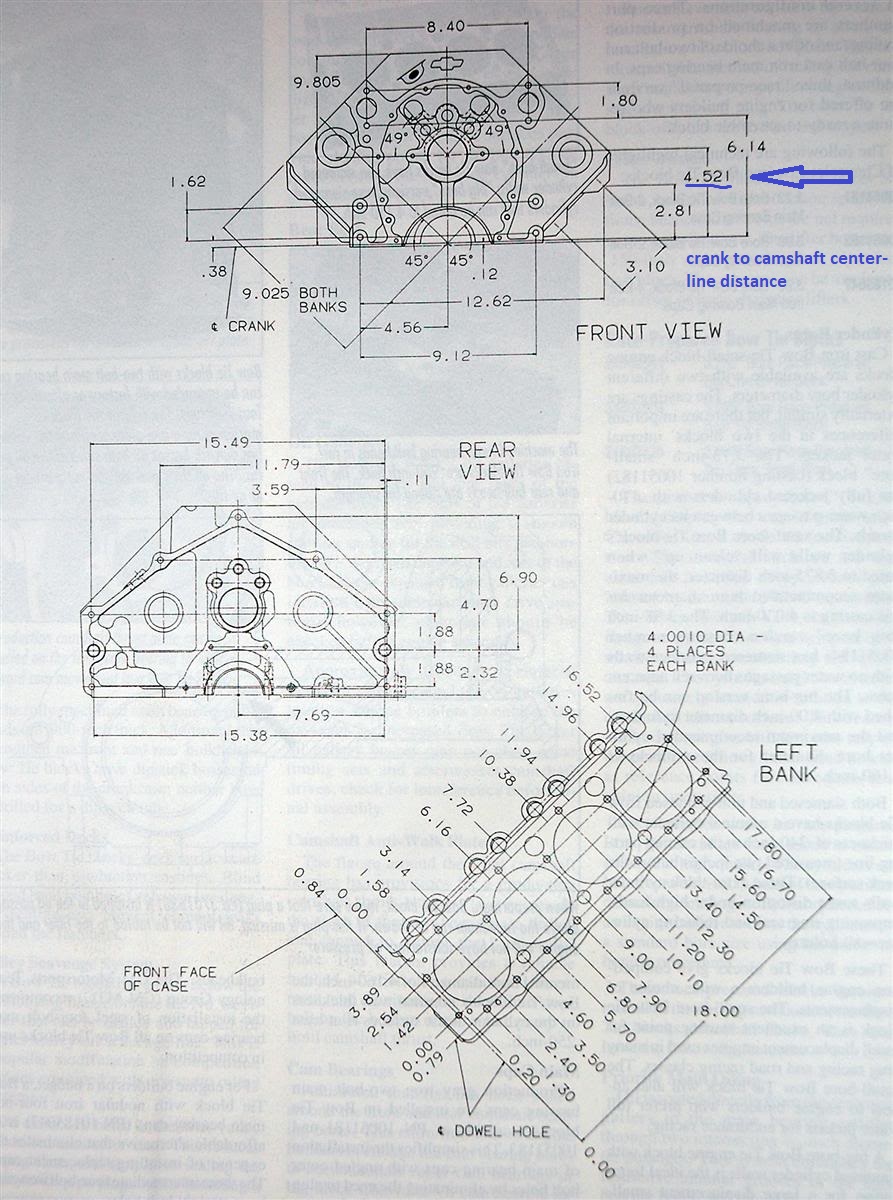

283-350-400 SBC ----------------------9.025

LS Gen III/IV/V------------------------9.240

396-454 MK IV Gen V/VI BBC------ 9.80

348-409 ---------------------------------9.60

366-427 Truck Tall Deck BBC --------10.20

Ford

BlockDeck Height

289-302 -----------------------------------8.206

Boss 302 / SVO------------------------ 8.201/ 8.210

4.6L – 5.0L Modular-------------------- 8.937

351W------------------------------- 9.480 - 9.503

351 C Boss --------------------------9.206

351M -------------------------------10.297

Ford Racing 351W ----------------9.206 – 9.503

351C, 400-2V ---------------------10.292 – 10.302

FE 332-428 ------------------------10.17

429-460 “385” ---------------------10.300 – 10.310 – 10.322

4.6L-5.0L Mod --------------------- 8.937

5.4L Mod ---------------------------10.079

Chrysler

273-318- Poly ----------------------9.60

273-318-340-360 LA -------------- 9.60

Chrysler LA Race -------------------9.56

361-383-400 B ---------------------9.98

413-426-440 RB -------------------10.725

426 Hemi ---------------------------10.725

5.7L- 6.4L Hemi ------------------- 9.240

Buick

400-430-455 -----------------------10.57

Oldsmobile

400-425-455 ----------------------- 10.625

Pontiac

326-350-389-400-428-455 ---------10.20

lots of good related linked info

yeah I'M AWARE MANY PEOPLE SKIP READING RELATED LINKS

BUT THEY ALSO EVENTUALLY WILL REALIZE IT COSTS THEM MORE,

TIME, EFFORT AND CASH TO DO THAT IN THE LONG TERM

AN HOUR OR TWO SPENT READING LINKS USUALLY IS TIME VERY WELL SPENT

