Johnatthebox

Active Member

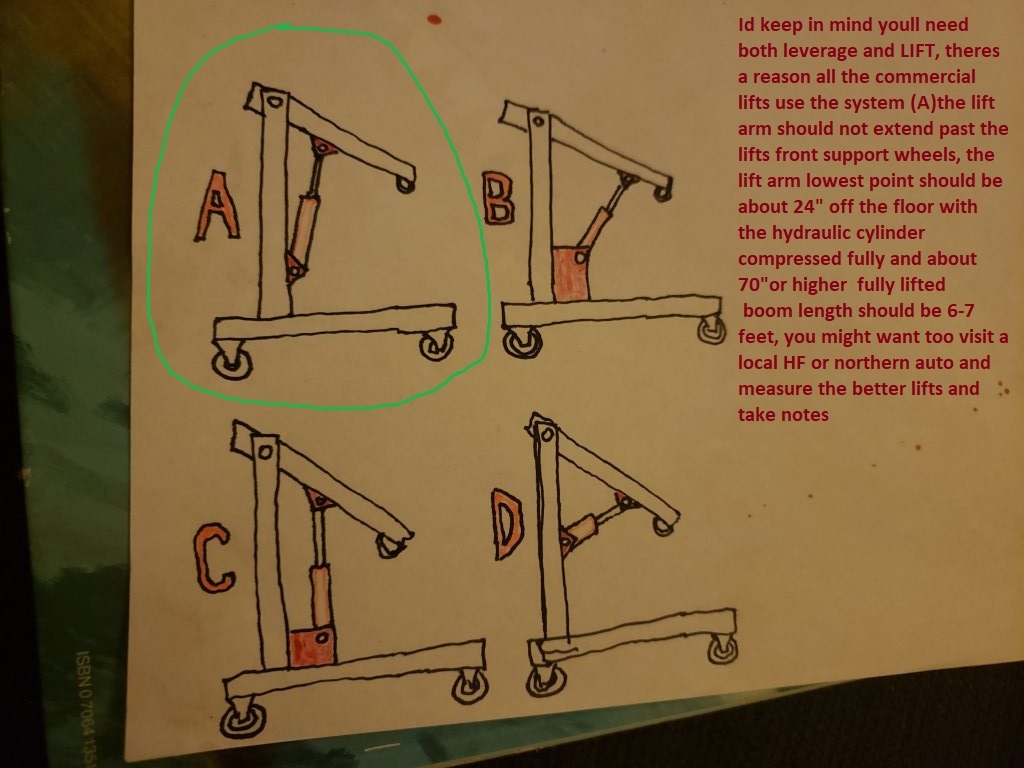

I'm making my own engine hoist out of parts I salvaged and its come time to mount the hydraulic ram. The ram I'm using is long enough that I could mount it any way I wsnted- which way will make it the strongest? (see pic.) They all kind of make sense for different reasons(in my head)

** I know, I know, Im not a gifted illustrator, but you get the idea anyway....

** I know, I know, Im not a gifted illustrator, but you get the idea anyway....