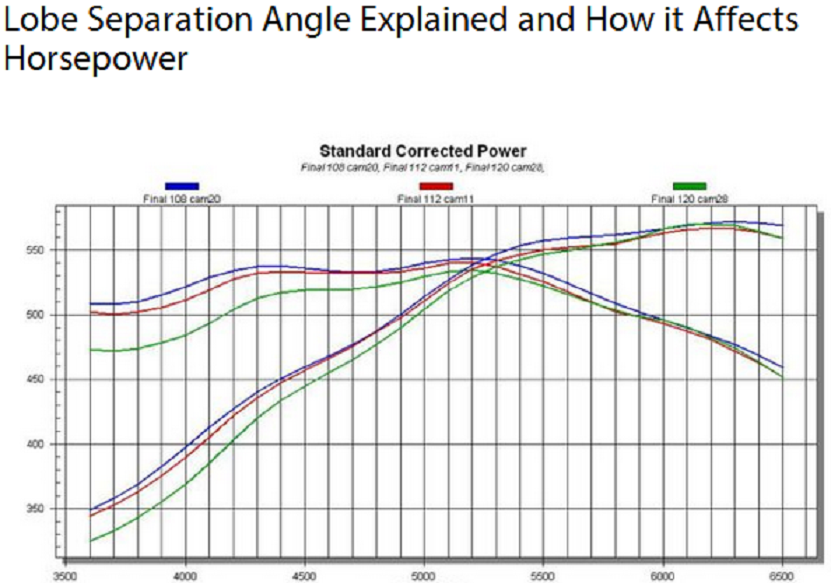

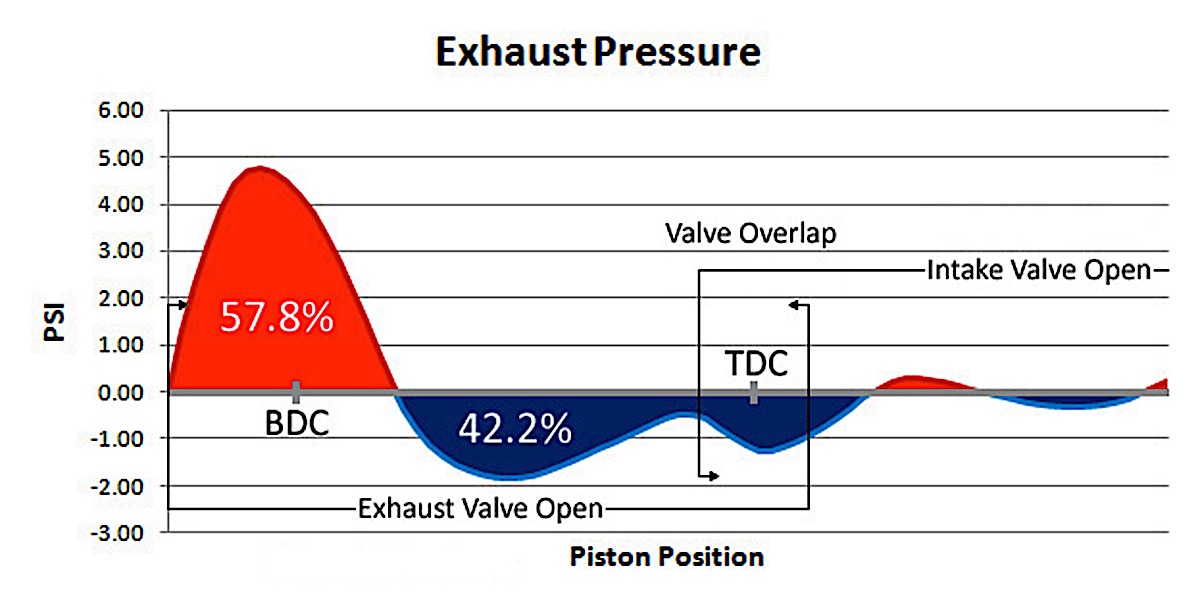

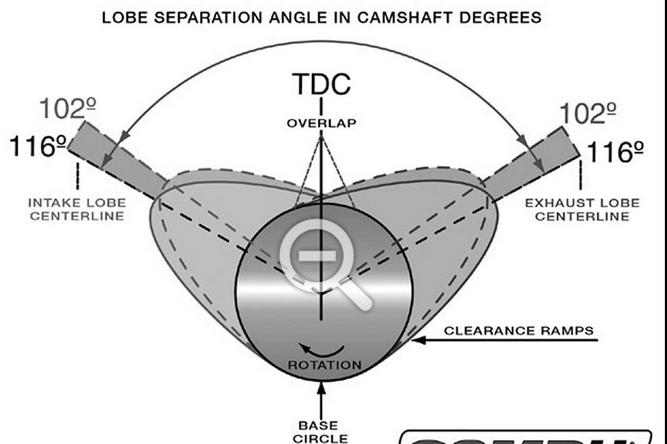

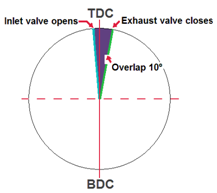

TIGHTER 104-110 LSA tend to increase scavenging efficincy but at the cost of less smooth idle

LSA lobe separation angle is locked into the cam when its ground and can not change, if its ground at 110,degrees or 114 degrees it will stay that figure

and

LCA lobe center angle, can be changed

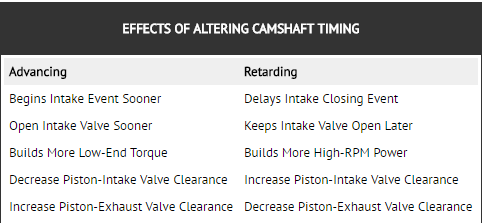

if you advance the cam 4 degrees both the intake and exhaust lobe opening and closing points open and close 4 degrees earlier.

if you RETARD the cam 4 degrees both the intake and exhaust lobe opening and closing points open and close 4 degrees later.

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.velocity-of-sound.com/velocity_of_sound/calculator1.htm

READING THESE RELATED LINK'S WILL HELP

http://garage.grumpysperformance.com/index.php?threads/cams-explained.324/

http://garage.grumpysperformance.com/index.php?threads/camshafts-8-lessons.5154/

http://victorylibrary.com/mopar/cam-tech-c.htm

http://garage.grumpysperformance.com/index.php?threads/oil-stained-intake-runners.14209/#post-72145

Camshaft Lobe Separation Angle: The Untold Truth of LSA!! How to Pick LSA the right way@DavidVizard

Today on Unity Motorsports Garage, We (David Vizard and myself) talk about LSA and how the major Cam companies get it wrong! We discuss the how and why of p...

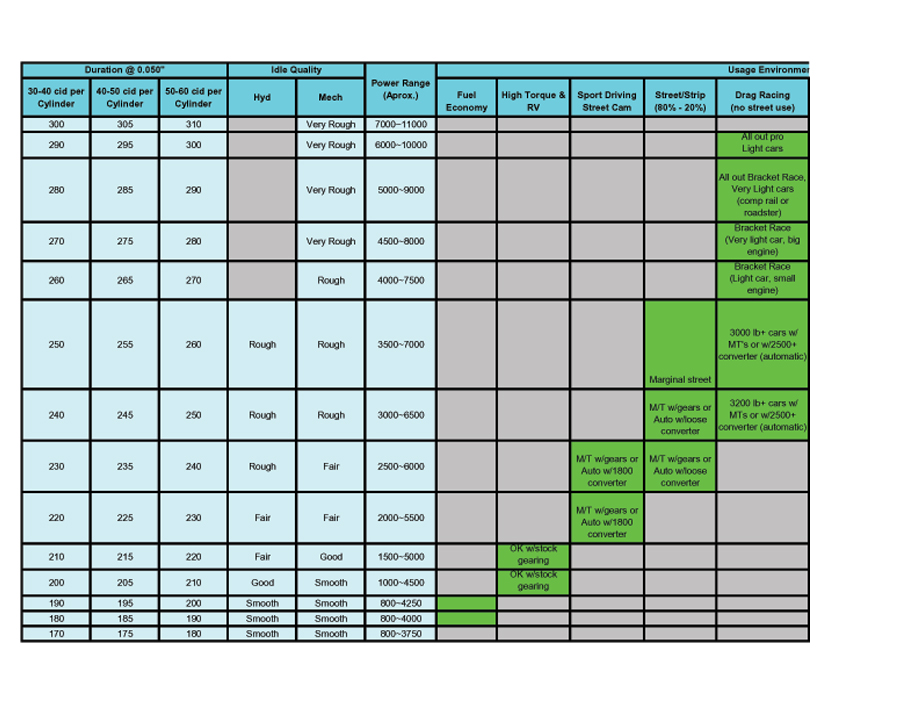

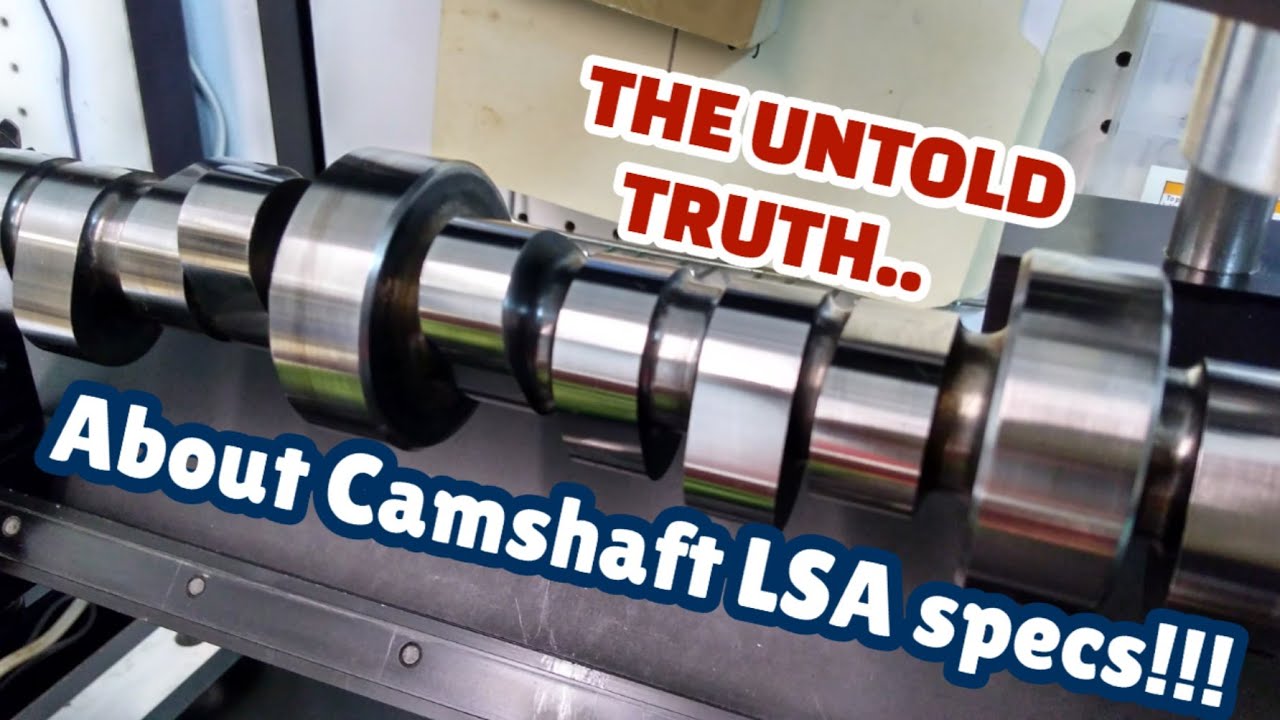

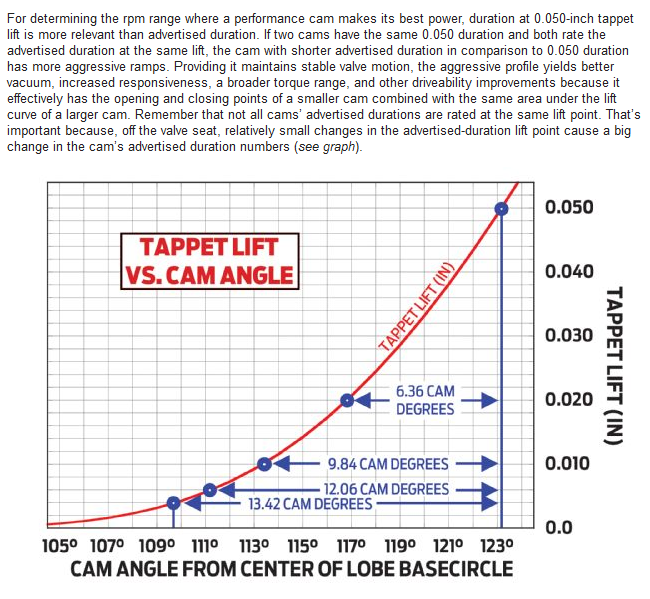

the chart above can be used as a rough guide to match cam duration at .050 lift and static compression in engines obviously other factors come into play so its only a rough guide

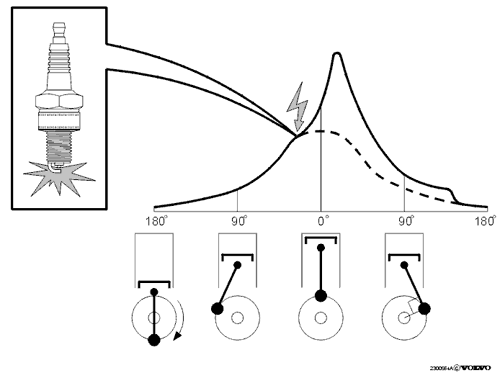

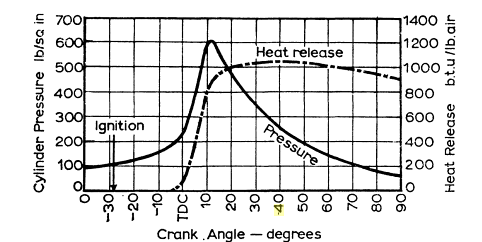

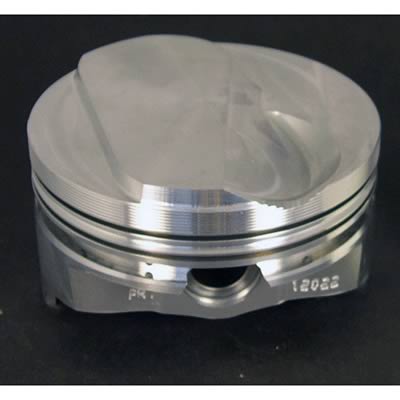

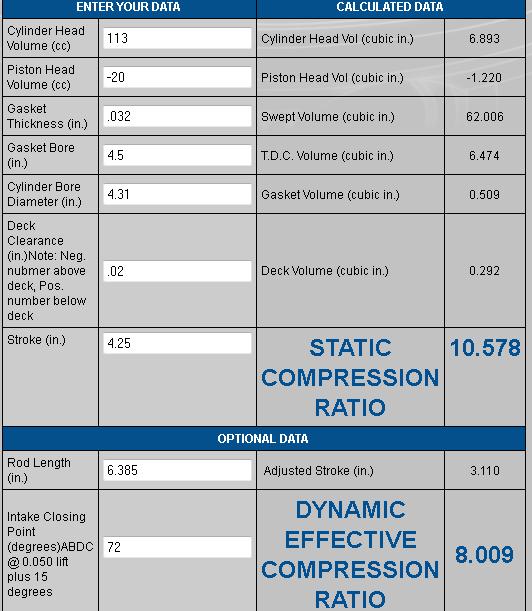

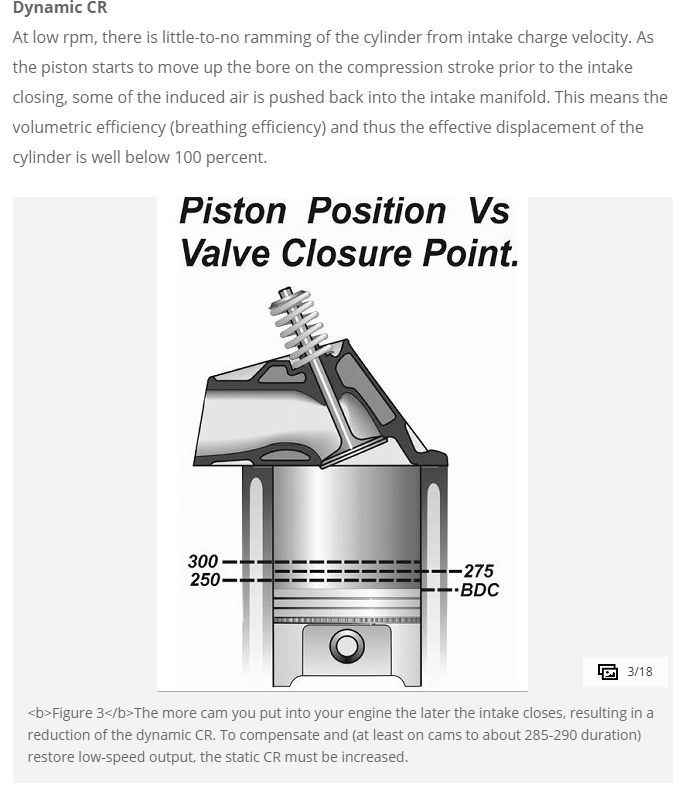

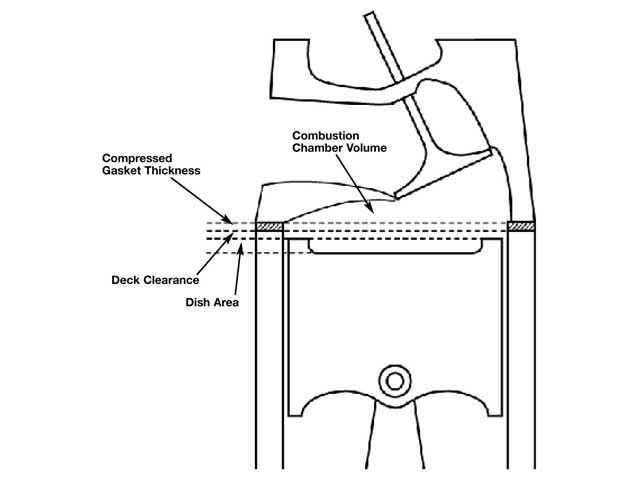

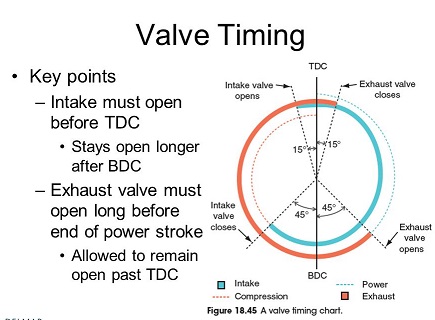

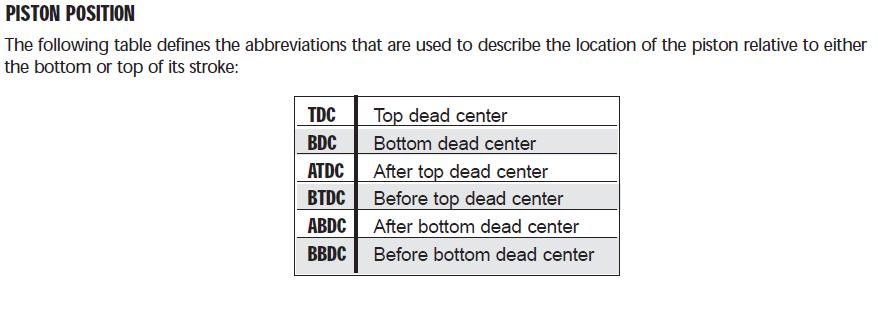

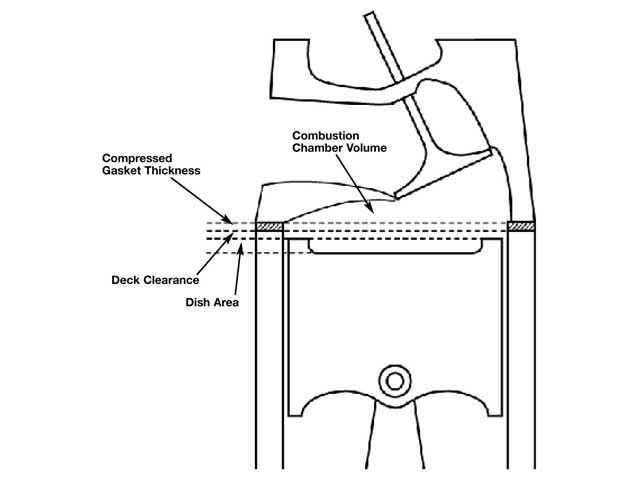

OK, first fact! the piston can,t compress anything until both valves fully seat, static compression is based on the volume compressed between the piston starting at bottom dead center and compressing everything into the combustion chamber , head gasket quench,volume, that remains when the pistons at TDC

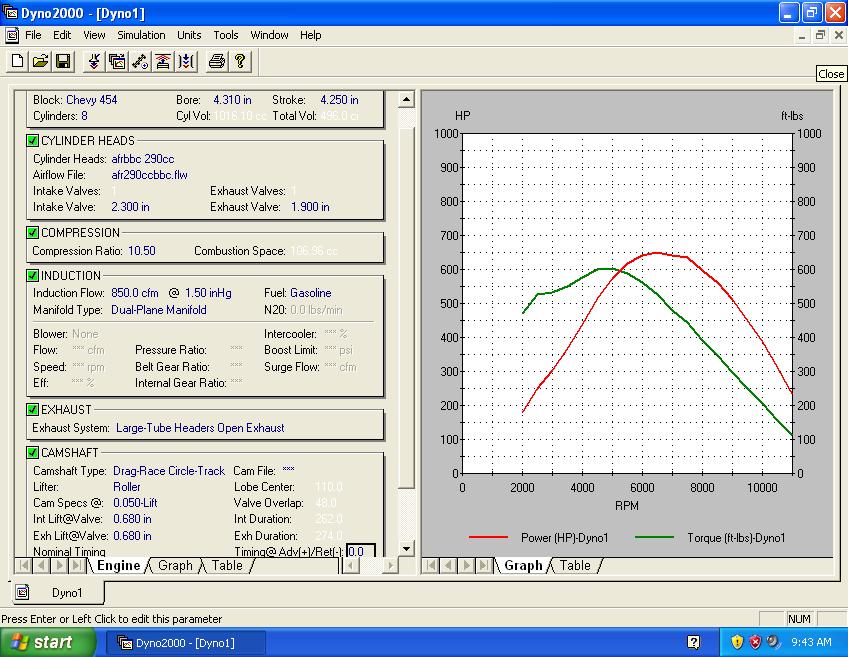

there are quite useful ,cam selection soft ware programs that get you in the ball park, but the final selection is based on far more factors than most of those software programs address

http://http://www.camquest.com/ http://www.camquest.com/

http://www.cpgnation.com/forum/threads/... ngle.2406/

http://www.wallaceracing.com/camcalc.php

http://www.wallaceracing.com/Calculators.htm

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

dynamic compression is the ONLY compression the engine ever sees or deals with, it measure compression from the time both valves seal the chamber,and that is always lower simply because the valves always seat after the piston is already moving upwards on the compression stroke.

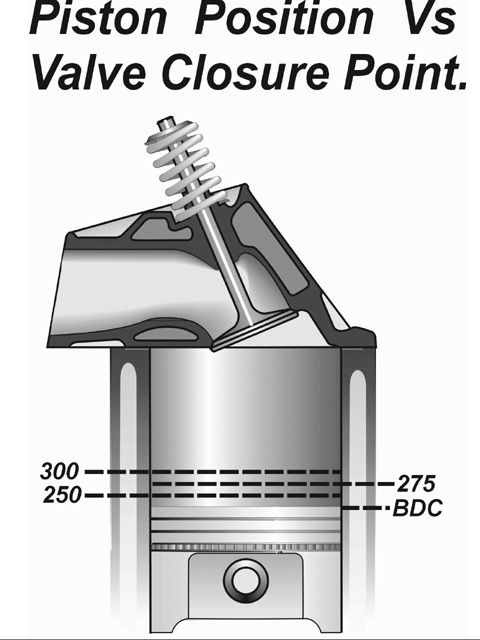

if we look at the crane cam I linked earlier you see the valves seat at about 75 degrees after bottom dead center

RELATED INFO YOU MIGHT NEED

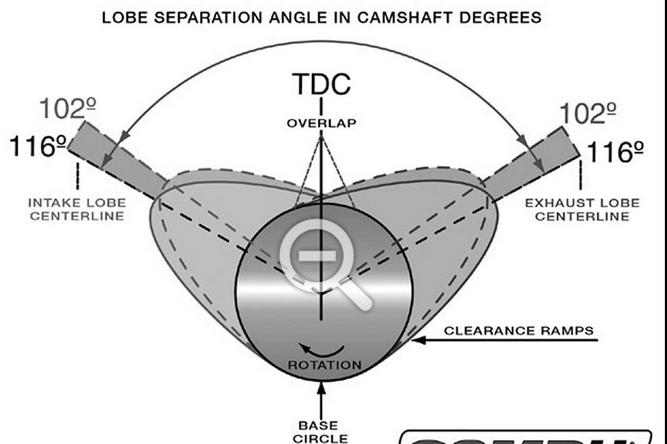

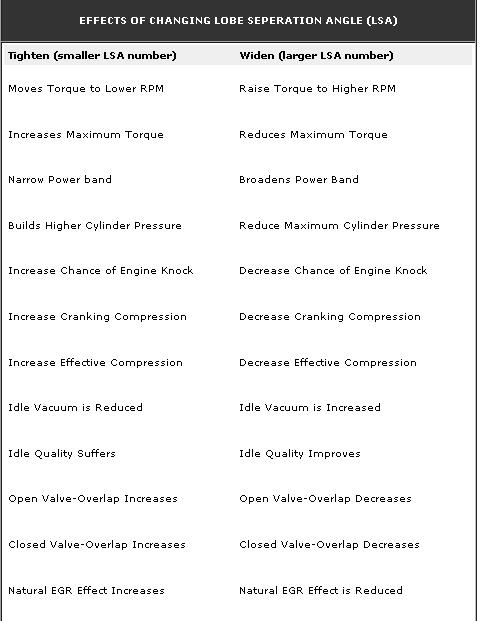

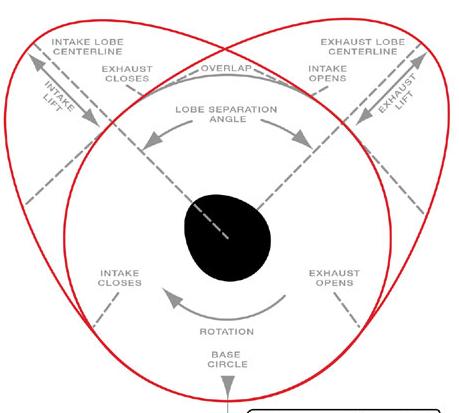

Lobe Separation Angle (LSA) is NOT the same as Lobe Centerlines (LC), although the two are directly connected.

keep in mind that the piston moves a great deal slower per degree of rotation

near the top and bottom of the stroke than it does near the mid stroke in the bore, so thers more time for flow and presure to build per degree of crank rotation,making those areas of rotation more critical to performance

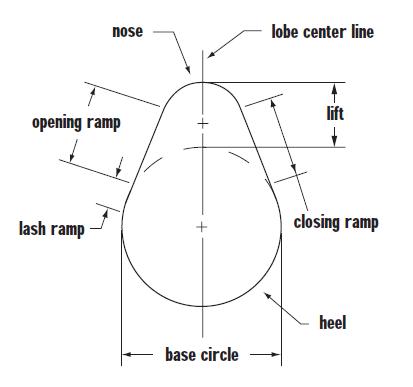

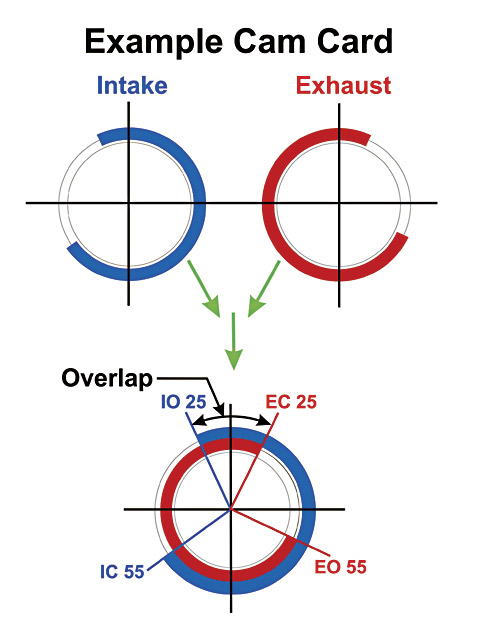

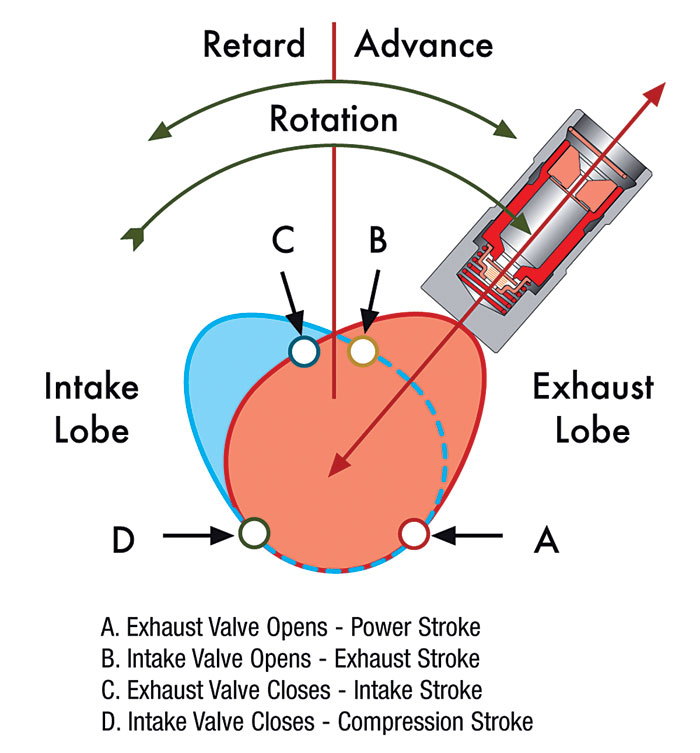

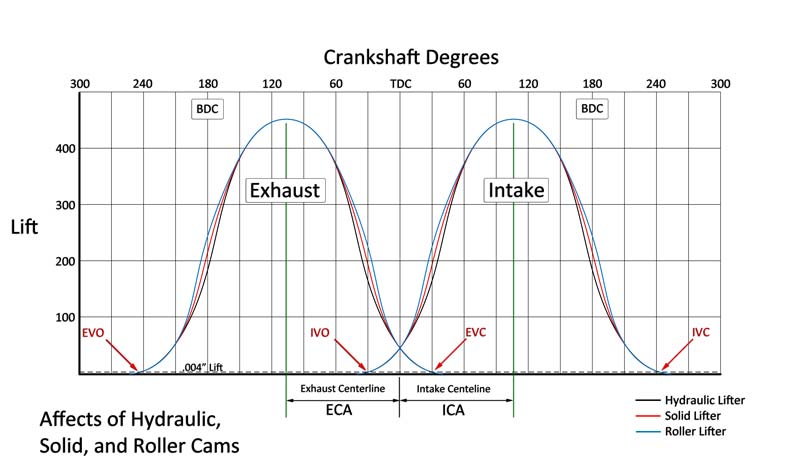

The Lobe center Angle is measured as the degrees that the crankshaft rotates BETWEEN the exhaust valves maximum lift point (aka: Exhaust Centerline) and the intake valves maximum lift point (aka: Intake Centerline). Check the lead illustration in this story from COMP Cams to show this effect. The highest lift points on the lobes are referred to as the cam œLobe Centerlines and are usually ground somewhere between 102 and 122 crankshaft degrees. Since Lobe Centerline is referenced in relation to crankshaft degrees as well, it can be moved around, depending on where you install the cam.

When you degree the cam, youre usually checking to see if it s installed at the cam manufacturer™s recommended Intake Centerline point. Lets say your cam manufacturer recommends installing the cam at a 112-degree Intake Centerline. Using the degree wheel you check the intakes highest lift point to be exactly at 112-degrees. That means youve now installed the cam Straight Up . If the degree wheel shows an intake max lift point of 110-degrees, the cam is now INSTALLED 2-degrees advanced from the manufacturer s settings. If the degree wheel showed an installed position of 114-degrees, the cam is now INSTALLED 2-degrees retarded.

Lobe Separation Angle, on the other hand, is ground into the cam and it cannot be changed (see red arc in illustration). To check your LSA you calculate it by adding the intake and exhaust Lobe Centerline figures together and dividing their sum by two (Ex: 112 intake Centerline + 116 exhaust Centerline = 228 / 2 = 114-degree LOBE SEPARATION ANGLE).

There s more. These are also the figures used to indicate how much the cam s intake lobe was ground advanced or retarded from the factory. To find intake lobe advance/retard, simply subtract the Intake Lobe Centerline from the Lobe Separation Angle (i.e.: LSA 114 IC 112 = 2-degree advance). This difference is how far advanced or retarded your cam was ground at the factory, 2-degrees in our example here. You cannot change Lobe Separation Angle because it is ground at the factory. But you can advance or retard the cam in relation to the crank when itâ s degreed-in."

"EXAMPLE, OF A

very common mis- conception, is that a cam which is ground on a 108 degree lobe center. which has more overlap and will reduce your DCR due to greater overlap."

PROBABLY one of the MOST COMMON MYTHS

( is that overlap with a tight LSA bleeds off compression)

Overlap has nothing to due with DCR. A cam with 108 LSA will close the intake valve sooner on the compression stroke and create MORE cylinder pressure than a cam with 112 LSA. That assumes durations and cam lobe designs are the same of course "

this is correct

example

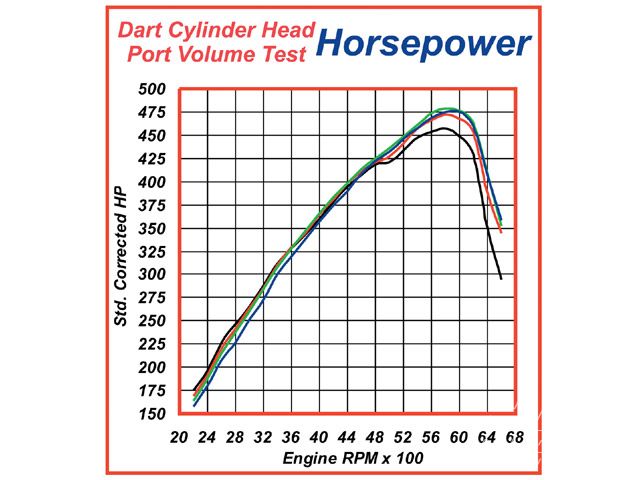

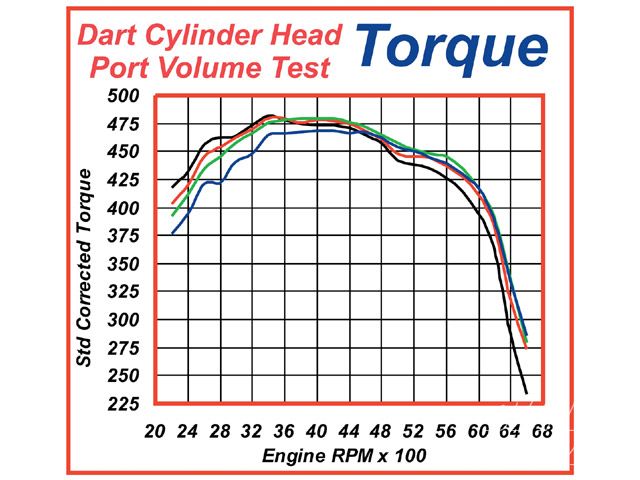

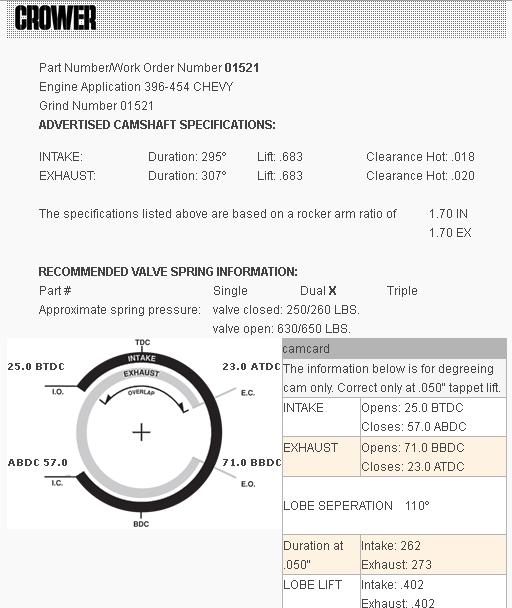

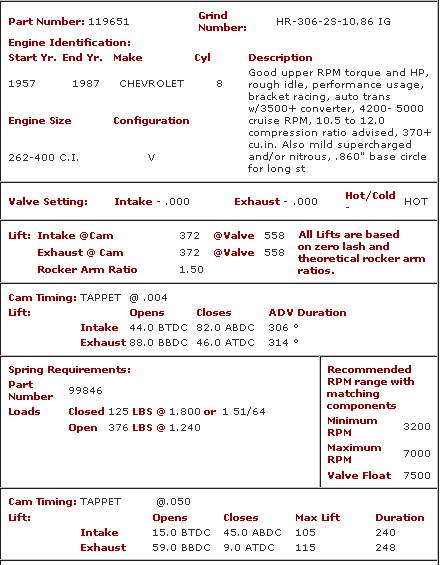

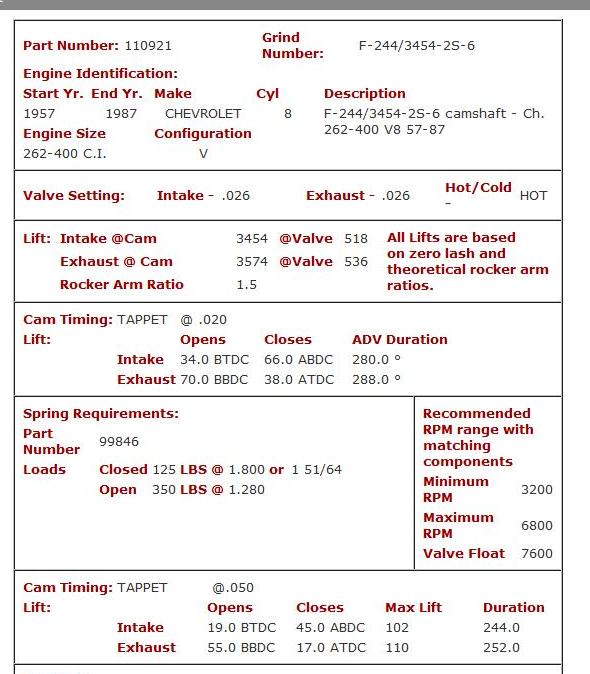

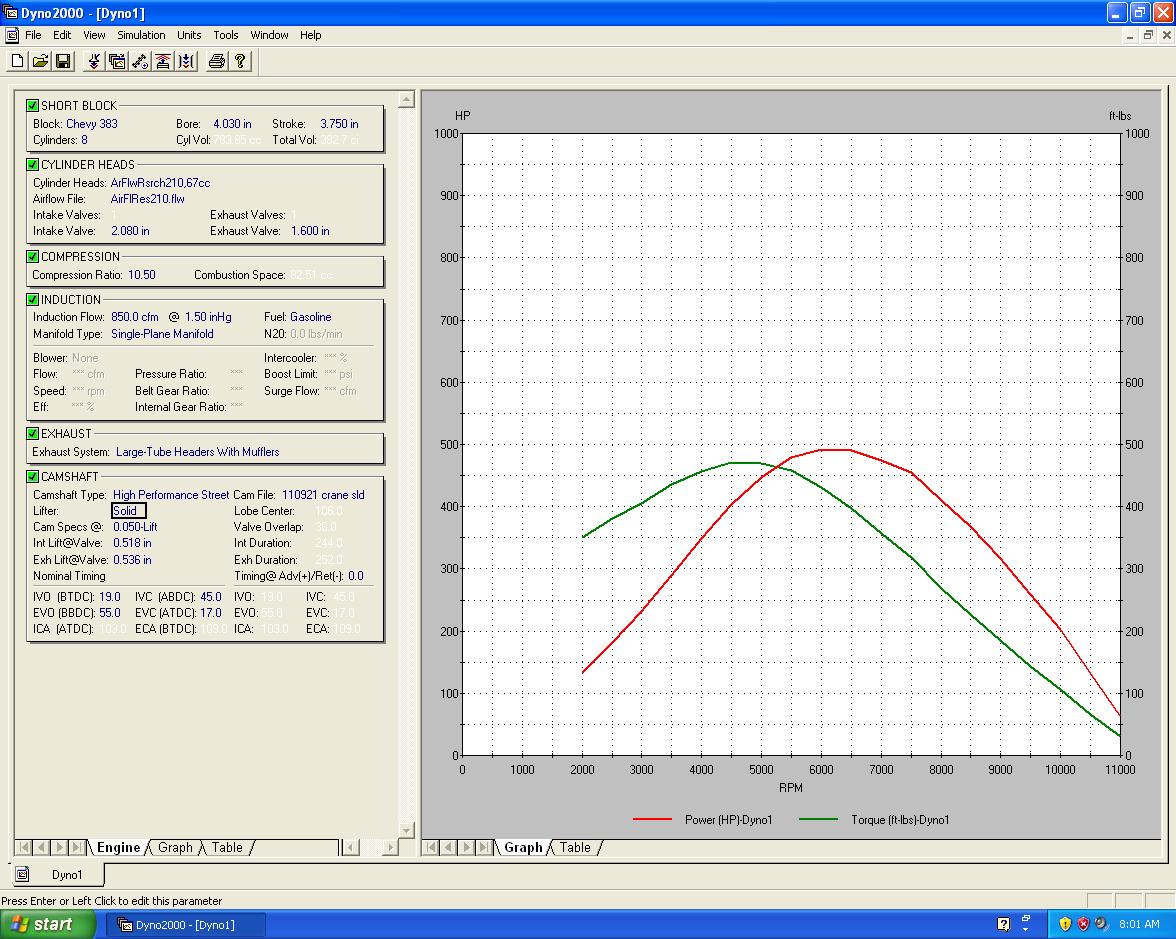

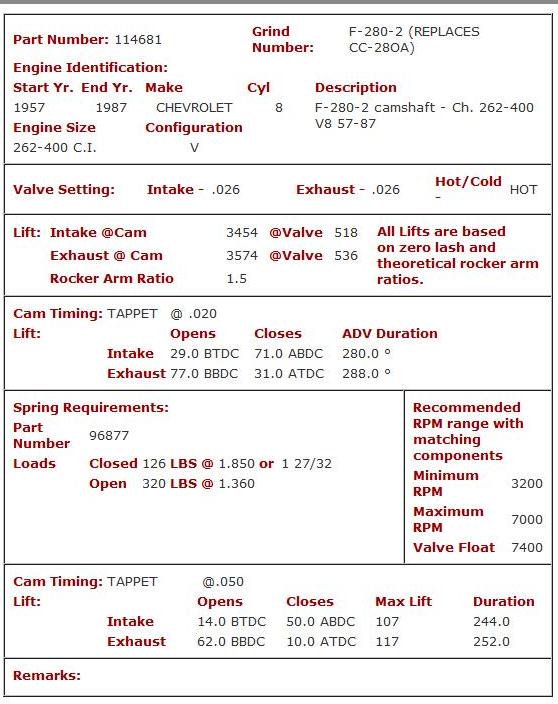

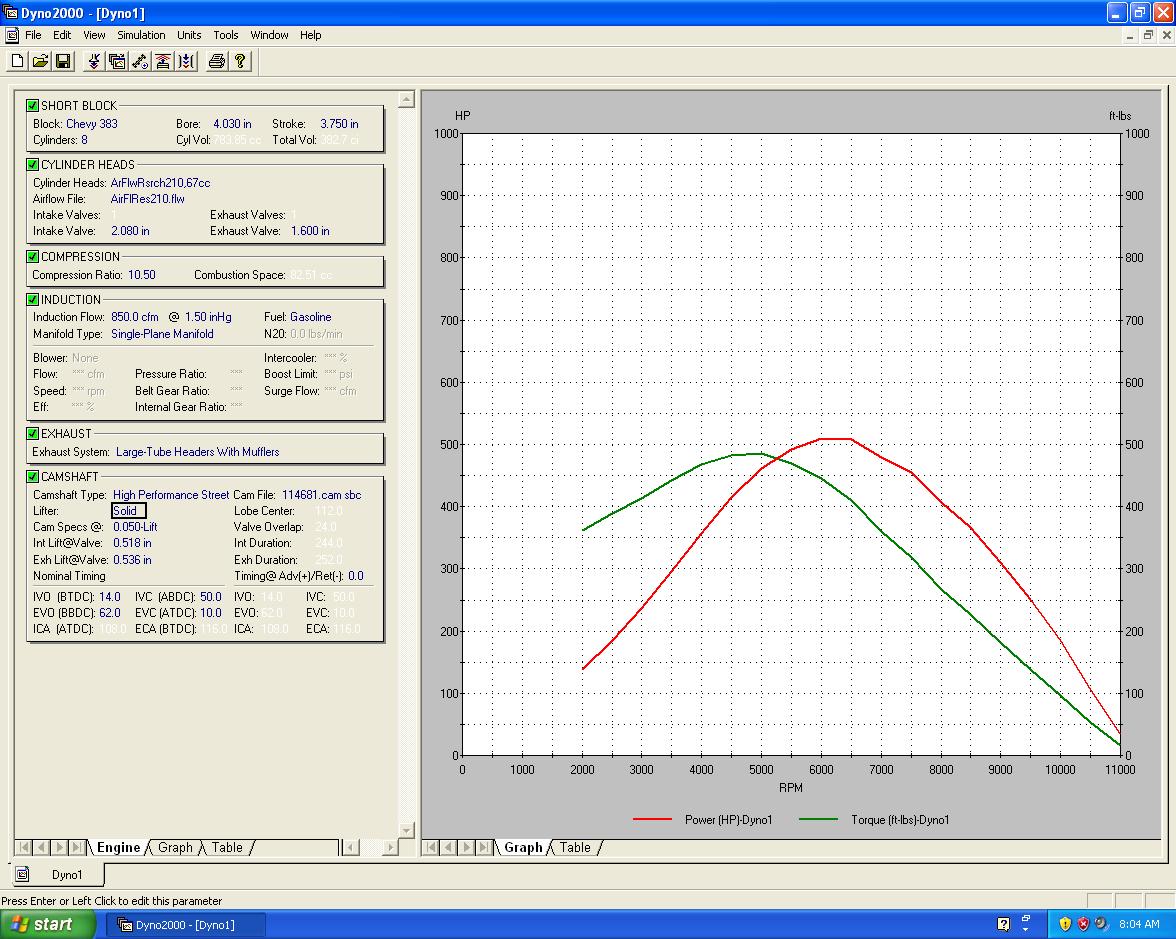

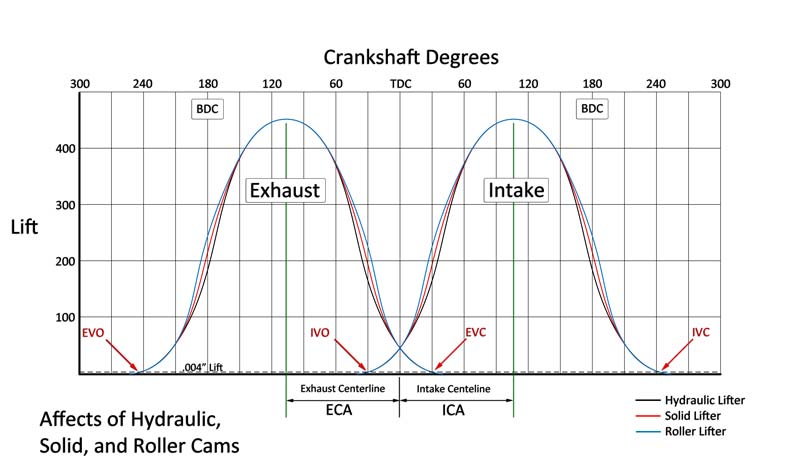

LOOK heres TWO cams WITH IDENTICAL DURATION EXCEPT FOR THE LSA,(LOBE SEPARATION ANGLES) assuming both cams are installed with identical LCA (LOBE CENTER LINE ANGLE)remember lobe center angles can be changed thru indexing the cam when degreeing it in, LSA is ground into the cam during manufacture, the tighter LSA of the crane 110921 builds a bit more cylinder pressure, AS THE VALVES CLOSE ABOUT 5 degrees earlier (ABDC AFTER BOTTOM DEAD CENTER)

110921 intake valve closed at 45 degrees after bottom dead center

114681 intake valve closed at 50 degrees after bottom dead center

and results in slightly more torque over a NARROWER rpm band so its better with a manual transmission, the crane 114681 with its wider LSA tends to work better with an auto trans with its wider torque band but very slightly lower peak torque, the crane 110921 has more overlap and better savaging in the mid rpm band, but it idles rougher at low rpms and that overlap doesn,t help if you use nitrous

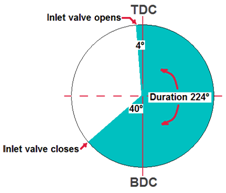

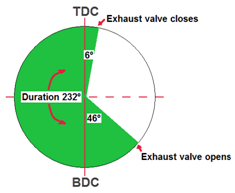

COMPARE the TIMING

narrower LSA, more overlap & more effective compression, because the intake valve closes earlier

wider LSA, less overlap & less effective compression, because the intake valve closes later

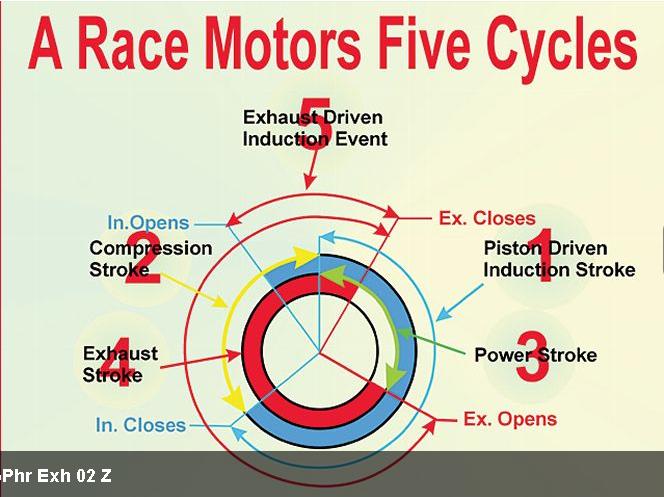

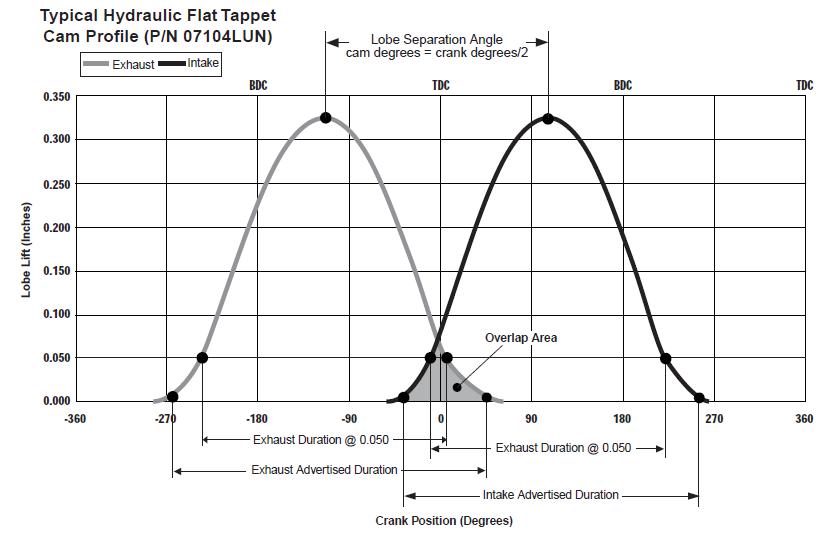

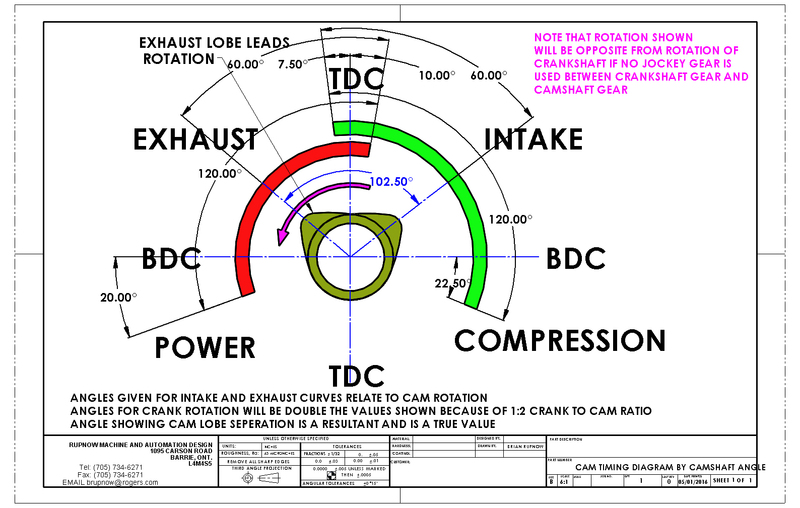

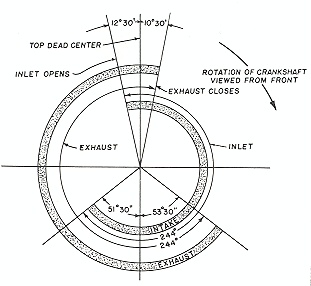

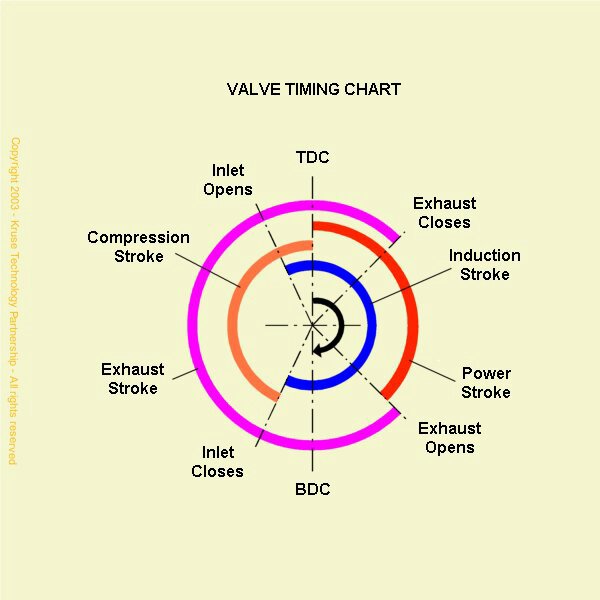

when your reading a cam spec card, you'll want too keep in mind theres 720 degrees in a cycle and the cam turns at 1/2 the speed of the crank so the piston reaches TDC twice in one complete rotation of the cam, plus cam cards generally start with the exhaust valve opening not the intake valve as most of us might assume

http://www.projectpontiac.com/ppsite15/ ... calculator

while all cam timing figures will varry this might help

READ THREAD

USING THE .050 LIFT figures, notice that the tighter LSA (LOBE SEPARATION ANGLE)cam CRANES 110921 has the intake close at 45 degrees ABDC while the wider lsa CRANES 114681closes the valves at 50.0 ABDC (the wider LSA results in the valve closing 5 degrees later on the pistons compression stroke, effectively reducing the effective compression ratio

The quickest, and most accurate, way of finding ICL :

1.--Install dial indicator on top of retainer.

2.--Turn to max valve lift.

3.--Zero dial indicator.

4.--Turn engine backwards to -.100 drop on indicator.

5.--Turn engine forwards until indicator reads -.050.

6.--Record this in degrees ATDC.

7.--Continue turning engine over max valve lift until indicator reads -.050 down on closing side of intake.

8.--Record this too as degrees ATDC. It should be close to, but before, BDC.

9.--Add the 2 readings ATDC, then divide by 2. This is the ICL.

10.-Advance the cam with a button to where you want it to be.

11.-Repeat all steps to verify the cam is where you want it to be.

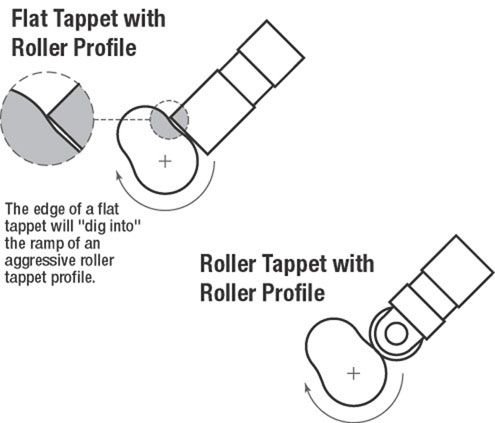

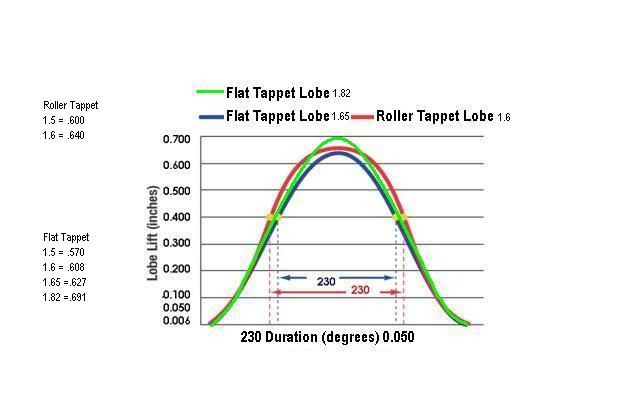

tight 108 LSA

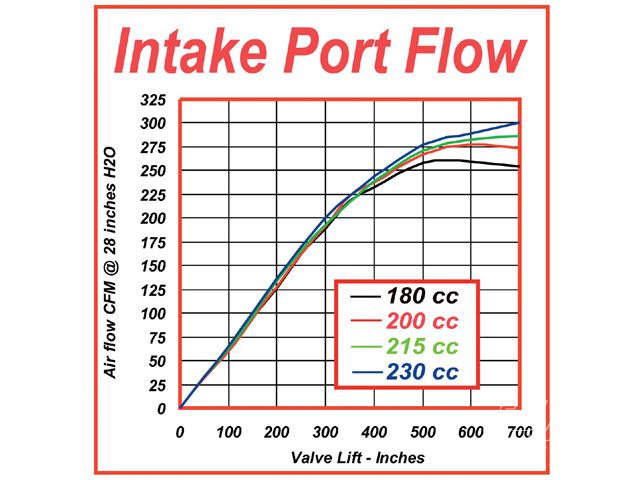

notice its right where the roller cams lobe design maximized the extra air flow potential that is the most effective flow area during the whole valve flow curve

and yes it frequently helps to match a roller cam to roller rockers as the reduced friction further helps the engines durability and ability to easily cope with faster valve train component acceleration, that tends to reduce heat and wear.

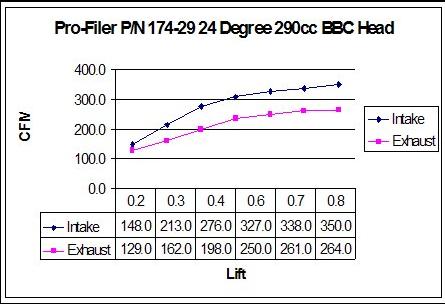

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches, thus it makes a great deal of sense to push the valve lift a bit over .500, and have an intake port that is at least 3.2 square inches in cross sectional area, if you want to maximize flow on a 2.02" intake valve

http://garage.grumpysperformance.co...-the-extra-cost-vs-a-flat-tappet-design.3802/

wide 114 LSA

http//users.erols.com/srweiss/tablehdc.htm [URL][URL][URL][URL][URL]http://users.erols.com/srweiss/tablehdc.htm[/URL][/URL][/URL][/URL][/URL]

http://www.enginebuildermag.com/Article ... teria.aspx

http://www.lunatipower.com/Tech/Pistons ... eight.aspx

http://www.hotrod.com/techarticles/engi ... z2FeQk91VU

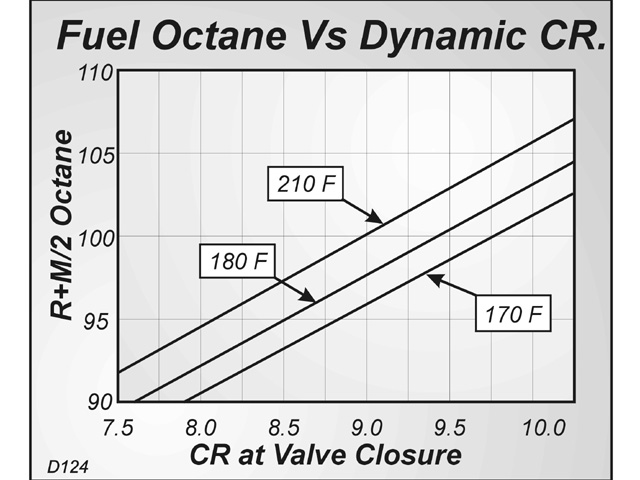

aluminum cylinder heads tend to allow you to run about 1/4-to-1/2 point more effective compression, IE, if iron heads get into detonation at 10:1 ALUMINUM might ALLOW YOU TO RUN 10.3-10.4:1 BEFORE GETTING INTO DETONATION, BUT ON THE PLUS SIDE AT LEAST IN THEORY IRON HEADS AT ANY GIVEN CPR WILL HAVE A SLIGHT ADVANTAGE IN HP

but in my real world testing the difference is much closer almost non-existent

the main advantage I see in aluminum heads is lighter weight and their much easier to repair when damaged

an aluminum cylinder head allows heat transfer to the engine coolant at a significantly higher rate than an iron head, and generally about .25-.50 higher compression can be tolerated but theres No absolute real definite answer, depends on quench, cam LSA, cylinder head design, advance curve, fuel/air mixture, intake temperature, coolant temp, spark plug design, piston design, heat barrier coatings, combustion chamber surface texture, and a bunch of other parameters.

[URL][URL][URL]http://www.iskycams.com/ART/techinfo/ncrank1.pdf[/URL][/URL][/URL]

here's a cam timing chart to use with it

http://www.crower.com/valve-timing-chart

http://www.amotion.com/tech/camselect.html

http://www.auto-ware.com/calcs/sep_adv.htm

http://www.projectpontiac.com/ppsite15/ ... calculator ]

READ THRU THESE CAREFULLY

http://www.compcams.com/Community/Artic ... 2026144213

http://www.enginebuildermag.com/2016/02/theres-no-simple-formula-to-choosing-the-perfect-camshaft/

http://www.popularhotrodding.com/tech/0 ... index.html

http://www.hotrod.com/techarticles/113_ ... index.html

http://www.circletrack.com/techarticles ... ation.html

http://www.popularhotrodding.com/tech/0 ... index.html

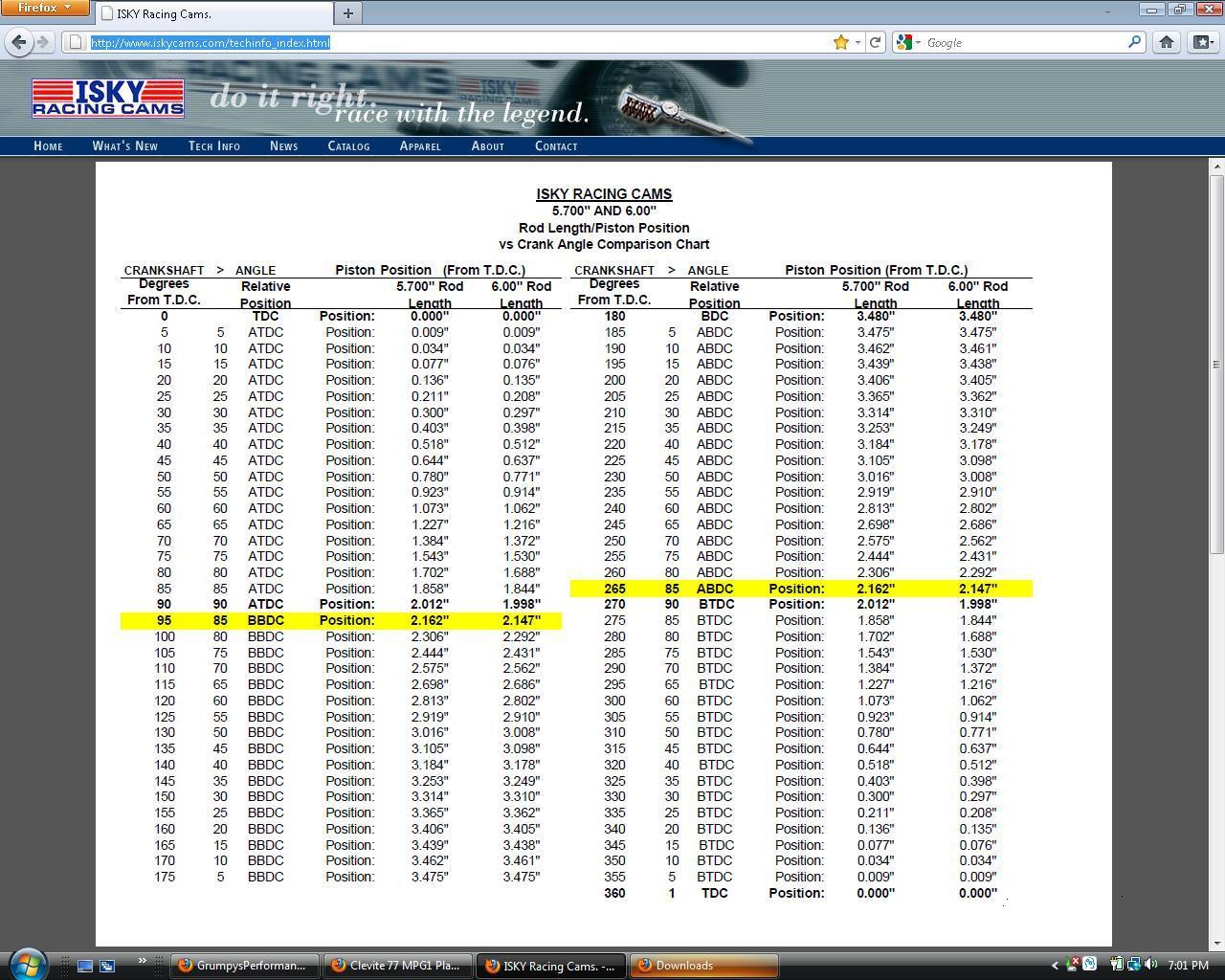

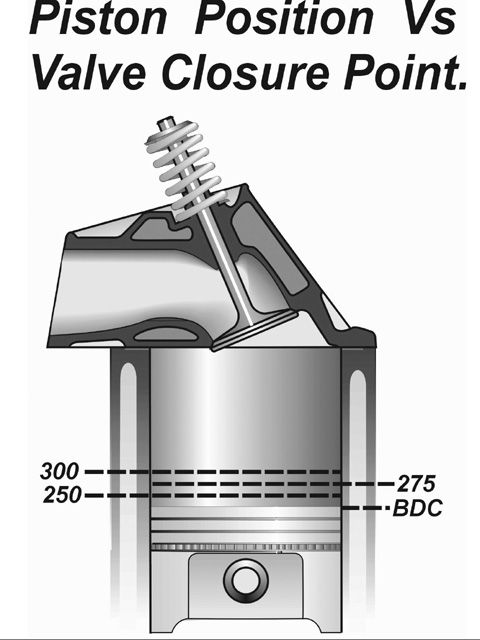

showing degrees of rotation and piston position, as you can see the valve on the wider LSA closes 5 degrees later on the wider LSA and the piston can,t compress ANYTHING until both valves are closed, the tighter LSA allows the piston to compress almost a tenth of an inch more cylinder volume, you'll find the tighter lca usually makes more low and mid rpm power , and in many cases more peak power but has a slightly rougher idle and the power peaks faster in the rpm curve were not talking a huge change, maybe 7-8 hp/ft lbs but the tighter lca tends to lope more, idles rougher and be more responsive, keep in mind that if you had selected a cam with 5-7 degrees more duration on the wider lca the overlap would be similar, but the effective compression would be even worse

as a general guide you want to get the valve open to well above the 1/4 of the valve diam. to maximize the potential flow as quickly after TDC as physically possible and hold it open as long as possible if you want to maximize the cylinder volumetric efficiency, but obviously factors like exhaust scavenging and compression and the cars gearing and the need to run well over a wide rpm range preclude, maximizing efficiency in a single narrow power band in most applications

valve seat and back face angles ,valve diameter and valve lift and duration effect the flow thru the curtain area

from an old Hot Rod Tech article with this comment from Joe Sherman:

“Fully assembled, the engine's static compression ratio came in at 11.02:1. Yikes! Compression is good for making power if the engine doesn't get into detonation, but at first glance, this high a ratio seems excessive for an iron-headed engine on 91-octane. However, with the big-overlap cam, cranking compression was only 182-185 psi, well within Sherman's comfort zone. In his experience, anything less than 200 psi is permissible for running a small-block Chevy successfully on pump gas. And in fact, running 91-octane, the engine would make its best numbers with 36 degrees of total advance with no evidence of detonation using NGK UR6 plugs gapped at 0.039 inch.”

keep in mind that valve may be forced off its seat, too full lift and re-seating 50 plus TIMES A SECOND at near 5500 rpm, so theres very little TIME for gases to move through the very restrictive space between the valve seat and valve edge

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

on the street youll almost always find that the lower duration cam in the choice between two similar cams will in the long term be a slightly more useful choice.

(the simple reason why is that most street cars spend the vast majority of the time operating well below 4500-5000 rpm, and lower and mid rpm torque not peak hp is used far more often) it hardly makes sense to build any engine to produce its peak power in the rpm range you,ll rarely use. and the extra duration will generally reduce the low and mid rpm torque you use the vast majority of the time, in exchange for a bit more peak power you'll rarely access.

heres a chart I found that I don,t fully agree with, I think its a bit conservative, by about 3%-5% on the required cam duration ,required to avoid detonation with todays crappy octane fuel, but it at least gives you a base to work from, but Id suggest selecting a bit more duration

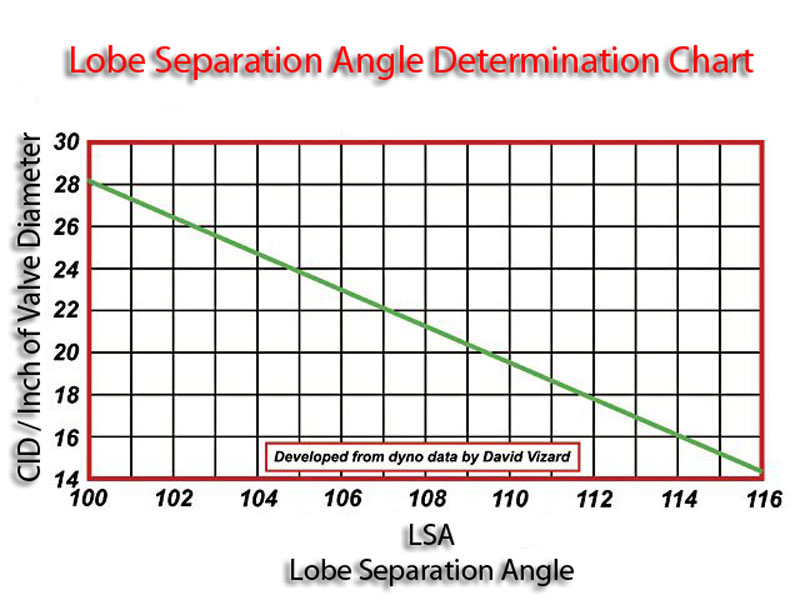

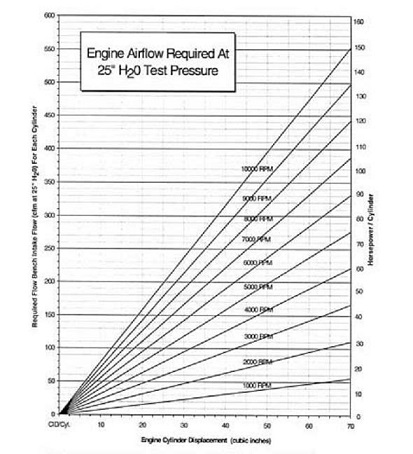

combining the info posted a 383 sbc has 47.8 cubic inches per cylinder divided by 2.02=23.7 on the chart above, so youll find cams in the correct duration range having a tight 105-108 lSA most efficient at filling the cylinders in many combos,

lets say we build a 496 big block with 2.19" intake valves,

496 divided by 8=62 cubic inches per cylinder, divided by 2.19=28.3. now look at the chart! you find youll need a rather tight 101-103 LSA

http://www.hotrod.com/techarticles/113_ ... ology.html

"LOBE SEPARATION ANGLE: This is the relationship between the centerlines of the intake and exhaust lobes. A 110-degree lobe separation angle means that the peak opening points of the intake and exhaust lobes are 110 degrees apart. This is ground into the cam and can't be changed without changing cams. Lobe separation angle is another way of expressing overlap, which is the term formerly used by cam manufacturers. Overlap is the amount of time that both valves are open in the same cylinder. When both valves are open at the same time, cylinder pressure drops. A cam with 106 degrees of lobe separation angle will have more overlap and a rougher idle than one with 112 degrees, but it'll usually make more midrange power."

ok first some facts

the valves reach max lift at a time when the pistons not even near TDC

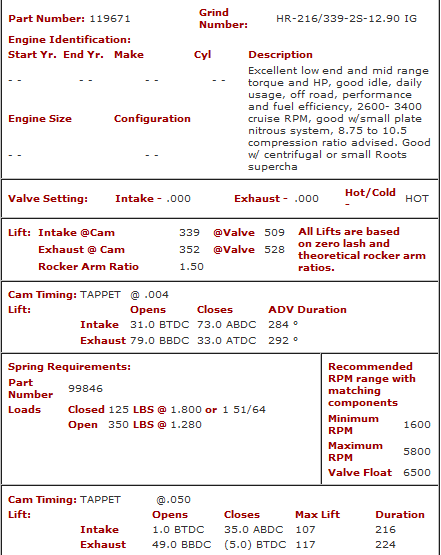

heres a typical cam timing on a good hydraulic roller cam for a SBC that IVE used frequently

heres a cam timing chart

http://www.crower.com/valve-timing-chart

heres a crank rotation and piston angle chart

http://www.iskycams.com/ART/techinfo/ncrank1.pdf

simple math shows the intake valve reaches max lift near 118 degrees atdc

when the pistons about 3" down the bore

the exhaust reached max lift while the exhaust valve and piston were also reasonably far apart or almost 2.5" down the bore , valves tend to come closest to pistons at about 10- 20 degrees before or after TDC while not nearly at full lift and the duration and LSA of the cam had far more effect than max lift

read this

read thru these sub links

http://www.hioutput.com/tech/343hp/343hp.html

(if your stuck using restrictive heads, follow this build and use much of what can be used as its designed to maximize restrictive heads)

http://www.webcamshafts.com/pages/cam_glossary.html

http://www.thirdgen.org/sbc-camshafts-primer

http://www.popularhotrodding.com/tech/1 ... index.html

http://www.popularhotrodding.com/tech/0 ... index.html

http://www.compcams.com/Community/Artic ... 2026144213

ERSON, http://www.pbm-erson.com/Catalog/Erson/Camshafts

ISKY, http://iskycams.com/cart/index.php

HERBERT, http://www.herbertcams.com/herbert-cams-cam-kits/

CROWER http://www.crower.com/camshafts.html?cat=854

ENGLE, http://www.englecams.com/

LUNATI ,http://www.lunatipower.com/Performance-Cams.aspx

HOWARD CAMS ,http://www.howard

CLAY SMITH CAMS, http://www.claysmithcams.com/camshafts/scams.com/

crane (386)310-4875

crower 619.661.6477

erson 800-641-7920

lunati..662-892-1500

ISKY 323.770.0930

clay smith 714-523-0530

http://www.compcams.com/Technical/TimingTutorial

http://www.circletrack.com/techarticles ... ation.html

Separating the Cam Issues

By Mike Petralia

http://www.cartechbooks.com/vstore/show ... 4&CATID=21

Camshaft Lobe Separation Angle Matters

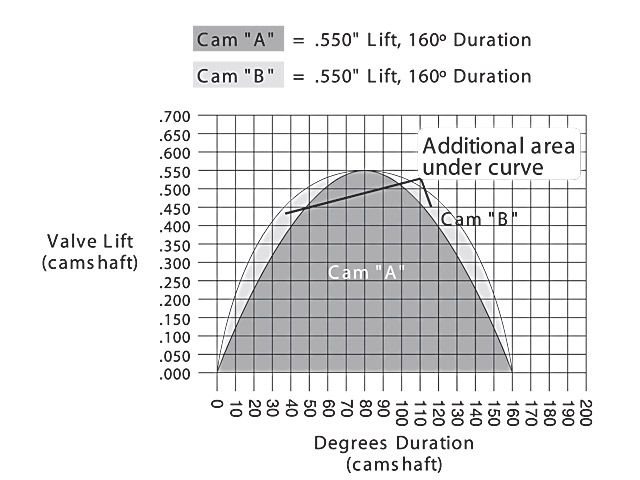

When finding the perfect cam for a street engine, Lobe Separation can help do the trick. Could you take two cams that are ground with EXACTLY the same lift and duration and still get one to make more power than the other? Of course, and if you picked the wrong lobe separation angle you might lose power. I think the cam companies do this just to keep us guessing. It’s an area where camshaft design gets very confusing.

LSA and LC

ZZ71s said:Alright you guys got me good and confused the stock zz4 uses 10 to 1 cr and has very poor quench it use a .0501 head gasket and the pistons are down in the block .025.

so why is there no detonation danger here

its not that theres no detonation danger, its that its fairly LOW, because of the cam timing, wide 112 lsa and aluminum heads, combustion chamber design, etc that your running, theres no absolute compression level that will induce detonation, where if your at %5 lower your totally immune

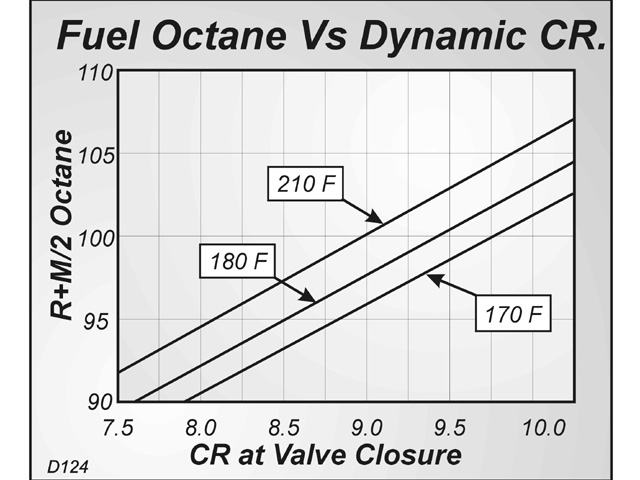

fuel octane, air coolant and oil temps, spark advance and plug heat range all effect the results, when you see a chart like these below, they provide a good guide to keep you out of potential trouble, but each combos unique and has a different potential to cause detonation, simply slowing the ignition advance , and changing to a different plug heat range, is sometimes all thats required to run lets say a 8.8:1 dynamic compression in one combo, but a similar one may only tollerat a 8.4 dynamic compression with the same mods

just be sure you verify all clearances

(piston to valve,

rocker to rocker stud,

rocker to retainers, etc. )

I think you made a good choice from what I see posted so far

Id install it strait up, IE no advance split overlap_

degree it in correctly and get it to last,cam install info,

IM frequently asked (why bother degreeing in a cam, the timing set comes with index marks to install it?) it basically comes down to, a question of do you accept a random install where the timing can be almost any place randomly or do you insist on maximizing the engines potential and know...

garage.grumpysperformance.com

checking piston to valve clearances

this is an old post I got asked to repost, naturally the first step is to install and correctly degree in your cam, http://garage.grumpysperformance.com/index.php?threads/measuring-piston-dome-volume.17255/...

garage.grumpysperformance.com

valve train clearances and problems

you might want to read thru these links and sub links it will help you avoid costly mistakes http://www.summitracing.com/parts/pro-66830/overview/ https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html...

garage.grumpysperformance.com

sellecting valve springs, and setting up the valve train

How do you determine the spring pressure needed to keep the valves under control for a given lift, duration, and max rpm. It might take you several hours to read thru all the links and sub links but its time very well spent as it could save your engine from destruction and save you thousands of...

garage.grumpysperformance.com

rocker/push rod wear issues

Put vortec heads on my L98 and ordered 1417 1.52 Roller Rockers and 7808 Pushrods from CompCams. Installed screw in rocker studs with guide tool before assembly of the engine. Checked valve geometry and the roller left a mark right on the center of the valve like its supposed to. Oil pressure...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/how-to-read-a-cam-spec-card.1477/

yeah lots of info/reading but it potentially prevents several issues

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-12997

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12050

http://garage.grumpysperformance.com/index.php?threads/degreeing-in-a-cam-correctly.3097/#post-8240

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4440

http://garage.grumpysperformance.co...rect-custom-length-pushrods.14241/#post-72355

Attachments

Last edited by a moderator: