yes its a P.I.T.A. but reading thru the links holds a lot of info you'll miss if you don,t take the time

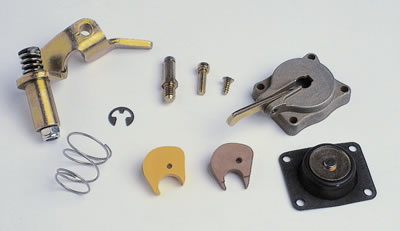

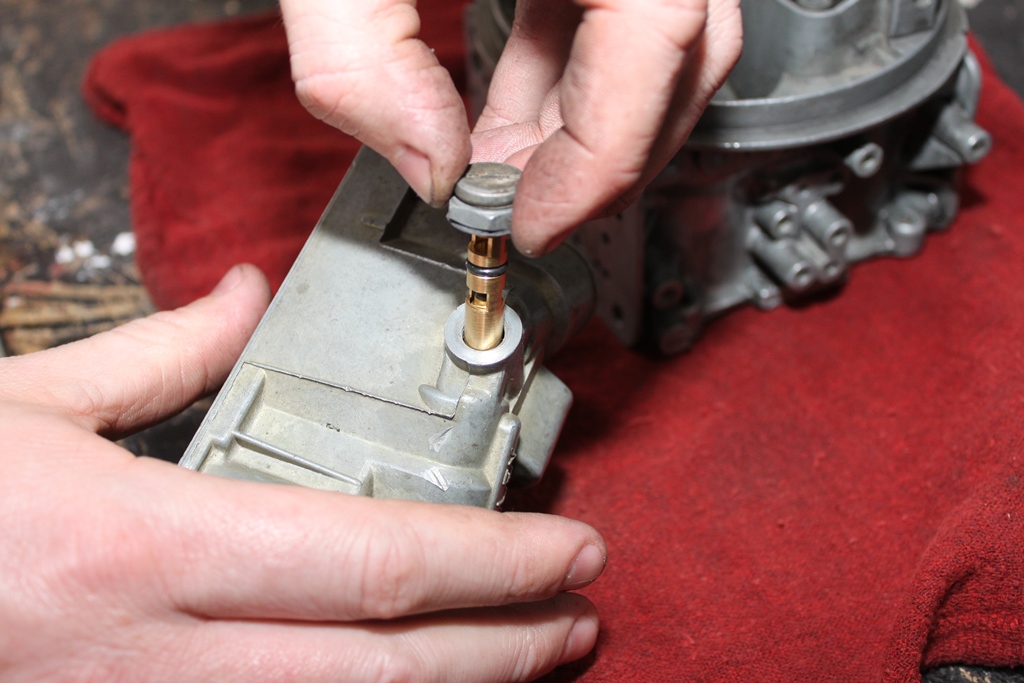

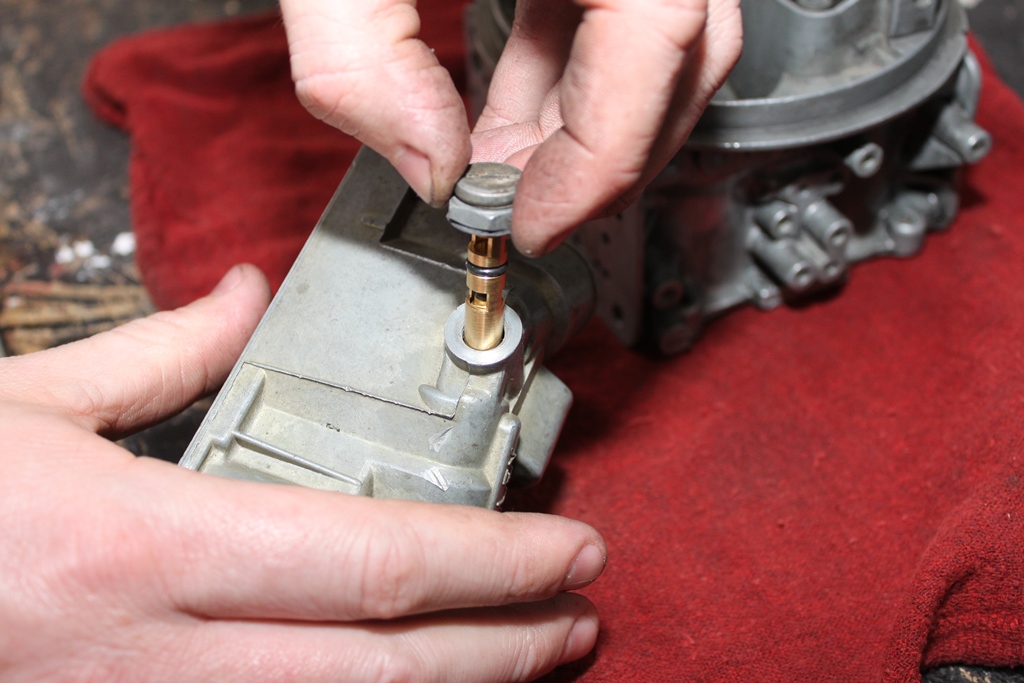

this is a power valve its screwed into a metering plate between the carb fuel bowl and the carb body in many carbs, it restricts additional fuel flow until the vacuum drops to a known level stamped on the power valve rim,

What the power valve is supposed to do is allow additional fuel flow, that comes in as the velocity of air through the carbs venturi speeds up and the vacuum reading drops,it opens, as the vacuum drops and the accelerator pump has mostly run out of stroke and is in the process of supplying a shot of extra fuel to cover the rapid increase in air flow during the transition from part to fully open throttle that starts during acceleration. the diaphram on the power valve senses the throttle is open and opens a valve which allows a richer fuel/air ratio mixture to flow until you lift off the throttle .

as the vacume reading increases the power valve senses the increase and then it closes and the carbs fuel delivery internal fuel routeing goes back to standard jetting, Leaning its mixture out for only partial throttle open operation used for steady speed operation like durring low speed cruising.

SO when you depress the throttle the accelerator pump cam forces fuel through the accelerator pump that sprays into the venturies, as the throttle blades open, and the vacuum drops away rappidly to much lower levels.

The power valve senses low vacuum and opens up and allows more fuel to flow through the carberator allowing a richer and better, less detonation prone power producing mixture, and thus you don,t get a big "BOG" or cough when the carb suddenly ingested more air and the carbs jetting alone can,t keep up with demand, the power valve fuel supply flows fuel until you lift off and the vacuum in the intake plenum increases, and shuts it off.

as with most subjects a few dollars spent on related reading material is money well spent

http://www.amazon.com/Holley-Carburetor ... lley+carbs

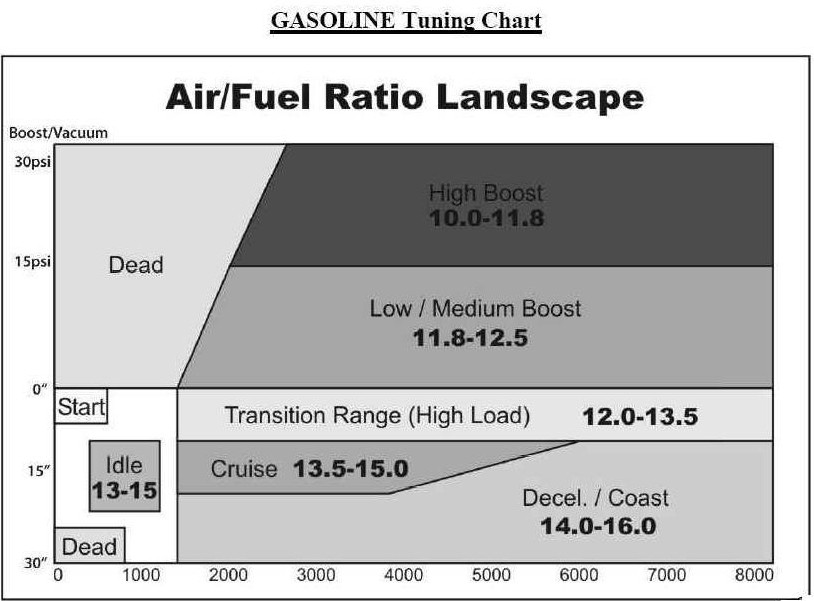

Perfect for naturally aspirated. It's sensing the engine and doing the right thing at the right time.

keep in mind the power valve supplys extra fuel as the vacuum drops as the throttle blades open in the transition process from idle to full throttle, the power valve allows additional fuel to flow, as the plenum vacuum drops.

Ive generally found youll want to START the tune with the power valve used being selected too be close to 1/2 the vacume/plenum reading at a steady cruise, at minimum throttle NOT at idle in neutral

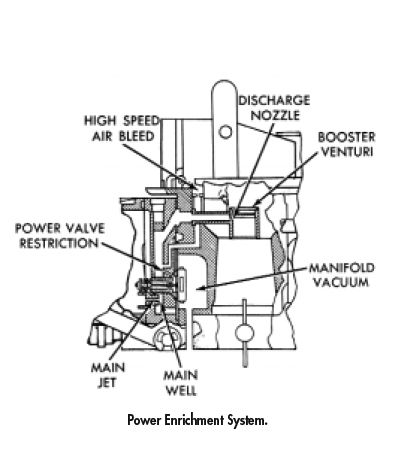

POWER ENRICHMENT SYSTEM

The power enrichment system supplies additional fuel to the

main system during heavy load or full power situations.

KEEP IN MIND that you TUNE based on the results youll see in actual operation, and you don,t assume anything here, your almost certainly going to need to change the power valve, jets and accelerator pump cam based on the results youll see under actual operating conditions.

Holley carburetors utilize a vacuum operated power enrichment system

and a selection of power valves is available to “time” this sys-

tem’s operation to your specific needs. Each Holley power

valve is stamped with a number to indicate the vacuum opening

point. For example, the number “65” indicates that the power

valve will open when the engine vacuum drops to 6.5" or

below. An accurate vacuum gauge, such as Holley P/N

26-501,

should be used when determining the correct power

valve to use. A

competition or race engine which has a long

duration high overlap camshaft will have low manifold vacuum

at idle speeds. If the vehicle has a manual transmission, take

the vacuum reading with the engine thoroughly warmed up and

at idle. If the vehicle is equipped with an automatic transmis-

sion, take the vacuum reading with the engine thoroughly

warmed up and idling in gear. In either case, the power valve

selected should be 1/2 the intake manifold vacuum reading

taken. EXAMPLE: 13” Hg vacuum reading divided by 2 = 6.5

power valve. If your reading divided by 2 lands on an even

number you should select the next lowest power valve. EXAM-

PLE: 8” Hg vacuum reading divided by 2 = 4 power valve.

Since there is no #4 power valve you should use a 3.5.

Most of the popular Holley “Street Legal” and “Street

Performance” carburetors incorporate a power valve blow-out

protection system. A special check valve is located in the throt-

tle body expressly for this purpose. This check valve is

designed to be normally open but will quickly seat to close off

the internal vacuum passage when a backfire occurs. Once

closed, the check valve interrupts the pressure wave caused by

the backfire, thus protecting the power valve.

If you have a carburetor older than 1992 (or you have experi-

enced an extreme backfire) and expect a blown power valve,

use this simple test. TEST: At idle turn your idle mixture screws

(found on the side of the metering block) all the way in. If your

engine dies the power valve is not blown

The purpose of a power valve is for it to add the needed extra fuel the engine needs to transition and maintain the correct fuel/air ratio,when you are under wide open throttle. It is not intended to be an enrichment circuit during normal throttle cruising.

If you are lean or rich during normal driving conditions, you need to tune the jets, not the power valve.

The reason you check the vacuum at idle and take that reading and divide it in half, is so you do not have a power valve that will open at idle as this will tend too cause an excessively rich mixture at idle, or just off idle. the power valve opens to flow extra fuel during the transition period and while the accelerator pump is also adding fuel, . Under WOT the vacuum of the engine will drop to a vacuum reading of 1.5 or even lower near zero and the power valve will then open adding the extra fuel needed during WOT.

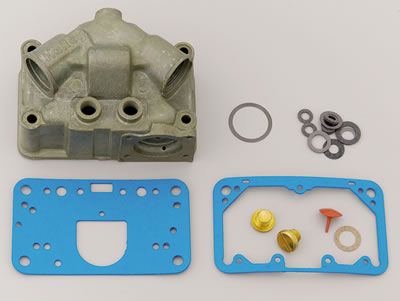

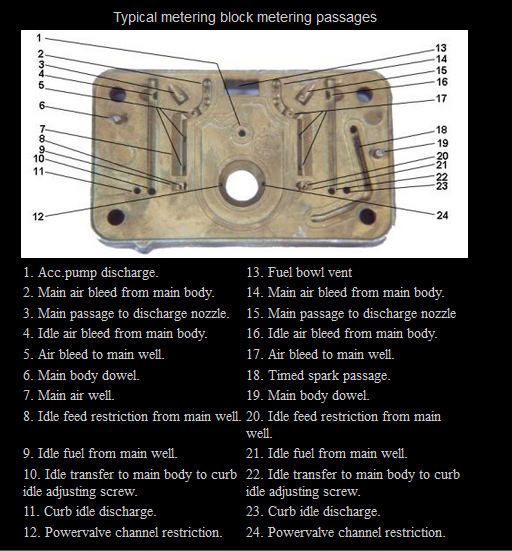

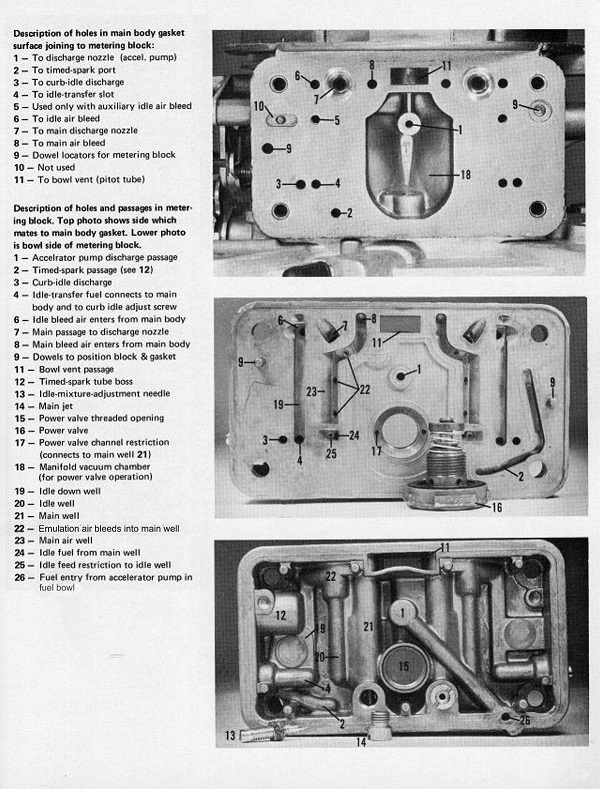

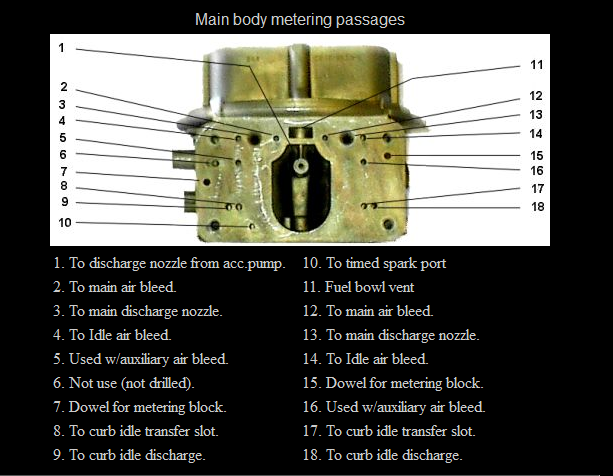

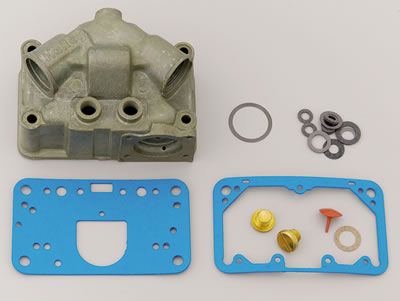

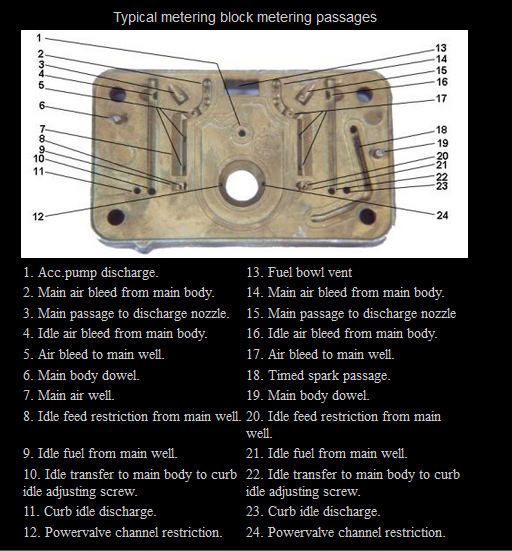

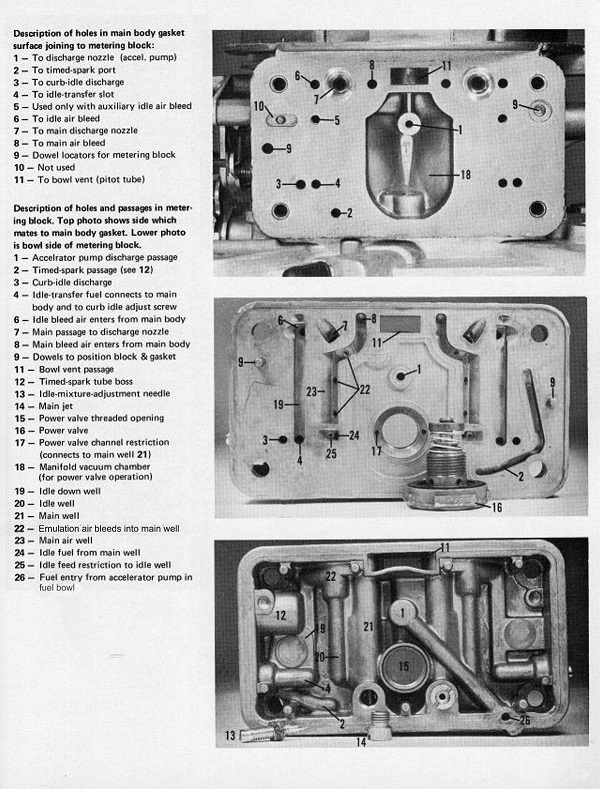

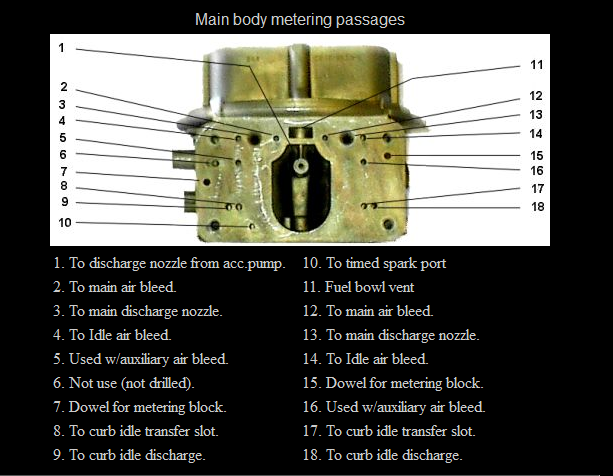

keep in mind theres lots of small passages that can get clogged and theres several different fuel bowl gaskets, these vary by manufacturer and carb model, so be sure you use the correct gasket on the meter block and fuel bowl, if you leave debris in the fuel bowl or use the wrong gaskets they can block passages and the carb won,t function

AS ALWAYS YOUR GOING TO MISS A TON OF INFO IF YOU SKIP THE SUB LINKS

GET A FUEL PRESSURE GAUGE AND MEASURE DON,T GUESS

how can you possibly set up your fuel system unless you know the pressure and flow rates required and what currently exist's

READ LINKS

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.com/index.php?threads/how-big-a-fuel-pump-do-you-need.1939/

http://garage.grumpysperformance.co...ss-fuel-pressure-regulators.12776/#post-65998

keep in mind a few basic concepts, you can select a 30cc or 50 cc accelerator pump volume ,

the accelerator pump cam will control how fast the carbs linkager starts to cover the transition between idle and fully open venturies when the engine could go lean, remember that a larger squirter size does not give you more total fuel, it only allows more volume to move through the squirter faster, but this only tends to result in a shorter duration squirt, of fuel befor and during the transition,as the power valves and secondary jetting add fuel and air flow, THE Only way to truly know how the combo of power valve,booster type, accelerator pump cam ,squirter, accelerator pump size and carb jets will work on your combo, is to try a couple different combos and see how the 60' times and the engine feels as you accelerate, and both experience and knowledge of how to read spark plugs and change ignition advance curves will help a great deal.

http://forums.holley.com/entry.php?430- ... lve-Tuning

http://www.holley.com/types/Power Valves.asp

http://garage.grumpysperformance.com/index.php?threads/locating-vacume-leaks.882/#post-45944

http://www.enginebuildermag.com/Article ... etors.aspx

THE O-RING ON THE NEEDLE AND SEAT, AND THE DIAPHRAGM IN THE ACCELERATOR PUMP, CAN BE DAMAGED BY ETHANOL IN FUEL UNLESS AN ETHANOL COMPATIBLE MATERIAL IS USED

http://www.streetperformance.com/m/cats ... valve.html

the first thing you need to understand is what a power valve does, the simple explanation is that there's a number stamped on the power valve (EXAMPLE 6.5), that relates to the VACUUM reading the carb will need to drop below (in that case 6.5" of vacuum) before the power valve opens and adds additional fuel to what the carbs jets already allow

the higher the number the faster the power valve opens as the vacuum drops as the throttle opens, they really should be called, vacuum activated fuel enrichment valves

at idle your car produces more vacuum because the throttle blades are almost closed restricting flow into the intake, as you open the carb throttle blades vacuum drops off and flow increases, at some point the carbs increased air flow requires additional fuel to maintain the correct fuel/air ratio, the power valve controls the point where that fuel starts to be added using the drop in intake vacuum as the trigger to release more fuel.

power valves have a diaphragm that can be ruptured, a BLOWN or busted power valve will leak fuel in an irregular manor,and not regulate flow, so if it does not test correctly, you'll need to replace it, the most common cause, for a busted power valve is carb back fires,

youll see most places advise you start with a power valve rated at 1/2 the vacume reading, the engine has at idle, if its a manual take the reading in neutral, if its an auto take the reading at idle in gear with your foot on the brake,

EXAMPLE if the vacuum reads, at 15-16" then youll want about a 6.5- 8.5 power valve,in many cases, your generally going to find that a power valve thats marked at about 1/2 the vacuum at idle is a good starting place IE, if your pulling 17" of vacuum the 7.5-8.5 power valves about correct,if your pulling 11" of vacuum the 5.5- 6.5 power valves about correct

Holley's instructions, to use a PV that's half of your idle vacuum, are some what miss leading. They will ALWAYS lead you to choose too low a PV number, which in turn will force you to use too large jets, too much pump, etc. youll generally want to select a slightly higher number power valve if your getting a flat spot,. Keep raising the PV number until that flat spot clears up.

you take the vacuum reading at idle and cut it in 1/2 then jump up or down one -two numbers depending on how the plugs look, the engine runs and what your fuel/air ratio meter indicates example if your pulling 16" at idle that would be a power valve in the 6.5-9.5 range

youll also see advise saying that Basing the PV selection on idle vacuum is BAD advise that has floated around for a long time. If you take CRUISE vacuum, divide it in half and add about 2" you will be close.

read what holley says

http://www.holley.com/data/TechService/ ... 20Info.pdf

http://www.holley.com/data/TechService/ ... valves.pdf

http://www.onallcylinders.com/2013/03/07/how-to-tune-the-power-valves-on-a-holley-carburetor/

[/size][/color]

read thru these threads also

viewtopic.php?f=55&t=1790

viewtopic.php?f=55&t=1442

http://www.holley.com/types/Power Valves.asp

viewtopic.php?f=55&t=8126&p=28205#p28205

http://www.chevyhiperformance.com/tech/ ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.jegs.com/p/Holley/Holley-Pow ... 1/10002/-1

http://www.holley.com/data/TechService/ ... valves.pdf

http://video.google.com/videosearch?hl= ... &ct=title#

http://www.classictrucks.com/tech/0806c ... alves.html

http://www.jegs.com/p/Holley/743661/10002/-1

http://www.summitracing.com/parts/MOR-65222/?rtype=10

viewtopic.php?f=44&t=773&p=1123#p1123

http://www.wonderhowto.com/how-to/video ... ve-267173/

http://store.summitracing.com/partdetai ... toview=sku

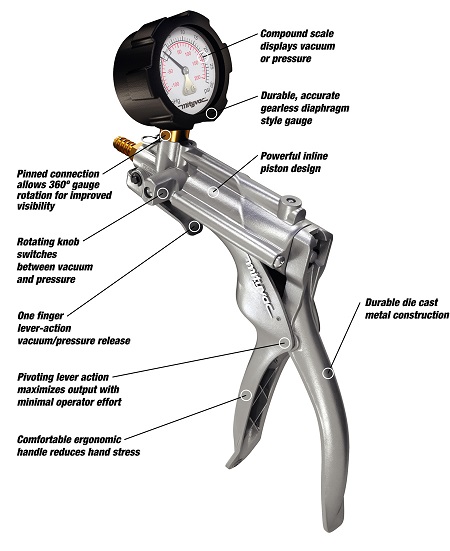

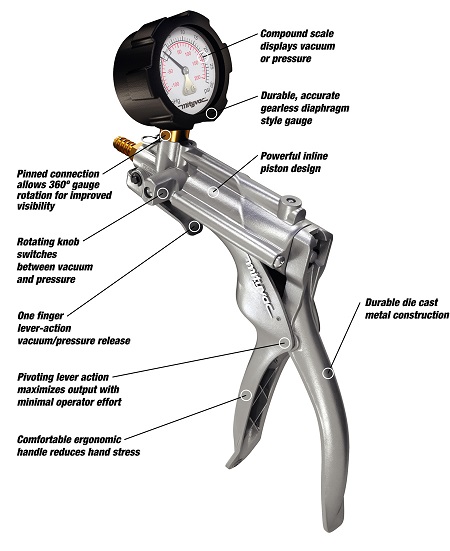

Ive had a vacuum pump tool for years to test Holley power valves with this adapter, pictured below and I recommend using the tester as it quickly locates leaky power valves, which can make you 1/2 crazy wondering why the carbs f/a ratio won,t be consistent

http://www.summitracing.com/parts/MOR-62295/?rtype=10

http://www.harborfreight.com/mityvac-va ... 39522.html

http://www.mityvac.com/pages/products_hvpo.asp#

http://www.mityvac.com/pages/products_hvp.asp

http://www.harborfreight.com/cpi/ctaf/d ... mber=93547

http://www.harborfreight.com/cpi/ctaf/d ... mber=92474

https://www.homedepot.com/p/Powerbuilt-Vacuum-Pump-Kit-648744/203120693

with a few cheap components you can test a power valve

read this also

viewtopic.php?f=55&t=1790

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=1411

viewtopic.php?f=70&t=875

viewtopic.php?f=70&t=294

keep in mind there's many guys chasing carb problems that are eventually traced to the ignition, or fuel system, verify the damper and timing tab really do reflect TDC and your ignition advance is working correctly, and verify you have 5 psi of steady fuel pressure at the carb and the floats are set correctly and the cars valves are adjusted and there's no vacuum leaks before you go swearing its solely a carb problem

BTW someone is bound to ask eventually ,what is the difference between "standard flow".

SEE WHAT READING THE PART DESCRIPTION RESULTS IN???

http://www.summitracing.com/parts/hly-125-105/overview/

and "high flow"? in a power valve?

http://www.summitracing.com/parts/hl...1005/overview/

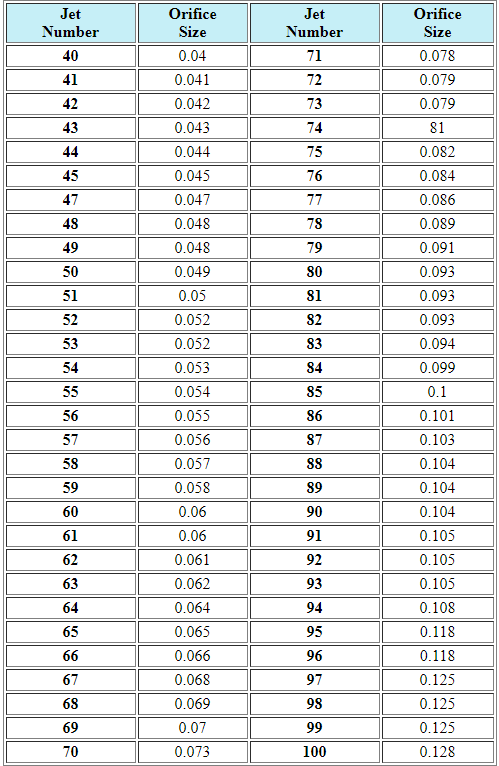

theres both a standard and a high flow rate version in each power valve, generally like with carburetor jets youll want to match the fuel flow rate of the power valve to the engines needs , I've generally found the standard flows work well on anything up to 350 cubic inch and the high flows work better on the big blocks,396 and up, and yes matching the carb jetting and reading the spark plugs and having a FUEL/AIR RATIO METER and a bit of testing is mandatory

this is a power valve its screwed into a metering plate between the carb fuel bowl and the carb body in many carbs, it restricts additional fuel flow until the vacuum drops to a known level stamped on the power valve rim,

What the power valve is supposed to do is allow additional fuel flow, that comes in as the velocity of air through the carbs venturi speeds up and the vacuum reading drops,it opens, as the vacuum drops and the accelerator pump has mostly run out of stroke and is in the process of supplying a shot of extra fuel to cover the rapid increase in air flow during the transition from part to fully open throttle that starts during acceleration. the diaphram on the power valve senses the throttle is open and opens a valve which allows a richer fuel/air ratio mixture to flow until you lift off the throttle .

as the vacume reading increases the power valve senses the increase and then it closes and the carbs fuel delivery internal fuel routeing goes back to standard jetting, Leaning its mixture out for only partial throttle open operation used for steady speed operation like durring low speed cruising.

SO when you depress the throttle the accelerator pump cam forces fuel through the accelerator pump that sprays into the venturies, as the throttle blades open, and the vacuum drops away rappidly to much lower levels.

The power valve senses low vacuum and opens up and allows more fuel to flow through the carberator allowing a richer and better, less detonation prone power producing mixture, and thus you don,t get a big "BOG" or cough when the carb suddenly ingested more air and the carbs jetting alone can,t keep up with demand, the power valve fuel supply flows fuel until you lift off and the vacuum in the intake plenum increases, and shuts it off.

as with most subjects a few dollars spent on related reading material is money well spent

http://www.amazon.com/Holley-Carburetor ... lley+carbs

Perfect for naturally aspirated. It's sensing the engine and doing the right thing at the right time.

keep in mind the power valve supplys extra fuel as the vacuum drops as the throttle blades open in the transition process from idle to full throttle, the power valve allows additional fuel to flow, as the plenum vacuum drops.

Ive generally found youll want to START the tune with the power valve used being selected too be close to 1/2 the vacume/plenum reading at a steady cruise, at minimum throttle NOT at idle in neutral

POWER ENRICHMENT SYSTEM

The power enrichment system supplies additional fuel to the

main system during heavy load or full power situations.

KEEP IN MIND that you TUNE based on the results youll see in actual operation, and you don,t assume anything here, your almost certainly going to need to change the power valve, jets and accelerator pump cam based on the results youll see under actual operating conditions.

Holley carburetors utilize a vacuum operated power enrichment system

and a selection of power valves is available to “time” this sys-

tem’s operation to your specific needs. Each Holley power

valve is stamped with a number to indicate the vacuum opening

point. For example, the number “65” indicates that the power

valve will open when the engine vacuum drops to 6.5" or

below. An accurate vacuum gauge, such as Holley P/N

26-501,

should be used when determining the correct power

valve to use. A

competition or race engine which has a long

duration high overlap camshaft will have low manifold vacuum

at idle speeds. If the vehicle has a manual transmission, take

the vacuum reading with the engine thoroughly warmed up and

at idle. If the vehicle is equipped with an automatic transmis-

sion, take the vacuum reading with the engine thoroughly

warmed up and idling in gear. In either case, the power valve

selected should be 1/2 the intake manifold vacuum reading

taken. EXAMPLE: 13” Hg vacuum reading divided by 2 = 6.5

power valve. If your reading divided by 2 lands on an even

number you should select the next lowest power valve. EXAM-

PLE: 8” Hg vacuum reading divided by 2 = 4 power valve.

Since there is no #4 power valve you should use a 3.5.

Most of the popular Holley “Street Legal” and “Street

Performance” carburetors incorporate a power valve blow-out

protection system. A special check valve is located in the throt-

tle body expressly for this purpose. This check valve is

designed to be normally open but will quickly seat to close off

the internal vacuum passage when a backfire occurs. Once

closed, the check valve interrupts the pressure wave caused by

the backfire, thus protecting the power valve.

If you have a carburetor older than 1992 (or you have experi-

enced an extreme backfire) and expect a blown power valve,

use this simple test. TEST: At idle turn your idle mixture screws

(found on the side of the metering block) all the way in. If your

engine dies the power valve is not blown

The purpose of a power valve is for it to add the needed extra fuel the engine needs to transition and maintain the correct fuel/air ratio,when you are under wide open throttle. It is not intended to be an enrichment circuit during normal throttle cruising.

If you are lean or rich during normal driving conditions, you need to tune the jets, not the power valve.

The reason you check the vacuum at idle and take that reading and divide it in half, is so you do not have a power valve that will open at idle as this will tend too cause an excessively rich mixture at idle, or just off idle. the power valve opens to flow extra fuel during the transition period and while the accelerator pump is also adding fuel, . Under WOT the vacuum of the engine will drop to a vacuum reading of 1.5 or even lower near zero and the power valve will then open adding the extra fuel needed during WOT.

keep in mind theres lots of small passages that can get clogged and theres several different fuel bowl gaskets, these vary by manufacturer and carb model, so be sure you use the correct gasket on the meter block and fuel bowl, if you leave debris in the fuel bowl or use the wrong gaskets they can block passages and the carb won,t function

AS ALWAYS YOUR GOING TO MISS A TON OF INFO IF YOU SKIP THE SUB LINKS

how can you possibly set up your fuel system unless you know the pressure and flow rates required and what currently exist's

READ LINKS

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.com/index.php?threads/how-big-a-fuel-pump-do-you-need.1939/

http://garage.grumpysperformance.co...ss-fuel-pressure-regulators.12776/#post-65998

keep in mind a few basic concepts, you can select a 30cc or 50 cc accelerator pump volume ,

the accelerator pump cam will control how fast the carbs linkager starts to cover the transition between idle and fully open venturies when the engine could go lean, remember that a larger squirter size does not give you more total fuel, it only allows more volume to move through the squirter faster, but this only tends to result in a shorter duration squirt, of fuel befor and during the transition,as the power valves and secondary jetting add fuel and air flow, THE Only way to truly know how the combo of power valve,booster type, accelerator pump cam ,squirter, accelerator pump size and carb jets will work on your combo, is to try a couple different combos and see how the 60' times and the engine feels as you accelerate, and both experience and knowledge of how to read spark plugs and change ignition advance curves will help a great deal.

http://forums.holley.com/entry.php?430- ... lve-Tuning

http://www.holley.com/types/Power Valves.asp

http://garage.grumpysperformance.com/index.php?threads/locating-vacume-leaks.882/#post-45944

http://www.enginebuildermag.com/Article ... etors.aspx

THE O-RING ON THE NEEDLE AND SEAT, AND THE DIAPHRAGM IN THE ACCELERATOR PUMP, CAN BE DAMAGED BY ETHANOL IN FUEL UNLESS AN ETHANOL COMPATIBLE MATERIAL IS USED

http://www.streetperformance.com/m/cats ... valve.html

the first thing you need to understand is what a power valve does, the simple explanation is that there's a number stamped on the power valve (EXAMPLE 6.5), that relates to the VACUUM reading the carb will need to drop below (in that case 6.5" of vacuum) before the power valve opens and adds additional fuel to what the carbs jets already allow

the higher the number the faster the power valve opens as the vacuum drops as the throttle opens, they really should be called, vacuum activated fuel enrichment valves

at idle your car produces more vacuum because the throttle blades are almost closed restricting flow into the intake, as you open the carb throttle blades vacuum drops off and flow increases, at some point the carbs increased air flow requires additional fuel to maintain the correct fuel/air ratio, the power valve controls the point where that fuel starts to be added using the drop in intake vacuum as the trigger to release more fuel.

power valves have a diaphragm that can be ruptured, a BLOWN or busted power valve will leak fuel in an irregular manor,and not regulate flow, so if it does not test correctly, you'll need to replace it, the most common cause, for a busted power valve is carb back fires,

youll see most places advise you start with a power valve rated at 1/2 the vacume reading, the engine has at idle, if its a manual take the reading in neutral, if its an auto take the reading at idle in gear with your foot on the brake,

EXAMPLE if the vacuum reads, at 15-16" then youll want about a 6.5- 8.5 power valve,in many cases, your generally going to find that a power valve thats marked at about 1/2 the vacuum at idle is a good starting place IE, if your pulling 17" of vacuum the 7.5-8.5 power valves about correct,if your pulling 11" of vacuum the 5.5- 6.5 power valves about correct

Holley's instructions, to use a PV that's half of your idle vacuum, are some what miss leading. They will ALWAYS lead you to choose too low a PV number, which in turn will force you to use too large jets, too much pump, etc. youll generally want to select a slightly higher number power valve if your getting a flat spot,. Keep raising the PV number until that flat spot clears up.

you take the vacuum reading at idle and cut it in 1/2 then jump up or down one -two numbers depending on how the plugs look, the engine runs and what your fuel/air ratio meter indicates example if your pulling 16" at idle that would be a power valve in the 6.5-9.5 range

youll also see advise saying that Basing the PV selection on idle vacuum is BAD advise that has floated around for a long time. If you take CRUISE vacuum, divide it in half and add about 2" you will be close.

read what holley says

http://www.holley.com/data/TechService/ ... 20Info.pdf

http://www.holley.com/data/TechService/ ... valves.pdf

http://www.onallcylinders.com/2013/03/07/how-to-tune-the-power-valves-on-a-holley-carburetor/

[/size][/color]

read thru these threads also

viewtopic.php?f=55&t=1790

viewtopic.php?f=55&t=1442

http://www.holley.com/types/Power Valves.asp

viewtopic.php?f=55&t=8126&p=28205#p28205

http://www.chevyhiperformance.com/tech/ ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.jegs.com/p/Holley/Holley-Pow ... 1/10002/-1

http://www.holley.com/data/TechService/ ... valves.pdf

http://video.google.com/videosearch?hl= ... &ct=title#

http://www.classictrucks.com/tech/0806c ... alves.html

http://www.jegs.com/p/Holley/743661/10002/-1

http://www.summitracing.com/parts/MOR-65222/?rtype=10

viewtopic.php?f=44&t=773&p=1123#p1123

http://www.wonderhowto.com/how-to/video ... ve-267173/

http://store.summitracing.com/partdetai ... toview=sku

Ive had a vacuum pump tool for years to test Holley power valves with this adapter, pictured below and I recommend using the tester as it quickly locates leaky power valves, which can make you 1/2 crazy wondering why the carbs f/a ratio won,t be consistent

http://www.summitracing.com/parts/MOR-62295/?rtype=10

http://www.harborfreight.com/mityvac-va ... 39522.html

http://www.mityvac.com/pages/products_hvpo.asp#

http://www.mityvac.com/pages/products_hvp.asp

http://www.harborfreight.com/cpi/ctaf/d ... mber=93547

http://www.harborfreight.com/cpi/ctaf/d ... mber=92474

https://www.homedepot.com/p/Powerbuilt-Vacuum-Pump-Kit-648744/203120693

with a few cheap components you can test a power valve

read this also

viewtopic.php?f=55&t=1790

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=1411

viewtopic.php?f=70&t=875

viewtopic.php?f=70&t=294

keep in mind there's many guys chasing carb problems that are eventually traced to the ignition, or fuel system, verify the damper and timing tab really do reflect TDC and your ignition advance is working correctly, and verify you have 5 psi of steady fuel pressure at the carb and the floats are set correctly and the cars valves are adjusted and there's no vacuum leaks before you go swearing its solely a carb problem

BTW someone is bound to ask eventually ,what is the difference between "standard flow".

SEE WHAT READING THE PART DESCRIPTION RESULTS IN???

http://www.summitracing.com/parts/hly-125-105/overview/

and "high flow"? in a power valve?

http://www.summitracing.com/parts/hl...1005/overview/

theres both a standard and a high flow rate version in each power valve, generally like with carburetor jets youll want to match the fuel flow rate of the power valve to the engines needs , I've generally found the standard flows work well on anything up to 350 cubic inch and the high flows work better on the big blocks,396 and up, and yes matching the carb jetting and reading the spark plugs and having a FUEL/AIR RATIO METER and a bit of testing is mandatory

Last edited by a moderator: