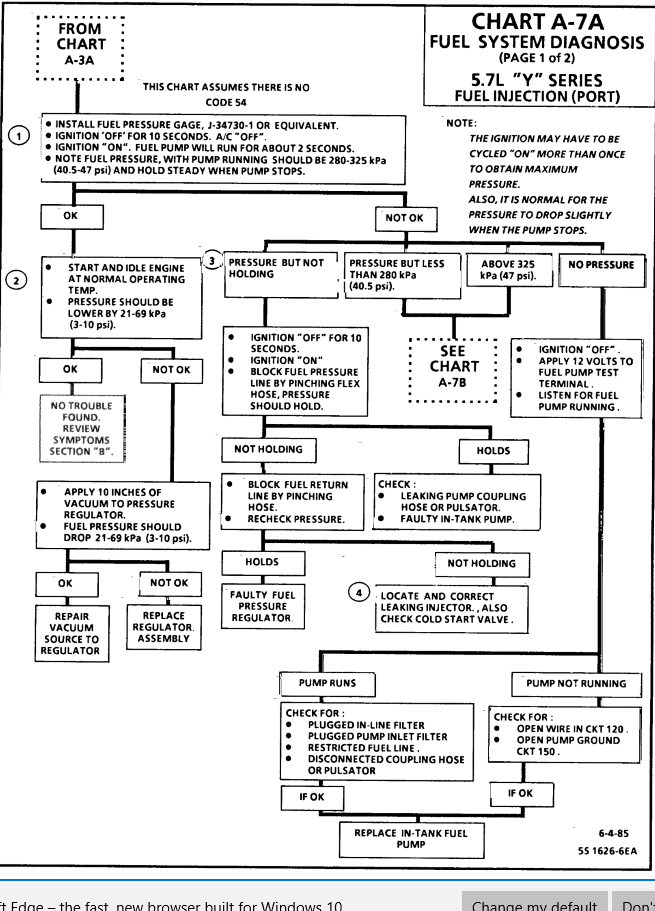

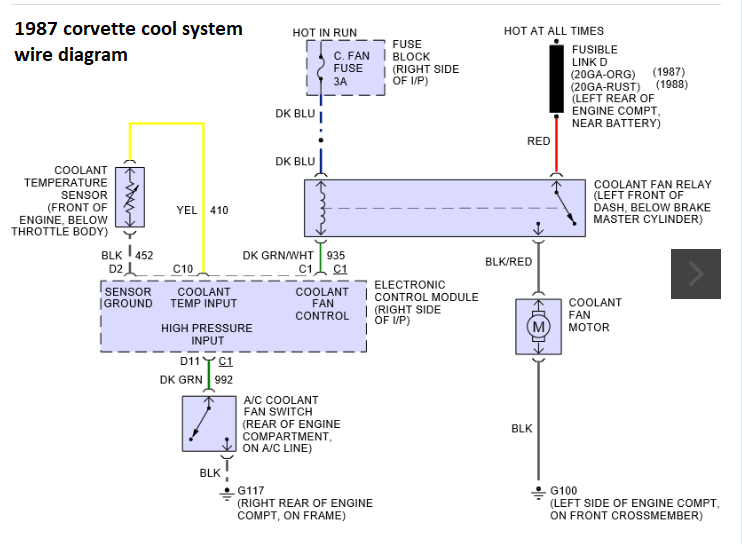

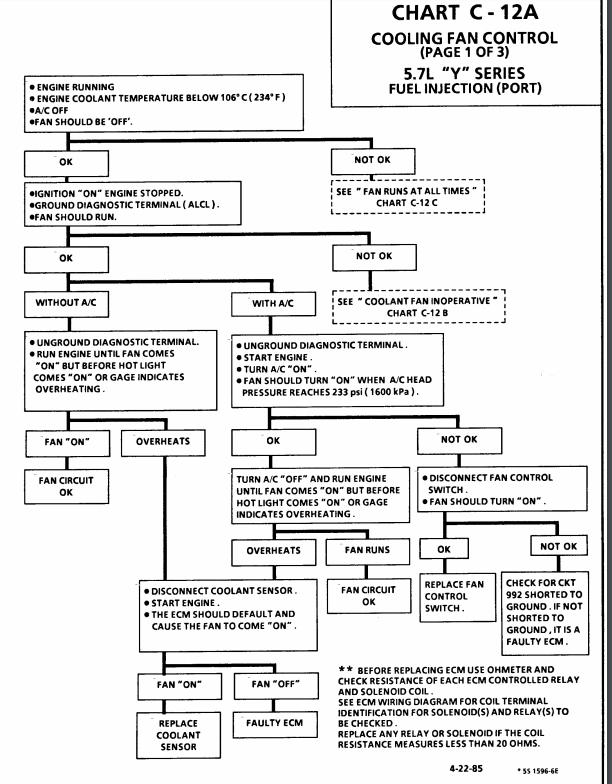

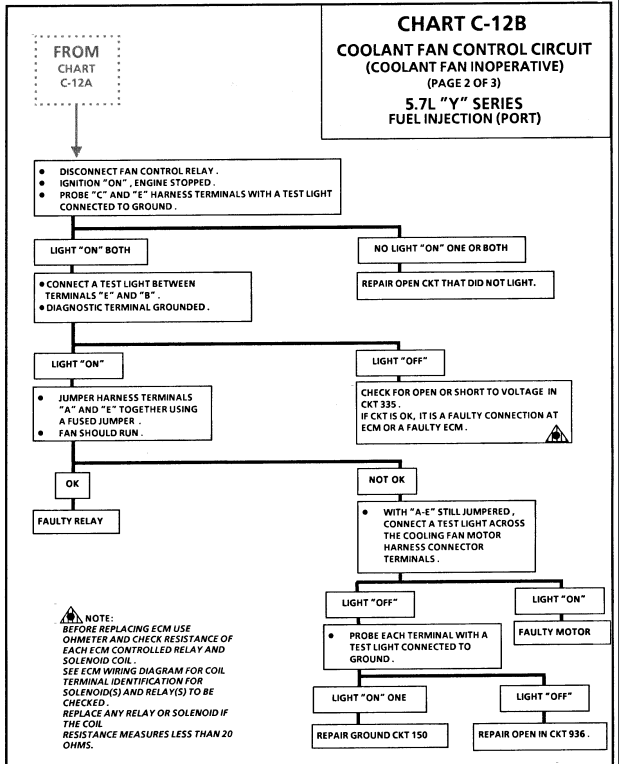

I am having a problem with my '87 C-4 Corvette. I have no power to my fuel pump, fuel pump relay or the 10amp fuel pump fuse.

I have checked the wiring from my ECM to the FPR and it is good.

I also have no power to the 3amp dash lights fuse next to the 10amp fuse.

Is there a common Iam missing?

Where does the ECM receive power that goes to the fuel pump relay.

Thanks

Tony

I have checked the wiring from my ECM to the FPR and it is good.

I also have no power to the 3amp dash lights fuse next to the 10amp fuse.

Is there a common Iam missing?

Where does the ECM receive power that goes to the fuel pump relay.

Thanks

Tony