HOW FAR CAN YOU BORE A BLOCK?

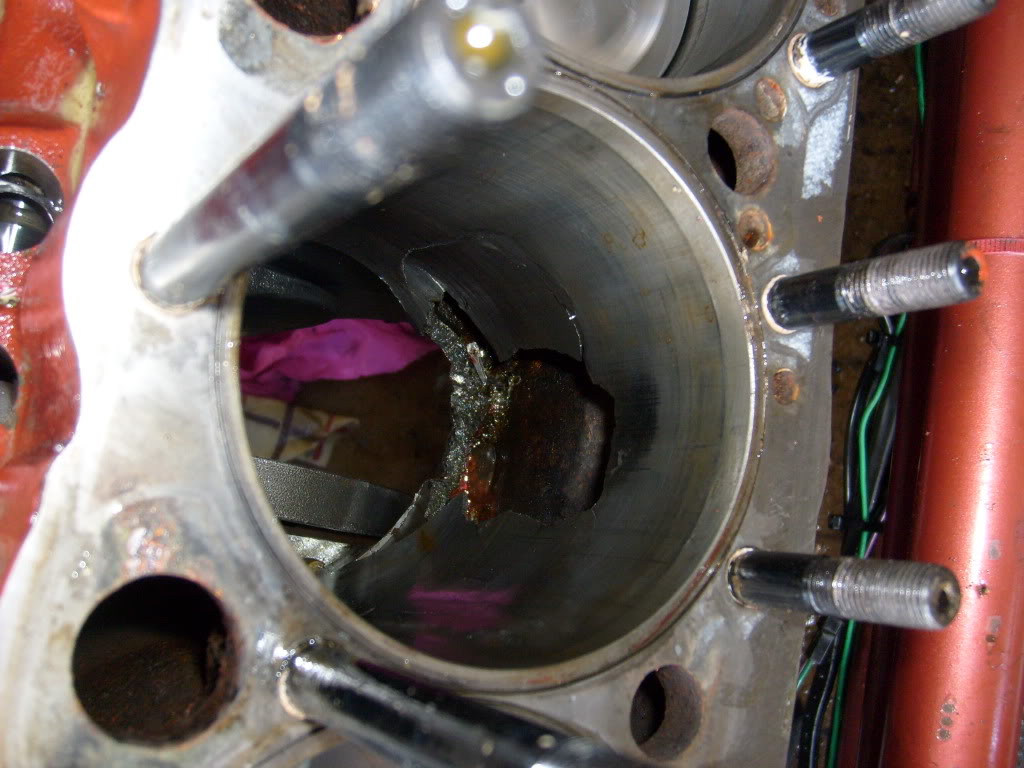

before you begin to have a engine block bored more than about .030 over size its a good idea to have the blocks bore walls sonic tested

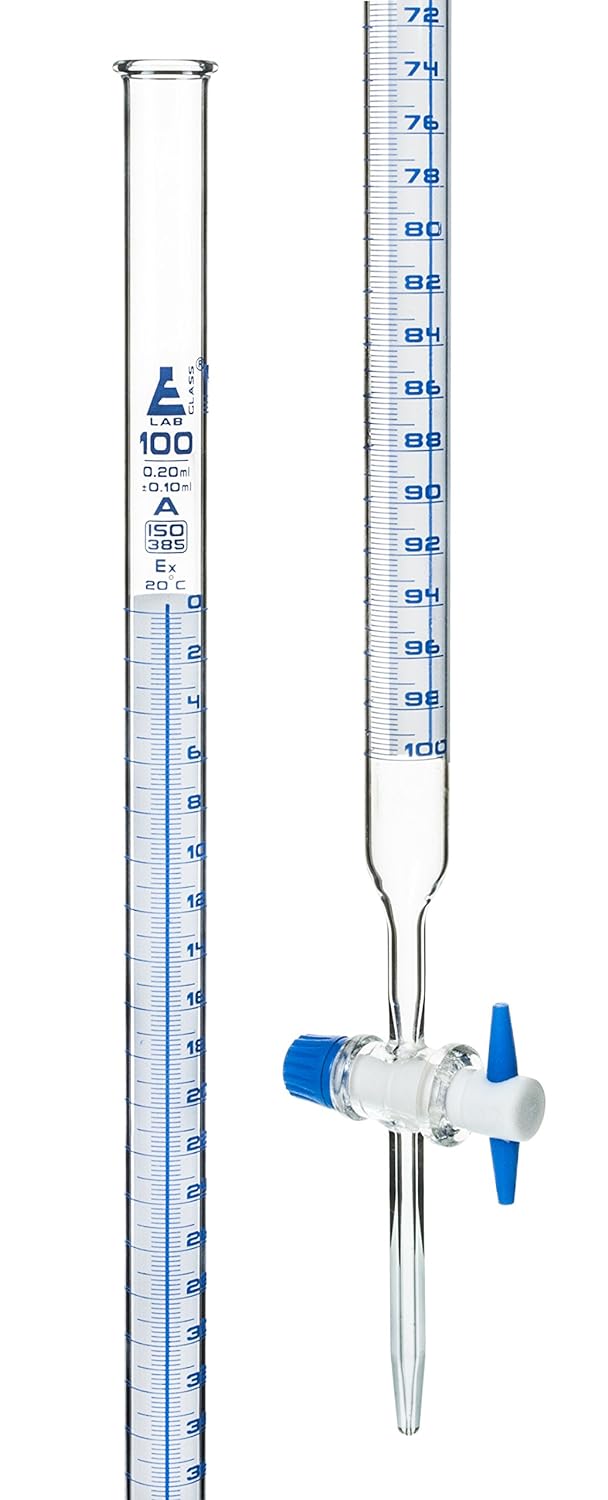

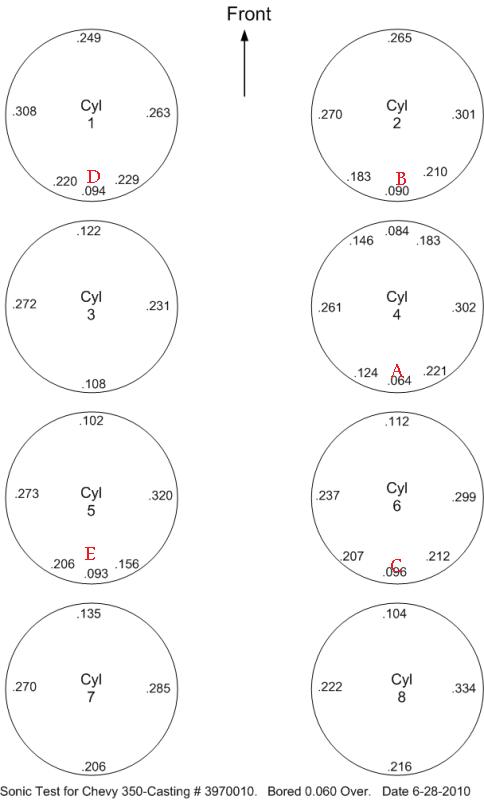

Have your machinist sonic check the block before you bore it.

calculate the remaining bore wall thickness, and if its not thick enough for safe use don,t bother

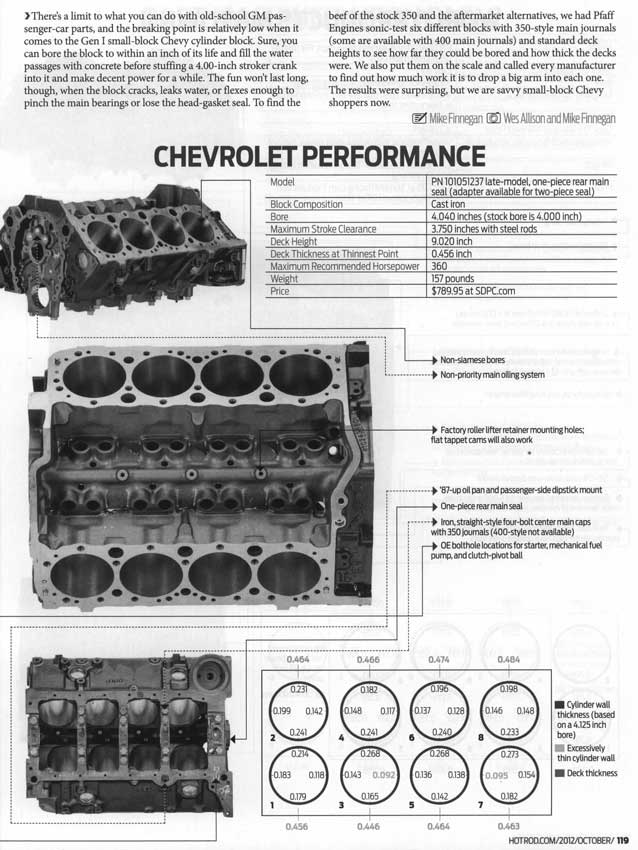

, bore walls are rarely if ever uniform in thickness from top to bottom or side to side, or concentric with the bore center line. and the STOCK O.E.M. production sbc block is well known to be fairly weak structually

REMEMBER PARTS TEND TO BREAK AT THE WEAK POINTS NOT THE STRONGEST AREAS THUS IGNORING THE THIN SECTIONS OF A CYLINDER BORE WALL BECAUSE MOST OF ITS FAIRLY RIGID IS NOT ALWAYS WISE!

its common for one wall in a cylinder to be significantly thinner than the other walls

this might sound like a unneeded extra expense but if your going to put several hundred dollars in machine work into a block you want to be fairly sure it won,t fail under stress wasting all that time and money, plus any resulting damage that might result.

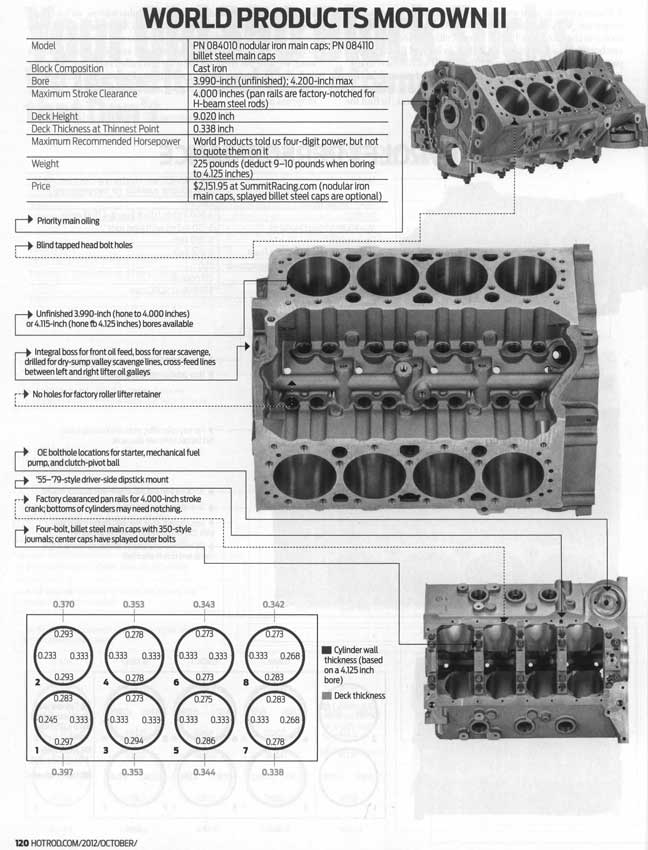

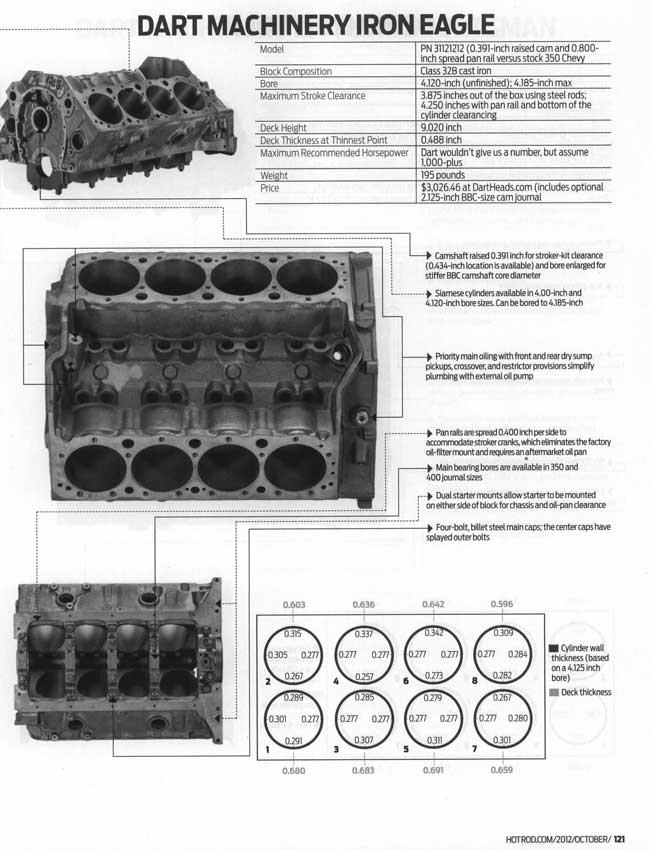

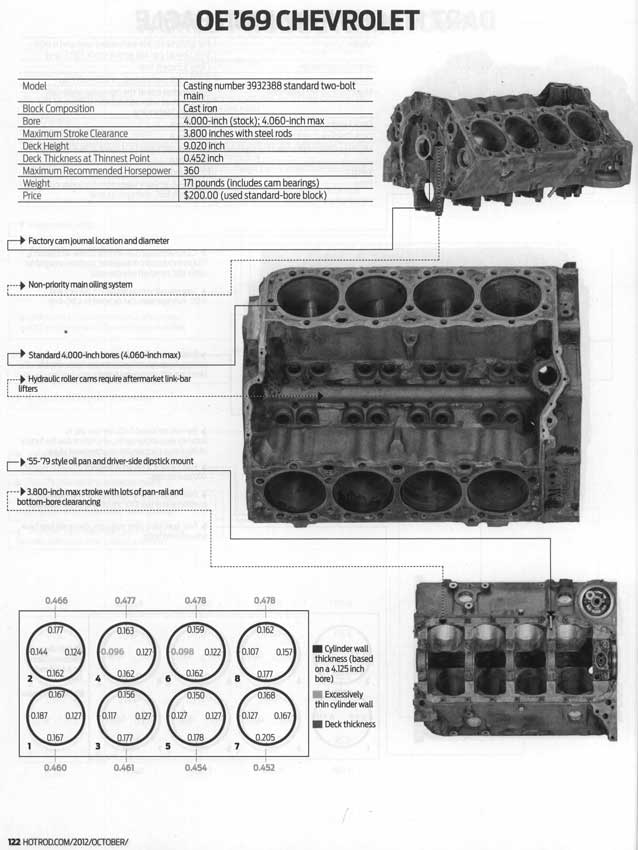

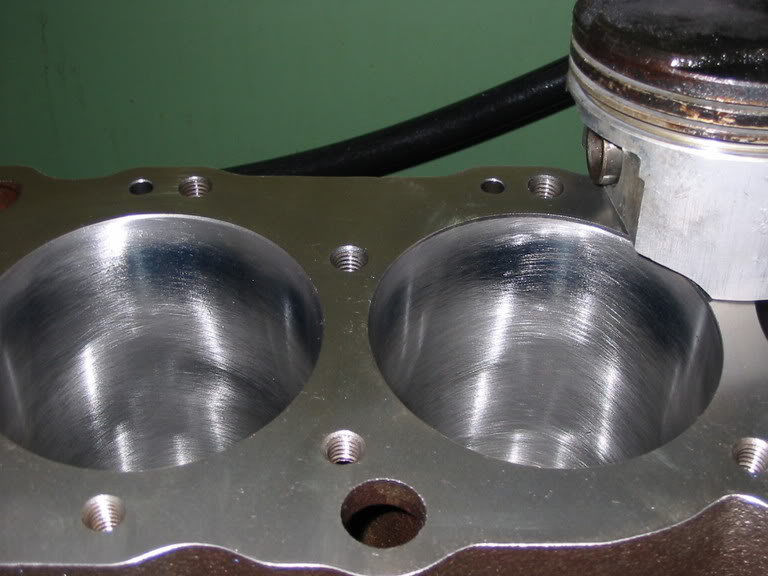

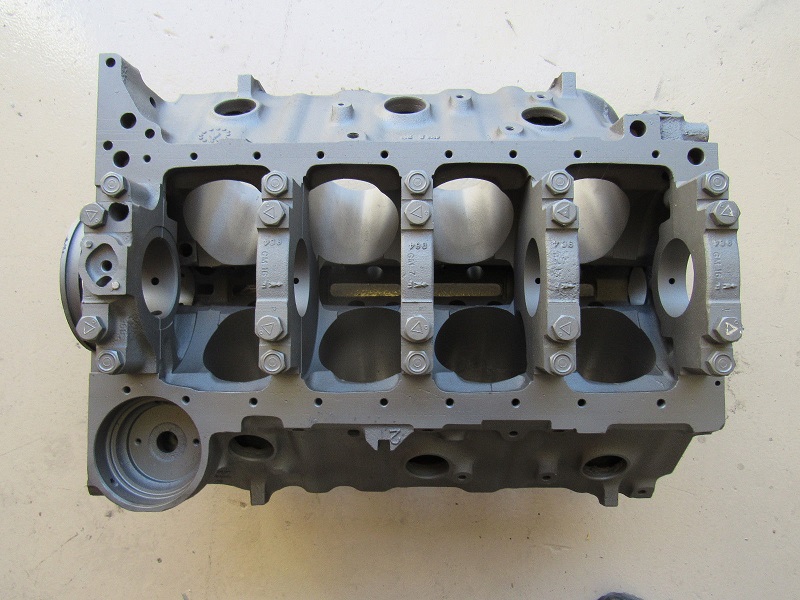

boring a BIG BLOCK CHEVY block to more than about .060 over its original intended bore diameter,or sleeving the bore ,some times its the only way to save a block, but in many cases the O.E.M. blocks are so thinly cast that you'll have bore distortion and less than ideal bore, to piston ring sealing due to the cylinder wall thickness and /or less than ideal ring sealing, once the blocks really hot. making swapping to an aftermarket DART , world products or BOWTIE block with the thicker castings and better alloy metal,a better long term option, you cant tell how thick your cylinder walls are without sonic testing them as casting flaws, core shift and years of rust can make any block walls far thinner than you might assume them to be

let me point out a few facts, boring a cylinder takes 1/2 the bore increase off each side of the cylinder wall, and almost any big block will allow a careful machine shop to physically cut the finished bore size to be .100-.125 oversize , or a SBC .060 over bore,THAT IN NO WAY MEANS the remaining wall thickness thats left will be RIGID enough and STIFF enough to maintain a solid ring seal,or not flex and crack after repeatedly being stressed, at higher rpms and if the bore wall flexes to any significant degree it rapidly results in loss of effective compression rapid ring wear and potentially a cracked or busted cylinder wall.

yes you can have the block sleeved, but having more than two sleeves per cylinder bank on blocks that are not factory designed to have self supported individual cylinders generally results in a weaker block.

filling the lower coolant passages up to the level of the lower freeze plugs has a minimal effect on cooling but it reduces the UN-supported length of the cylinder walls making them stiffer.

KEEP IN MIND THAT YOU CAN PURCHASE BOTH NEW AND USED OEM AND AFTERMARKET CYLINDER BLOCKS, SO YOUR NOT STUCK USING, YOUR ORIGINAL PRODUCTION BLOCK WITH OVERLY THIN WALLS, IF ITS ALREADY RATHER THIN BUT REQUIRES A LARGER SIZE BORE

,https://garage.grumpysperformance.com/index.php?threads/sleeving-a-block.1516/#post-3467

www.motortrend.com

www.motortrend.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

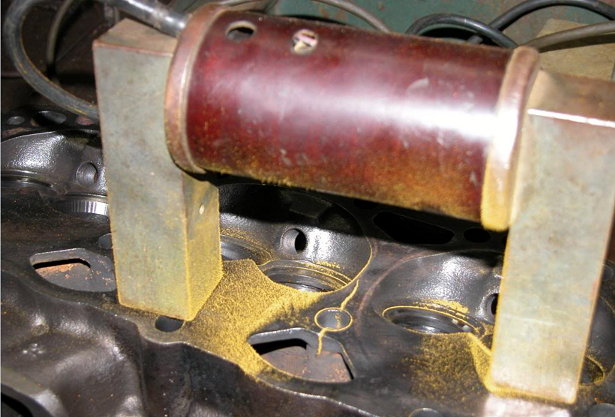

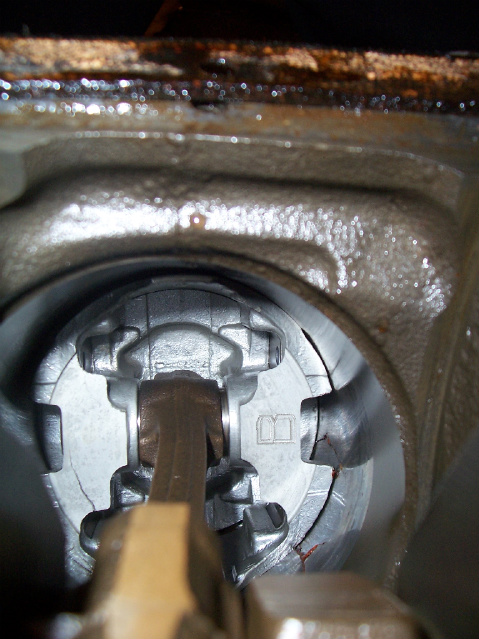

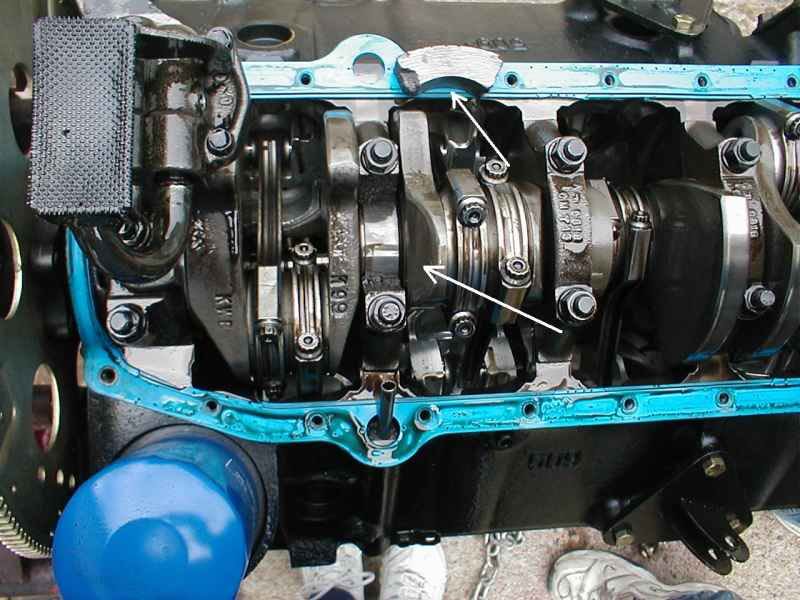

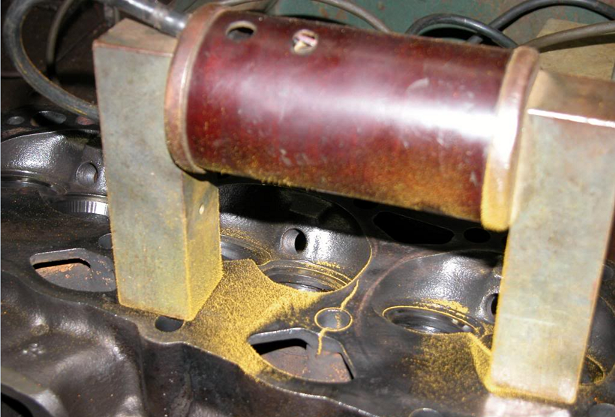

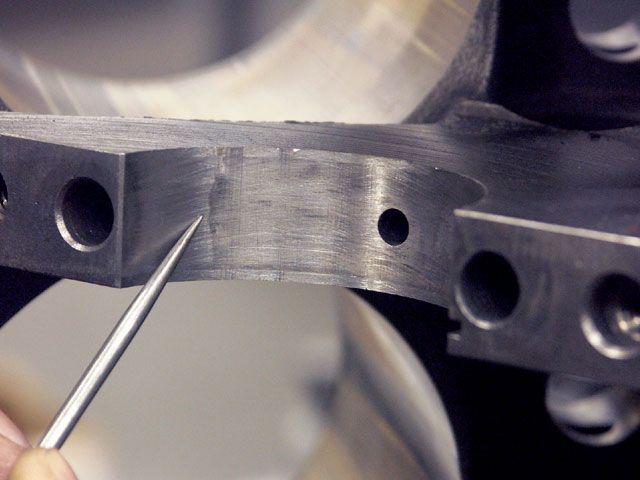

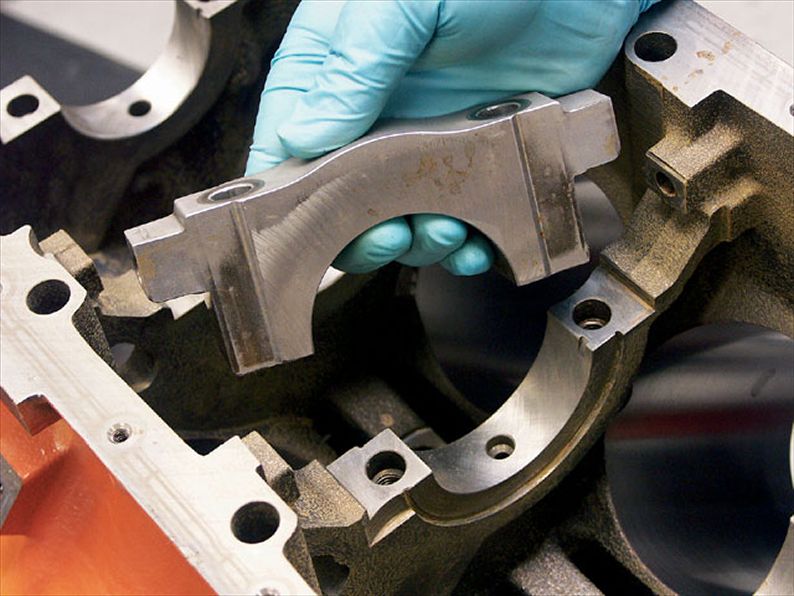

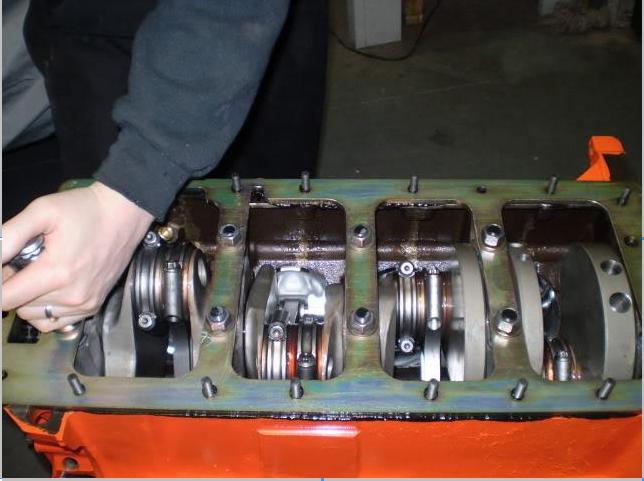

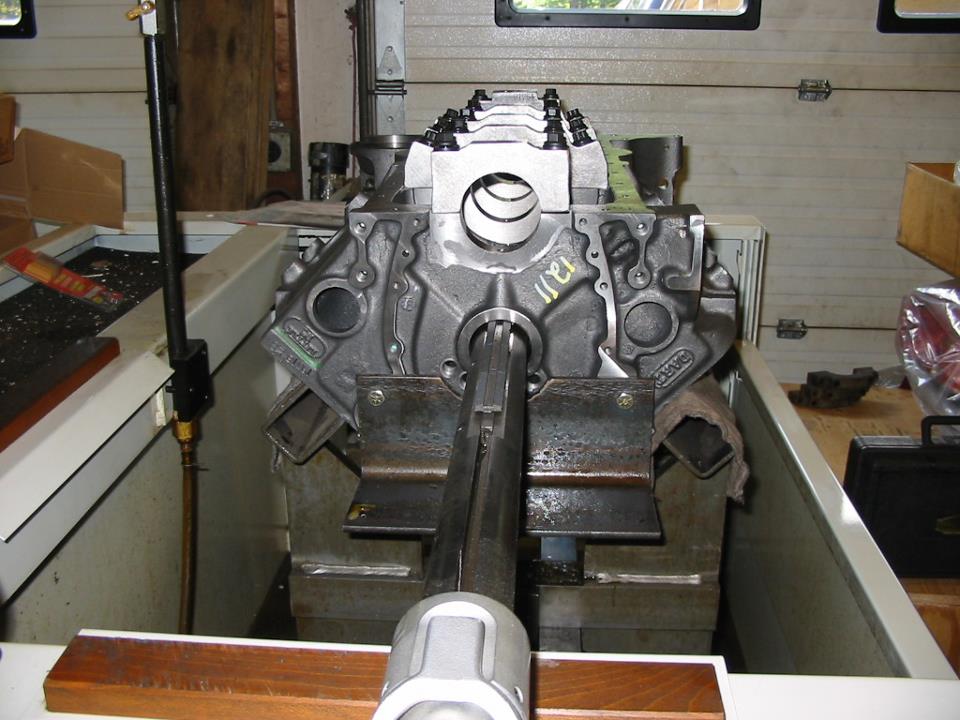

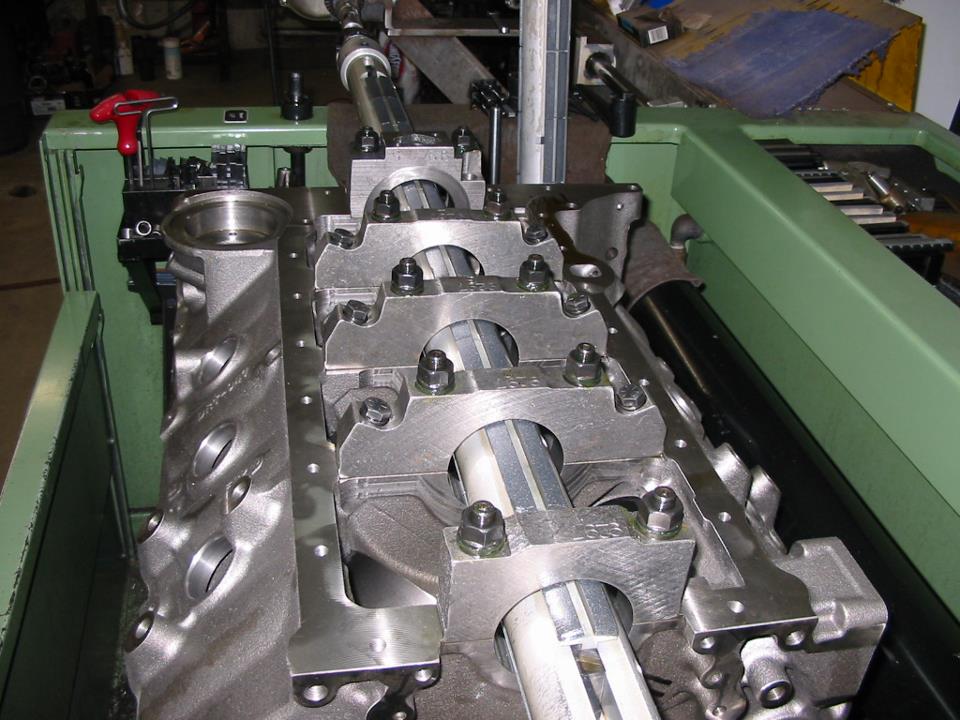

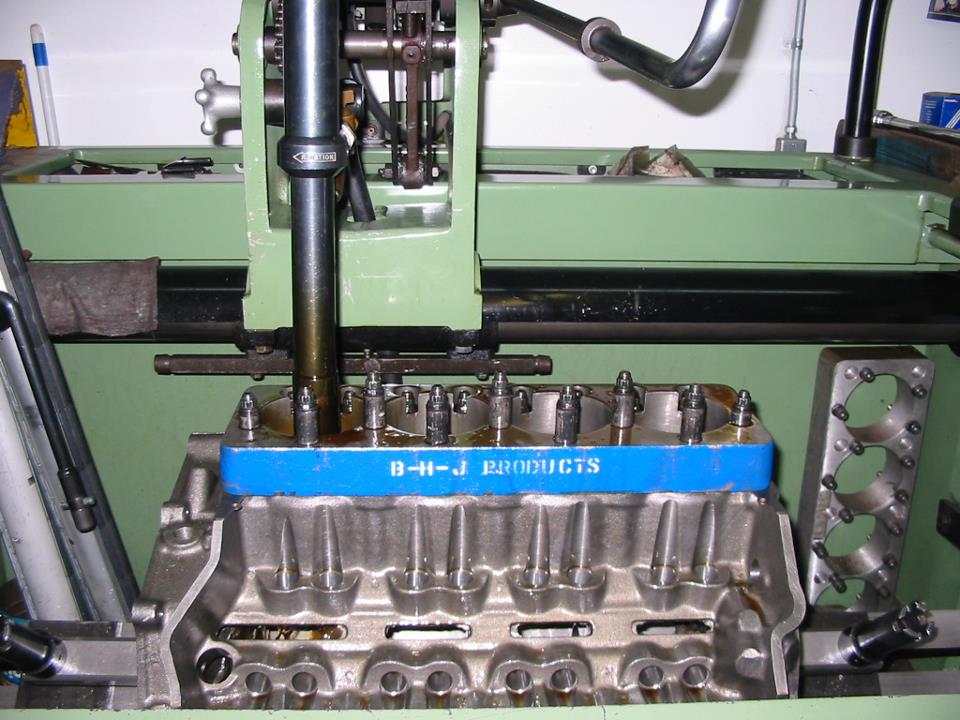

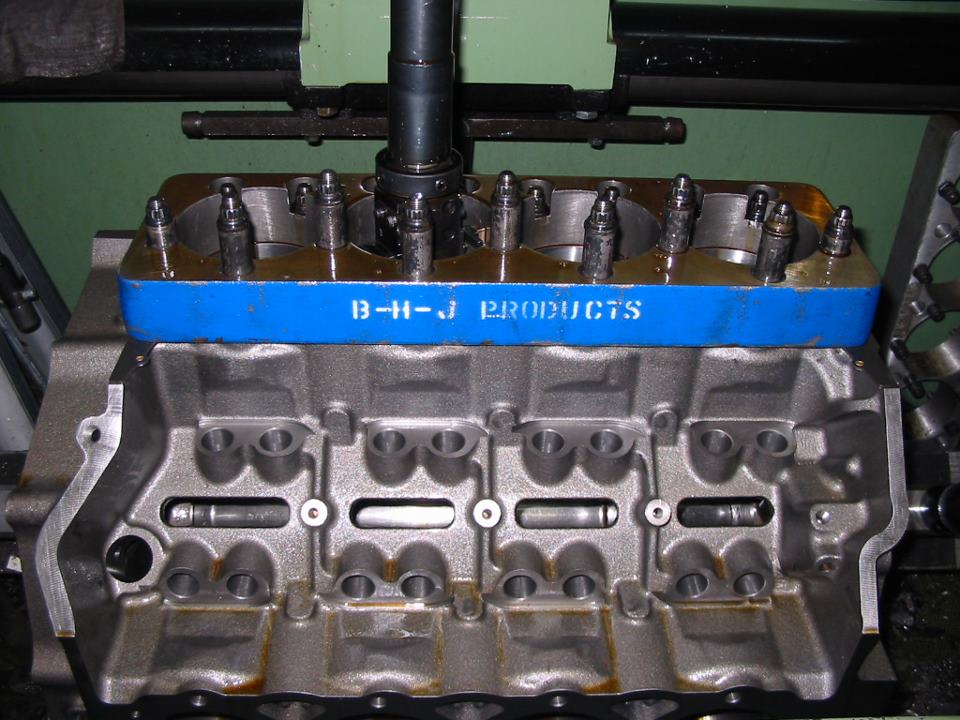

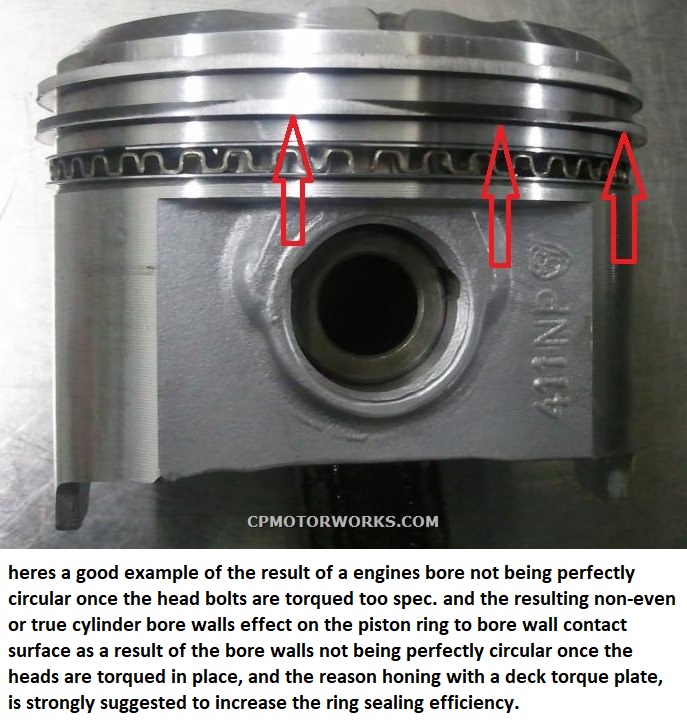

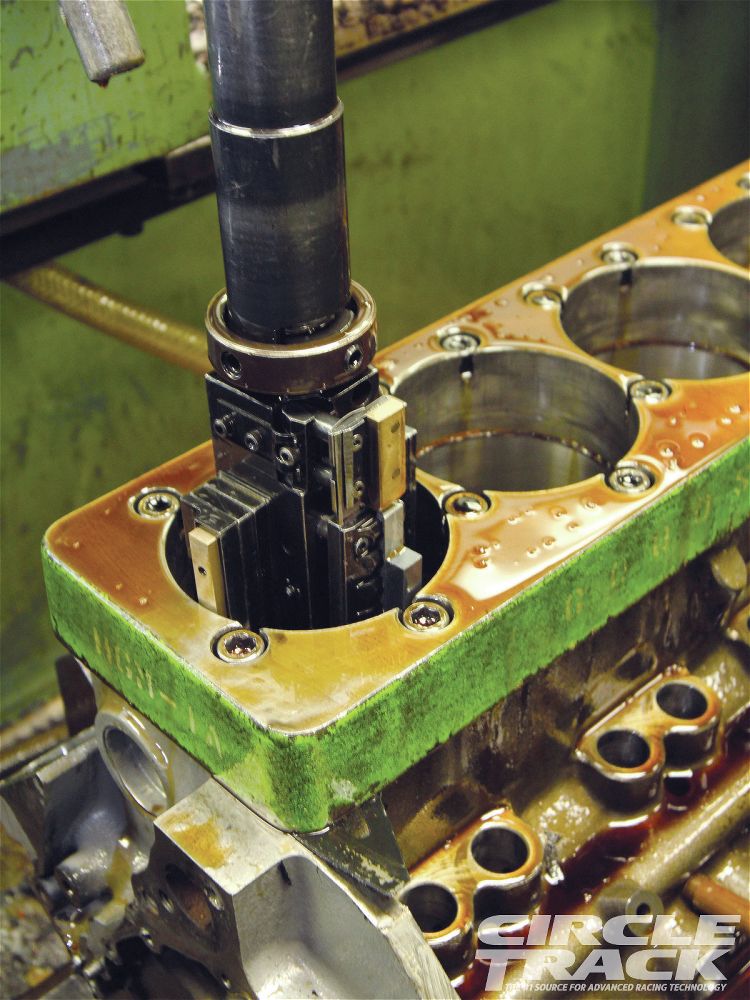

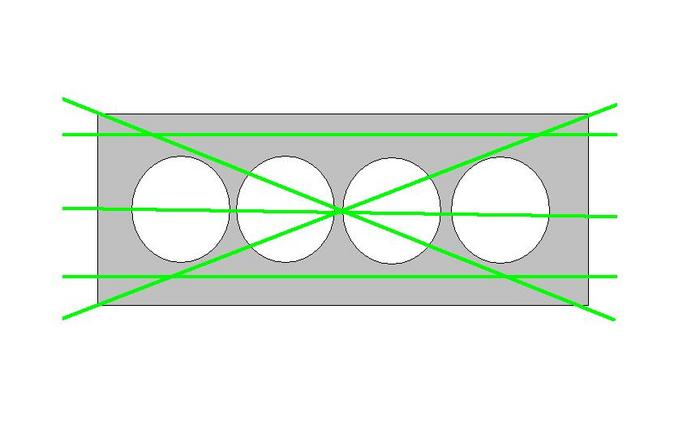

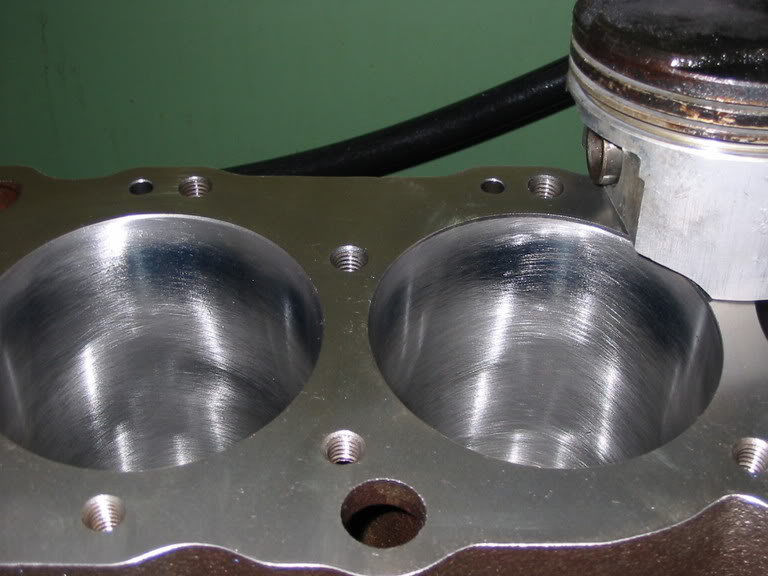

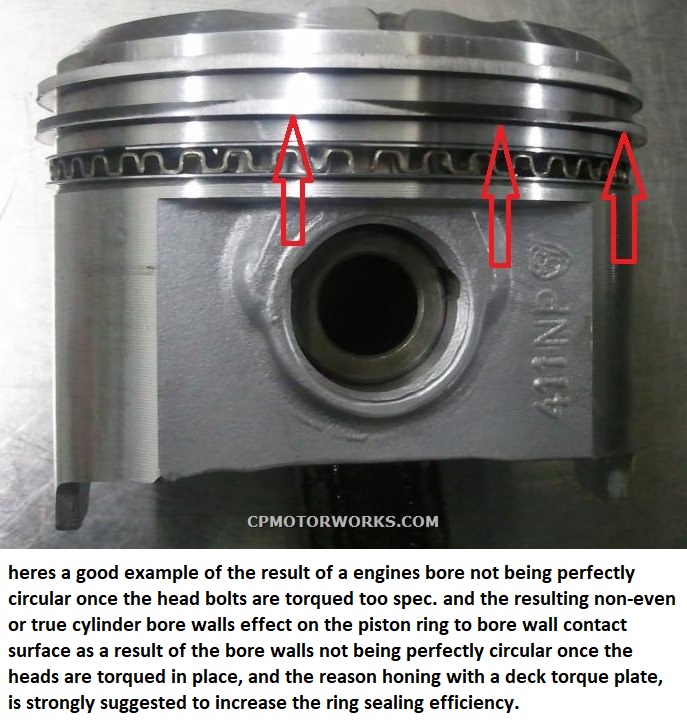

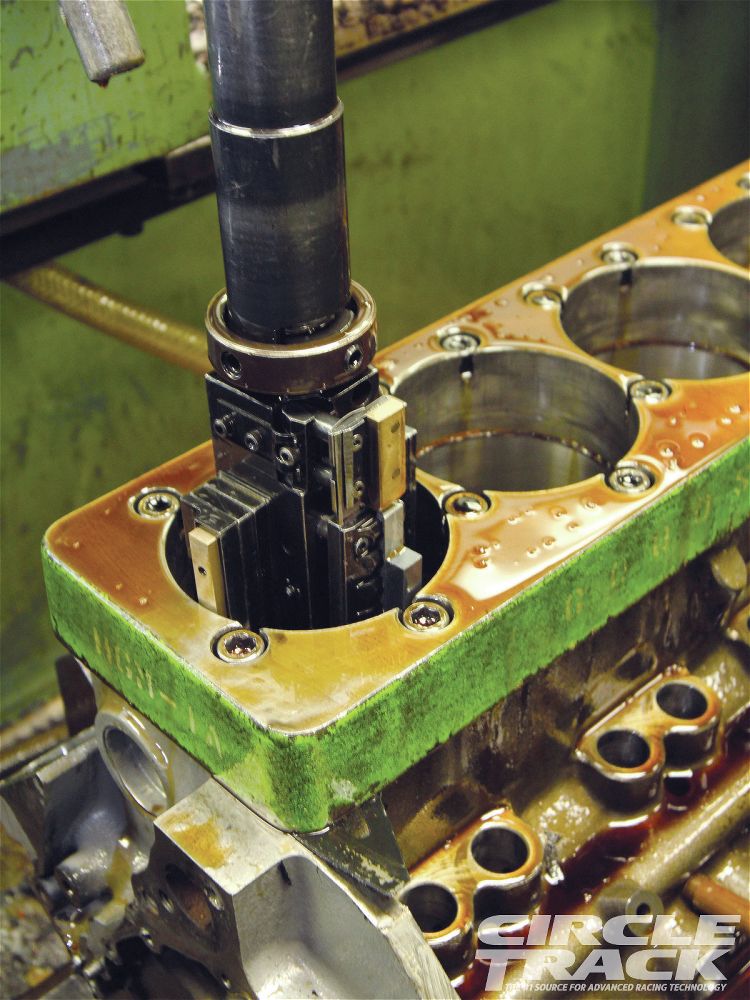

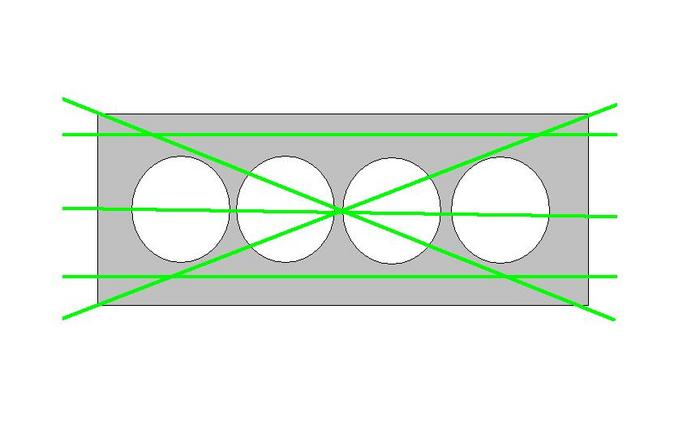

bores must be honed with a deck torque plate to simulate the stress of a installed cylinder head stress , the torqued bolts exert on the bore walls, the torque plate induces and duplicates that stress so that the bore walls will be pulled into the same relationship when you hone the walls concentric, rings won,t seal correctly in a non concentric bore, aftermarket blocks with thicker and stiffer castings are less prone to bore distortion

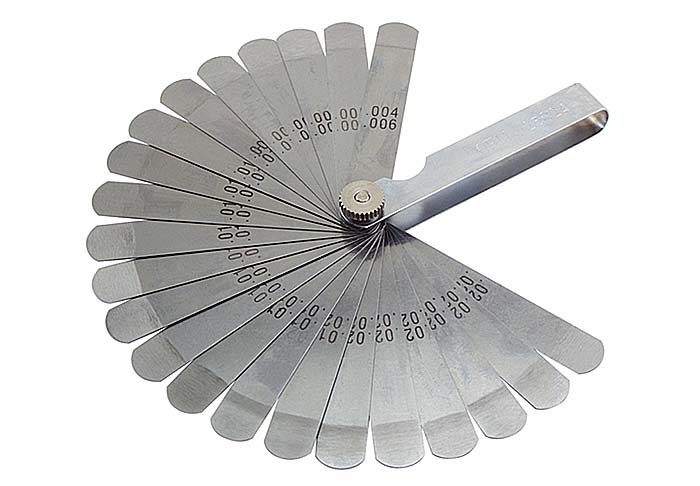

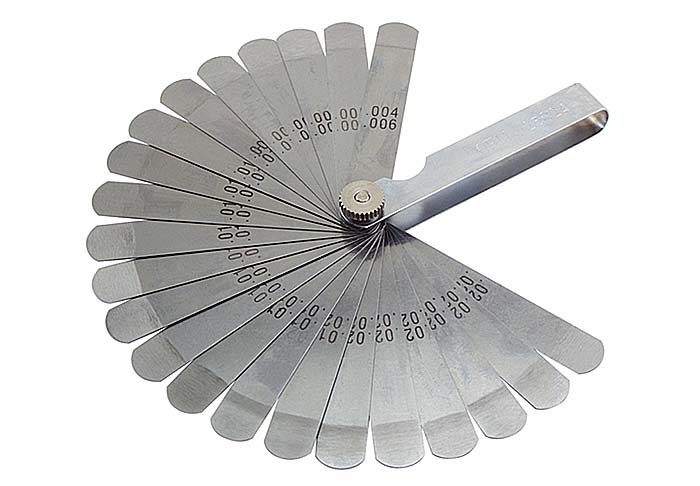

a bit of reading here might be useful... get out a feeler gauge and look at how thick .060, .090, .120 actually is , and consider how easily a thin section of cylinder wall can flex and crack!

when G.M. or most manufactures "RATE" a block or any other component at lets say 350 hp what they are saying is that at that level of stress it should last a very long time, they are not suggesting that if its rated at 350hp, that at 360 hp its going to fall apart, only that the expected durability life span is being reduced, generally they build in some "cushion" usually 20%-25% or more because theres always going to be manufacturing tolerances and flaws

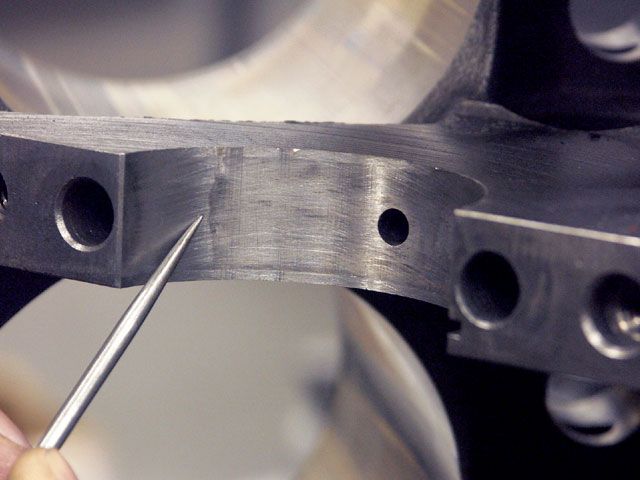

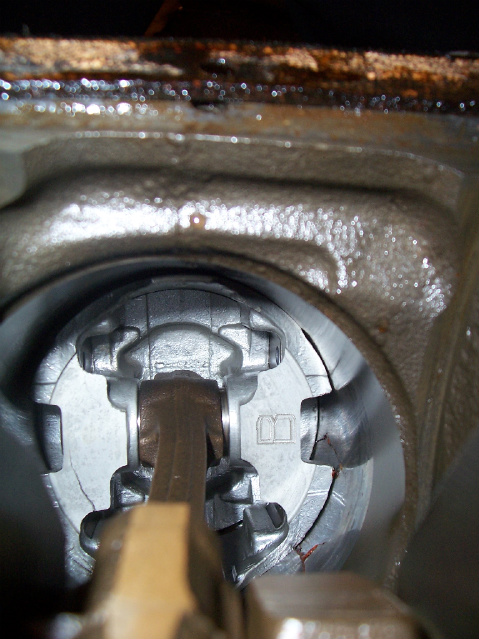

when you have a block magnetically or dye checked for cracks , and sonic tested for bore wall thickness, don,t forget to check lifter bores, and lifter gallery areas, and main cap webs etc. just because its not easy to access does not mean cracks can be ignored

when blocks are cast the molten metal can shift locations in the casting mold slightly, the machinery that machines the block is all indexed off

specific locations as its held in place, this results in some variation in the resulting casting thickness if the core mass has shifted marginally , thus most machine shops vastly prefer to work with ,

castings that maximize all casting metal thickness, in all directions from machined surfaces.

http://www.project33.com/Categoryarticle.cfm?ID=13&Category=Engine

core shift results in one side of the cylinder bore walls tending to be noticeably thinner than ideal, this results in un-equal stress and more failures

Chevy Performance BBC Bow Tie Race Engine Blocks | JEGS

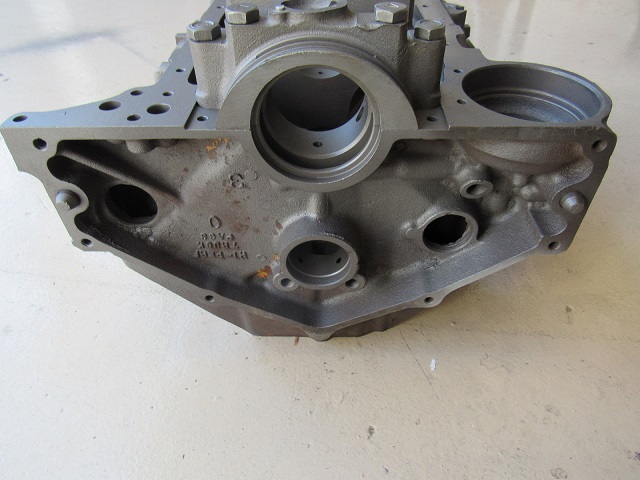

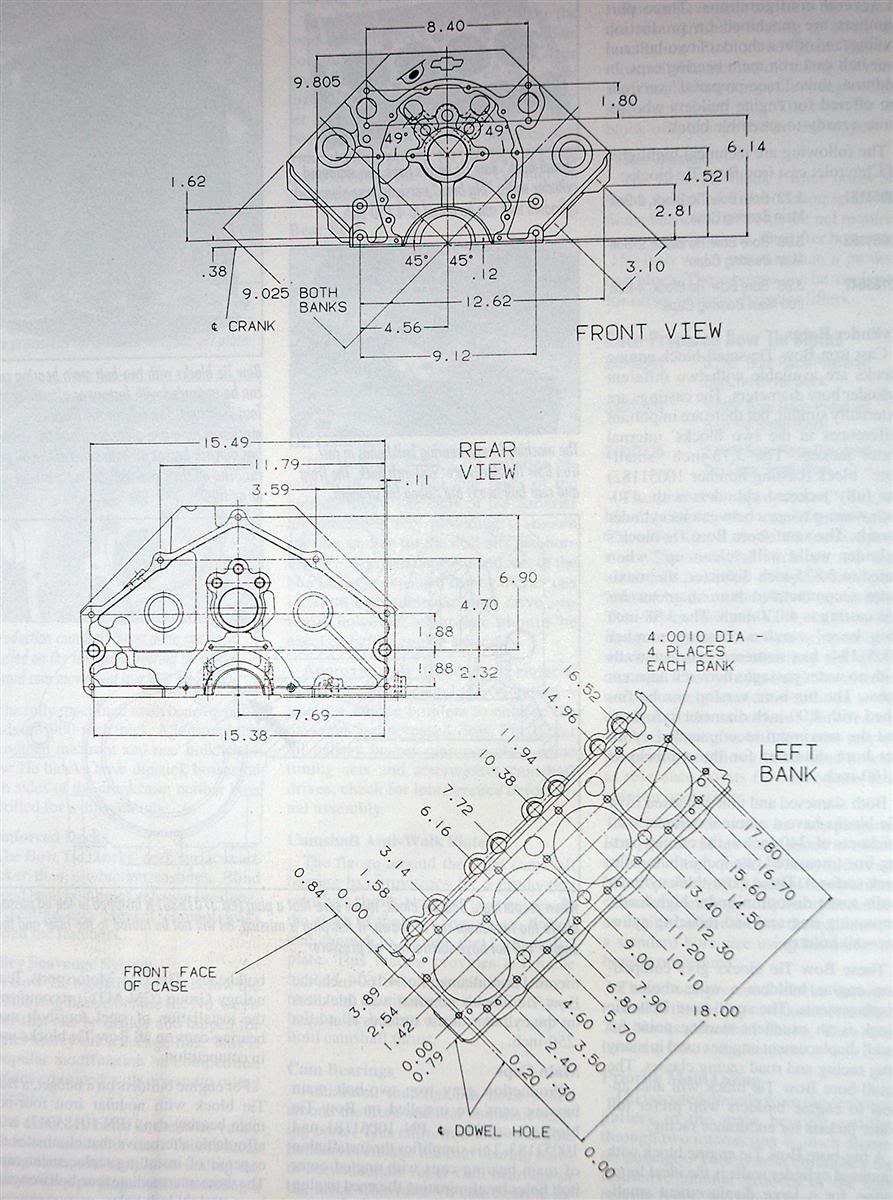

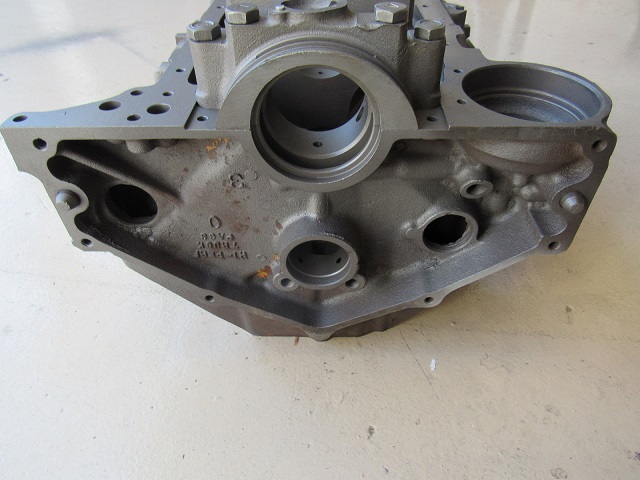

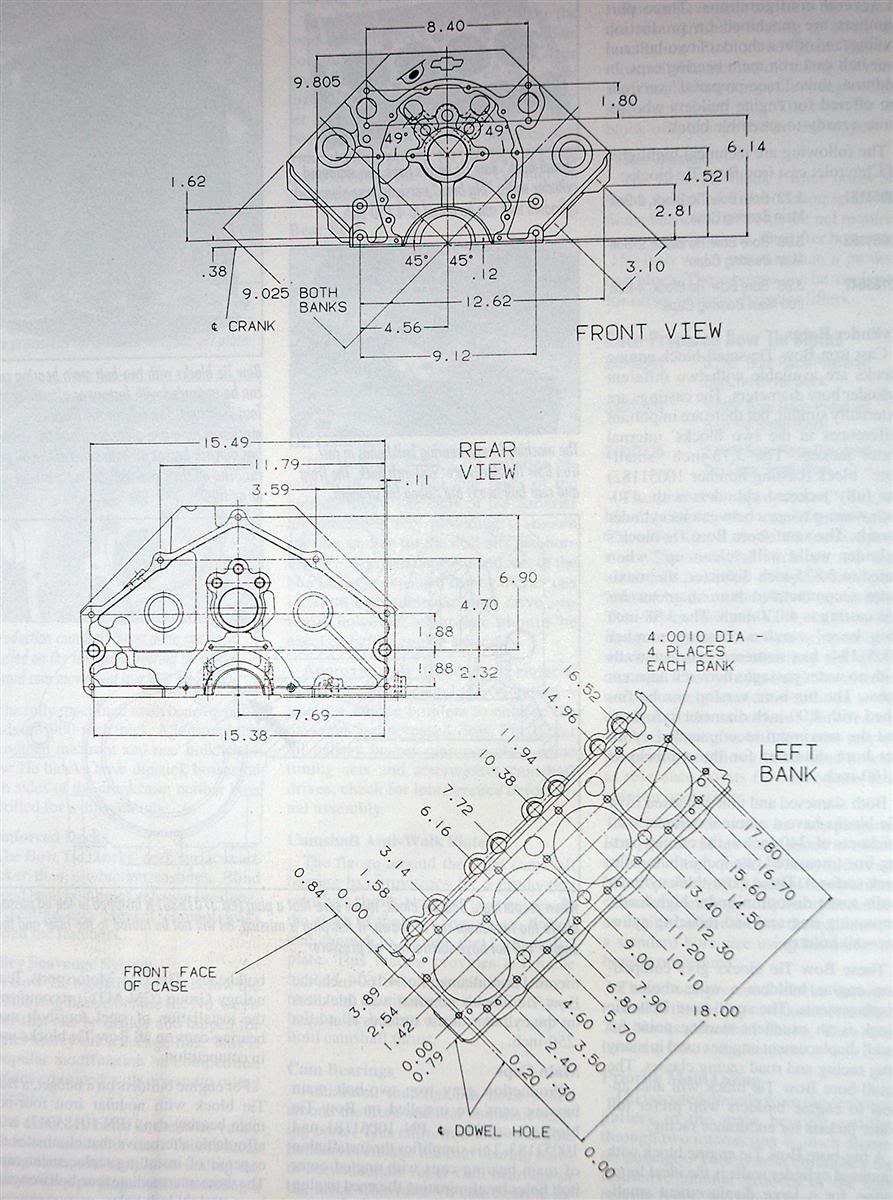

Cast Iron Bow Tie Race Block Technical Notes

Precision CNC-machining means +/- 0.001'' tolerances

Standard deck (9.800'') or tall deck (10.200'')

4.240'' Finish Bore (4.600'' Maximum Bore, .250'' Minimum Wall Thickness)

A sonic bore check data sheet is provided with each block

Lifter bores are .300'' taller than standard blocks

Siamese cylinder bores

Improved cooling around number 1 cylinder

Accepts Mark IV or Gen V, Gen VI cylinder heads

Use Gen V head gaskets with Mark IV and Gen V cylinder heads

Use Gen VI head gaskets with Gen VI cylinder heads

Requires Mark IV design 2-piece rear main seal oil pans

Requires Mark IV design crankshafts

Can use Mark IV and Gen V, Gen VI camshafts, timing sets, lifters and timing cover

(aftermarket belt drive timing covers may require clearancing)

Blind-tapped head bolt holes; extra inner head bolt bosses provided

4-bolt SAE 8620 main caps splayed 16° on the three center mains

Priority main oiling wet sump system

Provisions for dry sump oil line provided

Honed camshaft and crankshaft bores

0.842'' lifter bores (maximum 1.06'') may be relocated

Distributor gear clearance at bottom of number 8 cylinder bore should be checked

Machined mechanical fuel pump pad

Tested to 1,200 horsepower!

READ THESE LINKS, YOULL MISS 80% OF THE INFO IGNORING THE LINKS

http://hotrodenginetech.com/how-to-build-racing-engines-cylinder-block-guide/

http://www.hotrod.com/articles/hrdp-1210-chevrolet-350-small-block-comparison/

http://www.chevydiy.com/ultimate-guide-building-chevy-big-blocks-cylinder-blocks-instruction/

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.com/index.php?threads/splayed-main-caps.1014/#post-3831

http://www.jegs.com/tech-articles/bbc-engine-specs.html

http://www.hotrod.com/techarticles/engi ... omparison/

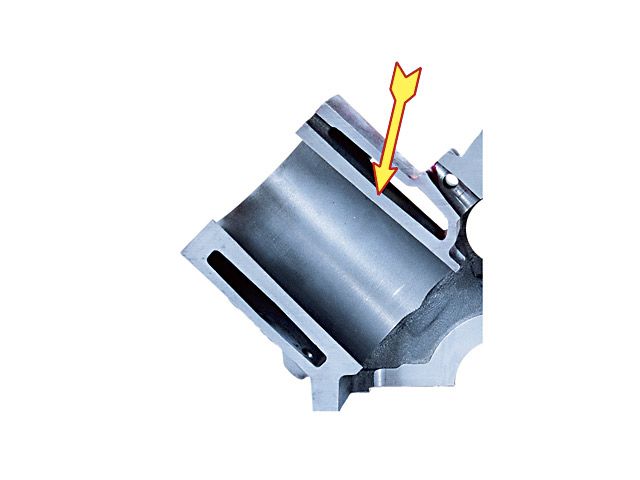

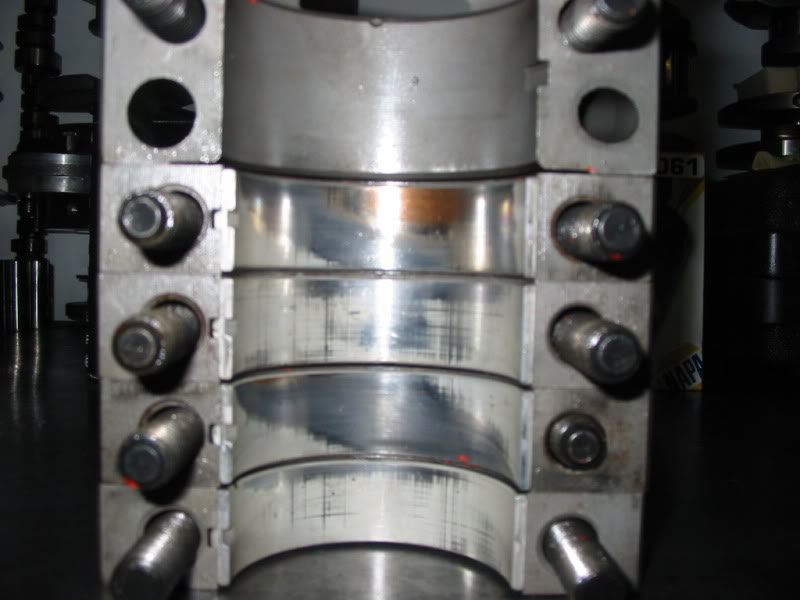

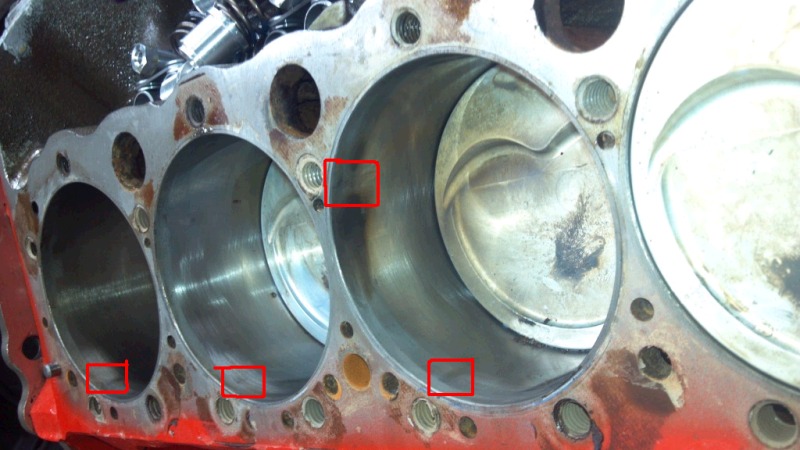

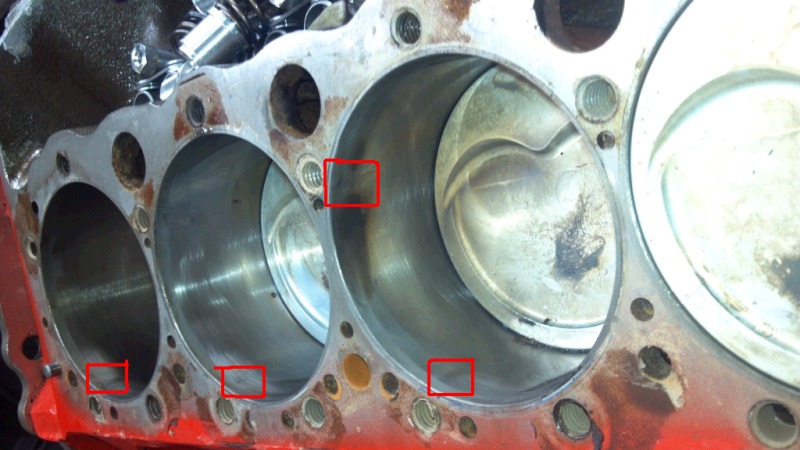

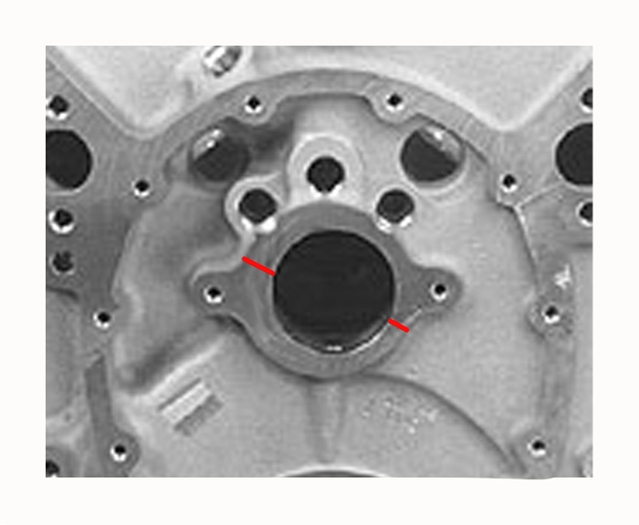

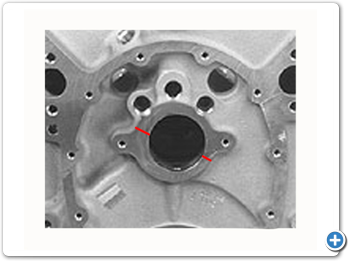

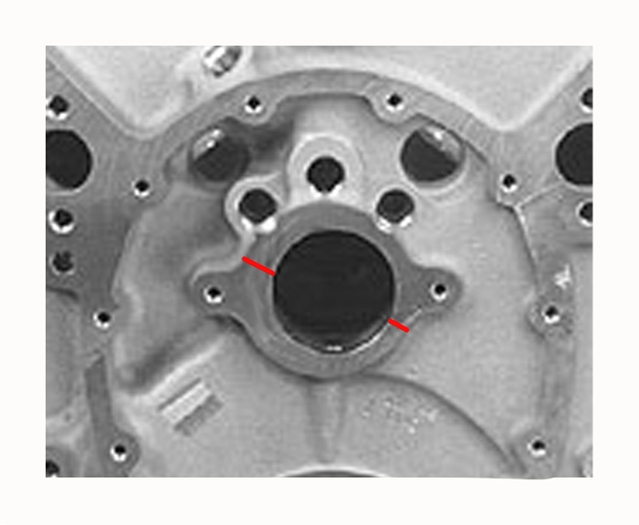

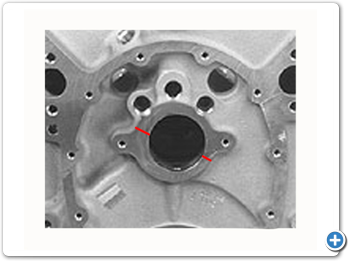

Core shift is a result of a block, cylinder head, or other engine casting shifting in its mold when the molten metal is poured in. When core shift occurs the cylinder bores, lifter bores, main bearing and cam tunnels shift from their blueprinted positions. If the shift is significant, mechanical problems can occur and some cylinder walls may be critically thin. This is especially of concern if the engine is to be used for racing applications.

The only way to guarantee cylinder wall thickness is to have the block sonic-tested, but this can be difficult when you go to purchase a used engine.

Core shift example

Core shift example

On engines with in-block cams, you can always take a look at the cam bearing bore. If it is noticeably offset in its machined boss, you should suspect core shift.

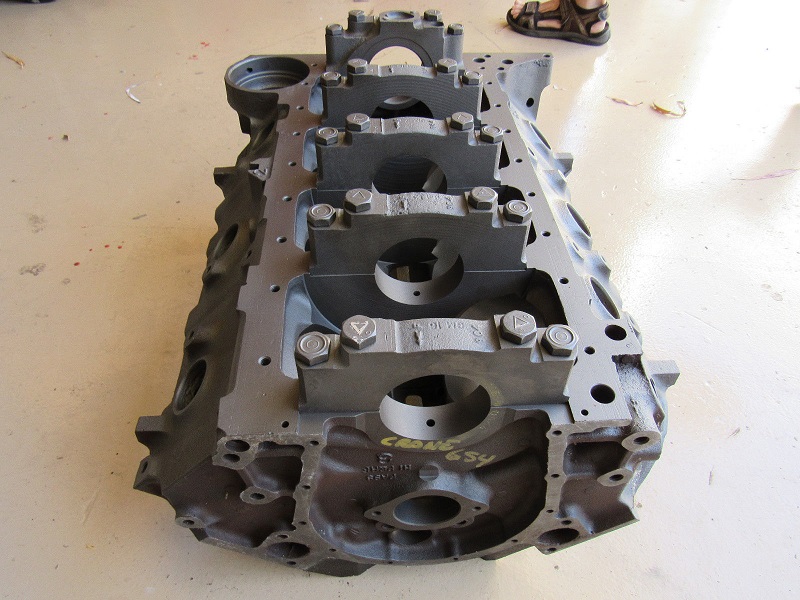

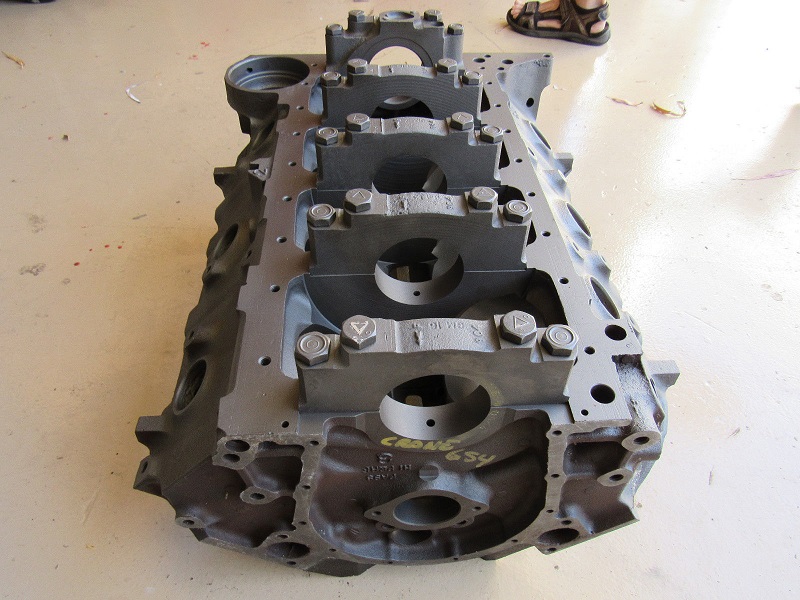

the block pictured above is NOT A CHEVY, but it gives you some idea of what the block internal coolant passages and cylinder walls look like

read this

http://www.project33.com/Categoryarticl ... ory=Engine

and understand its deck and cylinder wall thickness you need to verify more than core shift, its not the average cylinder wall thickness its both the MINIMUM and WHERE in the bore wall the thin section is that matters as the head bolts distort the bore, far more in some areas than in others.

(1) yes youll need to have the block under stress with bolts, or studs and a torque plate to duplicate the stress on the bore walls , that a clamped cylinder head induces on the bore walls to get the hone done correctly

http://www.prostart.com.au/crisis/350chev/350-p3.html

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24529

http://racingarticles.com/article_racing-73.html

http://www.matweb.com/search/datasheetT ... =PDEVCON05

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://www.drillspot.com/products/31915 ... num_Liquid

http://www.hardblok.com/product-info/

what does it mean to fill the block?

http://www.caribbean.basf-cc.com/en/pro ... 85-Ing.pdf

get the

block deck perfectly level on each bank before you pour is critical

24" carpenter levels are generally priced under $9

https://www.zoro.com/stanley-level-24in-42-468/i/G2998992/

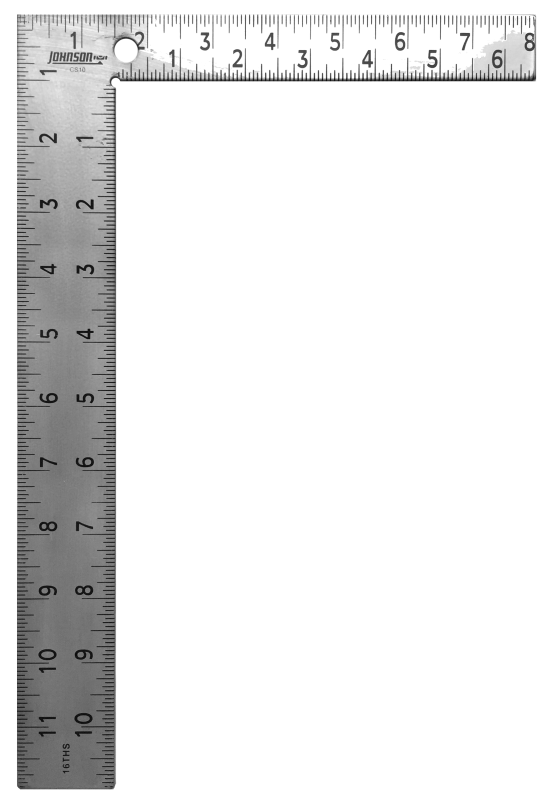

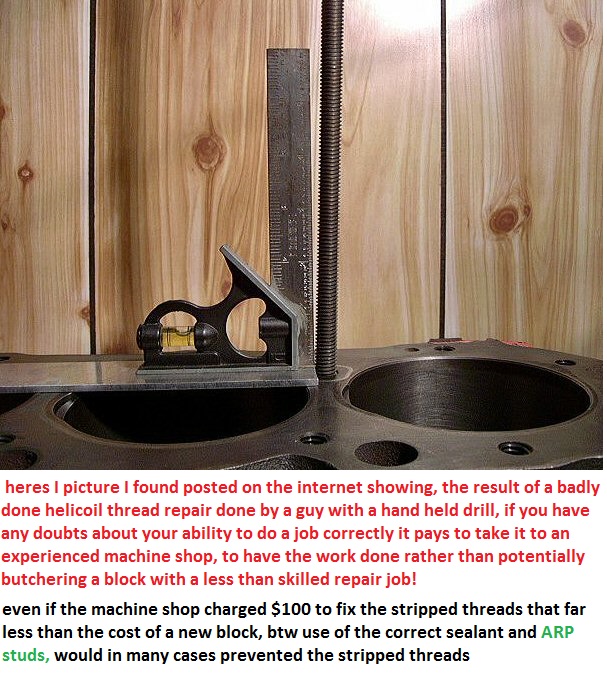

It might be a surprise to many guys but a $10, METAL CARPENTERS SQUARE can be used , to verify a block thats is significantly warped on the deck surface

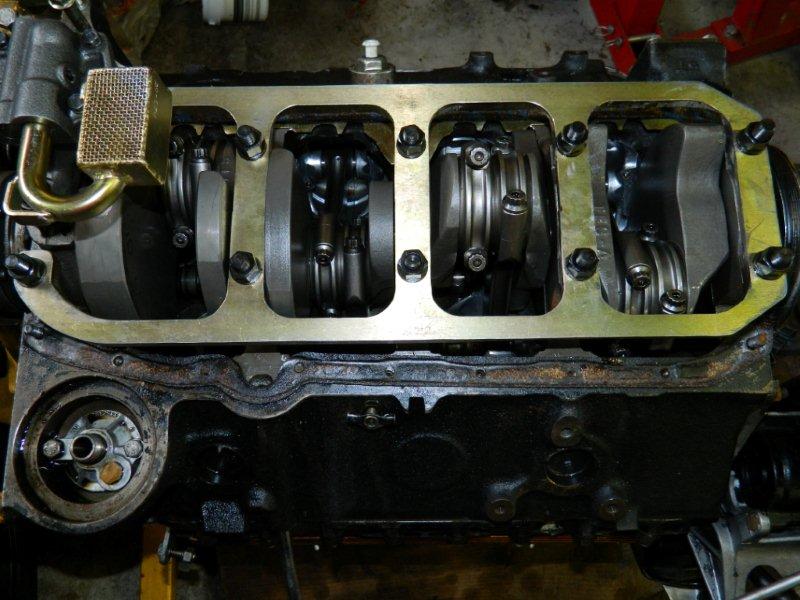

heres a cross section of a block used strictly for drag racing with about 80% of the coolant passage filled, you can fill a block up to the lower edge of the freeze plugs and add significant support with only a minimal effect on cooling as about 90% of the heats generated in the cylinders upper 2.5" of bore

Ive also seen guys forget to install a plastic or metal tube in the lower coolant passage to allow the block to drain when they partly fill blocks to add block rigidity on thin cylinder walls, so remember to do that if your filling the block to increase cylinder wall strength up too the lower edge of the freeze plugs as forgetting thats a common new guy mistake

watch this video, but remember , if you intend to partially fill a block to add cylinder wall rigidity, the block should be filled at least 48 hours prior to any machine work being done on the block, as the fill in the coolant passages will generally expands slightly as it sets and will change the bore dimensions slightly.

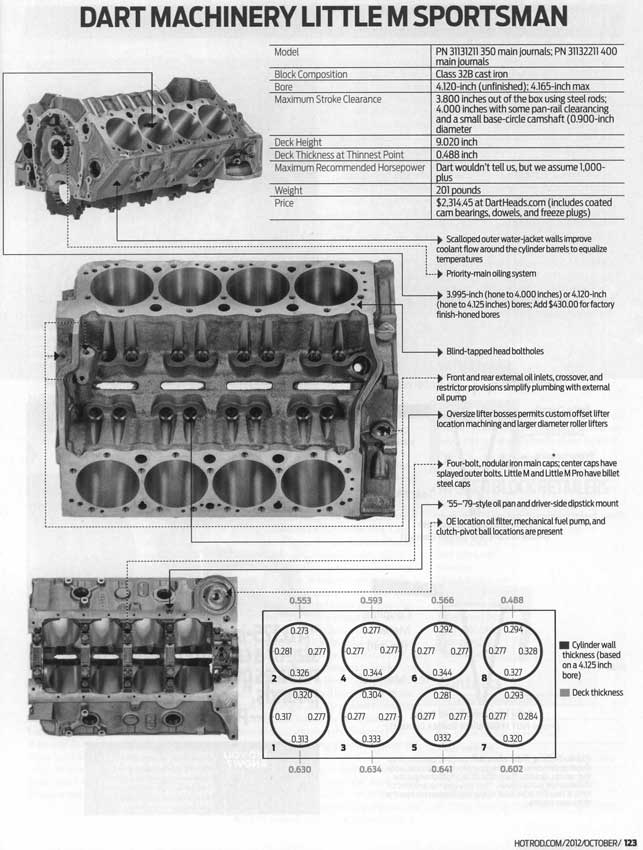

Id also point out that a DART after market blocks significantly thicker and stiffer and made from a stronger alloy than the OEM production block casting

on most cars used on the street your limited too filling to the bottom of the freeze plugs

Filling a block is when you use a concrete like substance fill, that you pour into the water jacket of your motor.

The idea is to strengthen your block from the inside.

One of the main benefits is to control bore flexing.

Most people do two different types of fill.

1. Street fill-you fill up to the bottom of the lower freeze plugs.

2. Race fill- you fill to the bottom of your water pump holes.

All fills should be done "Before" you do your machine work.[/color]

ok, generally you want an absolute minimum cylinder wall thickness, on a stock production block of .180 and .230 or thicker is generally considered to be ideal, anytime your bore reduces the cylinder wall thickness below .200 in my opinion, if you intend to race the engine, you should fill the block to the lower freeze plugs with a block coolant passage filler to reduce the unsupported cylinder walls tendency to flex, which reduces ring seal., and generally the semi-safe limit, with the block filled is at about .200-.180, below that, wall thickness, becomes a potential major problem and the blocks life expectancy, is usually lower,

Id reject a block as a race engine if the upper cylinder wall thickness is under about .145" as an absolute minimum,and only go below .180 if that thin wall area is supported by block fill now Im sure youll find guys who have raced thinner cylinder wall thickness, but its pushing your luck.

A great deal of the engines heat is produced in the cylinder heads and upper 2" of the cylinder bore, and very little comparatively in the lower engine so filling the coolant passages up to the lower edge of the freeze plugs has a minimal effect on cooling if you've got a good radiator and water pump ETC.you check this with a sonic tester AFTER FIRST verifying the TESTER accuracy on parts of the engine you can verify with a caliper.

you certainly don,t want to dump bunches of cash into a block that will likely crack if subjected to the stress of racing!

IF your a bit under that .180 minimum, you generally strengthen the cylinder wall by filling the coolant passages in the block surrounding the cylinder wall up to the lower edge of the freeze plugs with a block filler, I prefer a slurry of about 85% steel shot of size .180" -.200", and 15%- epoxy block filler , if you use more epoxy the epoxy won,t expand at the same rate as the block when its hot, filling the lower cylinder wall coolant passage up to the lower edge of the freeze plugs has little effect on cooling,because about 90% of the heat is generated in the top 3" of the bores stroke and heads (JUST REMEMBER TO INSERT A DRAIN TUBE SO THE EPOXY DOESN,T BLOCK THE BLOCK COOLANT DRAIN PASSAGE ON EACH SIDE)

SUMMIT SELLS G.M. BLOCKS you can use to build a 383 for $700 plus shipping , but ID suggest limiting power to about 500 hp with these

http://www.summitracing.com/parts/sum-150100

I personally thing anything less than .145 is pushing things even WITH a partially filled coolant passage area, ask

your self a couple questions, have you got a written quote on the required machine work? have you had the block walls sonic thickness checked, and found out what the bore walls remaining thickness will be after being bored and honed at both the top and bottom of each cylinder wall at every 90 degrees?

how much money have you already sunk into that block in machining costs, or what it the likely cost of a line hine, bore job , maybe adding splayed man caps and having the decks trued up and how much more cash with getting the stock block prepped correctly cost, will you waste that money , what if the block cracks after you get it assembled and start running it?

I think almost all of us start out making the same mistake of trying to get the block we already own re-machined to save costs ,not realizing in most cases its wasted effort and cash.

you could very easily dump $800-$1200 IN MACHINE WORK ON AN OEM BLOCK, AND STILL HAVE A VERY WEAK BLOCK CASTING,THATS FAR MORE LIKELY TO CRACK AND FLEX, IN COMPARISON TO A DART, or world products BLOCK.

if you spend roughly $1500 on a much thicker dart block you won,t be nearly as likely to have block failure related problems.

OR you can spend a bit more and get a far stronger and thicker DART BLOCK casting for about $1550.

yes $1550 or so is a LOT of money,and I know how difficult coming up with cash is! but this is NOT a cheap hobby and if you put $800-$1200 in an OEM block the fails and trashes the rest of your parts you hardly save any money

http://www.summitracing.com/search/prod ... e%20Blocks

http://www.precisionreloading.com/steel_shot.htm

(#4 or #2 shot, or BB size preferred) buy the 40lb bag

http://www.ballisticproducts.com/Steel- ... info/SH04/

there are several block fill products that are basically high strength mortar or concrete

http://www.hardblok.com/

http://www.labsafety.com/Magnacrete-Con ... _24531183/

is popular, for filling blocks up to the lower edge of the freeze plugs

Ive used a slurry of steel bird shot and liquid EPOXY for my blocks

http://www.precisionreloading.com/mm5/m ... STEEL_SHOT

http://www.alvinproducts.com/Products/Products.asp?id=1

but almost everyone uses moroso concrete/grout mix as its readily available, this generally has very little effect on the cooling as most of the heat is generated in the heads and the first 2" of the upper bore of the cylinders.

http://moroso.com/catalog/categorydispl ... Code=22008

BTW you generally fill the coolant area BEFORE the BORE/HONE WORK

http://www.ndtsystems.com/Automotive/automotive.html

http://raceology.com/2004/11/sonic-test ... y-how.html

http://www.geinspectiontechnologies.com ... index.html

http://www.qualitest-inc.com/2000b-utg.htm

http://www.popularhotrodding.com/engine ... index.html

http://www.qualitest-inc.com/pr-82.htm

http://www.popularhotrodding.com/tech/0 ... index.html

http://books.google.com/books?id=-csSm0 ... q=&f=false

http://www.checkline.com/sonic_testers/

http://www.racecarmagazine.com/Articles ... .asp?ID=26

http://raceology.com/2004/11/sonic-test ... y-how.html

http://www.abqindustrial.net/store/soni ... -c-40.html

http://www.dakotaultrasonics.com/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24529

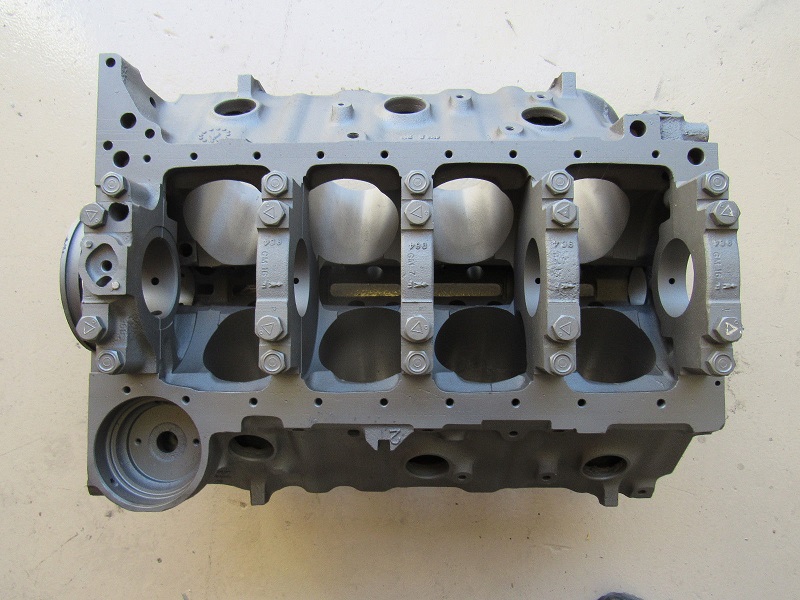

This is where the aftermarket performance engine blocks generally have a huge advantage over the standard production blocks, core shift and casting thickness is generally much better controlled on the better aftermarket performance engine blocks like DART sells as an

EXAMPLE.

and yeah! at first the $1500-$3000 for a block seems absurd,

but it comes machined if you order it that way, (EXTRA COST OPTION IN MOST CASES) and its a whole lot stronger,stiffer,thicker and less likely to self destruct under hard use than a factory block., and its NEW not something that's been sitting around rusting and being over heated for 30-40 plus years, like some sbc cores, and the dart block cylinder walls can easily be twice as thick or more than a Chevy block and made from better materials.

here is where you, or your machine shop can screw things up on ring to bore seal, when you hone the bores,get and use block deck hone plates, during the hone process , keep in kind you want to use the same (STUDS OR BOLTS) the machine shop used and the same torque settings they used when the cylinders were honed with deck plates or the distortion of the bore and ring seal won,t be identical (exactly round)or ideal , aftermarket blocks can and usually do have significantly thicker cylinder walls, the thicker the cylinder wall the less the distortion , that effects ring seal will tend to be,under the load the bolts or studs used to fasten the heads to the block produce which will tend to distort the block

STEEL SHOT GUN PELLETS AND EPOXY WORKS AS A COOLANT PASSAGE FILLER

http://easy-strike.com/prod_liquid.html

http://www.adperformance.com/index.php? ... 82_105_309

http://www.adperformance.com/index.php? ... =69_82_106

http://www.circletrack.com/techarticles ... index.html

http://www.scatcrankshafts.com/PDFs/ScatWorld.pdf

http://www.arengineering.com/articles/sonicbig.html

http://www.hotrodpitstop.com/engine-block-prep.php

http://www.e30m3project.com/e30m3perfor ... sonic2.htm

before you begin to have a engine block bored more than about .030 over size its a good idea to have the blocks bore walls sonic tested

Have your machinist sonic check the block before you bore it.

calculate the remaining bore wall thickness, and if its not thick enough for safe use don,t bother

, bore walls are rarely if ever uniform in thickness from top to bottom or side to side, or concentric with the bore center line. and the STOCK O.E.M. production sbc block is well known to be fairly weak structually

REMEMBER PARTS TEND TO BREAK AT THE WEAK POINTS NOT THE STRONGEST AREAS THUS IGNORING THE THIN SECTIONS OF A CYLINDER BORE WALL BECAUSE MOST OF ITS FAIRLY RIGID IS NOT ALWAYS WISE!

its common for one wall in a cylinder to be significantly thinner than the other walls

this might sound like a unneeded extra expense but if your going to put several hundred dollars in machine work into a block you want to be fairly sure it won,t fail under stress wasting all that time and money, plus any resulting damage that might result.

boring a BIG BLOCK CHEVY block to more than about .060 over its original intended bore diameter,or sleeving the bore ,some times its the only way to save a block, but in many cases the O.E.M. blocks are so thinly cast that you'll have bore distortion and less than ideal bore, to piston ring sealing due to the cylinder wall thickness and /or less than ideal ring sealing, once the blocks really hot. making swapping to an aftermarket DART , world products or BOWTIE block with the thicker castings and better alloy metal,a better long term option, you cant tell how thick your cylinder walls are without sonic testing them as casting flaws, core shift and years of rust can make any block walls far thinner than you might assume them to be

let me point out a few facts, boring a cylinder takes 1/2 the bore increase off each side of the cylinder wall, and almost any big block will allow a careful machine shop to physically cut the finished bore size to be .100-.125 oversize , or a SBC .060 over bore,THAT IN NO WAY MEANS the remaining wall thickness thats left will be RIGID enough and STIFF enough to maintain a solid ring seal,or not flex and crack after repeatedly being stressed, at higher rpms and if the bore wall flexes to any significant degree it rapidly results in loss of effective compression rapid ring wear and potentially a cracked or busted cylinder wall.

yes you can have the block sleeved, but having more than two sleeves per cylinder bank on blocks that are not factory designed to have self supported individual cylinders generally results in a weaker block.

filling the lower coolant passages up to the level of the lower freeze plugs has a minimal effect on cooling but it reduces the UN-supported length of the cylinder walls making them stiffer.

KEEP IN MIND THAT YOU CAN PURCHASE BOTH NEW AND USED OEM AND AFTERMARKET CYLINDER BLOCKS, SO YOUR NOT STUCK USING, YOUR ORIGINAL PRODUCTION BLOCK WITH OVERLY THIN WALLS, IF ITS ALREADY RATHER THIN BUT REQUIRES A LARGER SIZE BORE

,https://garage.grumpysperformance.com/index.php?threads/sleeving-a-block.1516/#post-3467

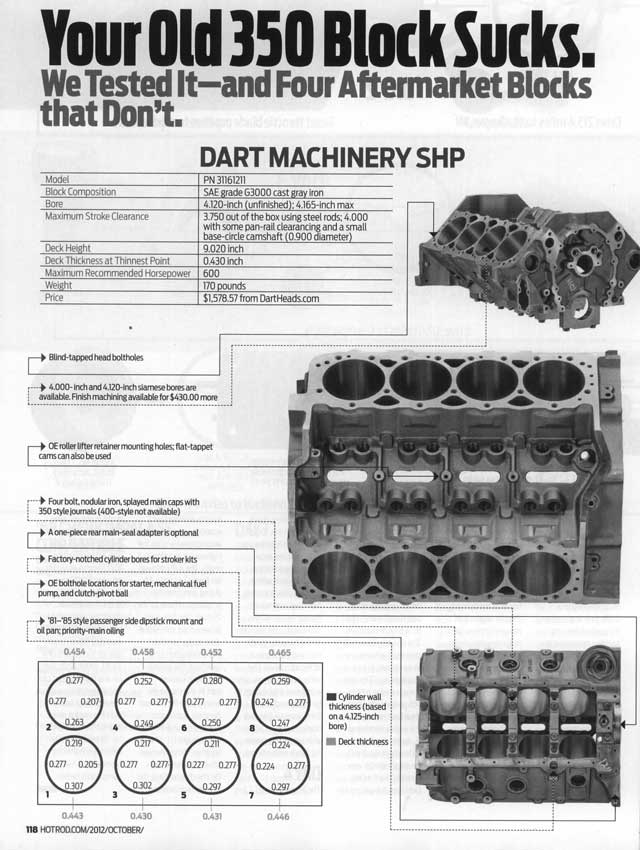

Chevrolet 350 Small-Block Comparison - Your Old 350 Block Sucks - Hot Rod Magazine

We compare a stock small-block and four aftermarket blocks to determine what fits your needs better. Check it out in the October 2012 issue of Hot Rod Magazine

block prep.

you really should read these links for a lot more USEFUL info, on block pre prep one of the least discussed & acknowledged, and yet more common reasons engines fail , is related to micro metallic crud left in the engine while its being assembled, especially engine's built on newly machined...garage.grumpysperformance.com

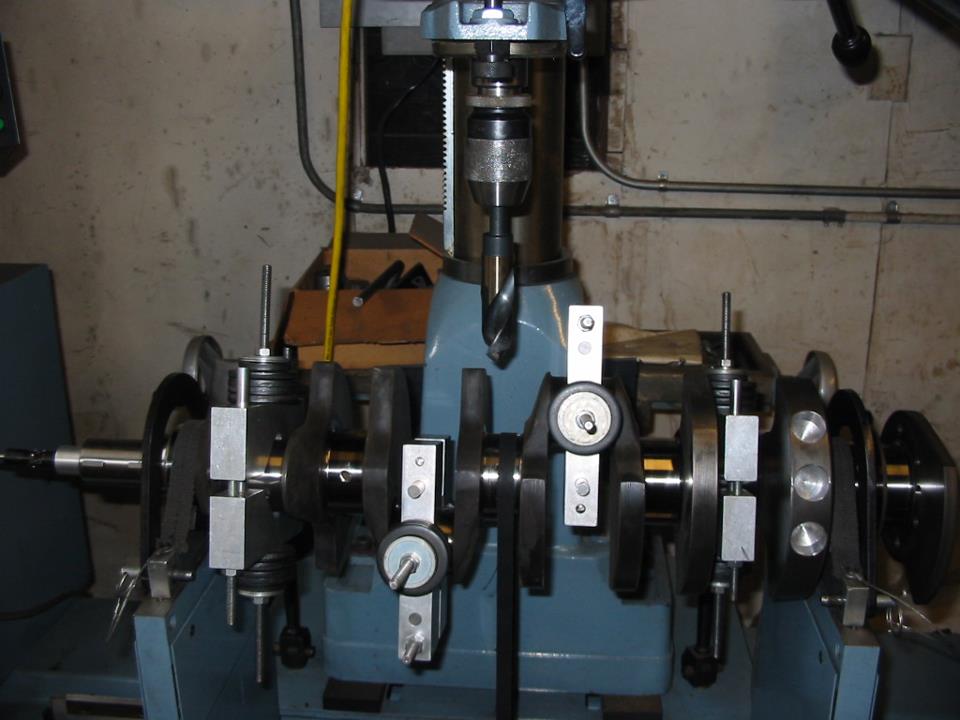

grinding block for stroker assembly

I finished grinding my block for 383 stroker assembly a couple of weeks ago. I found a tip to help cut down on metal dust particles. Take a magnet any type, and put it in a zip lock bag, then place the bag as close as you can to the area your grinding. I put mine in the direction of the flow...garage.grumpysperformance.com

Engine Block Cylinder Wall Thickness

HOW FAR CAN YOU BORE A BLOCK? before you begin to have a engine block bored more than about .030 over size its a good idea to have the blocks bore walls sonic tested Have your machinist sonic check the block before you bore it. calculate the remaining bore wall thickness, and if its not thick...garage.grumpysperformance.com

bores must be honed with a deck torque plate to simulate the stress of a installed cylinder head stress , the torqued bolts exert on the bore walls, the torque plate induces and duplicates that stress so that the bore walls will be pulled into the same relationship when you hone the walls concentric, rings won,t seal correctly in a non concentric bore, aftermarket blocks with thicker and stiffer castings are less prone to bore distortion

a bit of reading here might be useful... get out a feeler gauge and look at how thick .060, .090, .120 actually is , and consider how easily a thin section of cylinder wall can flex and crack!

when G.M. or most manufactures "RATE" a block or any other component at lets say 350 hp what they are saying is that at that level of stress it should last a very long time, they are not suggesting that if its rated at 350hp, that at 360 hp its going to fall apart, only that the expected durability life span is being reduced, generally they build in some "cushion" usually 20%-25% or more because theres always going to be manufacturing tolerances and flaws

when you have a block magnetically or dye checked for cracks , and sonic tested for bore wall thickness, don,t forget to check lifter bores, and lifter gallery areas, and main cap webs etc. just because its not easy to access does not mean cracks can be ignored

when blocks are cast the molten metal can shift locations in the casting mold slightly, the machinery that machines the block is all indexed off

specific locations as its held in place, this results in some variation in the resulting casting thickness if the core mass has shifted marginally , thus most machine shops vastly prefer to work with ,

castings that maximize all casting metal thickness, in all directions from machined surfaces.

http://www.project33.com/Categoryarticle.cfm?ID=13&Category=Engine

core shift results in one side of the cylinder bore walls tending to be noticeably thinner than ideal, this results in un-equal stress and more failures

Chevy Performance BBC Bow Tie Race Engine Blocks | JEGS

Cast Iron Bow Tie Race Block Technical Notes

Precision CNC-machining means +/- 0.001'' tolerances

Standard deck (9.800'') or tall deck (10.200'')

4.240'' Finish Bore (4.600'' Maximum Bore, .250'' Minimum Wall Thickness)

A sonic bore check data sheet is provided with each block

Lifter bores are .300'' taller than standard blocks

Siamese cylinder bores

Improved cooling around number 1 cylinder

Accepts Mark IV or Gen V, Gen VI cylinder heads

Use Gen V head gaskets with Mark IV and Gen V cylinder heads

Use Gen VI head gaskets with Gen VI cylinder heads

Requires Mark IV design 2-piece rear main seal oil pans

Requires Mark IV design crankshafts

Can use Mark IV and Gen V, Gen VI camshafts, timing sets, lifters and timing cover

(aftermarket belt drive timing covers may require clearancing)

Blind-tapped head bolt holes; extra inner head bolt bosses provided

4-bolt SAE 8620 main caps splayed 16° on the three center mains

Priority main oiling wet sump system

Provisions for dry sump oil line provided

Honed camshaft and crankshaft bores

0.842'' lifter bores (maximum 1.06'') may be relocated

Distributor gear clearance at bottom of number 8 cylinder bore should be checked

Machined mechanical fuel pump pad

Tested to 1,200 horsepower!

READ THESE LINKS, YOULL MISS 80% OF THE INFO IGNORING THE LINKS

http://hotrodenginetech.com/how-to-build-racing-engines-cylinder-block-guide/

http://www.hotrod.com/articles/hrdp-1210-chevrolet-350-small-block-comparison/

http://www.chevydiy.com/ultimate-guide-building-chevy-big-blocks-cylinder-blocks-instruction/

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.com/index.php?threads/splayed-main-caps.1014/#post-3831

http://www.jegs.com/tech-articles/bbc-engine-specs.html

http://www.hotrod.com/techarticles/engi ... omparison/

Core shift is a result of a block, cylinder head, or other engine casting shifting in its mold when the molten metal is poured in. When core shift occurs the cylinder bores, lifter bores, main bearing and cam tunnels shift from their blueprinted positions. If the shift is significant, mechanical problems can occur and some cylinder walls may be critically thin. This is especially of concern if the engine is to be used for racing applications.

The only way to guarantee cylinder wall thickness is to have the block sonic-tested, but this can be difficult when you go to purchase a used engine.

Core shift example

Core shift exampleOn engines with in-block cams, you can always take a look at the cam bearing bore. If it is noticeably offset in its machined boss, you should suspect core shift.

the block pictured above is NOT A CHEVY, but it gives you some idea of what the block internal coolant passages and cylinder walls look like

read this

http://www.project33.com/Categoryarticl ... ory=Engine

and understand its deck and cylinder wall thickness you need to verify more than core shift, its not the average cylinder wall thickness its both the MINIMUM and WHERE in the bore wall the thin section is that matters as the head bolts distort the bore, far more in some areas than in others.

(1) yes youll need to have the block under stress with bolts, or studs and a torque plate to duplicate the stress on the bore walls , that a clamped cylinder head induces on the bore walls to get the hone done correctly

http://www.prostart.com.au/crisis/350chev/350-p3.html

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24529

http://racingarticles.com/article_racing-73.html

http://www.matweb.com/search/datasheetT ... =PDEVCON05

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://www.drillspot.com/products/31915 ... num_Liquid

http://www.hardblok.com/product-info/

what does it mean to fill the block?

http://www.caribbean.basf-cc.com/en/pro ... 85-Ing.pdf

get the

block deck perfectly level on each bank before you pour is critical

24" carpenter levels are generally priced under $9

https://www.zoro.com/stanley-level-24in-42-468/i/G2998992/

It might be a surprise to many guys but a $10, METAL CARPENTERS SQUARE can be used , to verify a block thats is significantly warped on the deck surface

heres a cross section of a block used strictly for drag racing with about 80% of the coolant passage filled, you can fill a block up to the lower edge of the freeze plugs and add significant support with only a minimal effect on cooling as about 90% of the heats generated in the cylinders upper 2.5" of bore

Ive also seen guys forget to install a plastic or metal tube in the lower coolant passage to allow the block to drain when they partly fill blocks to add block rigidity on thin cylinder walls, so remember to do that if your filling the block to increase cylinder wall strength up too the lower edge of the freeze plugs as forgetting thats a common new guy mistake

watch this video, but remember , if you intend to partially fill a block to add cylinder wall rigidity, the block should be filled at least 48 hours prior to any machine work being done on the block, as the fill in the coolant passages will generally expands slightly as it sets and will change the bore dimensions slightly.

Id also point out that a DART after market blocks significantly thicker and stiffer and made from a stronger alloy than the OEM production block casting

Filling a block is when you use a concrete like substance fill, that you pour into the water jacket of your motor.

The idea is to strengthen your block from the inside.

One of the main benefits is to control bore flexing.

Most people do two different types of fill.

1. Street fill-you fill up to the bottom of the lower freeze plugs.

2. Race fill- you fill to the bottom of your water pump holes.

All fills should be done "Before" you do your machine work.[/color]

ok, generally you want an absolute minimum cylinder wall thickness, on a stock production block of .180 and .230 or thicker is generally considered to be ideal, anytime your bore reduces the cylinder wall thickness below .200 in my opinion, if you intend to race the engine, you should fill the block to the lower freeze plugs with a block coolant passage filler to reduce the unsupported cylinder walls tendency to flex, which reduces ring seal., and generally the semi-safe limit, with the block filled is at about .200-.180, below that, wall thickness, becomes a potential major problem and the blocks life expectancy, is usually lower,

Id reject a block as a race engine if the upper cylinder wall thickness is under about .145" as an absolute minimum,and only go below .180 if that thin wall area is supported by block fill now Im sure youll find guys who have raced thinner cylinder wall thickness, but its pushing your luck.

A great deal of the engines heat is produced in the cylinder heads and upper 2" of the cylinder bore, and very little comparatively in the lower engine so filling the coolant passages up to the lower edge of the freeze plugs has a minimal effect on cooling if you've got a good radiator and water pump ETC.you check this with a sonic tester AFTER FIRST verifying the TESTER accuracy on parts of the engine you can verify with a caliper.

you certainly don,t want to dump bunches of cash into a block that will likely crack if subjected to the stress of racing!

IF your a bit under that .180 minimum, you generally strengthen the cylinder wall by filling the coolant passages in the block surrounding the cylinder wall up to the lower edge of the freeze plugs with a block filler, I prefer a slurry of about 85% steel shot of size .180" -.200", and 15%- epoxy block filler , if you use more epoxy the epoxy won,t expand at the same rate as the block when its hot, filling the lower cylinder wall coolant passage up to the lower edge of the freeze plugs has little effect on cooling,because about 90% of the heat is generated in the top 3" of the bores stroke and heads (JUST REMEMBER TO INSERT A DRAIN TUBE SO THE EPOXY DOESN,T BLOCK THE BLOCK COOLANT DRAIN PASSAGE ON EACH SIDE)

SUMMIT SELLS G.M. BLOCKS you can use to build a 383 for $700 plus shipping , but ID suggest limiting power to about 500 hp with these

http://www.summitracing.com/parts/sum-150100

I personally thing anything less than .145 is pushing things even WITH a partially filled coolant passage area, ask

your self a couple questions, have you got a written quote on the required machine work? have you had the block walls sonic thickness checked, and found out what the bore walls remaining thickness will be after being bored and honed at both the top and bottom of each cylinder wall at every 90 degrees?

how much money have you already sunk into that block in machining costs, or what it the likely cost of a line hine, bore job , maybe adding splayed man caps and having the decks trued up and how much more cash with getting the stock block prepped correctly cost, will you waste that money , what if the block cracks after you get it assembled and start running it?

I think almost all of us start out making the same mistake of trying to get the block we already own re-machined to save costs ,not realizing in most cases its wasted effort and cash.

you could very easily dump $800-$1200 IN MACHINE WORK ON AN OEM BLOCK, AND STILL HAVE A VERY WEAK BLOCK CASTING,THATS FAR MORE LIKELY TO CRACK AND FLEX, IN COMPARISON TO A DART, or world products BLOCK.

if you spend roughly $1500 on a much thicker dart block you won,t be nearly as likely to have block failure related problems.

OR you can spend a bit more and get a far stronger and thicker DART BLOCK casting for about $1550.

yes $1550 or so is a LOT of money,and I know how difficult coming up with cash is! but this is NOT a cheap hobby and if you put $800-$1200 in an OEM block the fails and trashes the rest of your parts you hardly save any money

http://www.summitracing.com/search/prod ... e%20Blocks

http://www.precisionreloading.com/steel_shot.htm

(#4 or #2 shot, or BB size preferred) buy the 40lb bag

http://www.ballisticproducts.com/Steel- ... info/SH04/

there are several block fill products that are basically high strength mortar or concrete

http://www.hardblok.com/

http://www.labsafety.com/Magnacrete-Con ... _24531183/

is popular, for filling blocks up to the lower edge of the freeze plugs

Ive used a slurry of steel bird shot and liquid EPOXY for my blocks

http://www.precisionreloading.com/mm5/m ... STEEL_SHOT

http://www.alvinproducts.com/Products/Products.asp?id=1

but almost everyone uses moroso concrete/grout mix as its readily available, this generally has very little effect on the cooling as most of the heat is generated in the heads and the first 2" of the upper bore of the cylinders.

http://moroso.com/catalog/categorydispl ... Code=22008

BTW you generally fill the coolant area BEFORE the BORE/HONE WORK

http://www.ndtsystems.com/Automotive/automotive.html

http://raceology.com/2004/11/sonic-test ... y-how.html

http://www.geinspectiontechnologies.com ... index.html

http://www.qualitest-inc.com/2000b-utg.htm

http://www.popularhotrodding.com/engine ... index.html

http://www.qualitest-inc.com/pr-82.htm

http://www.popularhotrodding.com/tech/0 ... index.html

http://books.google.com/books?id=-csSm0 ... q=&f=false

http://www.checkline.com/sonic_testers/

http://www.racecarmagazine.com/Articles ... .asp?ID=26

http://raceology.com/2004/11/sonic-test ... y-how.html

http://www.abqindustrial.net/store/soni ... -c-40.html

http://www.dakotaultrasonics.com/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24529

This is where the aftermarket performance engine blocks generally have a huge advantage over the standard production blocks, core shift and casting thickness is generally much better controlled on the better aftermarket performance engine blocks like DART sells as an

EXAMPLE.

and yeah! at first the $1500-$3000 for a block seems absurd,

but it comes machined if you order it that way, (EXTRA COST OPTION IN MOST CASES) and its a whole lot stronger,stiffer,thicker and less likely to self destruct under hard use than a factory block., and its NEW not something that's been sitting around rusting and being over heated for 30-40 plus years, like some sbc cores, and the dart block cylinder walls can easily be twice as thick or more than a Chevy block and made from better materials.

here is where you, or your machine shop can screw things up on ring to bore seal, when you hone the bores,get and use block deck hone plates, during the hone process , keep in kind you want to use the same (STUDS OR BOLTS) the machine shop used and the same torque settings they used when the cylinders were honed with deck plates or the distortion of the bore and ring seal won,t be identical (exactly round)or ideal , aftermarket blocks can and usually do have significantly thicker cylinder walls, the thicker the cylinder wall the less the distortion , that effects ring seal will tend to be,under the load the bolts or studs used to fasten the heads to the block produce which will tend to distort the block

STEEL SHOT GUN PELLETS AND EPOXY WORKS AS A COOLANT PASSAGE FILLER

http://easy-strike.com/prod_liquid.html

http://www.adperformance.com/index.php? ... 82_105_309

http://www.adperformance.com/index.php? ... =69_82_106

http://www.circletrack.com/techarticles ... index.html

http://www.scatcrankshafts.com/PDFs/ScatWorld.pdf

http://www.arengineering.com/articles/sonicbig.html

http://www.hotrodpitstop.com/engine-block-prep.php

http://www.e30m3project.com/e30m3perfor ... sonic2.htm

Last edited by a moderator: