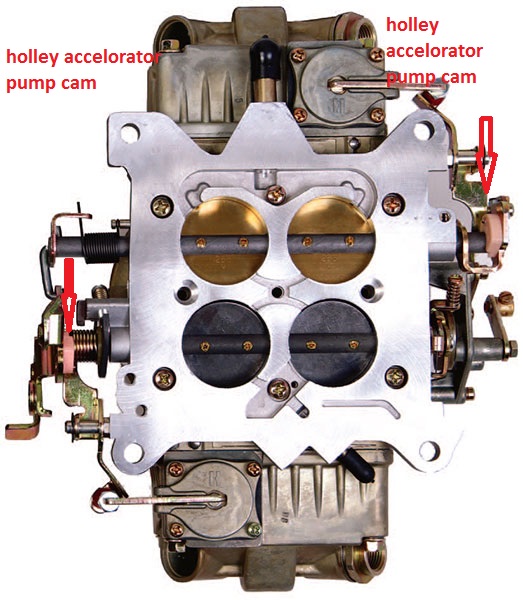

HOLLEY ACCELERATOR PUMP CAMS

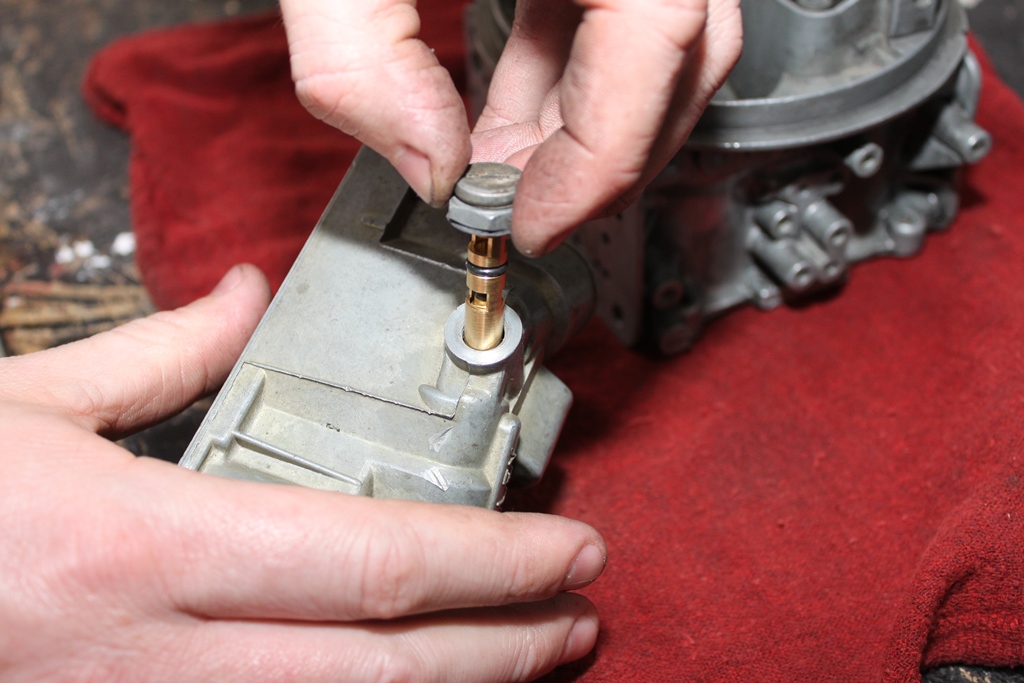

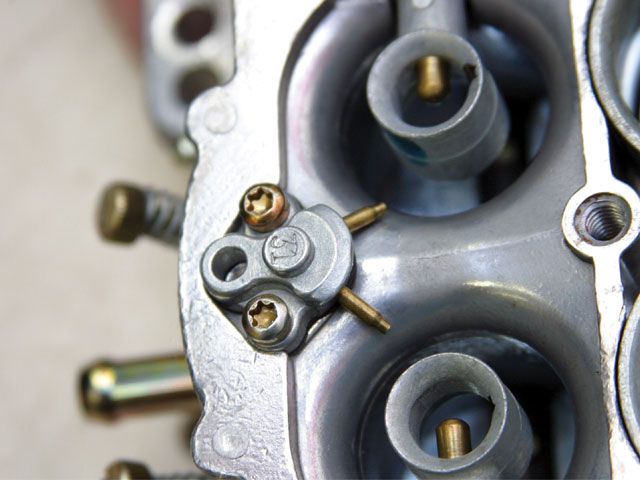

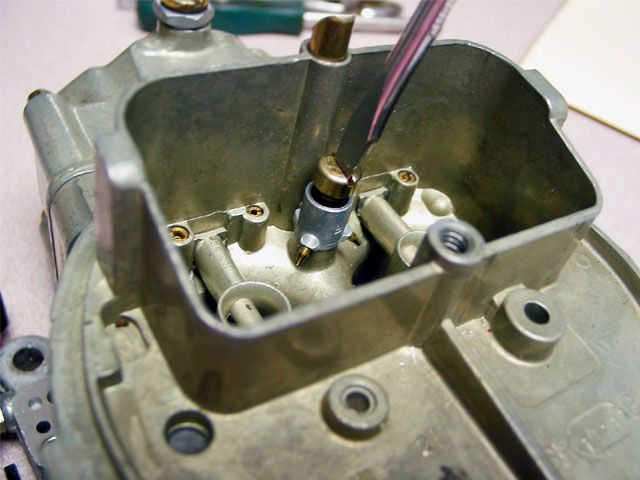

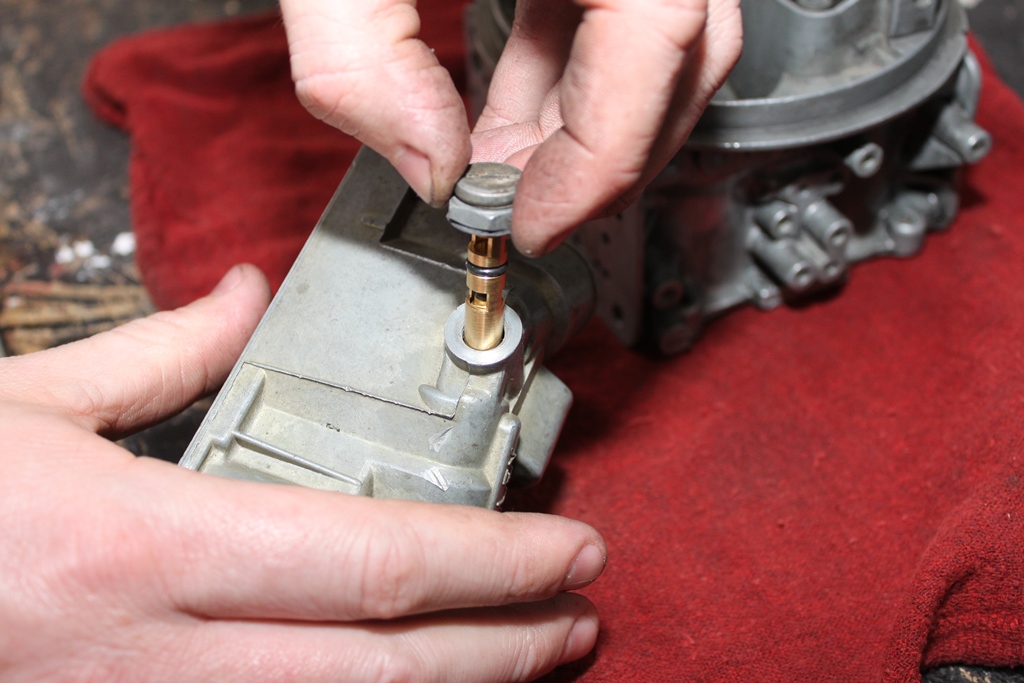

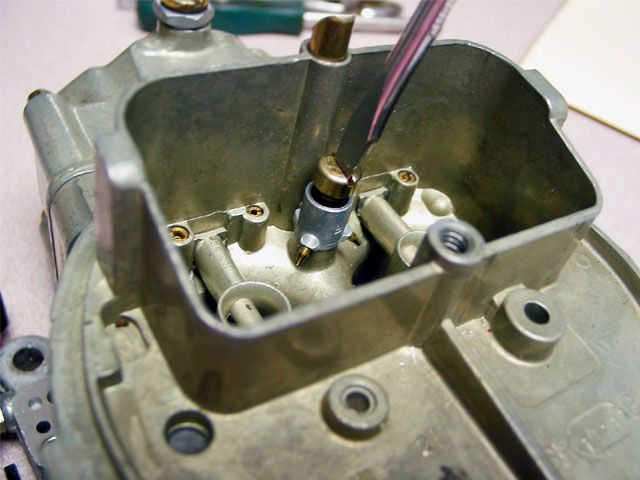

heres a needle and seat fuel valve

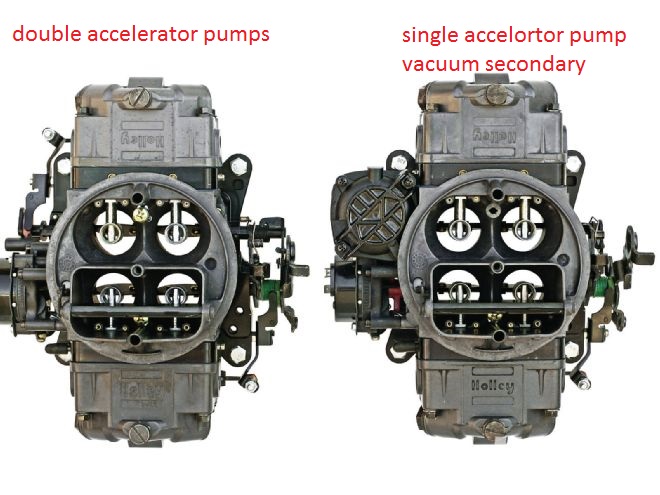

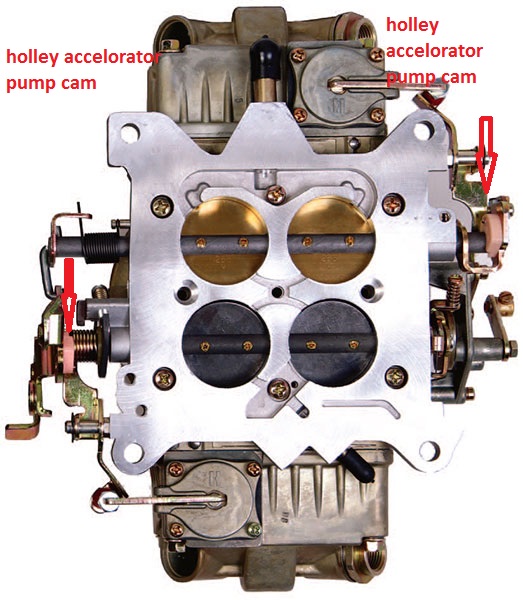

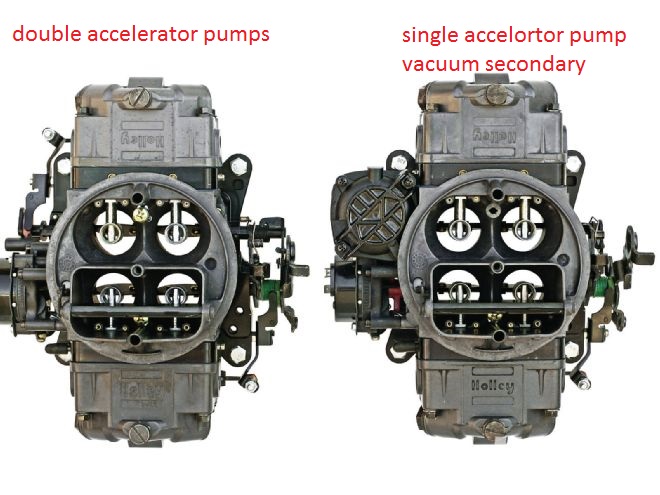

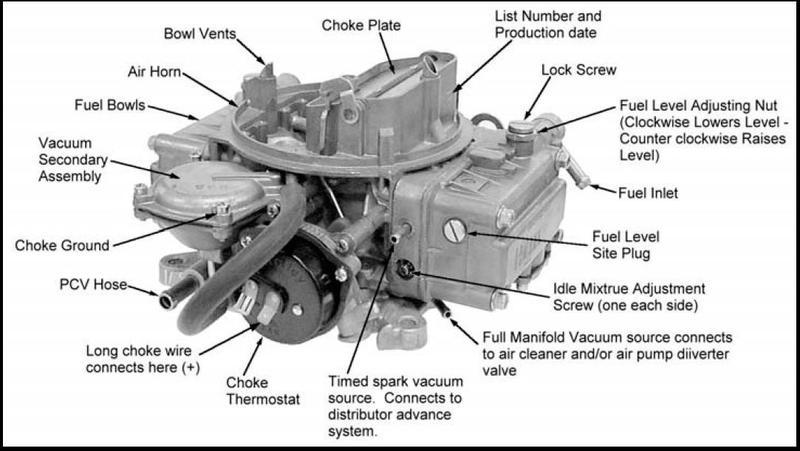

Here's a picture, Double Pumper on the left, Vacuum secondary on the right... Note on the upper left of each carb, the DP has linkage attached to the base plate/throttle shaft that actuates the secondary pump lever... The Vacuum carb has the large vacuum pod on the upper left side of the carb...

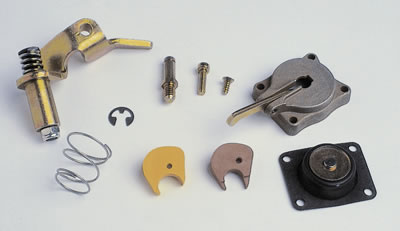

THE O-RING ON THE NEEDLE AND SEAT, AND THE DIAPHRAGM IN THE ACCELERATOR PUMP, CAN BE DAMAGED BY ETHANOL IN FUEL UNLESS AN ETHANOL COMPATIBLE MATERIAL IS USED

YOU REALLY SHOULD WATCH THESE SHORT VIDEOS

YOU REALLY SHOULD WATCH THESE SHORT VIDEOS

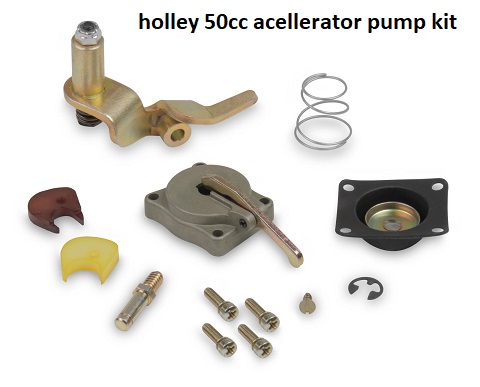

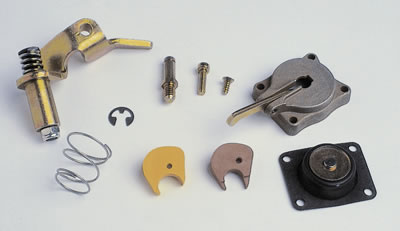

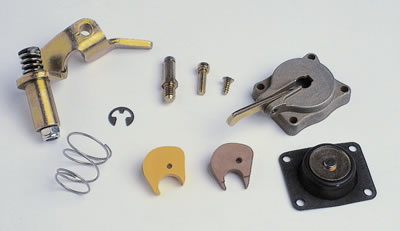

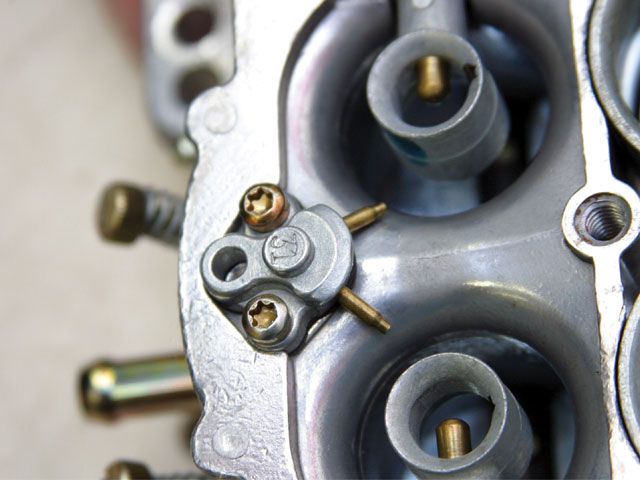

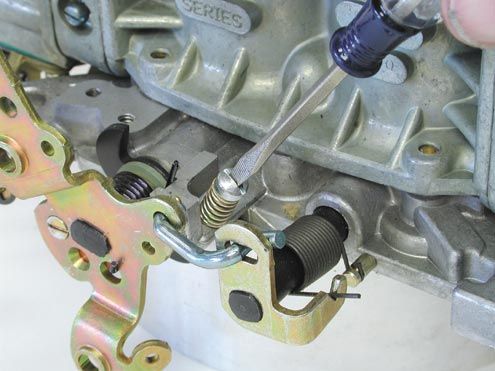

if your running great but seeing a momentary bog as the throttles snapped from idle to wot, I think youll find its a momentary lean condition, your going to easily fix that momentary hic-cup, just swap to a richer cam on the acceleration pump and or a #37 squirt-er , or you may need the 50cc accelerator pump upgrade should make the response damn near instantaneous, during the throttle transition stage

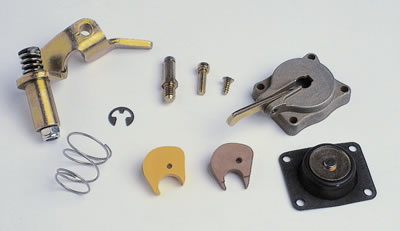

be aware the diaphragm must be the newer off green/blue version if your local fuel contains ethanol, as the older black diaphragm in the acceleration pumps eventually degrade and leak badly (FIRE HAZARD)

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

http://www.summitracing.com/parts/hly-135-9/overview/

If you get a momentary bog in first gear on acceleration, the sudden increase in inertial load on the fuel pump , due to the weight of the fuel its pushing slamming back into the fuel pump, might stall some electric fuel pumps for a couple seconds , or it may be a problem with the carbs acceleration fuel pump not covering the fuel demands , allowing a momentary lean-out in the fuel/air ratio.

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

swapping to a BLUE Holley Accelerator Pump Cam, (and maybe a 500 cc accelerator pump vs a stock 35cc pump) might help

http://www.summitracing.com/parts/hly-20-11/overview/

http://www.youtube.com/watch?v=k-Nx5HEz ... _embedded#!

http://www.youtube.com/watch?feature=pl ... -Nx5HEzvlY

http://www.youtube.com/watch?v=eiRIfcrc ... _embedded#

READ THESE RELATED THREADs /LINKS

viewtopic.php?f=32&t=6011&p=18597#p18597

http://www.stockcarracing.com/techartic ... index.html

viewtopic.php?f=55&t=5229

http://www.quickfueltechnology.com/tech ... -continued

https://documents.holley.com/pumpcamgraph.pdf

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

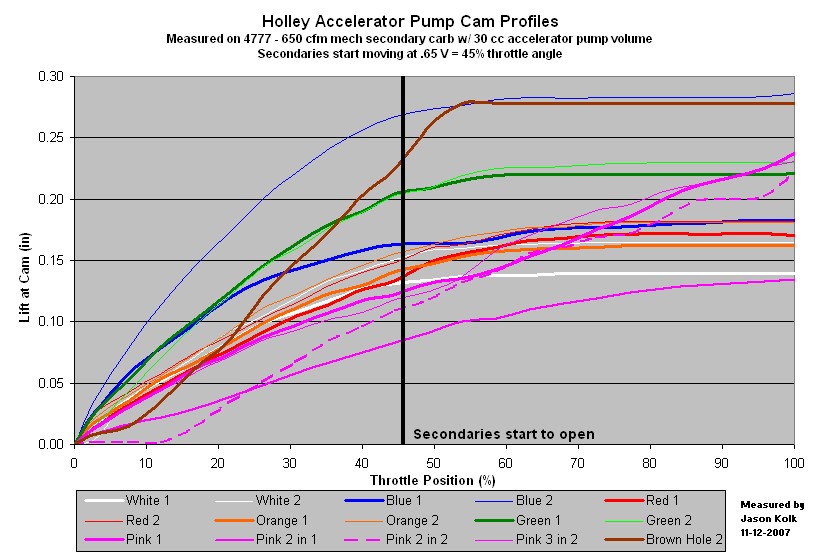

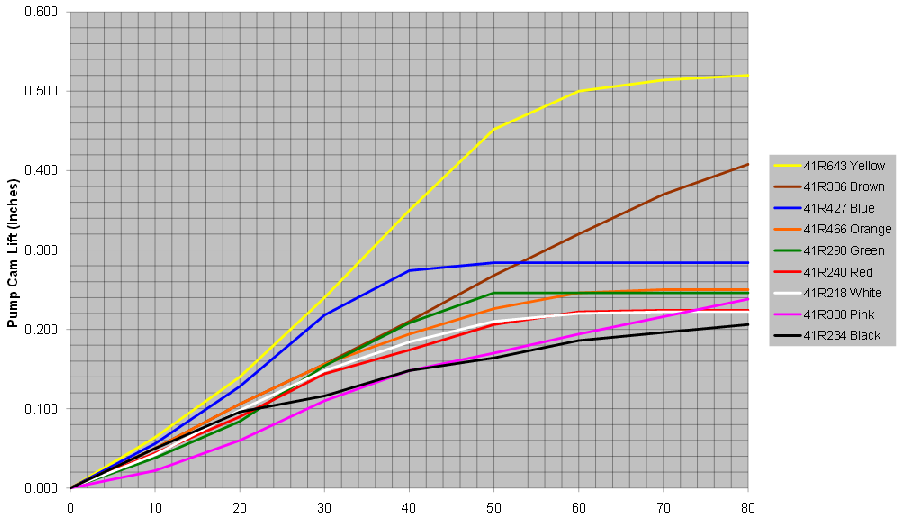

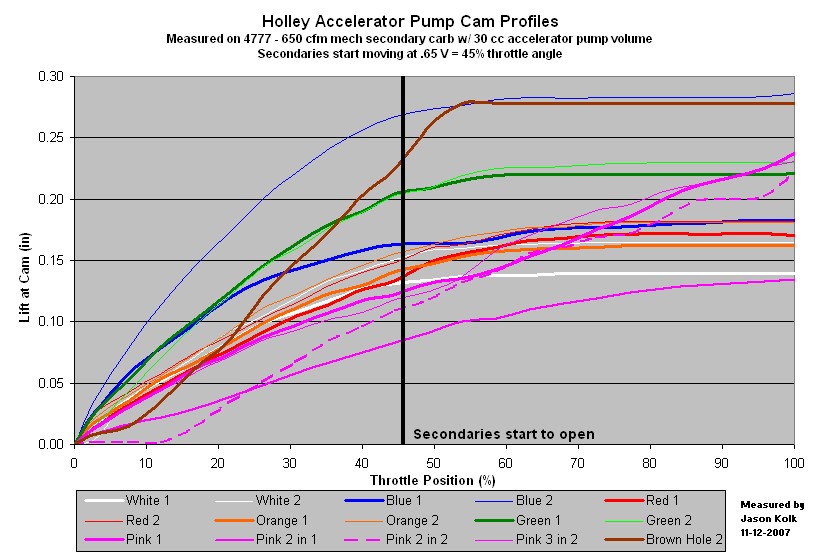

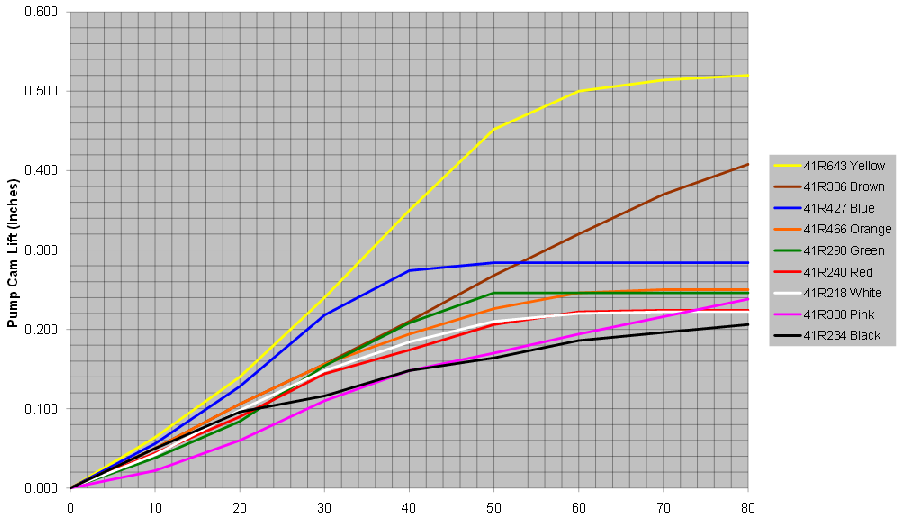

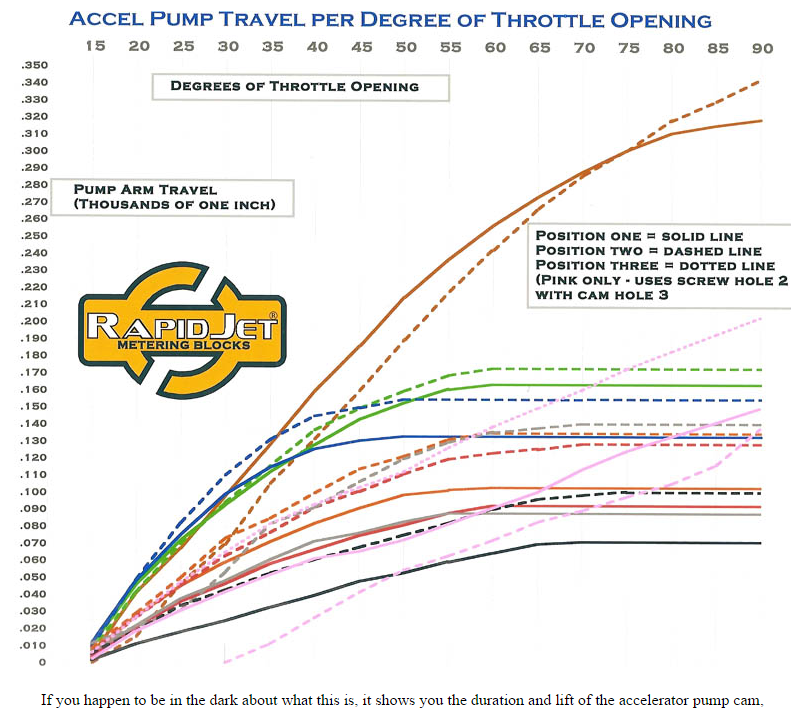

Holley Accelerator Pump Cam Chart (above)

Holley Accelerator Pump Cam Chart , INDEPENDENT TESTING DONE, notice its NOT an exact match to what HOLLEY tech guys posted

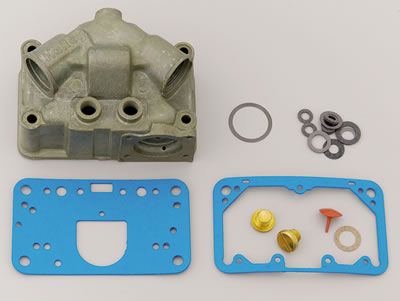

don,t forget the accelerator pump itself can be upgraded from 35cc to a 50cc version on many holley carbs

http://www.stockcarracing.com/techartic ... index.html

http://www.holley.com/types/Accelerator ... 0Parts.asp

http://www.holley.com/types/Accelerator ... 0Parts.asp

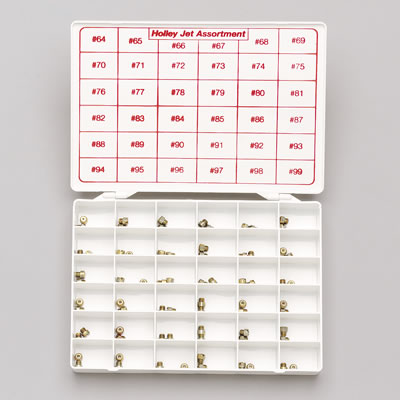

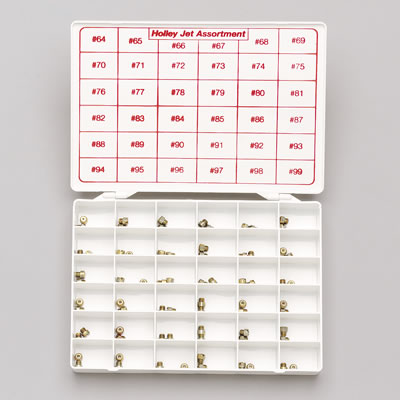

This chart gives the pump shot volume in CCs for each cam in each position.

Position 1 Position 2

White 17 19.5

Blue 18 20

Red 18.5 20

Orange 19 24

Black 19 18

Green 24 30

Pink 30 37.5

Brown 36

http://store.summitracing.com/partdetai ... toview=sku

don,t forget the squirters or Accelerator Pump Discharge Nozzles

They come in 3 different types. Straight - anti pullover - and tube types. and different sizes

anti pullover

Straight

tube types.

the accelerator pumps shot should hit the lower edge of the booster nozzle for better atomization, so the squirter you've selected should in part depend on the type of booster, accelerator pump volume and the distance from squirter to that booster, the type of squirter used should also depend on the pump volume and carburetor vacuum readings as exceptionally high plenum vacuum can draw fuel from the squirters. the anti pull over design is just needed for special applications like using a 2 barrel or a small 4 barrel on a larger displacement V-8 where the plenum vacuum is strong enough at WOT suck fuel from the squirter , occasionally causing a over rich condition

http://www.summitracing.com/parts/MOR-65222/?rtype=10

http://store.summitracing.com/egnsearch ... toview=sku

http://store.summitracing.com/egnsearch ... toview=sku

http://holley.com/data/TechService/Tech ... 20Info.pdf

(READ PG 4)

http://www.automedia.com/Holley_Carbure ... 000718hm/1

http://www.nationaltbucketalliance.com/ ... /carbs.asp

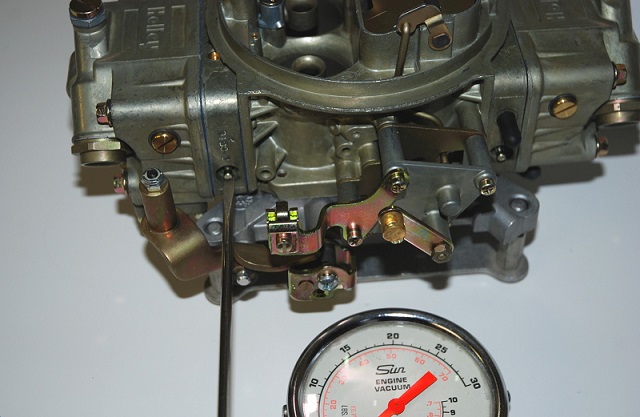

You generally select a power valve thats 1/2 the vacuum at idle , example if your pulling 17" at idle you select a 8.5-or 9.5 power valve, if your pulling 12" you select a 5.5 -6.5 power valve, your running about 5" so youll want a 2.5 -3.5 power valve AS A START POINT THEN TUNE UP OR DOWN IN F?A RATIO AS REQUIRED READING PLUGS OR USING A F/A RATIO METER ON THE EXHAUST

yes its a P.I.T.A. but reading thru the links holds a lot of info you'll miss if you don,t take the time

this is a power valve its screwed into a metering plate between the carb fuel bowl and the carb body in many carbs, it restricts additional fuel flow until the vacuum drops to a known level stamped on the power valve rim,

keep in mind the HIGHER the number the earlier in the transition process from idle to full throttle, the power valve allows fuel to flow

POWER ENRICHMENT SYSTEM

The power enrichment system supplies additional fuel to the

main system during heavy load or full power situations. Holley

carburetors utilize a vacuum operated power enrichment system

and a selection of power valves is available to “time” this sys-

tem’s operation to your specific needs. Each Holley power

valve is stamped with a number to indicate the vacuum opening

point. For example, the number “65” indicates that the power

valve will open when the engine vacuum drops to 6.5" or

below. An accurate vacuum gauge, such as Holley P/N

26-501,

should be used when determining the correct power

valve to use. A

competition or race engine which has a long

duration high overlap camshaft will have low manifold vacuum

at idle speeds. If the vehicle has a manual transmission, take

the vacuum reading with the engine thoroughly warmed up and

at idle. If the vehicle is equipped with an automatic transmis-

sion, take the vacuum reading with the engine thoroughly

warmed up and idling in gear. In either case, the power valve

selected should be 1/2 the intake manifold vacuum reading

taken. EXAMPLE: 13” Hg vacuum reading divided by 2 = 6.5

power valve. If your reading divided by 2 lands on an even

number you should select the next lowest power valve. EXAM-

PLE: 8” Hg vacuum reading divided by 2 = 4 power valve.

Since there is no #4 power valve you should use a 3.5.

Most of the popular Holley “Street Legal” and “Street

Performance” carburetors incorporate a power valve blow-out

protection system. A special check valve is located in the throt-

tle body expressly for this purpose. This check valve is

designed to be normally open but will quickly seat to close off

the internal vacuum passage when a backfire occurs. Once

closed, the check valve interrupts the pressure wave caused by

the backfire, thus protecting the power valve.

If you have a carburetor older than 1992 (or you have experi-

enced an extreme backfire) and expect a blown power valve,

use this simple test. TEST: At idle turn your idle mixture screws

(found on the side of the metering block) all the way in. If your

engine dies the power valve is not blown

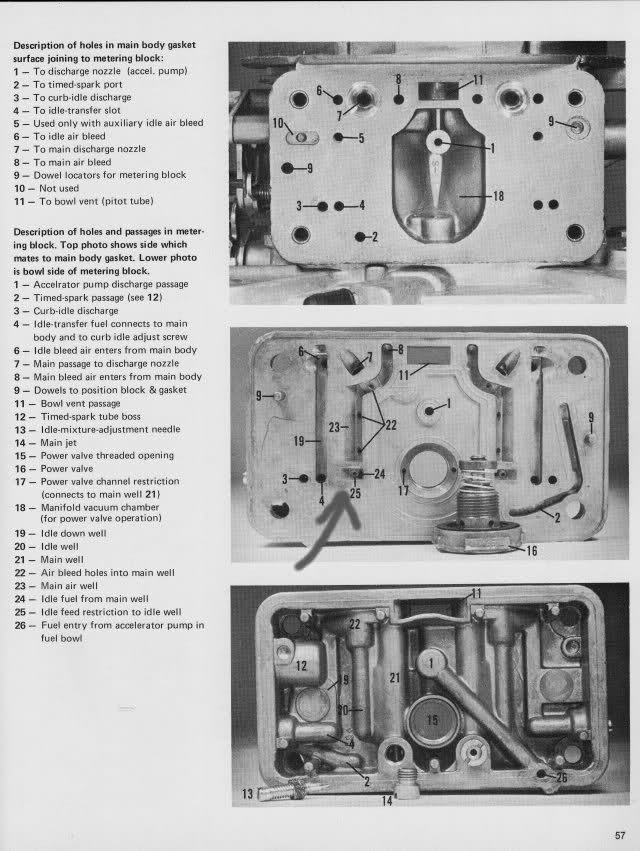

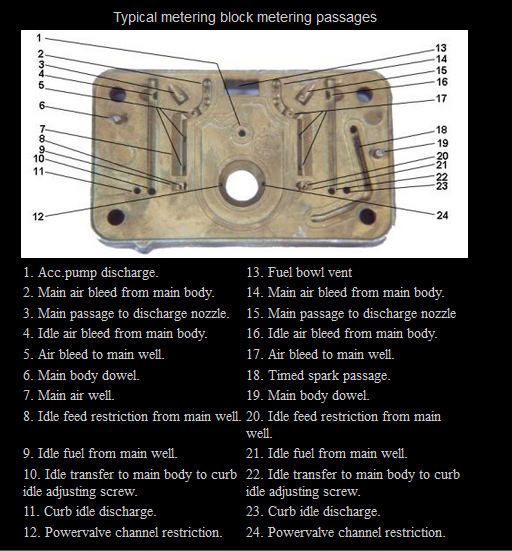

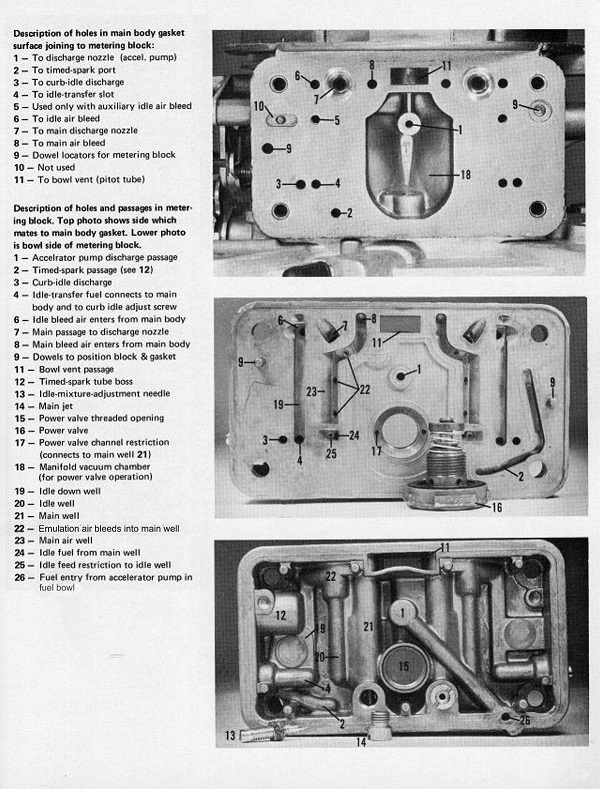

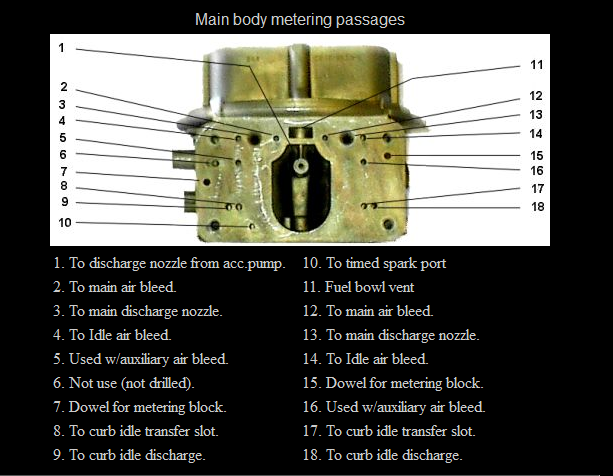

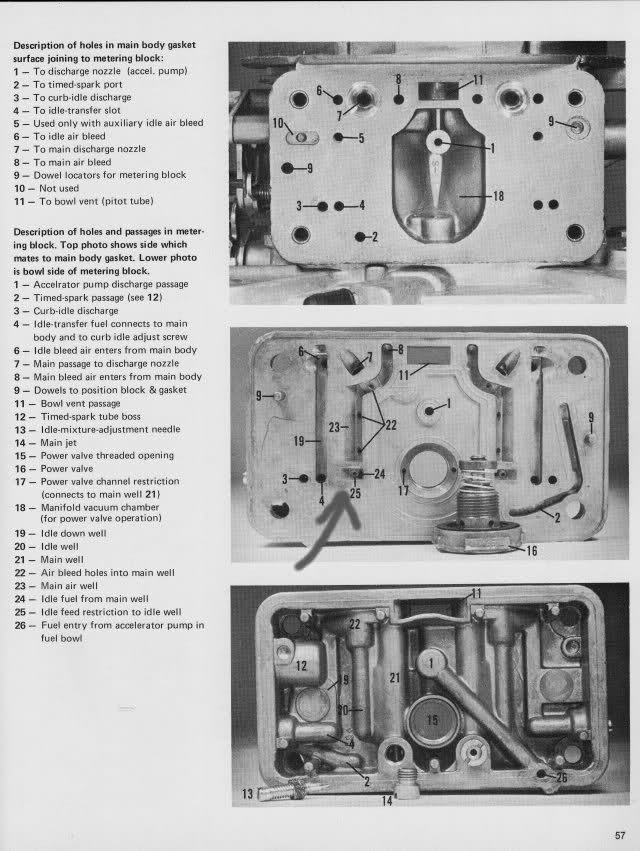

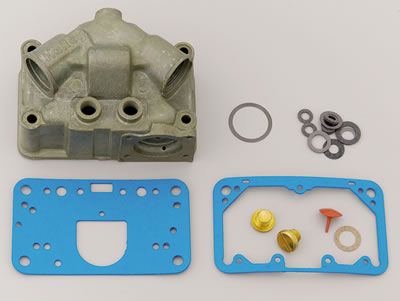

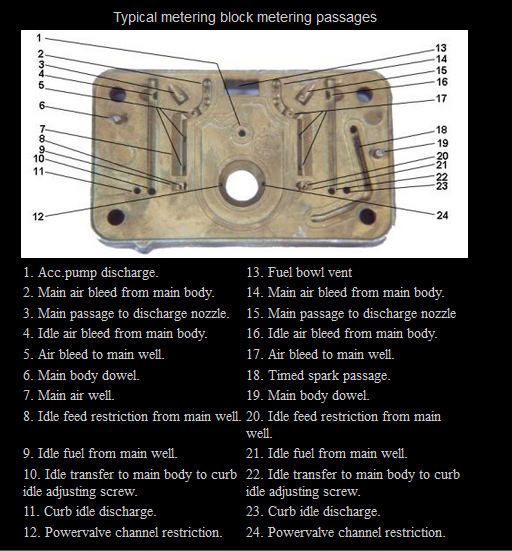

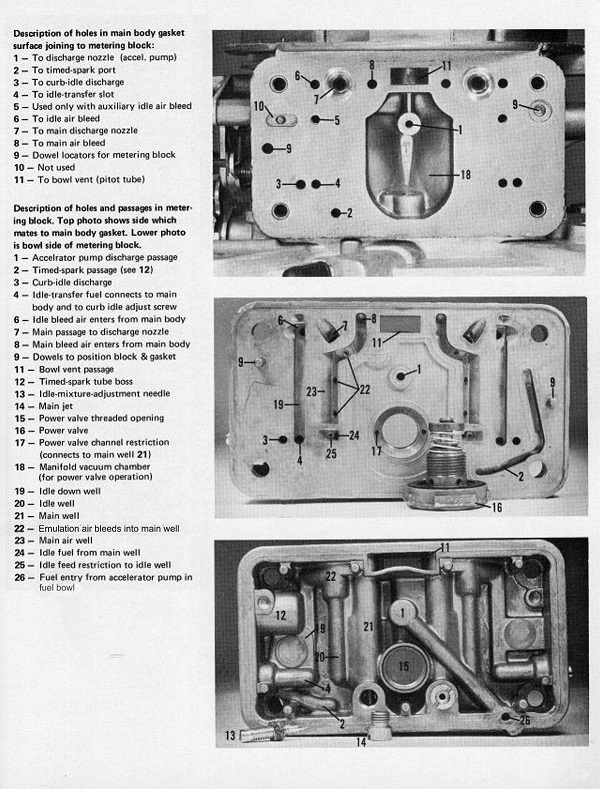

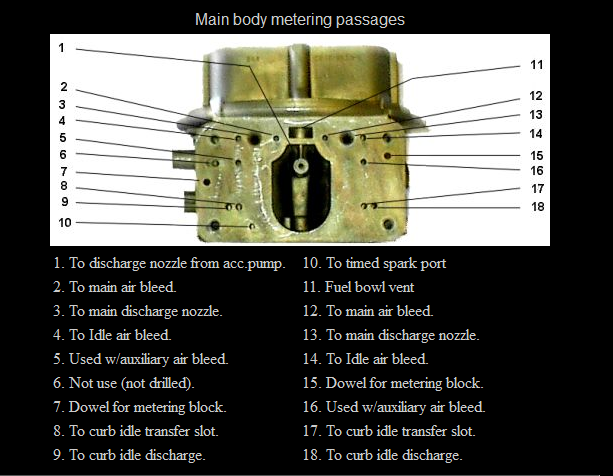

keep in mind theres lots of small passages that can get clogged and theres several different fuel bowl gaskets, these vary by manufacturer and carb model, so be sure you use the correct gasket on the meter block and fuel bowl, if you leave debris in the fuel bowl or use the wrong gaskets they can block passages and the carb won,t function

AS ALWAYS YOUR GOING TO MISS A TON OF INFO IF YOU SKIP THE SUB LINKS

keep in mind a few basic concepts, you can select a 30cc or 500 cc accelerator pump volume ,

the accelerator pump cam will control how fast the carbs linkager starts to cover the transition between idle and fully open venturies when the engine could go lean, remember that a larger squirter size does not give you more total fuel, it only allows more volume to move through the squirter faster, but this only tends to result in a shorter duration squirt, of fuel befor and during the transition,as the power valves and secondary jetting add fuel and air flow, THE Only way to truly know how the combo of power valve,booster type, accelerator pump cam ,squirter, accelerator pump size and carb jets will work on your combo, is to try a couple different combos and see how the 60' times and the engine feels as you accelerate, and both experience and knowledge of how to read spark plugs and change ignition advance curves will help a great deal.

http://www.summitracing.com/parts/HLY-20-12/

http://www.summitracing.com/parts/HLY-125-25/

If your tuning a holley carb having the 50cc accelerator pump kit and a selection of accelerator pump cams, a set of jets, squirters,and power valves in your tool box and a decent vacuum gauge, to tune with is a big help at times

Ive generally found the BLUE ACCELERATOR PUMP cam to be the best choice in most applications once the jets and power valves are correct, but obviously each application will need to be carefully tested

heres

bits of reference material.

Id try to get as close to the basic listed parameters below as a start point as you can, and the slight hesitation on acceleration might require a larger accelerator pump cam curve , or a power valve that kicks in at a bit higher vacuum level, example swapping from a 7.5 to and 8.5, make only a single change at a time and keep good detailed notes on results, and don,t discard parts, label them, keep in zip lock bags with labels

yeah I might not be up on the latest electronic data loggers but I have a good idea what an engine wants as far as a fuel/air ratio and combustion conditions and ignition advance curves and can read spark plugs, and while each engines a bit different you may be amazed at what consistent condition to start from does to help isolate any tuning problems

http://garage.grumpysperformance.com/index.php?threads/holley-carb-power-valves.1639/#post-4545

http://garage.grumpysperformance.co...annular-vs-down-leg-boosters.5229/#post-15353

set the float levels and verify the fuel pressure consistent at about 5 psi entering the carb inlet port.

your fuel/air ratio should be in these ranges

Idle- up too about 2500 rpm try for 14.7:1-15:1 f/a ratio

from about 2500 rpm- too about 4500 rpm try to smoothly and predictably transition the fuel/air ratio mix richer to about 13.5:1

from about 4500 rpm- too about 6500 rpm and higher ,try to smoothly and predictably transition the fuel/air ratio mix richer to about 12.5:1

this is only a starting point on the tune but it generally gets you in the ball park and tends to reduce the chances of the engine reaching detonation conditions.

the ignition advance curve needs to be checked, the chart below is a very good starting point to work from

set the plug gaps at about .045, make sure the valves are adjusted correctly

heres a needle and seat fuel valve

Here's a picture, Double Pumper on the left, Vacuum secondary on the right... Note on the upper left of each carb, the DP has linkage attached to the base plate/throttle shaft that actuates the secondary pump lever... The Vacuum carb has the large vacuum pod on the upper left side of the carb...

THE O-RING ON THE NEEDLE AND SEAT, AND THE DIAPHRAGM IN THE ACCELERATOR PUMP, CAN BE DAMAGED BY ETHANOL IN FUEL UNLESS AN ETHANOL COMPATIBLE MATERIAL IS USED

if your running great but seeing a momentary bog as the throttles snapped from idle to wot, I think youll find its a momentary lean condition, your going to easily fix that momentary hic-cup, just swap to a richer cam on the acceleration pump and or a #37 squirt-er , or you may need the 50cc accelerator pump upgrade should make the response damn near instantaneous, during the throttle transition stage

be aware the diaphragm must be the newer off green/blue version if your local fuel contains ethanol, as the older black diaphragm in the acceleration pumps eventually degrade and leak badly (FIRE HAZARD)

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

http://www.summitracing.com/parts/hly-135-9/overview/

If you get a momentary bog in first gear on acceleration, the sudden increase in inertial load on the fuel pump , due to the weight of the fuel its pushing slamming back into the fuel pump, might stall some electric fuel pumps for a couple seconds , or it may be a problem with the carbs acceleration fuel pump not covering the fuel demands , allowing a momentary lean-out in the fuel/air ratio.

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

swapping to a BLUE Holley Accelerator Pump Cam, (and maybe a 500 cc accelerator pump vs a stock 35cc pump) might help

http://www.summitracing.com/parts/hly-20-11/overview/

http://www.youtube.com/watch?v=k-Nx5HEz ... _embedded#!

http://www.youtube.com/watch?feature=pl ... -Nx5HEzvlY

http://www.youtube.com/watch?v=eiRIfcrc ... _embedded#

READ THESE RELATED THREADs /LINKS

viewtopic.php?f=32&t=6011&p=18597#p18597

http://www.stockcarracing.com/techartic ... index.html

viewtopic.php?f=55&t=5229

http://www.quickfueltechnology.com/tech ... -continued

https://documents.holley.com/pumpcamgraph.pdf

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

Holley Accelerator Pump Cam Chart (above)

Holley Accelerator Pump Cam Chart , INDEPENDENT TESTING DONE, notice its NOT an exact match to what HOLLEY tech guys posted

don,t forget the accelerator pump itself can be upgraded from 35cc to a 50cc version on many holley carbs

http://www.stockcarracing.com/techartic ... index.html

http://www.holley.com/types/Accelerator ... 0Parts.asp

http://www.holley.com/types/Accelerator ... 0Parts.asp

This chart gives the pump shot volume in CCs for each cam in each position.

Position 1 Position 2

White 17 19.5

Blue 18 20

Red 18.5 20

Orange 19 24

Black 19 18

Green 24 30

Pink 30 37.5

Brown 36

http://store.summitracing.com/partdetai ... toview=sku

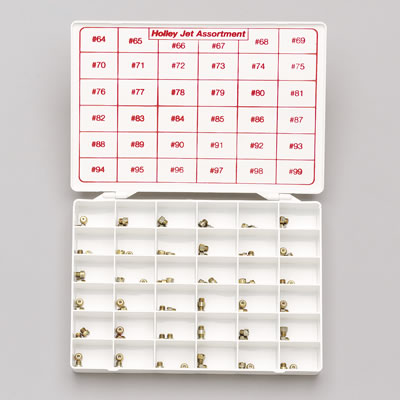

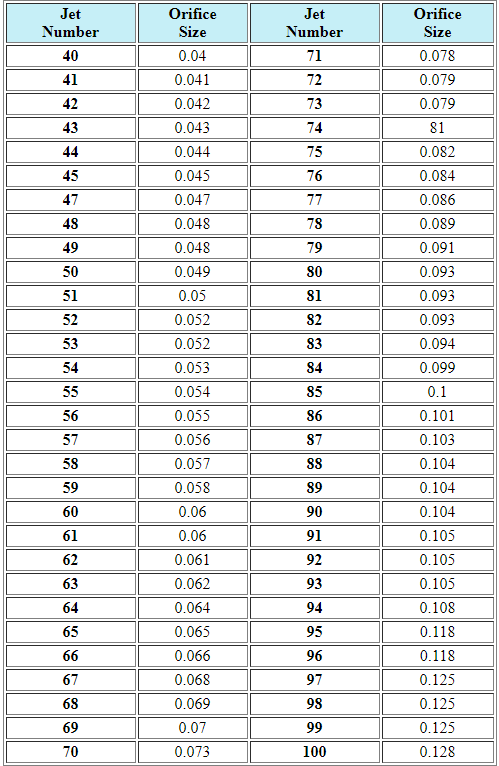

don,t forget the squirters or Accelerator Pump Discharge Nozzles

They come in 3 different types. Straight - anti pullover - and tube types. and different sizes

anti pullover

Straight

tube types.

the accelerator pumps shot should hit the lower edge of the booster nozzle for better atomization, so the squirter you've selected should in part depend on the type of booster, accelerator pump volume and the distance from squirter to that booster, the type of squirter used should also depend on the pump volume and carburetor vacuum readings as exceptionally high plenum vacuum can draw fuel from the squirters. the anti pull over design is just needed for special applications like using a 2 barrel or a small 4 barrel on a larger displacement V-8 where the plenum vacuum is strong enough at WOT suck fuel from the squirter , occasionally causing a over rich condition

http://www.summitracing.com/parts/MOR-65222/?rtype=10

http://store.summitracing.com/egnsearch ... toview=sku

http://store.summitracing.com/egnsearch ... toview=sku

http://holley.com/data/TechService/Tech ... 20Info.pdf

(READ PG 4)

http://www.automedia.com/Holley_Carbure ... 000718hm/1

http://www.nationaltbucketalliance.com/ ... /carbs.asp

You generally select a power valve thats 1/2 the vacuum at idle , example if your pulling 17" at idle you select a 8.5-or 9.5 power valve, if your pulling 12" you select a 5.5 -6.5 power valve, your running about 5" so youll want a 2.5 -3.5 power valve AS A START POINT THEN TUNE UP OR DOWN IN F?A RATIO AS REQUIRED READING PLUGS OR USING A F/A RATIO METER ON THE EXHAUST

yes its a P.I.T.A. but reading thru the links holds a lot of info you'll miss if you don,t take the time

this is a power valve its screwed into a metering plate between the carb fuel bowl and the carb body in many carbs, it restricts additional fuel flow until the vacuum drops to a known level stamped on the power valve rim,

keep in mind the HIGHER the number the earlier in the transition process from idle to full throttle, the power valve allows fuel to flow

POWER ENRICHMENT SYSTEM

The power enrichment system supplies additional fuel to the

main system during heavy load or full power situations. Holley

carburetors utilize a vacuum operated power enrichment system

and a selection of power valves is available to “time” this sys-

tem’s operation to your specific needs. Each Holley power

valve is stamped with a number to indicate the vacuum opening

point. For example, the number “65” indicates that the power

valve will open when the engine vacuum drops to 6.5" or

below. An accurate vacuum gauge, such as Holley P/N

26-501,

should be used when determining the correct power

valve to use. A

competition or race engine which has a long

duration high overlap camshaft will have low manifold vacuum

at idle speeds. If the vehicle has a manual transmission, take

the vacuum reading with the engine thoroughly warmed up and

at idle. If the vehicle is equipped with an automatic transmis-

sion, take the vacuum reading with the engine thoroughly

warmed up and idling in gear. In either case, the power valve

selected should be 1/2 the intake manifold vacuum reading

taken. EXAMPLE: 13” Hg vacuum reading divided by 2 = 6.5

power valve. If your reading divided by 2 lands on an even

number you should select the next lowest power valve. EXAM-

PLE: 8” Hg vacuum reading divided by 2 = 4 power valve.

Since there is no #4 power valve you should use a 3.5.

Most of the popular Holley “Street Legal” and “Street

Performance” carburetors incorporate a power valve blow-out

protection system. A special check valve is located in the throt-

tle body expressly for this purpose. This check valve is

designed to be normally open but will quickly seat to close off

the internal vacuum passage when a backfire occurs. Once

closed, the check valve interrupts the pressure wave caused by

the backfire, thus protecting the power valve.

If you have a carburetor older than 1992 (or you have experi-

enced an extreme backfire) and expect a blown power valve,

use this simple test. TEST: At idle turn your idle mixture screws

(found on the side of the metering block) all the way in. If your

engine dies the power valve is not blown

keep in mind theres lots of small passages that can get clogged and theres several different fuel bowl gaskets, these vary by manufacturer and carb model, so be sure you use the correct gasket on the meter block and fuel bowl, if you leave debris in the fuel bowl or use the wrong gaskets they can block passages and the carb won,t function

AS ALWAYS YOUR GOING TO MISS A TON OF INFO IF YOU SKIP THE SUB LINKS

keep in mind a few basic concepts, you can select a 30cc or 500 cc accelerator pump volume ,

the accelerator pump cam will control how fast the carbs linkager starts to cover the transition between idle and fully open venturies when the engine could go lean, remember that a larger squirter size does not give you more total fuel, it only allows more volume to move through the squirter faster, but this only tends to result in a shorter duration squirt, of fuel befor and during the transition,as the power valves and secondary jetting add fuel and air flow, THE Only way to truly know how the combo of power valve,booster type, accelerator pump cam ,squirter, accelerator pump size and carb jets will work on your combo, is to try a couple different combos and see how the 60' times and the engine feels as you accelerate, and both experience and knowledge of how to read spark plugs and change ignition advance curves will help a great deal.

http://www.summitracing.com/parts/HLY-20-12/

http://www.summitracing.com/parts/HLY-125-25/

If your tuning a holley carb having the 50cc accelerator pump kit and a selection of accelerator pump cams, a set of jets, squirters,and power valves in your tool box and a decent vacuum gauge, to tune with is a big help at times

Ive generally found the BLUE ACCELERATOR PUMP cam to be the best choice in most applications once the jets and power valves are correct, but obviously each application will need to be carefully tested

heres

bits of reference material.

Id try to get as close to the basic listed parameters below as a start point as you can, and the slight hesitation on acceleration might require a larger accelerator pump cam curve , or a power valve that kicks in at a bit higher vacuum level, example swapping from a 7.5 to and 8.5, make only a single change at a time and keep good detailed notes on results, and don,t discard parts, label them, keep in zip lock bags with labels

yeah I might not be up on the latest electronic data loggers but I have a good idea what an engine wants as far as a fuel/air ratio and combustion conditions and ignition advance curves and can read spark plugs, and while each engines a bit different you may be amazed at what consistent condition to start from does to help isolate any tuning problems

http://garage.grumpysperformance.com/index.php?threads/holley-carb-power-valves.1639/#post-4545

http://garage.grumpysperformance.co...annular-vs-down-leg-boosters.5229/#post-15353

set the float levels and verify the fuel pressure consistent at about 5 psi entering the carb inlet port.

your fuel/air ratio should be in these ranges

Idle- up too about 2500 rpm try for 14.7:1-15:1 f/a ratio

from about 2500 rpm- too about 4500 rpm try to smoothly and predictably transition the fuel/air ratio mix richer to about 13.5:1

from about 4500 rpm- too about 6500 rpm and higher ,try to smoothly and predictably transition the fuel/air ratio mix richer to about 12.5:1

this is only a starting point on the tune but it generally gets you in the ball park and tends to reduce the chances of the engine reaching detonation conditions.

the ignition advance curve needs to be checked, the chart below is a very good starting point to work from

set the plug gaps at about .045, make sure the valves are adjusted correctly

Last edited by a moderator:

Ram Air Restoratio...

Ram Air Restoratio...