https://www.enginebuildermag.com/20...avoid-when-resurfacing-cylinder-heads-blocks/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

https://www.hotrod.com/articles/ctrp-0701-engine-block-prep/#:~:text=Decking the Block Decking is,square up" the cylinder heads.

https://www.enginelabs.com/news/hit-the-deck-what-you-should-know-about-engine-block-deck-height/

http://garage.grumpysperformance.com/index.php?threads/head-gasket-roughness-ra.15927/#post-95850

https://drivcat.com/Docs/1425.pdf

http://garage.grumpysperformance.co...402-bbc-with-a-4-454-crank-or-even-4-25.2165/

http://garage.grumpysperformance.co...ng-piston-pin-height-compression-height.5064/

http://garage.grumpysperformance.com/index.php?threads/milling-heads-and-intakes.2988/#post-38975

http://garage.grumpysperformance.com/index.php?threads/head-gasket.10085/#post-39429

http://www.performanceracingengine.com/Engine_Block_Deck_Squaring.html

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68861

https://www.chevydiy.com/gaskets-fasteners-guide-big-block-chevy-engines/

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.co...late-honing-makes-a-differance.588/#post-7313

http://garage.grumpysperformance.com/index.php?threads/flex-hone.9538/#post-35100

http://garage.grumpysperformance.co...ing-piston-to-bore-ring-seal.3897/#post-26602

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

https://blog.k1technologies.com/what-is-deck-height-how-to-calculate-and-what-it-means

TW the question always comes up, "how do you seal the rings/pistons to the bore so the fluid you use to measure the piston dome volume does not leak past the rings?

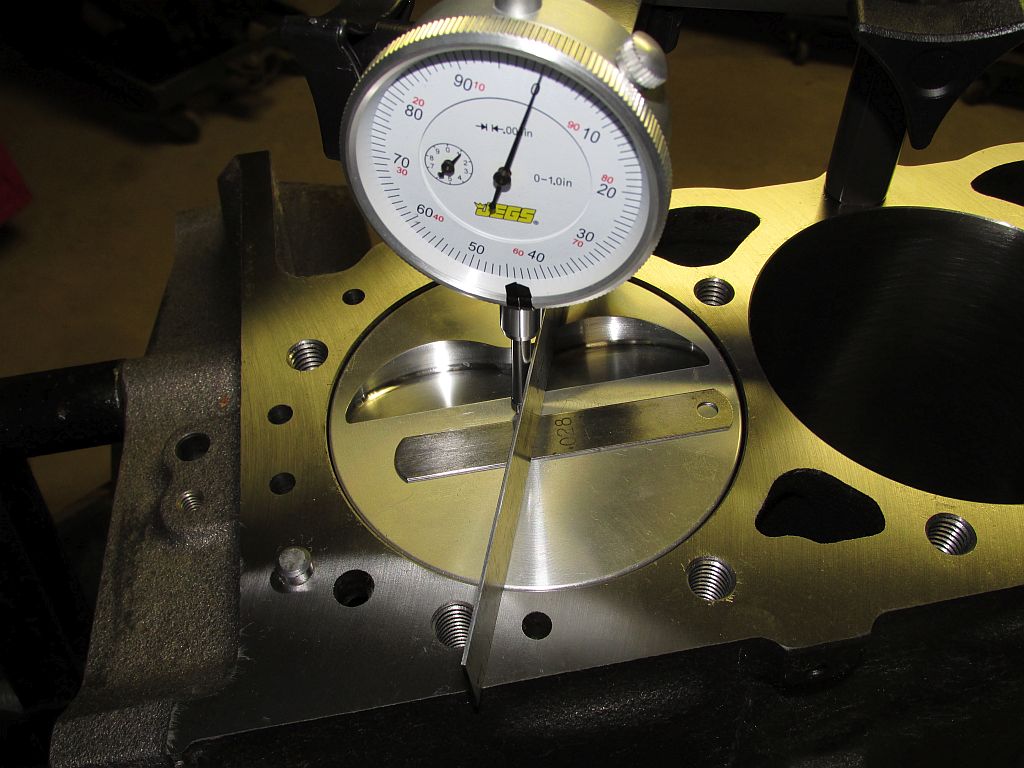

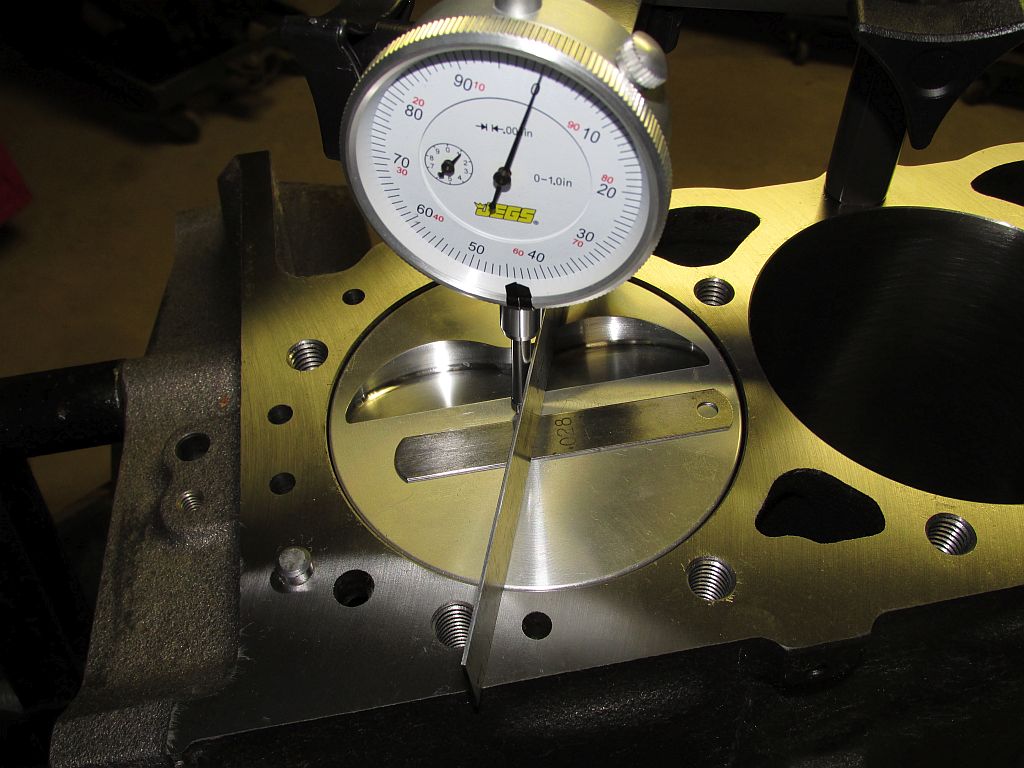

OK, most shops either use a piston bridge and dial indicator or maybe a custom fixture to place the flat or quench deck of the piston exactly 1" below the top of the cylinder bore, and they use a burret when ccing the bore volume vs the theoretical CC volume of a perfect flat bottom cylinder

most shops use a bit of moly grease, smeared 360 dregees around the and on the bore walls with the piston at bdc

and they rotate the crank up from BDC to 1" below TDC, then they use a few tissues and Q-tips to remove all excess grease above the piston or left on the bore wals , some shops pour a bit of melted PARRIFIN on the piston and wipe it into the piston to bore clearance and then they remove all excess off the piston before they measure the piston dome or recess in the piston, from that 1" down the bore location, with a burette of fluid, paraffin has the advantage that it rapidly melts and will burn off in use if a small amount is left in the oil, most oil already has a bit of paraffin in it,

you may need to use a floor jack to lift the engine to have the blocks deck read level, use a solid but reasonably soft spacer under the block if thats required to prevent damaging the blocks lower surfaces, a large block of wood may work,

garage.grumpysperformance.com

remember the formula for a cylinders volume is the radias (1/2 the diameter) squared times 3.147 times the depth (in this case 1"

1 cubic inch = 16.3871 cc's

so for example if the bore diameters 4.25" youll multiply 2.125 x 2.125 x 3.147 to get the cubic inch volume them multiply the result by 16.3871 to get the cc's

thats the expected volume above a flat top piston, you'll generally use a bit more because the valve clearance notches add 6-8 cc volume on a flat top piston or use a bit less fluid from the burret if the pistons got a dome.

obviously the difference is the dome volume

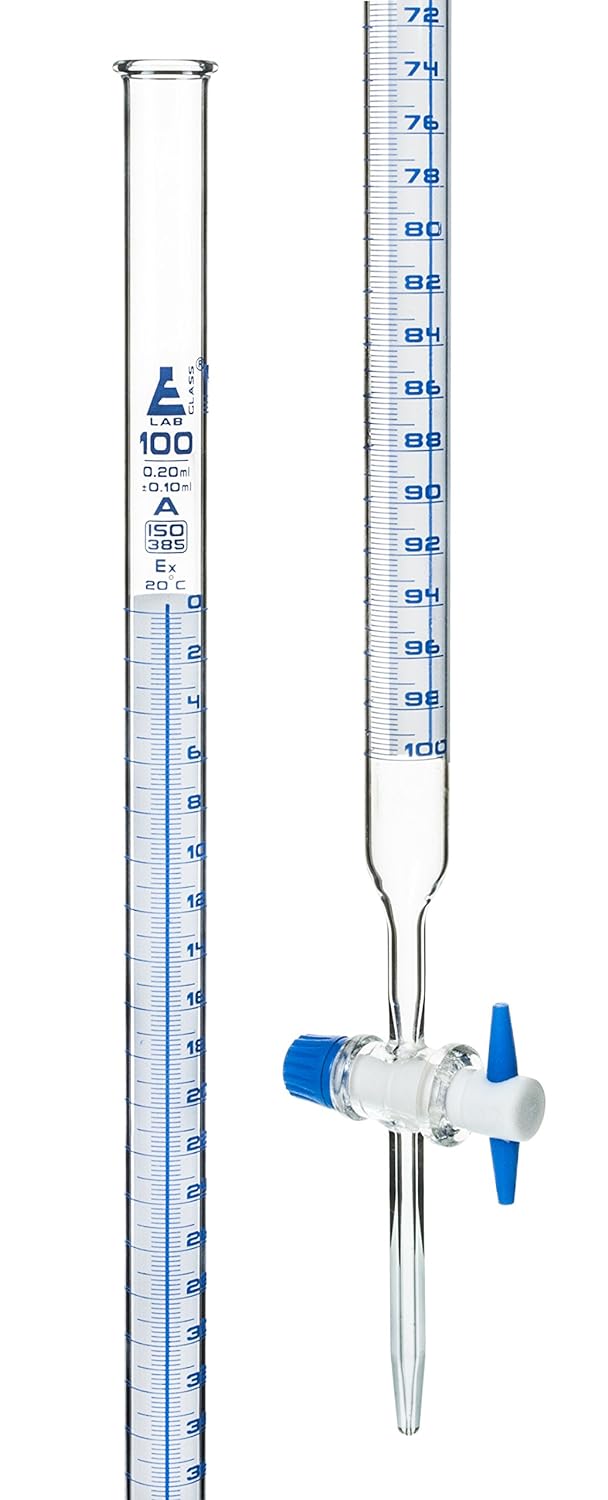

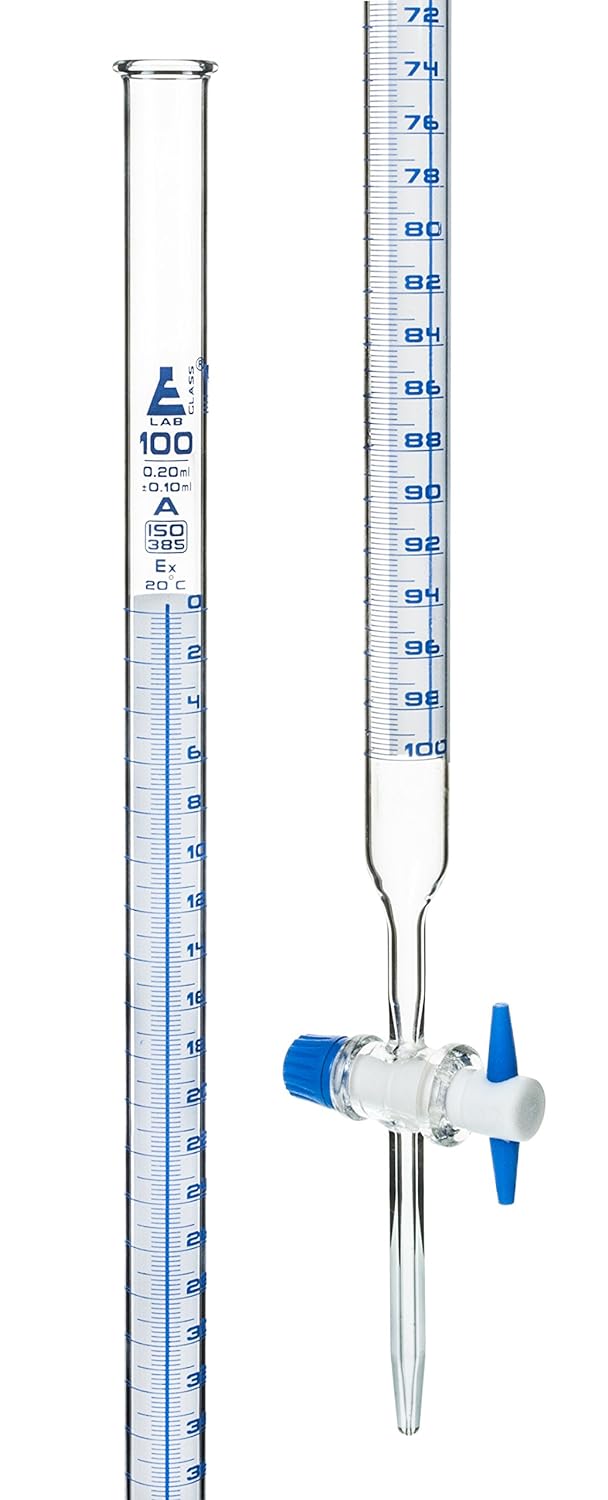

I generally use a 100cc-250cc BURRET and a 6" square sheet of LEXAN (they generally sell 12" square sheets so you get four to use to measure heads and piston volume ones you carefully saw then drill the 4 quarters) use with a small counter sunk hole drilled in the center over the bore for the burret to drip fluid through, a very small thin bead of grease or silicone around the bore to seal the lexan from leaking fluid is advised and of course the blocks deck must be both level and clean, before the blocks used to measure the piston dome volume,

this is a good time to use a 24" steel carpenters square and a set of feeler gauges to verify the block decks square and level,

https://www.amazon.com/SimbaLux-Ple...710&sprefix=6+square+1/2+lexan,aps,273&sr=8-9

read these links

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

\

if you don,t know what that, decking the block means,

its basically re-surfacing , or removing a few thousands of material from the block surface where the cylinder heads bolt on,

the head gasket is sandwiched between the block deck and cylinder heads and compressed with the head bolt tension.

for the gasket to provide the proper seal it must be between two flat, smooth parallel surfaces that are measured from the crank centerline.

most factory blocks are about .020-.025 taller than the listed deck height,

to allow a deck trim/mill to straighten and make the head gasket sealing surface true,

without milling the engine deck height under the listed deck height.

having a used block deck milled .005 to true up the surface is rather common before a rebuild, obviously, with most factory cast blocks having about a .024 over the design specs in deck height, this can be done more than once in an engines life and head gaskets vary from about .015-.080 to allow you to get proper quench

It might be a surprise to many guys but a $10,

METAL CARPENTERS SQUARE and feeler gauges, can be used ,

to verify a block thats is significantly warped

now just because you blow a head gasket its not almost mandatory,

but it could be required ,that you might need the block deck re-machined,

....the hotter the engine got and the longer the engine ran,

with a defective head gasket ,

the more likely the block needs to be re-decked.

it should be obvious that careful inspection and accurate measurement is required,

and

if in doubt, bring it to a local trusted machine shop

for cleaning inspection and having the,

new cam bearings and new brass freeze plugs installed

Here is a cutaway illustration of a piston at top dead center to show deck height in action.

hey measure the piston deck height after the machined block has the rotating assembly test fitted

Deck Heights of Popular Domestic V8 Engines

Chevy

BlockDeck Height

283-350-400 SBC ----------------------9.025

LS Gen III/IV/V------------------------9.240

396-454 MK IV Gen V/VI BBC------ 9.80

348-409 ---------------------------------9.60

366-427 Truck Tall Deck BBC --------10.20

Ford

BlockDeck Height

289-302 -----------------------------------8.206

Boss 302 / SVO------------------------ 8.201/ 8.210

4.6L – 5.0L Modular-------------------- 8.937

351W------------------------------- 9.480 - 9.503

351 C Boss --------------------------9.206

351M -------------------------------10.297

Ford Racing 351W ----------------9.206 – 9.503

351C, 400-2V ---------------------10.292 – 10.302

FE 332-428 ------------------------10.17

429-460 “385” ---------------------10.300 – 10.310 – 10.322

4.6L-5.0L Mod --------------------- 8.937

5.4L Mod ---------------------------10.079

Chrysler

273-318- Poly ----------------------9.60

273-318-340-360 LA -------------- 9.60

Chrysler LA Race -------------------9.56

361-383-400 B ---------------------9.98

413-426-440 RB -------------------10.725

426 Hemi ---------------------------10.725

5.7L- 6.4L Hemi ------------------- 9.240

Buick

400-430-455 -----------------------10.57

Oldsmobile

400-425-455 ----------------------- 10.625

Pontiac

326-350-389-400-428-455 ---------10.20

lots of good related linked info

yeah I'M AWARE MANY PEOPLE SKIP READING RELATED LINKS

BUT THEY ALSO EVENTUALLY WILL REALIZE IT COSTS THEM MORE,

TIME, EFFORT AND CASH TO DO THAT IN THE LONG TERM

AN HOUR OR TWO SPENT READING LINKS USUALLY IS TIME VERY WELL SPENT

https://www.enginebuildermag.com/20...avoid-when-resurfacing-cylinder-heads-blocks/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

https://www.hotrod.com/articles/ctrp-0701-engine-block-prep/#:~:text=Decking the Block Decking is,square up" the cylinder heads.

https://www.enginelabs.com/news/hit-the-deck-what-you-should-know-about-engine-block-deck-height/

http://garage.grumpysperformance.com/index.php?threads/head-gasket-roughness-ra.15927/#post-95850

https://drivcat.com/Docs/1425.pdf

http://garage.grumpysperformance.co...402-bbc-with-a-4-454-crank-or-even-4-25.2165/

http://garage.grumpysperformance.co...ng-piston-pin-height-compression-height.5064/

http://garage.grumpysperformance.com/index.php?threads/milling-heads-and-intakes.2988/#post-38975

http://garage.grumpysperformance.com/index.php?threads/head-gasket.10085/#post-39429

http://www.performanceracingengine.com/Engine_Block_Deck_Squaring.html

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68861

https://www.chevydiy.com/gaskets-fasteners-guide-big-block-chevy-engines/

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.co...late-honing-makes-a-differance.588/#post-7313

http://garage.grumpysperformance.com/index.php?threads/flex-hone.9538/#post-35100

http://garage.grumpysperformance.co...ing-piston-to-bore-ring-seal.3897/#post-26602

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

https://blog.k1technologies.com/what-is-deck-height-how-to-calculate-and-what-it-means

TW the question always comes up, "how do you seal the rings/pistons to the bore so the fluid you use to measure the piston dome volume does not leak past the rings?

OK, most shops either use a piston bridge and dial indicator or maybe a custom fixture to place the flat or quench deck of the piston exactly 1" below the top of the cylinder bore, and they use a burret when ccing the bore volume vs the theoretical CC volume of a perfect flat bottom cylinder

most shops use a bit of moly grease, smeared 360 dregees around the and on the bore walls with the piston at bdc

and they rotate the crank up from BDC to 1" below TDC, then they use a few tissues and Q-tips to remove all excess grease above the piston or left on the bore wals , some shops pour a bit of melted PARRIFIN on the piston and wipe it into the piston to bore clearance and then they remove all excess off the piston before they measure the piston dome or recess in the piston, from that 1" down the bore location, with a burette of fluid, paraffin has the advantage that it rapidly melts and will burn off in use if a small amount is left in the oil, most oil already has a bit of paraffin in it,

you may need to use a floor jack to lift the engine to have the blocks deck read level, use a solid but reasonably soft spacer under the block if thats required to prevent damaging the blocks lower surfaces, a large block of wood may work,

Valve To Piston Clearance??

A buddy of mine is about to drop off a set of fresh 215 closed chambered heads that I’m getting for next to nothing. Question here is does anyone know if the 2349 speed pro ls6 closed chamber replacement piston will work with them? I have a short block sitting here with those pistons ready to go...garage.grumpysperformance.com

remember the formula for a cylinders volume is the radias (1/2 the diameter) squared times 3.147 times the depth (in this case 1"

1 cubic inch = 16.3871 cc's

so for example if the bore diameters 4.25" youll multiply 2.125 x 2.125 x 3.147 to get the cubic inch volume them multiply the result by 16.3871 to get the cc's

thats the expected volume above a flat top piston, you'll generally use a bit more because the valve clearance notches add 6-8 cc volume on a flat top piston or use a bit less fluid from the burret if the pistons got a dome.

obviously the difference is the dome volume

I generally use a 100cc-250cc BURRET and a 6" square sheet of LEXAN (they generally sell 12" square sheets so you get four to use to measure heads and piston volume ones you carefully saw then drill the 4 quarters) use with a small counter sunk hole drilled in the center over the bore for the burret to drip fluid through, a very small thin bead of grease or silicone around the bore to seal the lexan from leaking fluid is advised and of course the blocks deck must be both level and clean, before the blocks used to measure the piston dome volume,

this is a good time to use a 24" steel carpenters square and a set of feeler gauges to verify the block decks square and level,

https://www.amazon.com/SimbaLux-Ple...710&sprefix=6+square+1/2+lexan,aps,273&sr=8-9

read these links

ccing my heads

HELP I hope some can help me with a prob I am having. I started to cc my heads so i check all and found that they need to be ground. I have one at 64.3 so I started grinding one of them to be at 64.3 or there abouts. I ground a lot off and got a reading of 62 so I ground more off and came up...garage.grumpysperformance.com

unshrouding valves, and polishing combustion chambers

I think you missed my point It was a pun intended towards Skipwhite performance..... Short of the long story Skipwhite performance build a motor for me in 2015 fast forward 2018 They built junk from what I have ran into, Grumpy and the gang have gave me all kinds of advice and help so far...garage.grumpysperformance.com

Valve To Piston Clearance??

A buddy of mine is about to drop off a set of fresh 215 closed chambered heads that I’m getting for next to nothing. Question here is does anyone know if the 2349 speed pro ls6 closed chamber replacement piston will work with them? I have a short block sitting here with those pistons ready to go...garage.grumpysperformance.com

\

Last edited: