When using an engine stand, what size are the bolts holding the block? Are certain bolt holes only used? Talking about a small block Chevy, I'm guessing other makes are different.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine stand bolt sizes?

- Thread starter chromebumpers

- Start date

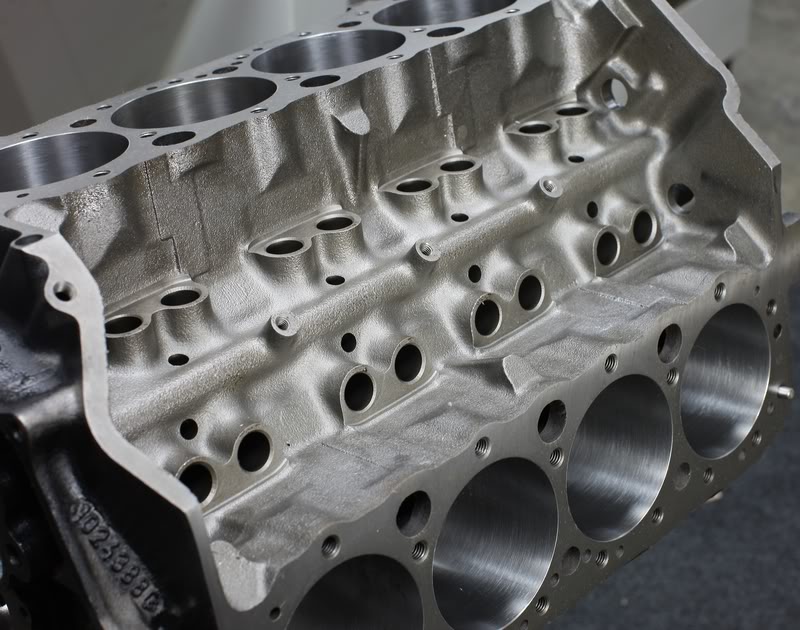

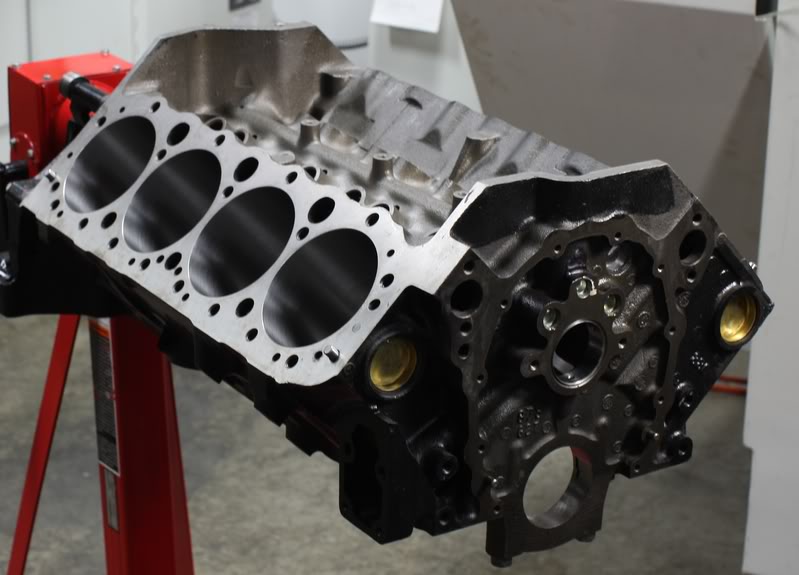

youll usually need (4) 3.5" long 3/8" NC thread ,grade #8 bolts that have several 3/8" fender washers slid on before they get inserted in the engine stand tool head, Id advise buying at least three to six extra 3/8" finder washers for each mount bolt, an if you slip a 2.75" section of 3/8" fuel line over the bolt shank before inserting the bolts in the tool head they tend to stay centered and are less likely to fall out as the engines mounted. try hard to center the engines rotating mass in line with the tool head, having it bolted way off center makes turning the engine around on the stand a huge P.I.T.A. and more dangerous.

BTW

Ive generally found its far less trouble to have the tool head removed temporarily from the engine stand and attach it to the engine while its hanging from the engine crane, because it far less trouble to slide the engine stand tool head back into the stand rotating collar than it is to be screwing around with 4 individual mount bolts.

VIDEO

http://www.ehow.com/video_2327468_tips- ... stand.html

(DON,T FORGET TO GREASE THE TOOL HEAD COLLAR and STAND ROTATING TOOL HEAD with a good molly GREASE, before re-sliding it together)

most of the rotating heads come with a 18" lever that makes rotating the engine a HUGE pain in the ass, Ive found that a 34" section of steel tube about the same diameter as the original handle with a section of THREAD rod that just slides thru it makes a far more useable handle with much more leverage, I cut the thread rod so its about 1.4" longer than the 34" tube so I can weld a nut and washer on one end and use a washer and nylock nut on the other.

BE AWARE that most engine stands have legs that are too wide to allow the engine crane to easily be positioned to allow easy engine mounting on the engine stand, if you have some welding skill and are willing to fabricate an extra set of engine stand leg mount brackets or use the taller casters that allow the engine stand to slide in easier this is fairly easy to rectify

THE ENGINE STAND BELOW IS probably a better design but not foldable

BUT ITS VERY STURDY and low enough that even with the new 8" swivel casters added I can sit on a stool and work on the engine,

I like what you did, that looks nice,btw,

Ive got two types of engine stands designs in my shop,(4 engine stands)but I added 4 of these wheels to each stand

http://www.northerntool.com/shop/tools/ ... _200442439

THIS IS THE STAND PICTURED ABOVE ,I USE THE MOST WHEN BUILDING MY ENGINES, I'VE added 4 8" casters

take your time and shop carefully, remember the cost difference between a cheaper P.O.S. quality stand and something that a great deal less likely to tip over or fall on you is generally well under $100 and that cost spent up front could allow you to skip a very painful and expensive trip to the emergency room.

and if you don,t want to have it taking up space in your garage after you build your engine and if your unlikely to do so again any time soon, you can usually get a large part of the cost back when and if you resell that engine stand., as they don,t really wear out and theres usually someone looking to buy one at a slight discount price.

you certainly won,t be the first guy to torque a head bolt or main cap, or try too roll an engine across an un-even floor, and have the engine stand fall over if you sellect a cheap poorly balanced engine stand

yes that issue of the legs on the crane not allowing the engine stand too roll into a location close enough under the crane too allow a direct transfer is an all too common issue I solved with swapping the casters on the engine stands thus they can allow the crane legs too slide under the stand legs o the crane can align with the stand to off load the engine

adding a set of 8" rubber swivel casters to replace the crappy 2.5" steel wheels makes the engine crane, or engine stands far easier to use, use of an engine leveler and a swivel on the hook is also a huge plus

http://www.northerntool.com/webapp/wcs/ ... _200305217

[/B]

http://www.northerntool.com/shop/tools/ ... _200305213

viewtopic.php?f=27&t=2986&p=7842&hilit=stand+thread+bolts#p7842

viewtopic.php?f=50&t=139&p=169&hilit=stand+bolts#p169

viewtopic.php?f=27&t=1018&p=2304&hilit=stand+bolts#p2304

viewtopic.php?f=27&t=3724&p=9669&hilit=stand+bolts#p9669

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore,f,EAFeatured+Weight,f,Sale+Rank,f&q=engine+stand

harbor freight sells a fairly decent quality CHEAP engine stand thats fully able to handle a big block chevy engine. and resist tipping, I have THREE IN MY SHOP

stands like the one below will usually hold the weight but are MUCH EASIER to tip over when your tightening bolts or rotating the engine, the cost difference is in my opinion well justified, and they have 20% off sale stickers frequently

https://www.harborfreight.com/1000-lb-capacity-engine-stand-69520.html

http://garage.grumpysperformance.co...finally-starting-to-sink-in.10477/#post-44048

http://garage.grumpysperformance.co...-stand-mods-accesories.3724/page-2#post-44298

http://garage.grumpysperformance.com/index.php?threads/storing-a-spare-engine.614/#post-46169

http://garage.grumpysperformance.co...-from-crane-to-engine-stand.11524/#post-53175

http://garage.grumpysperformance.com/index.php?threads/engine-testing-stand.11753/#post-67367

now I hear guys frequently ask about storing or transporting an engine and that can obviously be an issue, you will need a engine crane to lift it onto a trailer or pick-up bed and there are tow-able engine crane design's just as there are easily dis-assembled and re-assembled engine cranes,they make and sell or if you have a welder and minimal skills you can modify an existing engine crane design

one more in an endless list of reasons to own a decent mig welder and drill press

once you convert the engine crane to easy access as a trailer and get a modified engine stand that can easily be rolled on un-even pavement youll wonder how you ever lived without one in the shop,

the down side of the easily transportable engine crane is that all your buddys will constantly want to borrow it and not return it, the cost to convert it and the cost tio get a trailer tag renewed every year or two

but to maintain stability during transport an engine must be stable and secure to prevent damage,the average "red-neck" solution is to drop the engine oil pan in an old corvette tire to keep it more or less upright and stable and add a few straps and for short local hauls thats been done more than a few times

blocking the engine in place with a few carefully cut sections of 4"x 12" roof rafter and a few 60 penny spikes has been done plenty of times

but if you do that kind of thing often having a modified low center of gravity engine stand that can be easily rolled over less than even pavement with locking casters and a few eye bolts welded in place makes its presence worth its cost many times over for many years to come and then some, plus it can be used to store a spare shop engine you might have

drilling and installing (4) 1/2" forged eye bolts in the corners of a shortened height engine transport stand with locking casters makes a great deal of sense as does the use of several very sturdy nylon safety retention straps, securing the engine in the back of a pick-up bed with the tail gate fully raised and locked in placed, and a tow-able engine crane.

http://www.amazon.com/Heavy-Duty-Swivel-Casters-Double-Lock-Brake/dp/B008S52OHQ

http://www.uline.com/Product/Detail...gclid=CMWlopCH7cgCFQmoaQodhJ4NCQ&gclsrc=aw.ds

I occasionally see guys post pictures like this where they transport an engine back to their home or garage , supported like this but unsecured with no straps and no tail gate up and just shake my head in total amazement, the potential for that engine to slide in a sudden stop, in an accident, in a collision, taking a corner, during hard braking or even mild acceleration is absolutely leaving the diver open not only for the loss of the engine but open for a huge law suit for obvious neglect to public safety that all lawyers get orgasms over just thinking about, think about it, your driving home, the car in front changes lanes cutting you off you swerve the engine flips off the tailgate and the car behind hits it and the kid in the pass side car seats killed like a bug on a wind shield, lawyers dream about, owning your next 30 years of income over stuff like that!

roseville carl

Material 1000 lb hand winch HF on sale 14.00, old chev timing chain and gears free, Alum stock 3.50 lb about 7 bucks worth, old cam slug free, and a days worth of my time, not worth much.......

first remove outer cable drum

drill out cam bearing to fit od of winch shaft and id of cam gear

Braise together

Cut inside and outside of coupling to match existing stand shaft

cam gear bolts to alum slug

Drill new pin hole and pin to shaft

assemble winch and gears and attach to stand with secure mounting points use at least 1/4" material

and wa la you have a cheap rotater for your engine stand

that will lock in either direction

<!-- / message --><!-- sig -->__________________

"Keep Em Between the Whites"........

ROSEVILLE CARL, SEP 12, 2012

Last edited by a moderator:

Thanks Paul! If I were 30 years younger I would be begging you for a non-paid internship!