theres seems to be a lot of mis-information about , how the oil pump regulates its pressure curve, and the related subject of shimming oil pump springs and how your oil pumps pressure bye-pass circuit works.

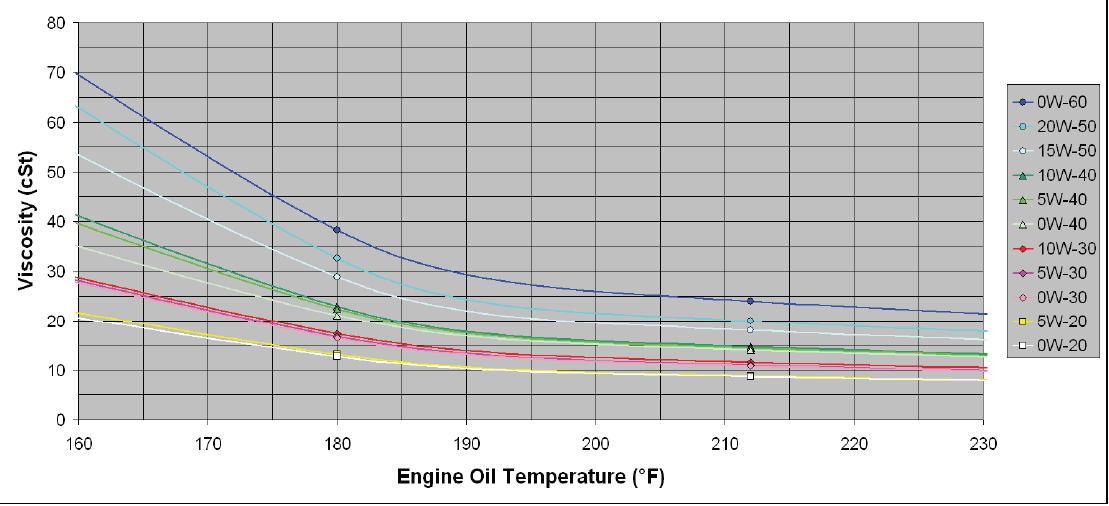

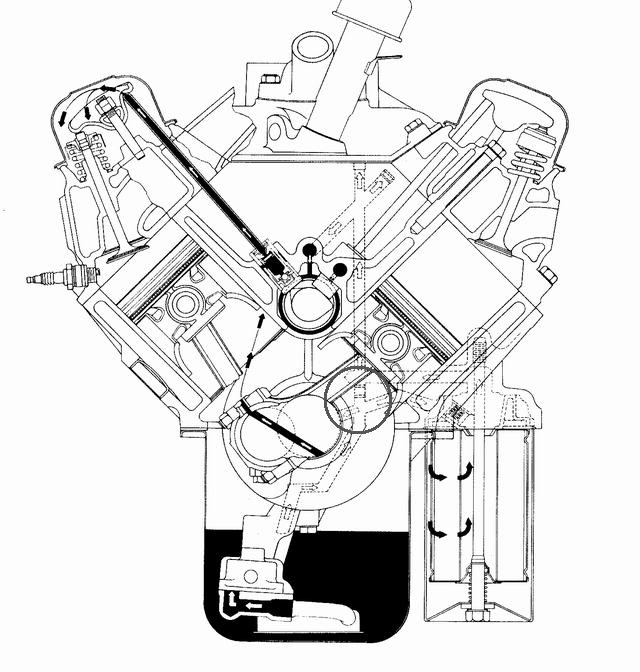

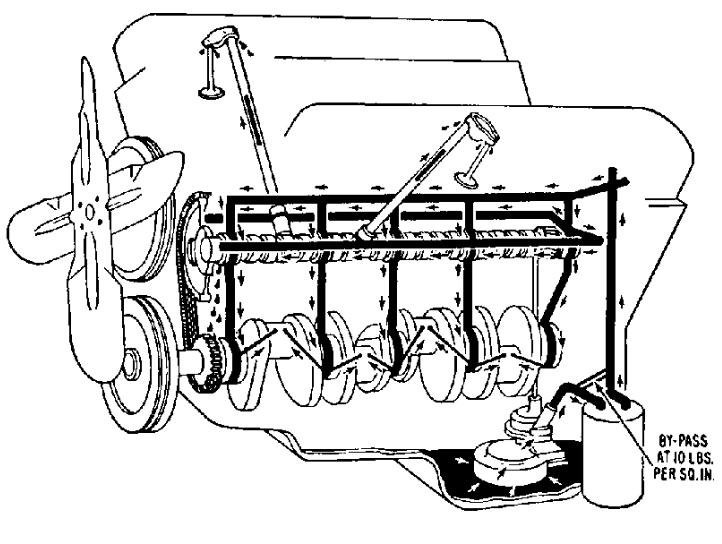

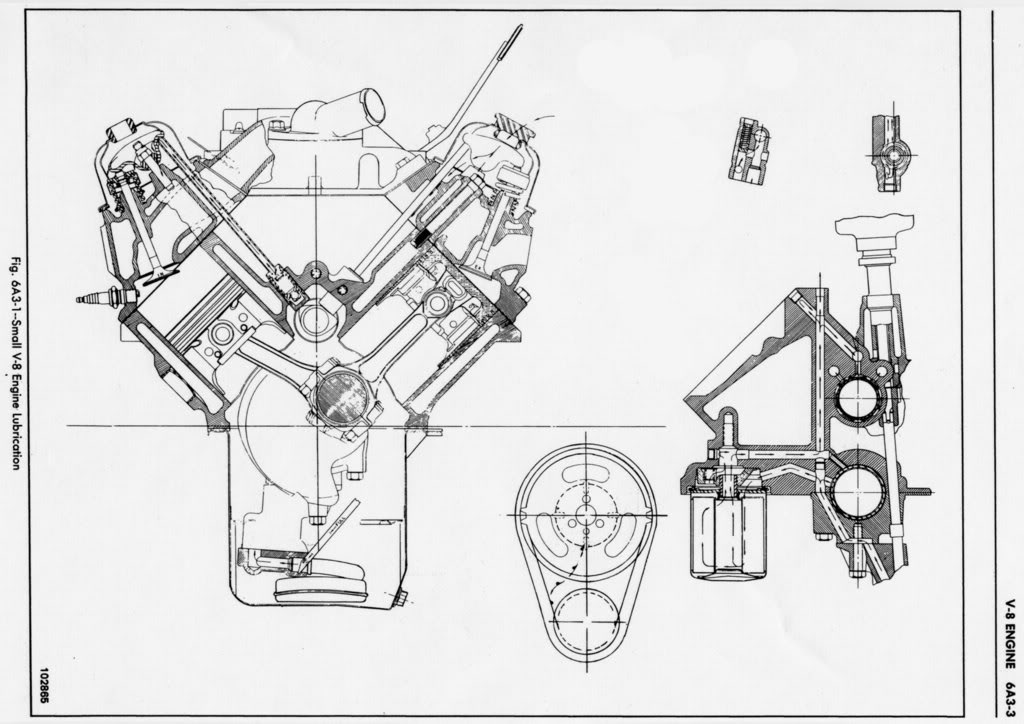

PRESSURE, that you see displayed on the oil pressure gauge is a measure of the RESISTANCE to oil FLOW thru the engines clearances and its dependent on moth flow volume and oil viscosity, plus the cross sectional area of those clearance,s, but remember the oil viscosity changes with temperature.

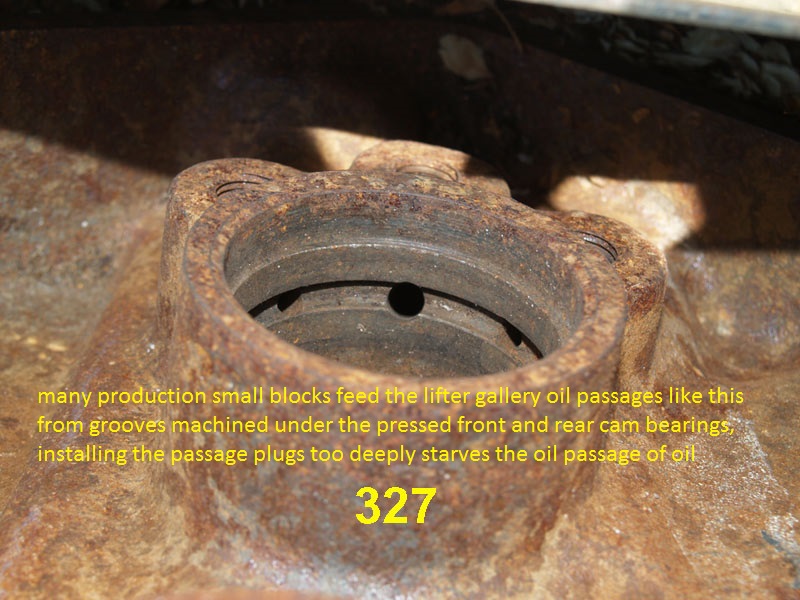

assuming the proper bearing clearances and proper oil pump, was selected,and oil pump pick-up installation were done,

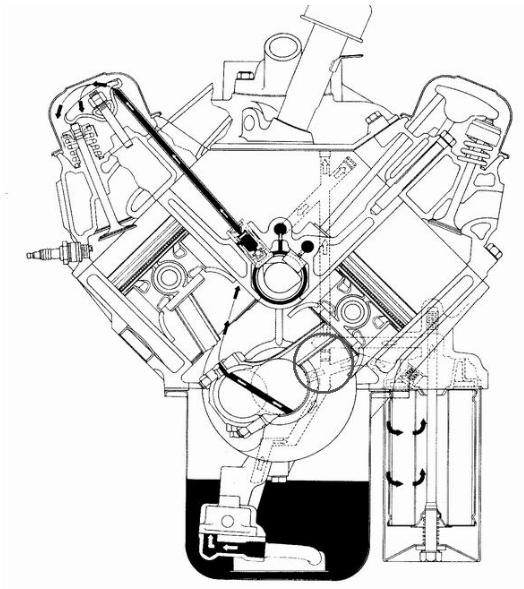

the two most common reasons I see for low oil pressure are related to either the oil pump pick-up mounted too close to the oil pan floor

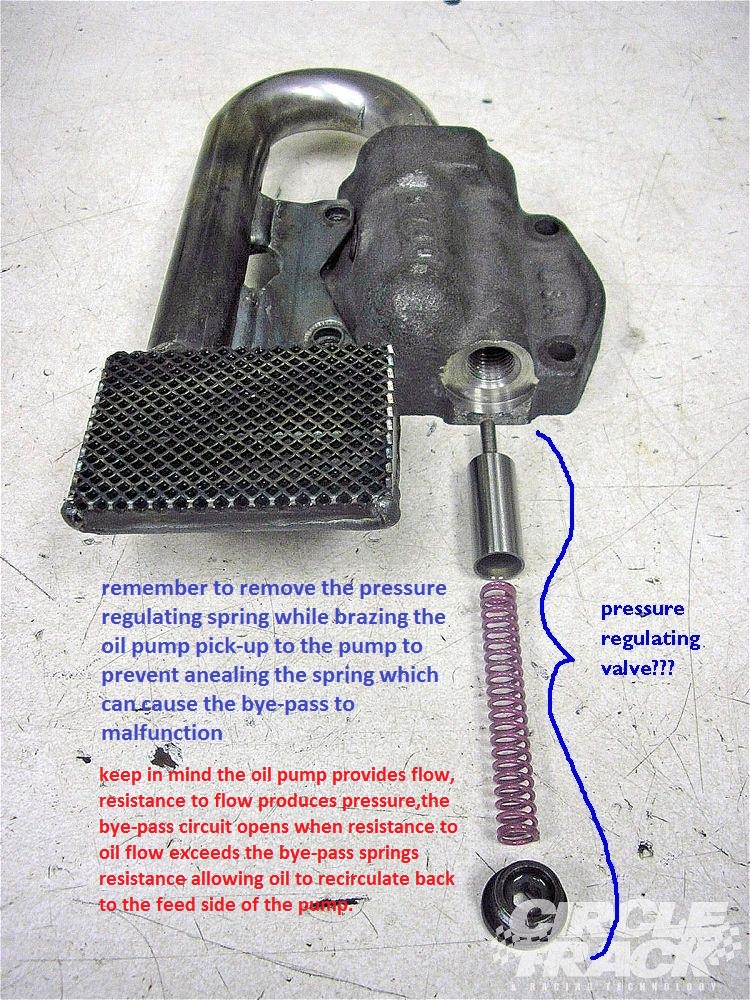

(3/8' clearance is about ideal) or trash/debris getting into the oil pressure bye-pass valve spring area

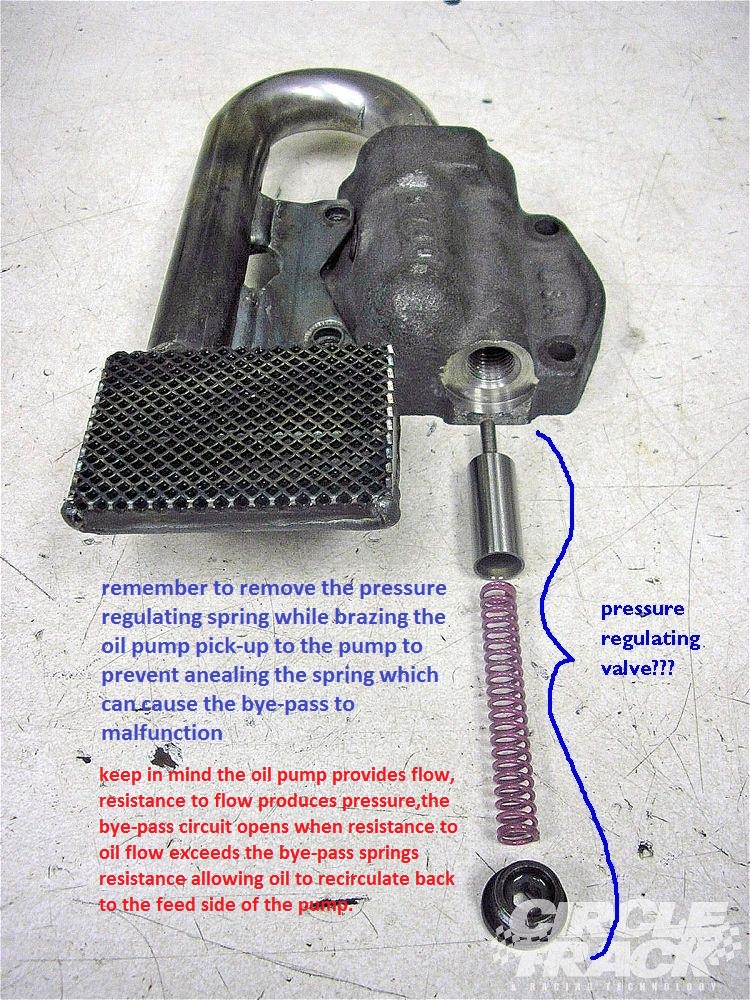

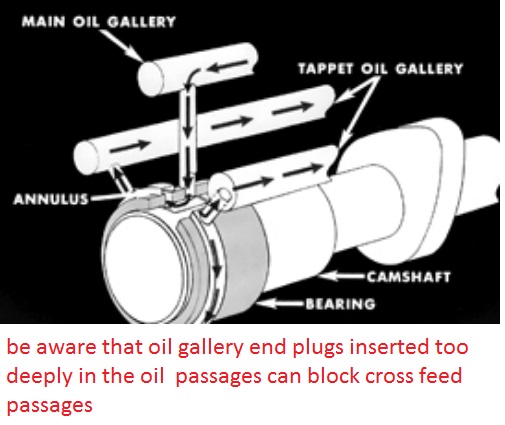

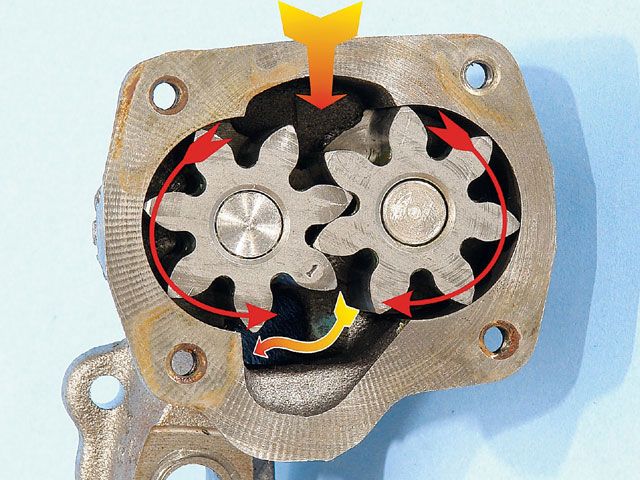

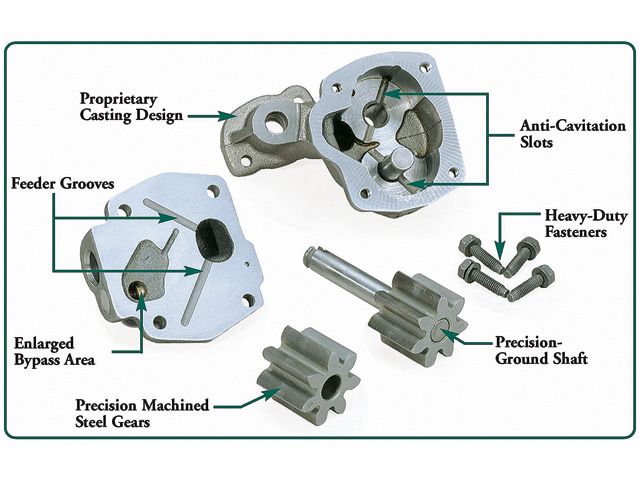

keep in mind the oil pump pressure relief spring has ZERO effect on oil pressure other that to limit the peak pressure, it has zero effect on pressure vs rpm until PEAK oil pressure is exceeded, when the pressure is limited by the pumps routing high pressure oil back to the intake side of the oil pump

read the related threads and linked info, below

it sure can't hurt and in most cases will help a great deal

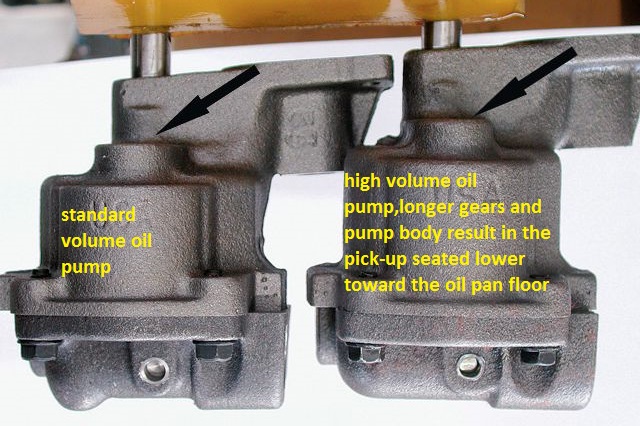

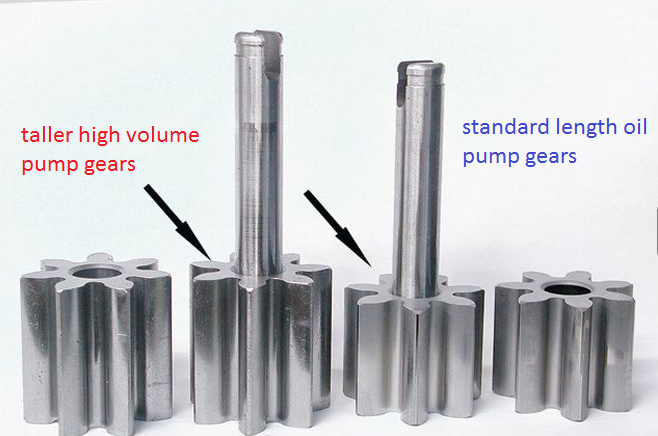

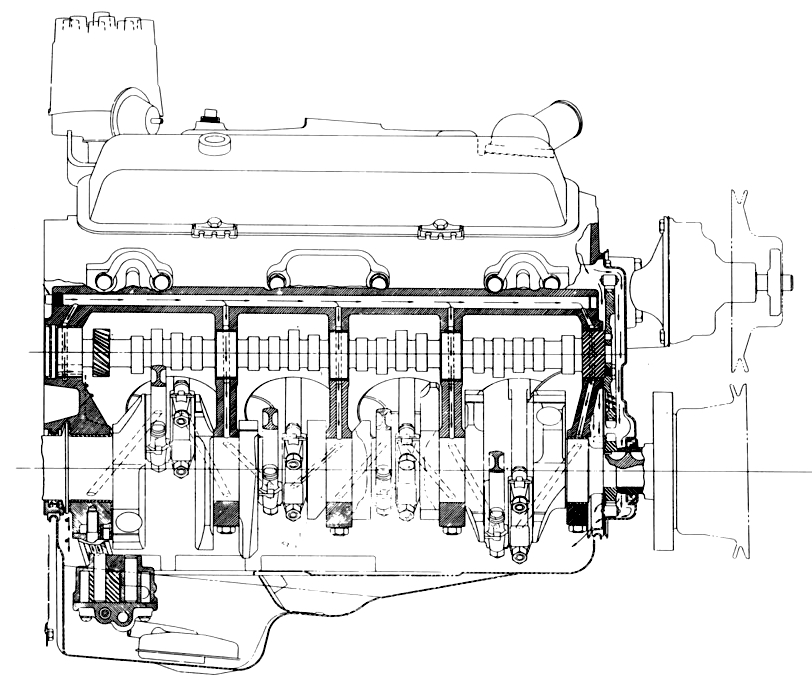

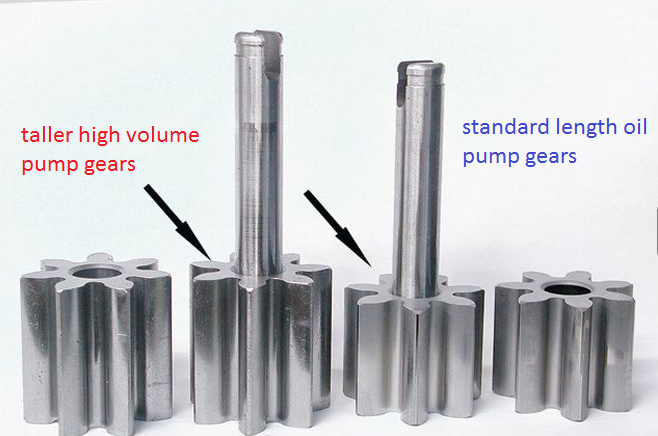

keep in mind the oil pump spins at 1/2 the speed of the crank so at 2000rpm on the tach the oil pumps spinning at 1000rpm. and the oil pump gears teeth move a set volume of oil flow thru the pump at any rpm level, the oil trapped by the pumps gears can only move as much oil volume as the gears sweep volume allows, high volume oil pumps have longer gears,of similar diameter to stock gears,the extended length is there to add more volume, so they trap and push a greater volume of oil thru the pump body, with each rotation.

standard volume oil pumps use shorter gears than high volume oil pumps, the 10%-25% extra flow is the result of the 10%-25% extra gear length

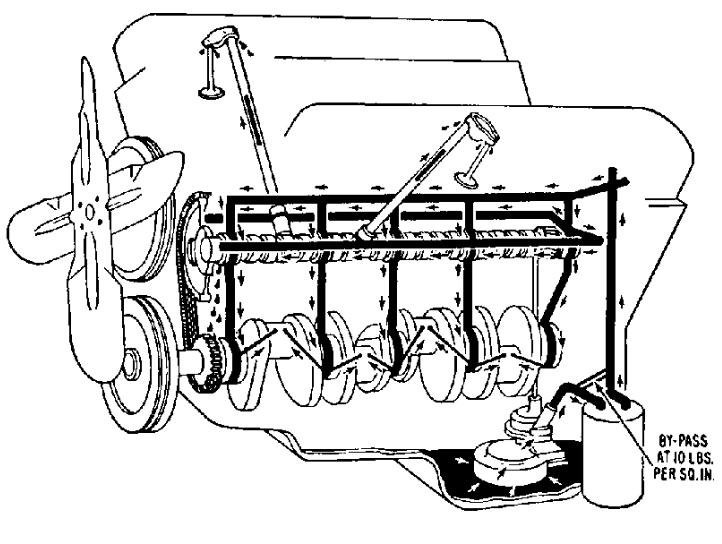

Ive always found the best results from keeping the low rpm pressure , in the 15psi-20psi at hot idle and no more than 65psi at high rpms,is really useful, the volume required depends on the way the engines clearances and oil systems designed or modified ,volume/viscosity/clearances in the approximately stock range works fine in most .oil pressure, will be determined by the difference in RESISTANCE too oil flow volume produced by the pump and the volume exiting the bearing clearances listed below, up to the point where the by-pass piston,held closed by the by-pass spring resistance , of that spring is forced open allowing oil to recirculate thru the pump to the low pressure side, limiting further pressure increases. as the oil temp increases the viscosity tends to decrease, this, lower viscosity or thinner easier to pump hot oil, flows thru the clearances faster,this lowers the resistance to flow thru clearances thus the pressure drops as the resistance to flow decreases

OIL PRESSURE read on the gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but it has zero to do with anything else, if its functioning correctly,During testing the bye-pass circuit in the oil pump should open, allowing high pressure oil to flow back to the feed or low pressure side of the oil pump, and limit oil increases,in pressure too either about 60-65psi or 65-70psi depending on the resistance of the bye-pass spring selected

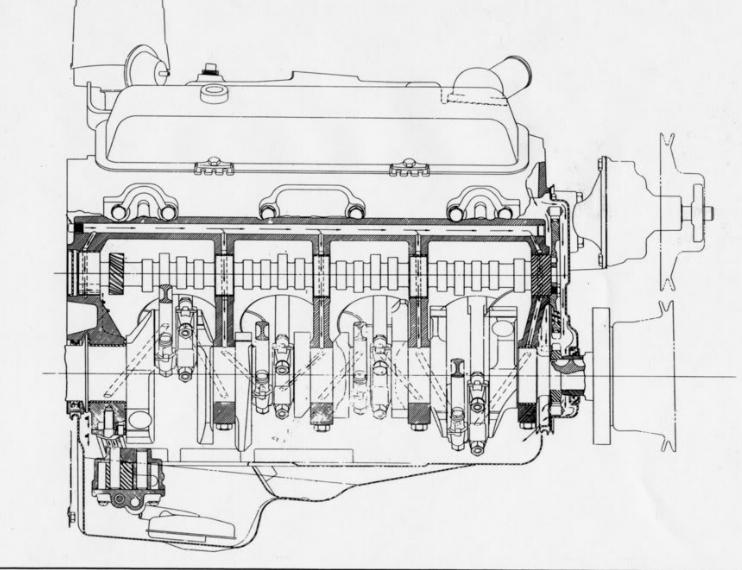

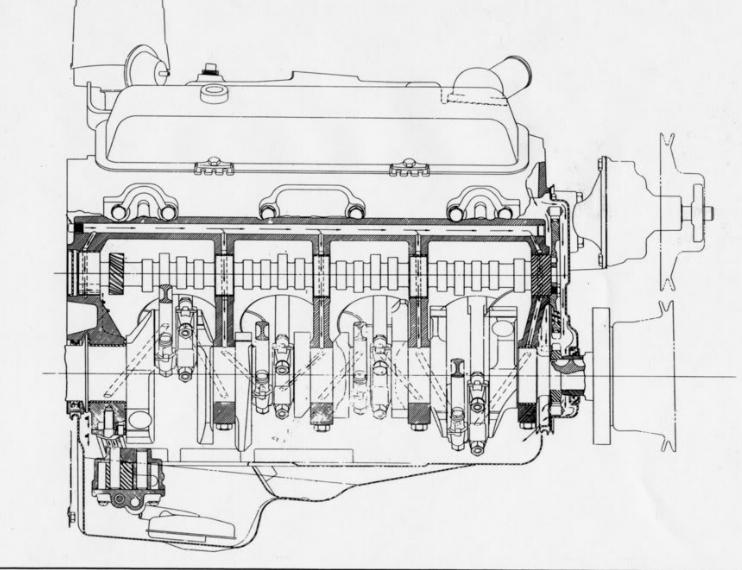

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

your 55 psi at idle serves no purpose as 15psi-25psi is all thats expected in a new engine with tight clearances using a good 10W30 oil, if your using a higher viscosity than 10w30 its reducing oil flow rates and reducing heat transfer rates, Id suggest using a good 10W30 oil. and use of a 7-8 quart, baffled oil pan and windage tray

the idea that you can 'pump the pan dry" with a high volume oil pump, in a properly set up chevy engine has been proven false dozens of times, thats a myth , oil pumped thru the engine drains back to the sump rapidly in a properly set up engine.that myth been repeated for decades and the reason its gained its supposed verification as fact is simply that guys install a high volume oil pump in the same engine that they just removed a stock oil pump from and find that they reve the engine and the oil pressure starts to go up then tops out or even drops off , the instant and wrong conclusion drawn is that the high volume oil pump sucked the oil pan dry, but what really happened in almost every case was a bit simpler.

high volume oil pumps have a longer body that moves the oil pump pick-up closer to the oil pan floor and if the clearance is not checked and corrected to maintain the required 3/8"-1/2" minimum clearance it severely restricts the flow into the oil pump and pressure drops of as a result of the restriction on the intake side of the oil pump pick-up.

www.summitracing.com

www.summitracing.com

when you inspect the bye-pass piston and spring or replace the oil pumps bye-pass spring, in the oil pump you must be certain it smoothly slides through the internal passage , if it binds it will cause issues with erratic oil pressure

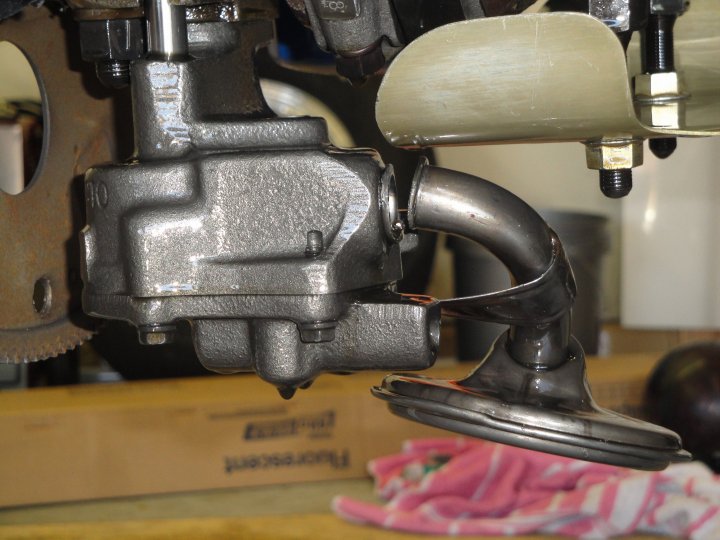

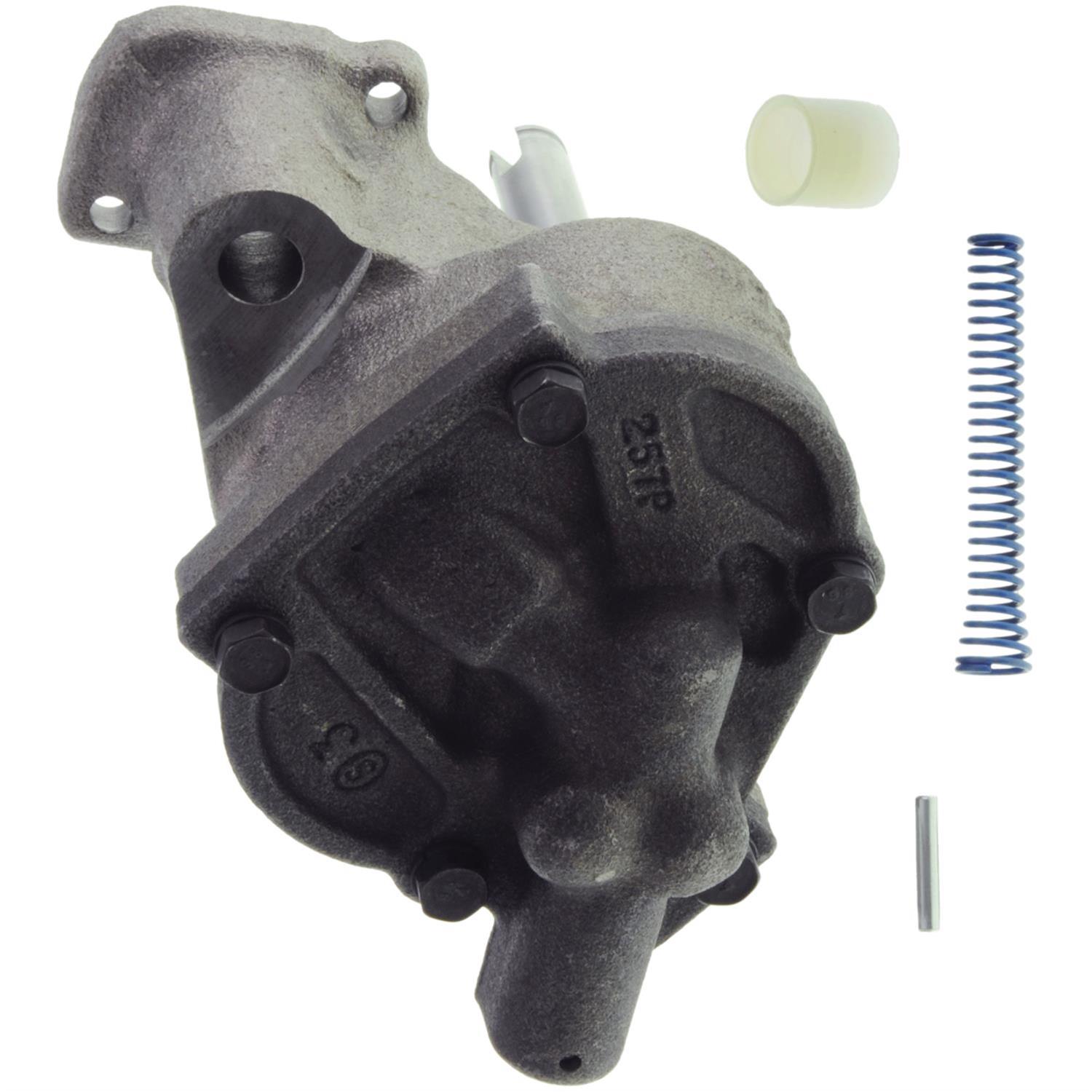

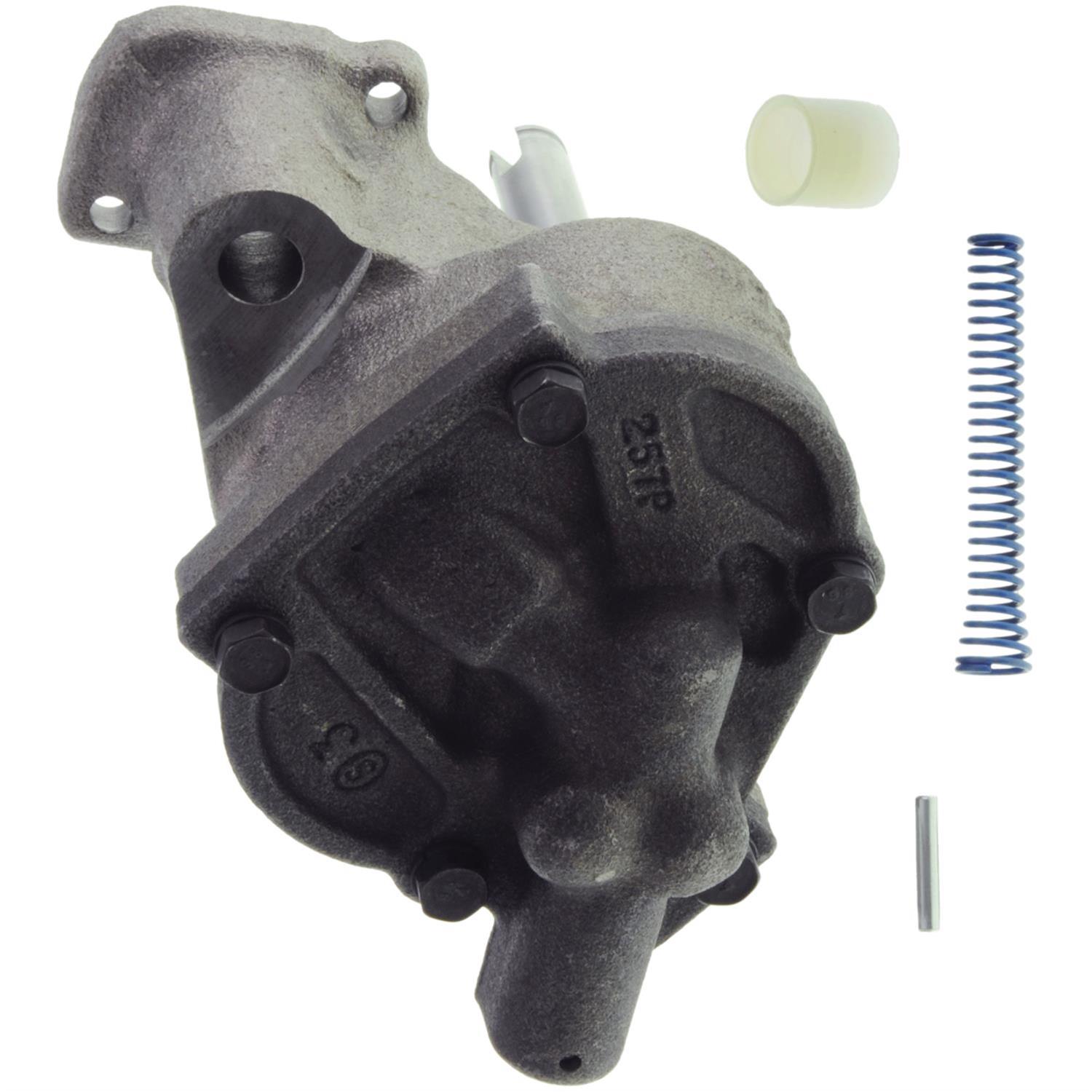

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

keep in mind that as oil temps increase the oil viscosity tends to decrease, thus cold oil, at lets say 70F might cause the oil pressure gauge to read 50 psi at idle but the pressure reading slowly goes down to 25 psi once the oils reached lets say 210F, this is normal and expected

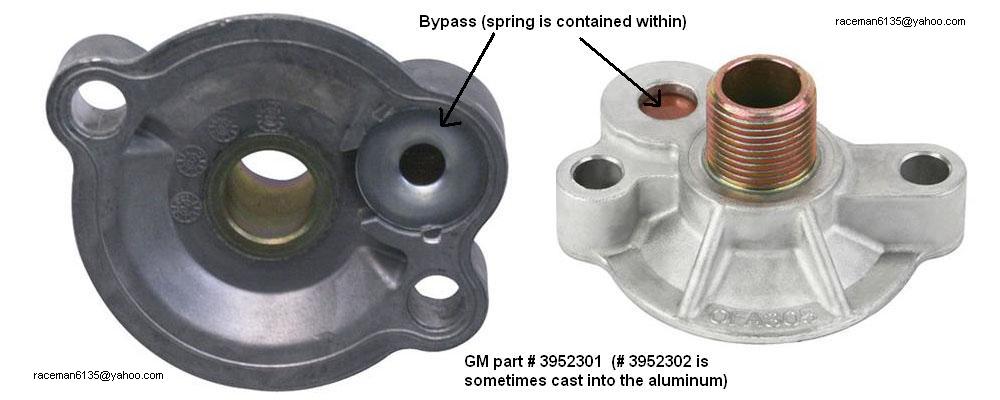

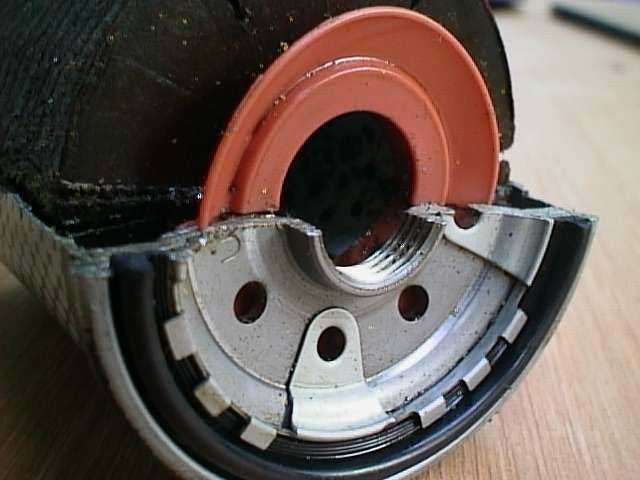

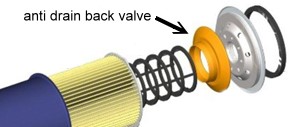

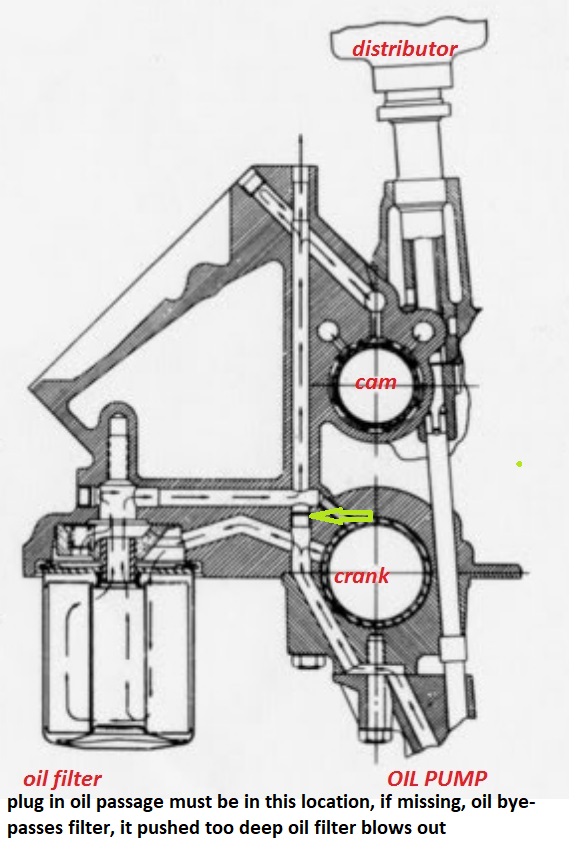

REMEMBER the oil pump bye-pass is designed to limit oil pressure reaching the oil passages in the block,to usually 65psi-75psi max, by opening and re-routing oil from the pressure side of the oil pump to the suction side of the gears one its forced open, this is not the same and has nothing to do with the oil filters oil bye-pass valve,

yes the BYE-PASS IN THE OIL FILTER DOES normally open on cold mornings, or under rapid changes in engine rpms, especially before the heat from the engine lowers the oils effective viscosity, Im fairly sure you have heard or remember hearing advise not to go doing stupid stuff like burn outs in your drive way until the engines reached and maintains operational temps

(usually oil and coolant has reached 190F-215F) well one big reason is that thicker oil viscosity when oils cooler ,takes a good deal more pressure to force thru the filter medium, once the oils fairly hot it flows better, and requires less pressure as it offers less resistance to flow thru the engines clearances and thru the filter, that in turn means that hot oil with its thinner effective viscosity tends to be far less likely to force open the filter bye-pass circuit and that means oil bye-passing the filter medium is far less likely to drag metallic trash held in suspension with it to reach the bearings to cause more rapid wear.the oil filter bye-pass is designed to bye-pass oil to the engine rather than forcing it thru the oil filter any time the pressure on the inlet side of the oil filter is higher than about 10 psi over oil pressure passing thru the oil filter, this in theory prevents the semi clogged oil filter from starving the bearing of oil.but it also means that during rapid rpm changes or before the oils up to operational temps some oil is routed around and past the filter, under the concept that dirty pressurized oil is far superior to no oil reaching the bearings.

MORE USEFUL INFO

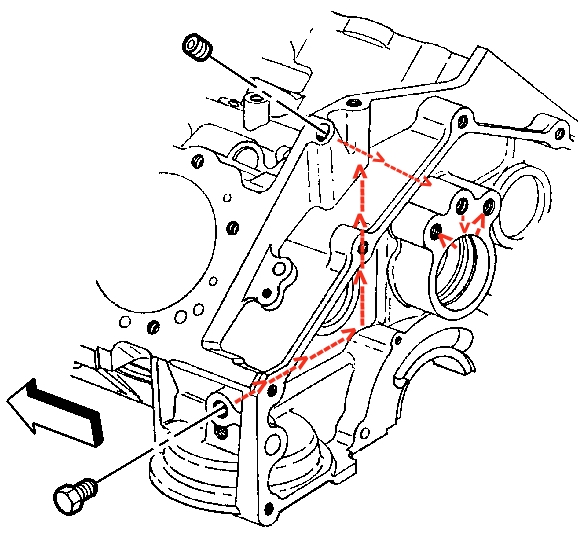

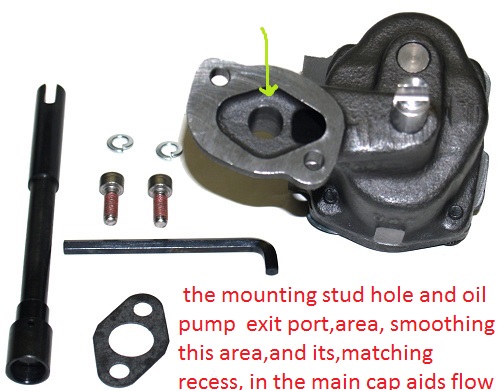

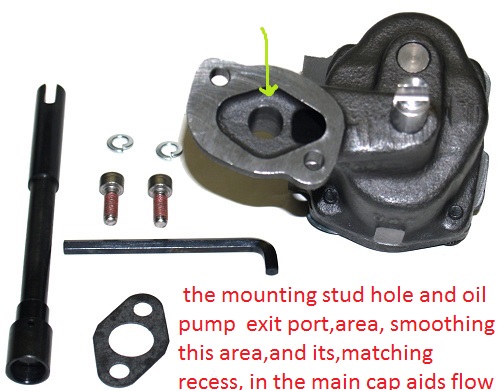

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

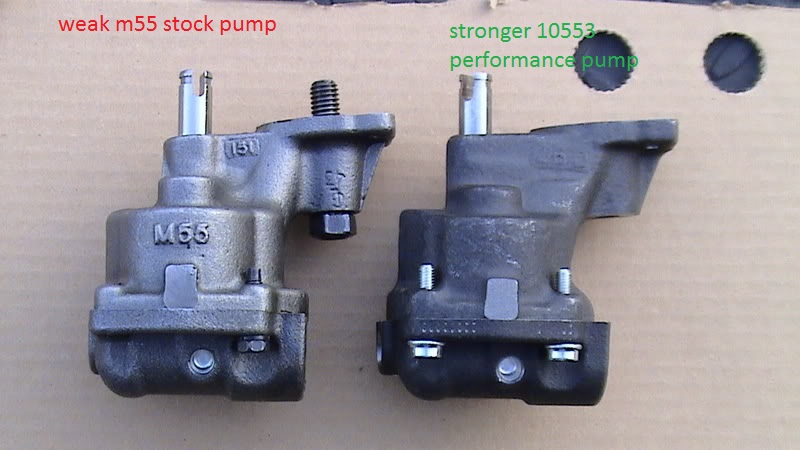

I like high voluum pumps but I certainly don,t use them IF the engines nearly stock as the standard Z28 SBC pump works fine

"the standard volume pump gears are about 1.2" long the high volume pump gears are about 1.5 inches long (depends on manufacturer)

heres the discriptions right from chevy

12555884

SBC Oil Pump, High Pressure Z28/LT1. Production high-pressure oil pump with 1.20" gears.Will produce 60-70 psi oil pressure. Does not include screen. The pickup tube dia. is 5/8" for this pump.

62.17

the true high voluum pumps like this below are not necessary UNTILL youve done extensive mods that require the expra oil flow voluum

14044872

SBC Oil Pump, High-Volume. This high-volume pump has1.50" long gears.It has approximately 25% more capacity than a production pump at standard pressure. Does not include screen."

http://www.melling.com/Aftermarket/Tech-Tip-Videos

viewtopic.php?f=54&t=2187

ONE VERY COMMON MISTAKE MADE by guys swapping to a high volume oil pump is failure to carefully measure the pick-up to oil pan floor clearances, because the high volume oil pump has longer gears it tends to move the location of the oil pump pick-up lower towards the oil pan floor, if that distance is reduced too less than about 3/8" the common symptom is good oil pressure at idle but rapidly falling pressure as the rpms build as the oil pump intake is restricted significantly, this results in the common MYTH that high volume oil pumps pump the pan dry as rpms increase. when the truth is that its the result of not carefully verifying clearances

the answer to that question of what SMALL BLOCK CHEVY PUMP TO USE, depends on the application and the size of your oil pan, if your using a windage tray, your bearing clearances and a dozen other factors, reading thru the links posted below should be very helpful.

youll seldom have any problem using melling 10552, if its properly installed, in almost any small block, is roughly similar to the old Z28 pump and supplies a bit of extra volume at near stock pressure if you don,t install the optional high pressure spring, that pump should be fine in about 90% of the street strip engine builds

http://www.summitracing.com/parts/mel-10552

related threads to read thru

OIL PUMP MODS

http://www.corvette-restoration.com/res ... ancing.htm

http://www.youtube.com/watch?v=tOiHdIXV ... r_embedded

READ THIS THREAD

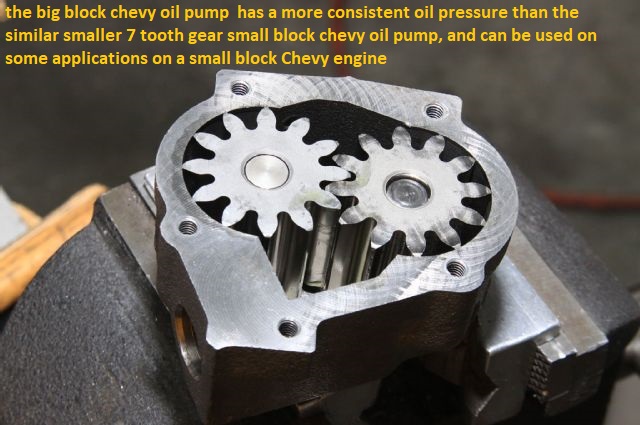

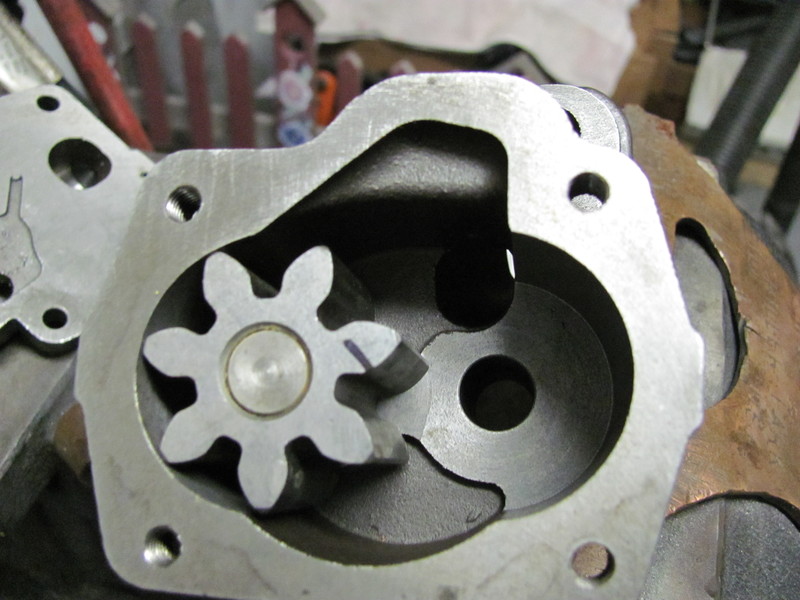

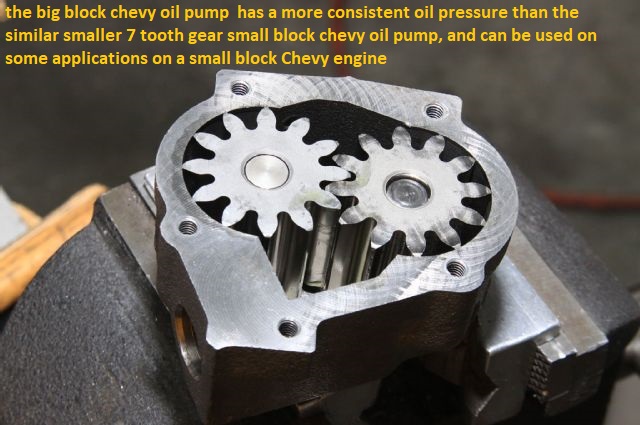

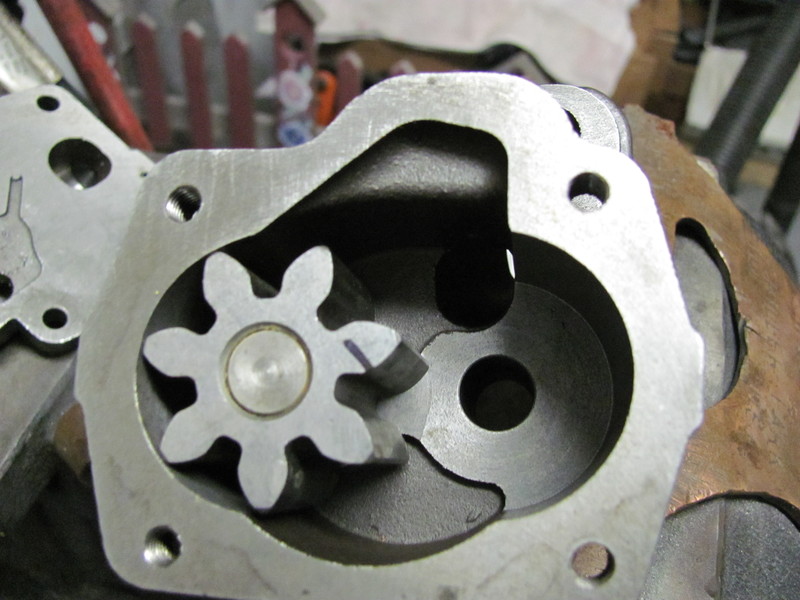

small block pumps have 7 tooth gears and 4 bolt covers and don,t provide the smooth oil flow rates the 12 tooth, and 5 bolt cover big block gear pumps provide

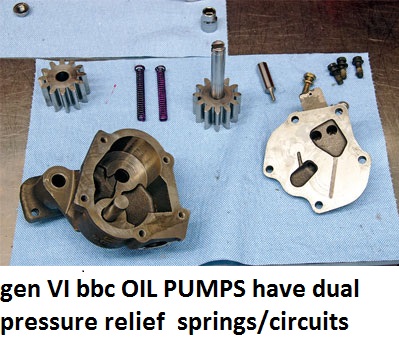

In this comparison, you can see the major difference between a high-volume small-block pump gear (left) and the Rat motor gear (right). The Rat motor pump enjoys a larger diameter and more pump teeth that should create a more stable output curve.

every choice you make is a compromise in some area

yes it takes a couple more horsepower to spin a high volume oil pump, at peak rpms, as its doing significantly more work, pushing cooling and lubricating oil flow at a higher volume, but in exchange your getting faster and greater volume of oil flow over the whole rpm range that is slightly more effective at cooling the valve train and bearings, and at start up this tends to reduce wear over time, and in my experience its to your advantage to use a standard volume bbc oil pump in SOME sbc performance applications

remember the oil pump drive only seats in two locations 180 degrees apart but it can be lined up anyplace you want with a 18" long large flat blade screw driver prior to installing the distributor from the top of the engine rather easily before you re-seat the distributor, but as the distributor gear teeth mesh the distributor will turn the rotor about 15 degrees

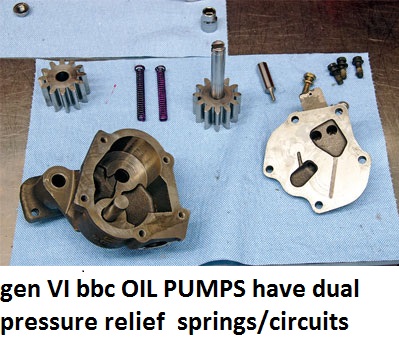

BTW, , on BIG BLOCKS the oil pumps and oil filter adapters are different due to the block oil filter recess and rear seals being different

GEN 4 or MARK IV

GEN V and VI

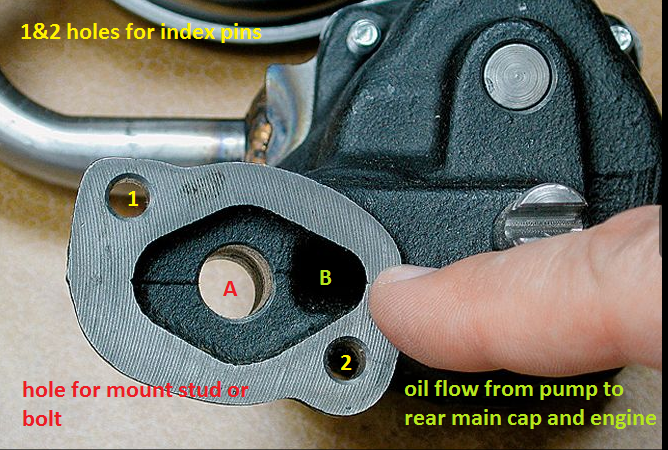

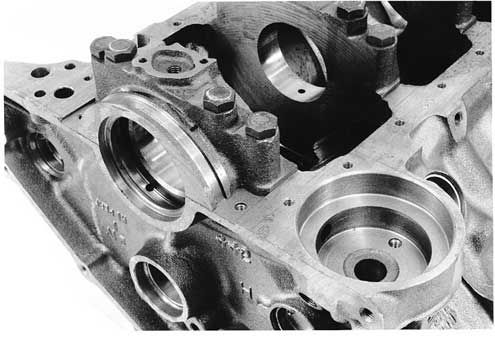

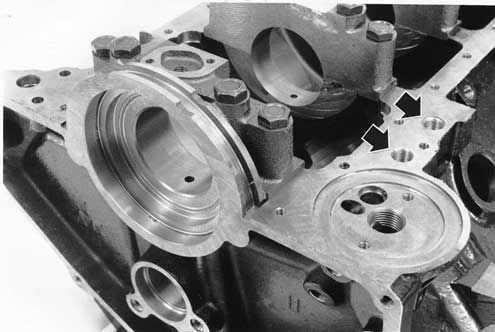

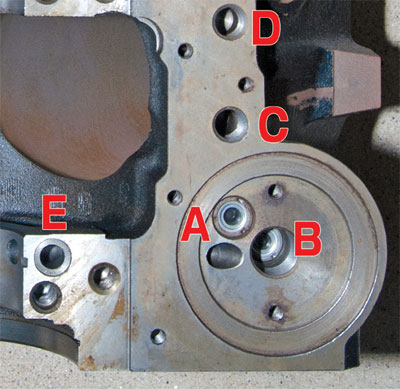

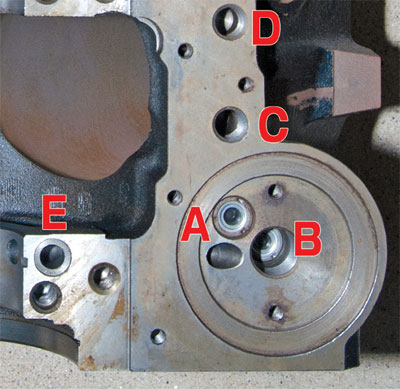

Gen V/VI oil filter pad contains two bypass valves, one for the oil filter (A) and one for the oil cooler (B). The filter adapter, which is nothing more than a threaded fitting to mount the filter, has been removed in this photo to show the recessed oil cooler bypass valve. Oil cooler fittings thread into the cooler outlets (C) to the oil cooler and the return (D) from the cooler. If you are not using an oil cooler, you should remove the cooler bypass valve (B) and plug the cooler line holes (C and D) with 1/4-inch NPT pipe plugs. The bypass valves are a light press fit in the block and may be removed by threading a long 3/8-16 bolt into the valve and wiggling it free, which usually damages the valve. That’s okay, because replacement valves are inexpensive and you want to replace the old one with a new bypass valve (GMPP PN 25013759). Note that Gen V/VI rear main caps require an O-ring that fits in a recess in the block (E) to seal oil delivery from the pump.

Read more: http://www.carcraft.com/techarticles/cc ... z2RyXV6xCI

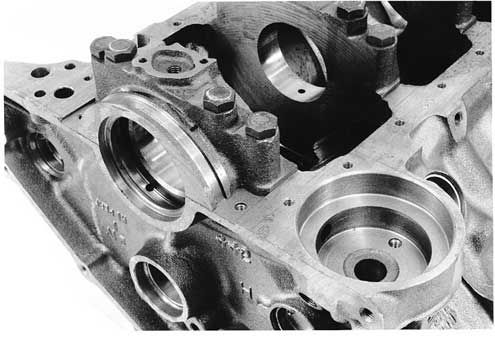

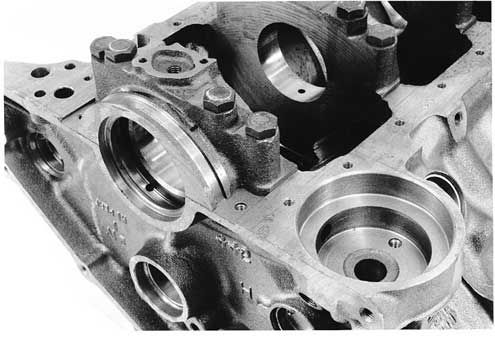

big block vs small block chevy oil pump

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears

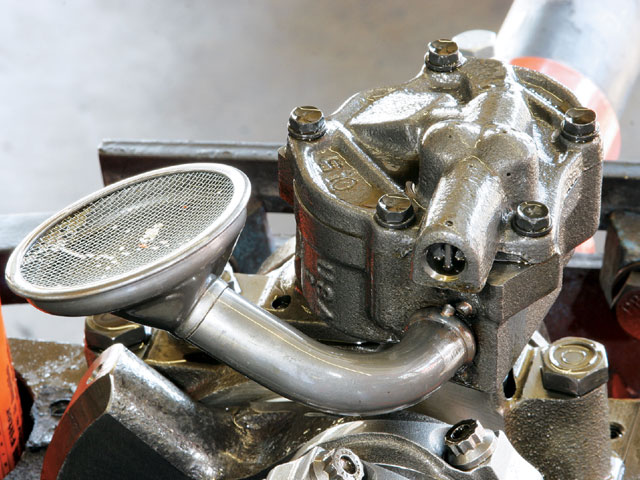

your typical big block oil pump has a 5 bolt cover, a 3/4" pick-up tube diameter and the pick-up presses into the pump body , it has the larger more efficient 12 tooth gears and in many cases can be mounted on a small block, but its usually not required

BIG BLOCK CHEVY 5 BOLT cover pump

SBC 4 BOLT COVER OIL PUMP

SBC pumps have 7 tooth gears and BBC pumps generally have 12 tooth gears making the flow more consistent

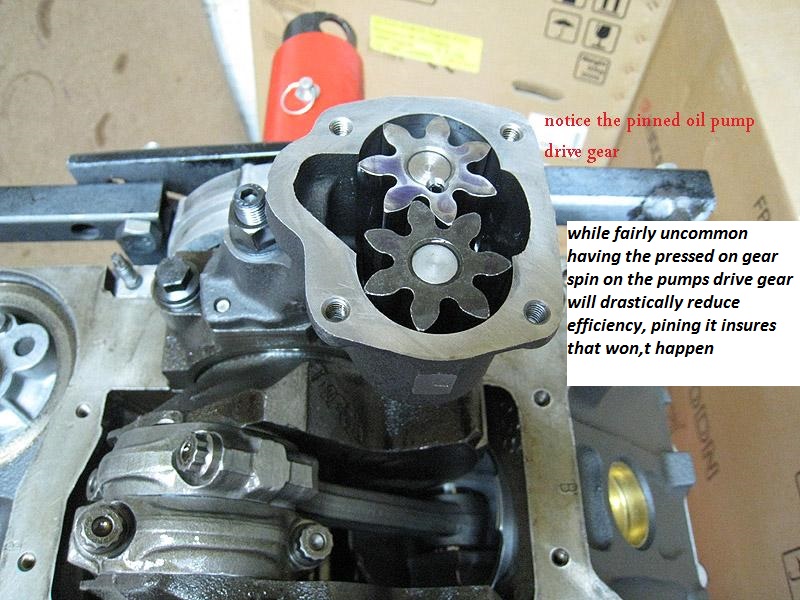

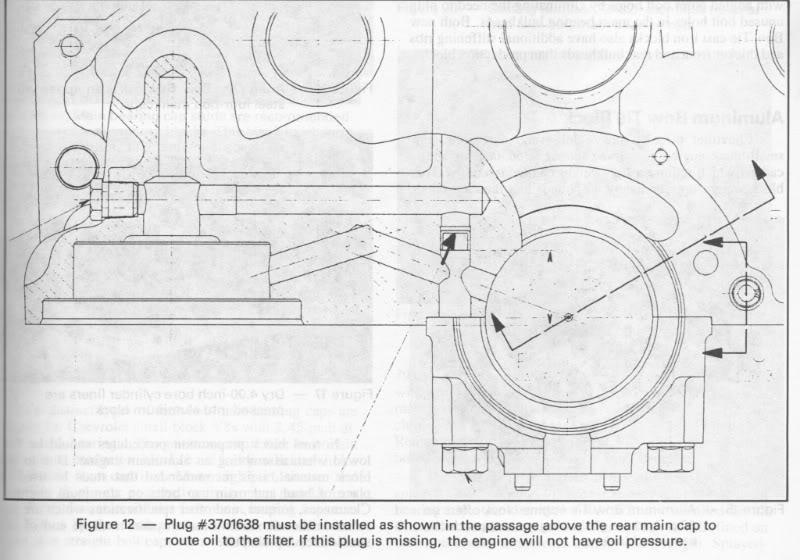

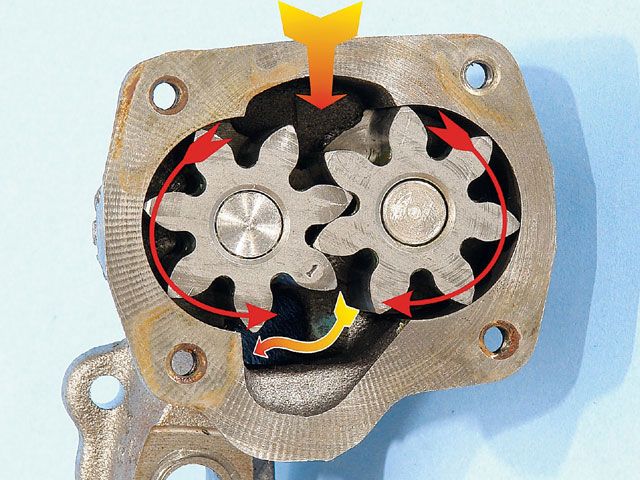

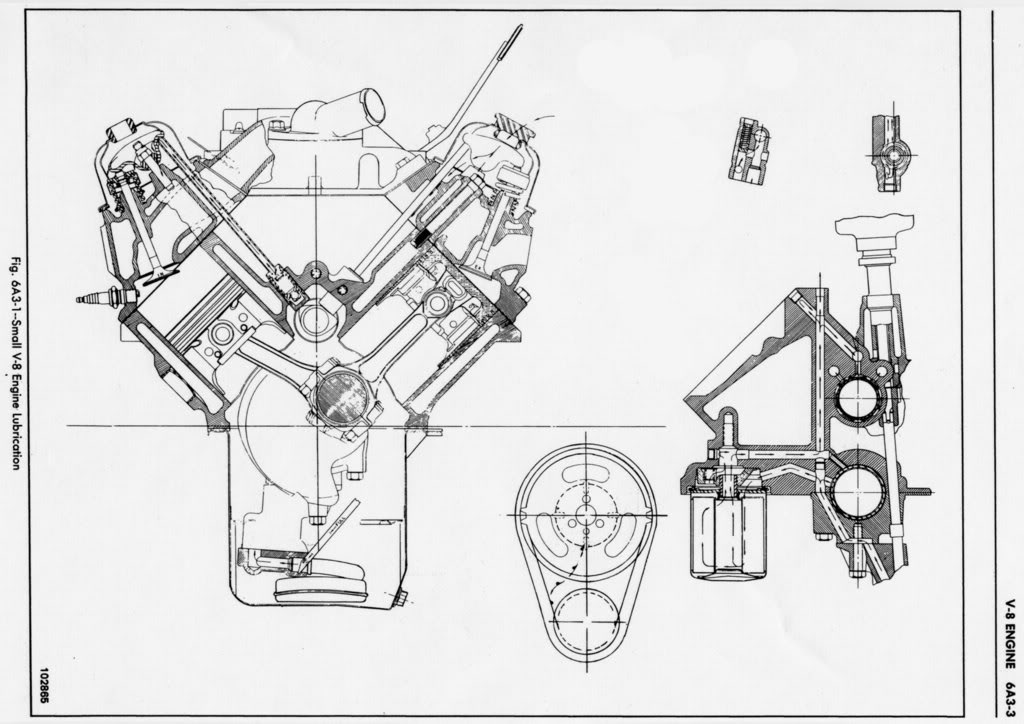

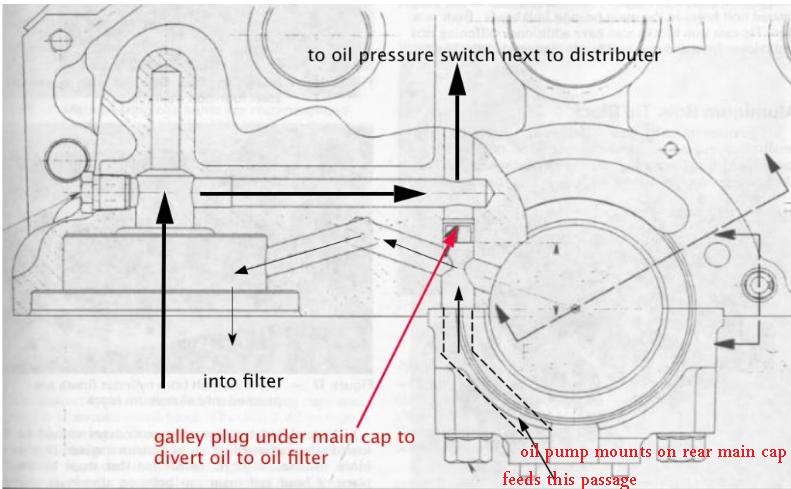

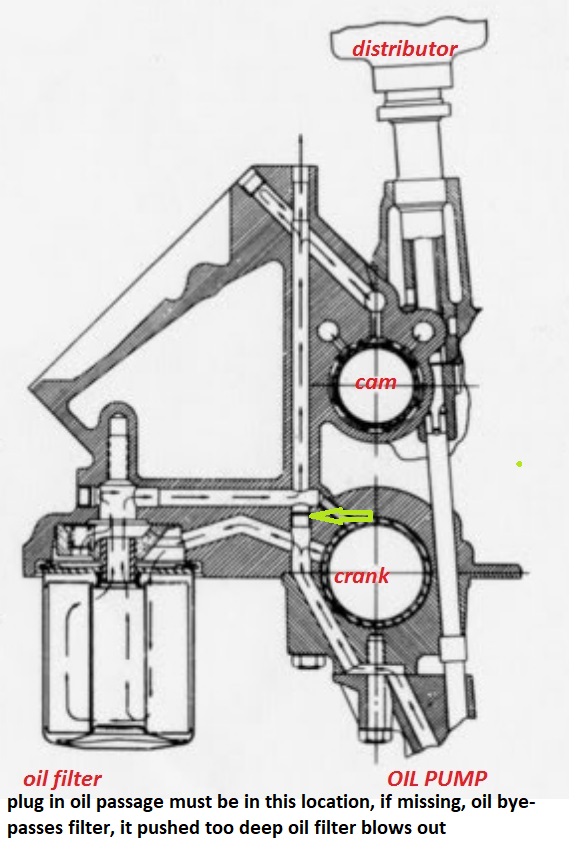

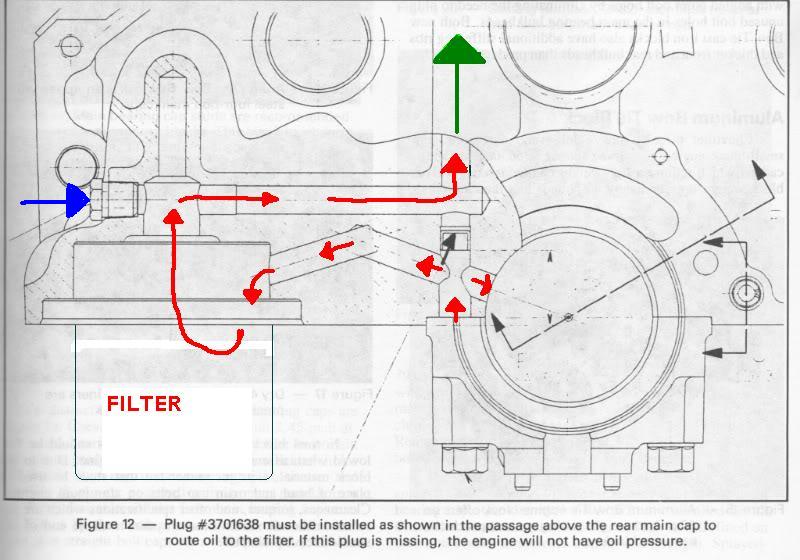

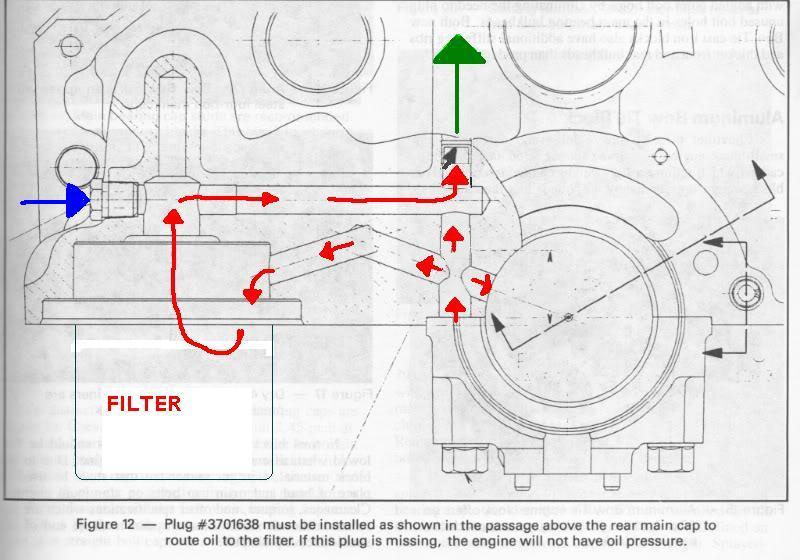

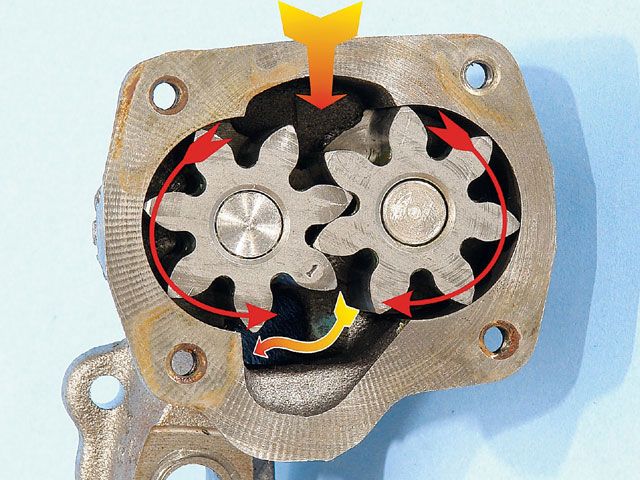

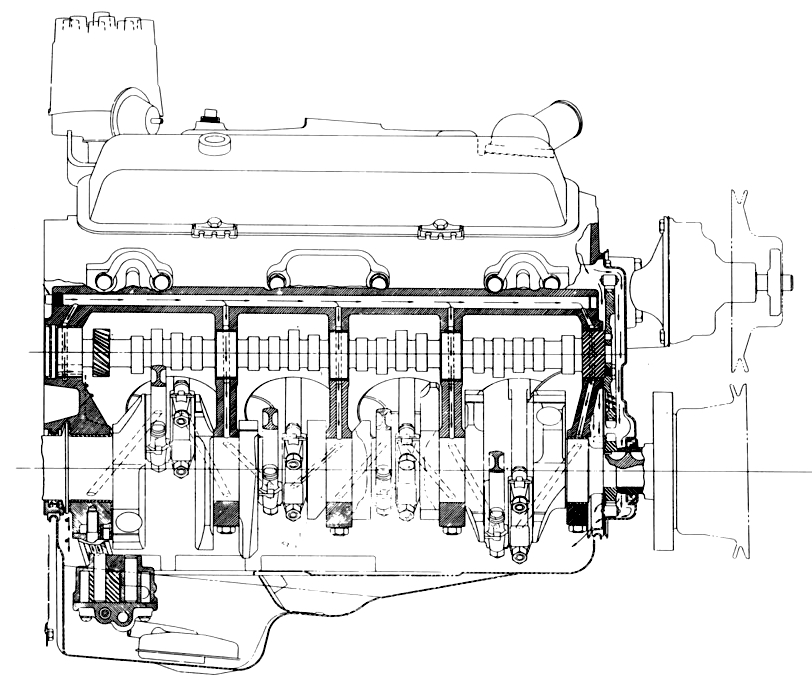

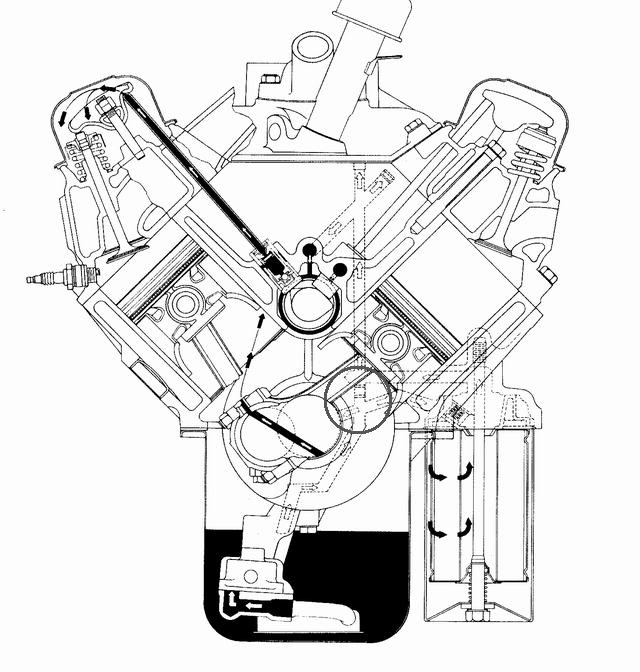

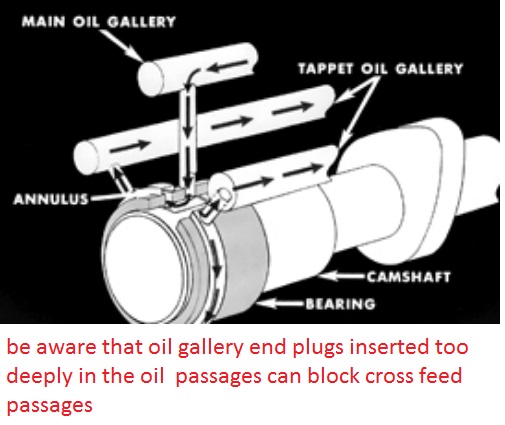

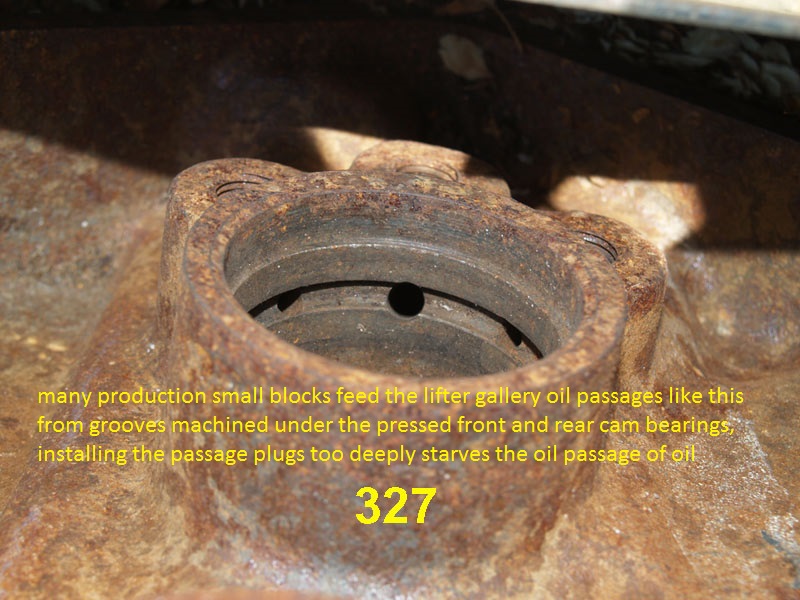

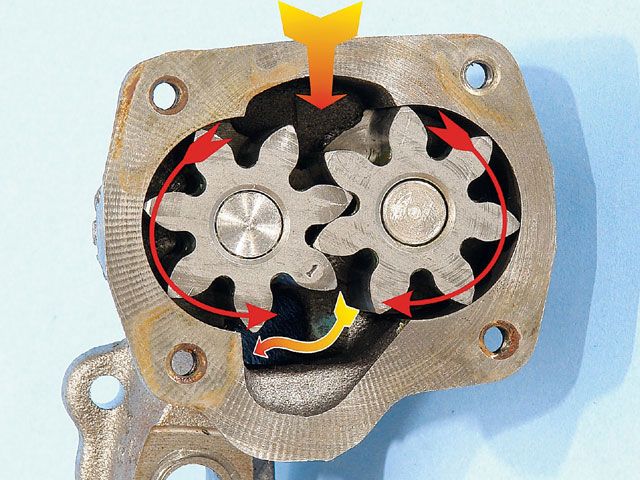

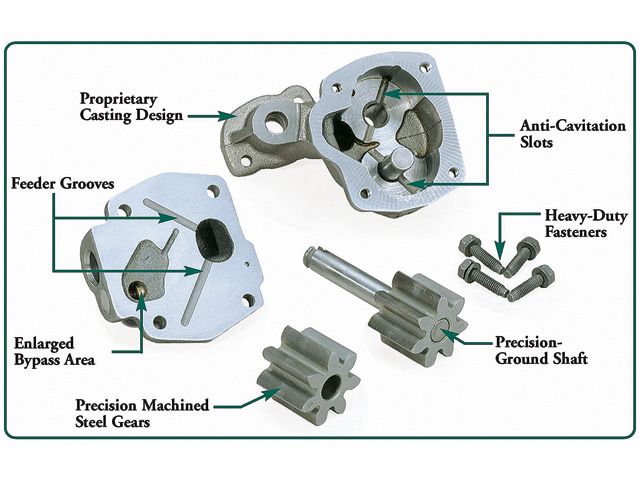

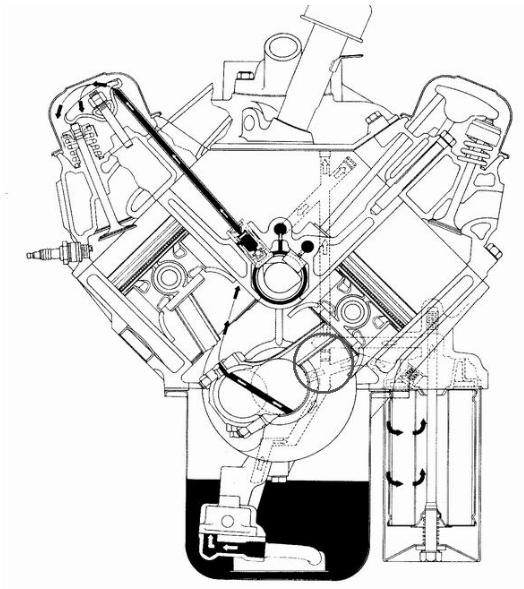

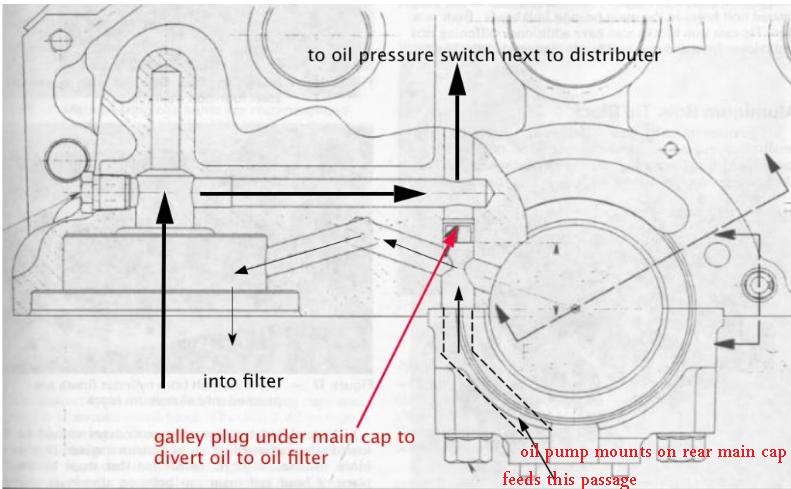

oil is sucked up the pick-up (or pushed in by the pressure difference, if you need to be technical) into the pump body and swept along the outside walls of the pump,by the rotating gear teeth,and forced thru the pumps pressurized exit port passage in the pump casting, then the pressurized oil is forced thru the rear main cap on the block, fluids are not compressible, so , if the resistance to the oil flow increases, the resulting oil pressure increases until it exceeds the bypass circuit springs resistance, on the bypass circuit piston , this forces open the bypass circuit piston in its bore allowing the excess pressurized oil to bleed back into the low pressure side of the oil pump casting, thru a passage in the oil pump casting designed to limit peak oil pressure,that the spring loaded piston in the pressure relief circuit controls, the flow rate, until the pressure drops below the oil pumps pressure relief spring resistance , when the spring forces the passage to close as the small piston on the spring closes the pressure relief passage acting as a valve, that controls and limits peak pressure.

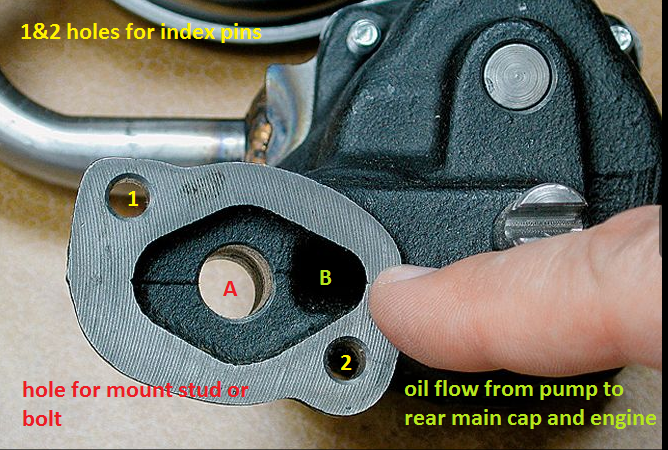

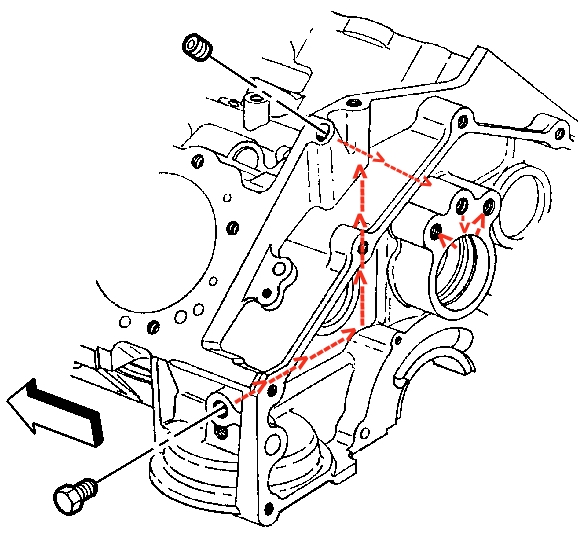

the pumps secured to the rear main cap with a stud or bolt and its indexed with the twin pins,in the rear main cap, that fit the holes in the pump casting.

the pumps spun with a drive shaft that connects the distributor gear and cam gear interface

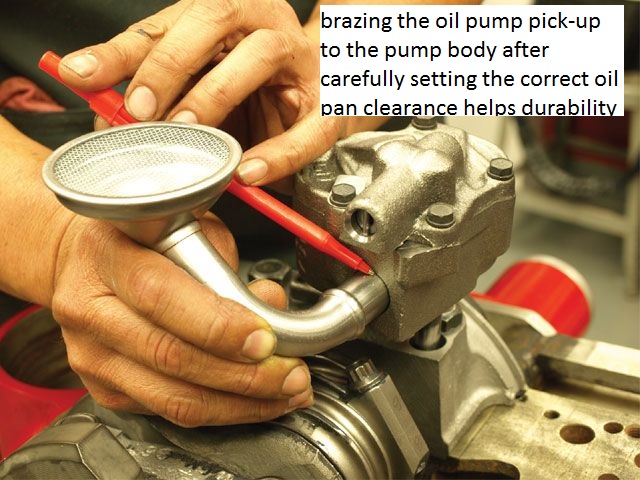

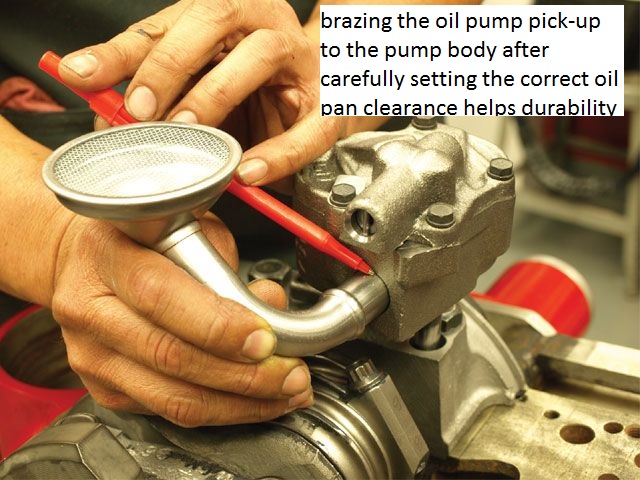

the by-pass circuit has no effect on oil pressure other than to control the peak pressure, that can be reached before the circuit opens and limits further increases, installing a stiffer spring only delays the circuit opening point until a higher pressure is reached and has zero effect on the oil pressure up to that point in the pressure curve. a common problem is guys failing to remove the spring & piston assembly prior to brazing the oil pump pick-up onto the pump casting as the heat can anneal the spring temper reducing its resistance, thus reducing the pumps peak pressure or failing to clean and oil and properly re-assemble the oil pumps by-pass circuit components which can result in the piston binding in its bore and not allowing the by-pass circuit to open and function at all.

in years past it was fairly common to use a small washer to shim the by-pass spring to add a few extra pounds of resistance before the circuit opened, if done correctly this worked but it was common for guys to screw it up and its not advisable to go that route, as stiffer springs designed for the job are cheap and easy to install.

I,d also point out that while oil pressures over 60 psi are certainly easily reached they provide little or no improvement in lubrication, you need to try to maintain a minimum of about 10-15 psi per 1000rpm and Ive generally found a 20-25 psi at hot idle and 60-65 psi at peak rpms to be ideal.

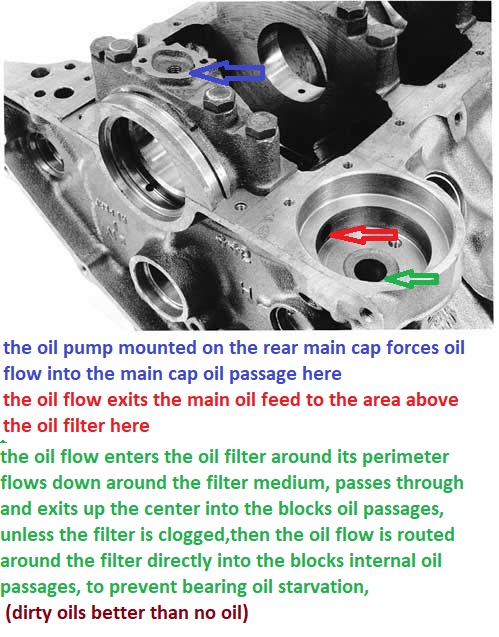

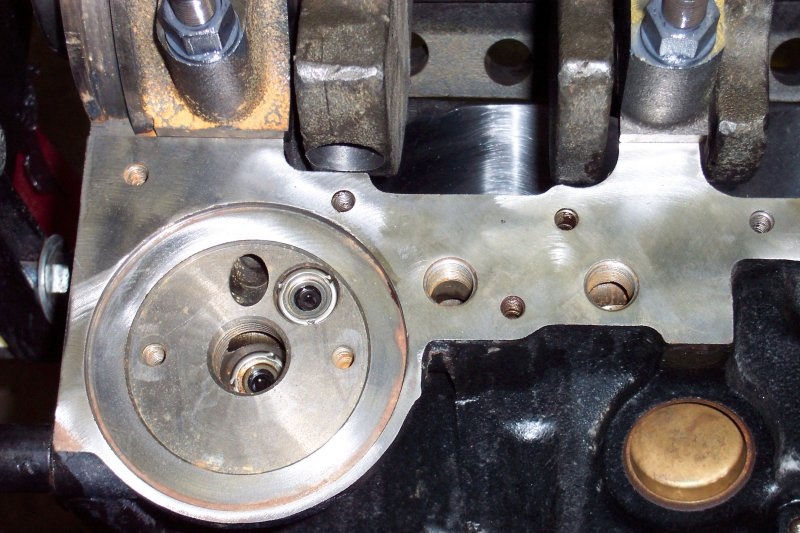

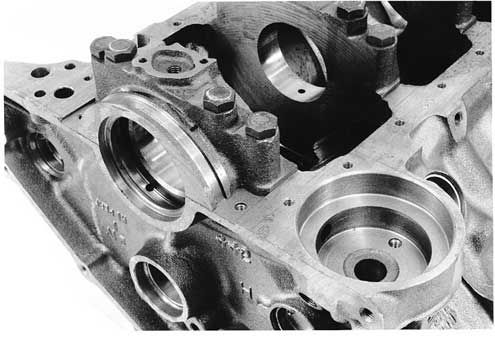

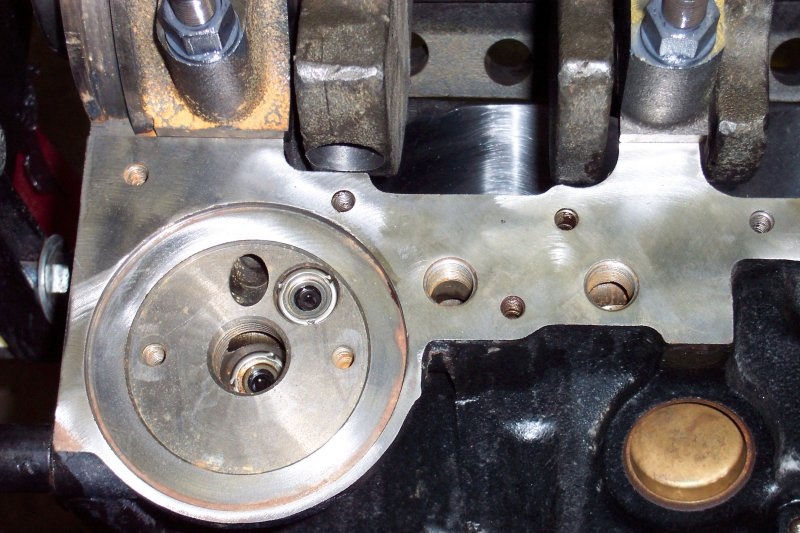

the oil pump pumps oil out this exit passage to the main cap

heres the matching rear main cap surface

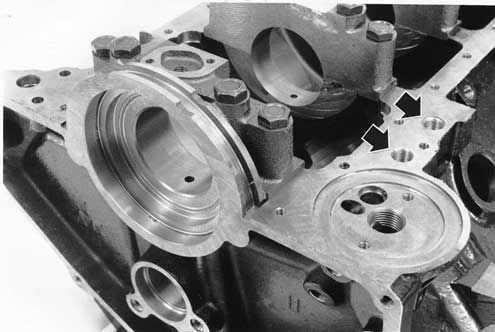

below you can see the inlet and outlet for the pressure relief passage in the big block oil pump(remember big block pumps have the pick-up in the main pump body while sbc pick-ups are mounted into the pump cover plate)

look at the picture below, the restrictive stock O.E.M. pickup if placed to close to the oil pan floor becomes a HUGE restriction to oil flow rates

you should NEVER shim an oil pumps pressure relief spring

back in the 1950s-1960s it was common to pull the pressure relief spring retaining pin in the oil pump that retains the pressure relief spring and insert a washer , between the pin and spring to add pressure to the spring, thus forcing the pump to build more pressure before the relief valve opened, this was before properly designed higher pressure springs were available, this could be done but it frequently caused problems

as it reduces the clearances and may cause spring coil stacking before the pressure valve opens fully,it may prevent the piston that pressure relief spring holds from moving back down its bore far enough to allow it to open the by-pass passage, that shim behind the spring causes a reduction of distance it can travel to open the oil pressure release, valve or allow return oil flow through that passage allowing the pressure on the high pressure side of the oil pump from bleeding off back into the intakes low pressure intake side of the oil pump, the oil pump relief springs come in several resistance strength levels, but extensive testing has shown no increased bearing protection at pressure levels exceeding 65 psi, higher strength pressure relief springs,

just increase engine rotational resistance

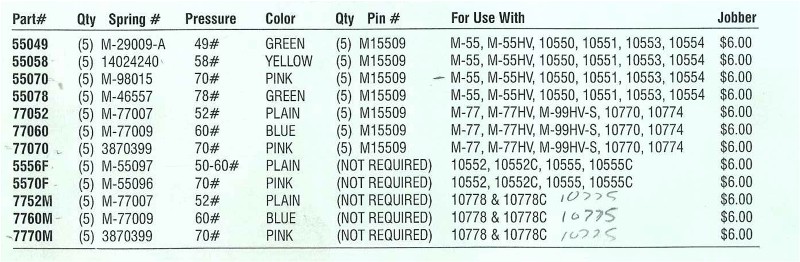

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

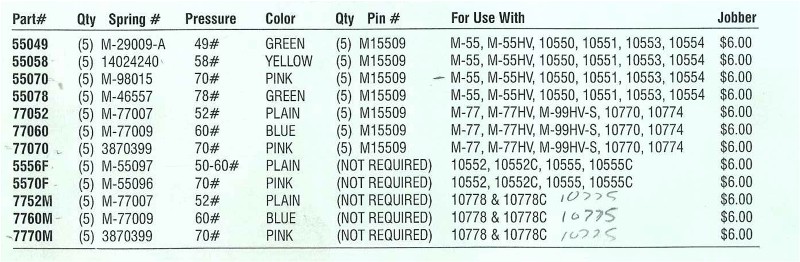

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

(1)

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

there are oil pump testers available commercially or if your mechanically inclined you can fabricate one with reasonable care, after a bit of measuring and purchasing a gauge

http://cvrproducts.com/oil-pressure-test-kit/

one point I should mention is that if you manage to wipe out a lifter and cam lobe, much of the the metallic trash is ALWAYS sucked thru the oil pump gears and its frequently packed into the pressure relief ports significantly reducing oil pump efficiency, so at a minimum it will require dis-assembly and careful inspection and cleaning and, if run awhile before you detect the problem, usually replacement

keep in mind fluids like oil, are not compressible the resistance to flow increases as the pump is turned simply because the oil flow exiting the oil pump is flowing through the bearing clearances thus the oil flow exiting the oil pump is being restricted, if the engine was rotating the restriction too oil flow is reduced.

if the oil pumps pressure relief valve opens as designed max resistance is limited to the pump producing flow rates that will build until resistance to that flow volume reaches about 60 psi, when the pressure relief valve opens recirculating additional oil flow back to the low pressure side of the oil pump.

remember volume increases as rpms increase up to the point where the relief valve opens limiting pump flow.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/page-2#post-75256

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/#post-68205

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

VS AROUND IT INTO THE BLOCKS OIL PASSAGES,

oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter,

down through the case and filter element and up through the central hollow screw retention stud,

into the blocks oil passages, if the resistance too flow is too great,

the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

theres a great deal more info in these threads & links

http://www.chevyhiperformance.com/techa ... index.html

http://www.livermoreperformance.com/gm_oil_acc.html

http://www.enginebuildermag.com/2012/07/performance-oil-systems/

http://www.hotrod.com/articles/ccrp-0911-small-block-chevy-oil-pumps/

http://www.enginebuildermag.com/2008/10/oil-pumps/

http://garage.grumpysperformance.co...high-volume-high-press-or-both-oil-pump.2294/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://www.superchevy.com/how-to/148-0506-lubrication-systems

http://www.onallcylinders.com/2014/10/23/oil-well-choosing-proper-pressure-volume-oil-pump/

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=1800&p=5526&hilit=brazed#p5526

viewtopic.php?f=50&t=382&p=467&hilit=MAIN+CAPS%E2%80%A6#p467

PRESSURE, that you see displayed on the oil pressure gauge is a measure of the RESISTANCE to oil FLOW thru the engines clearances and its dependent on moth flow volume and oil viscosity, plus the cross sectional area of those clearance,s, but remember the oil viscosity changes with temperature.

assuming the proper bearing clearances and proper oil pump, was selected,and oil pump pick-up installation were done,

the two most common reasons I see for low oil pressure are related to either the oil pump pick-up mounted too close to the oil pan floor

(3/8' clearance is about ideal) or trash/debris getting into the oil pressure bye-pass valve spring area

keep in mind the oil pump pressure relief spring has ZERO effect on oil pressure other that to limit the peak pressure, it has zero effect on pressure vs rpm until PEAK oil pressure is exceeded, when the pressure is limited by the pumps routing high pressure oil back to the intake side of the oil pump

read the related threads and linked info, below

it sure can't hurt and in most cases will help a great deal

not getting oil to rockers

" HEY GRUMPYVETTE??? What would cause 70lbs of oil pressure at idle and none to the push rods? Gauge is good. I put in a new hv oil pump and still no oil. HELP!!!!!!!!" just a tip guys, any ELECTRIC DRILL is going to have a difficult time spinning an oil pump priming tool , without heating up...

garage.grumpysperformance.com

Oil pump priming

I have attempted to prime and pre oil the system in my 355 build using the tool shown on Grumpy's stickys but am not sure if all is as it should be. The filter was filled pre installation and the balance of the 5 quarts of oil poured into the lifter valley. The tool in inserted and run with a...

garage.grumpysperformance.com

oil system mods that help

heres a short list REMEMBER the object or goal in building and maintaining the lubrication system is too maintain a 100% dependable pressurized cooling flow of lubricant to the bearings, rockers ,valves etc. your most important tool, is your ability to think about how things are supposed to...

garage.grumpysperformance.com

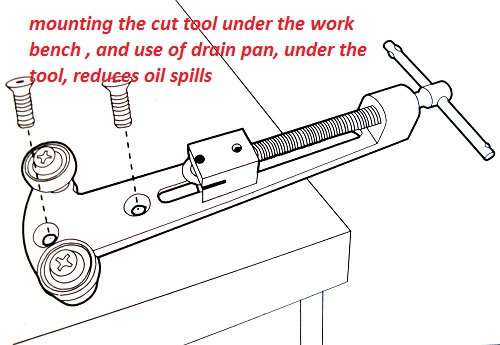

installing an oil pump pick-up tube

there's two ways ,...... you can use the correct tool, which is ADVISABLE! use this oil pump(link below) in most stock SBC builds, as it produces a 10% increase in oil volume and standard pressure which is just fine , but obviously check your bearing clearances and oil pump to oil pan floor...

garage.grumpysperformance.com

keep in mind the oil pump spins at 1/2 the speed of the crank so at 2000rpm on the tach the oil pumps spinning at 1000rpm. and the oil pump gears teeth move a set volume of oil flow thru the pump at any rpm level, the oil trapped by the pumps gears can only move as much oil volume as the gears sweep volume allows, high volume oil pumps have longer gears,of similar diameter to stock gears,the extended length is there to add more volume, so they trap and push a greater volume of oil thru the pump body, with each rotation.

standard volume oil pumps use shorter gears than high volume oil pumps, the 10%-25% extra flow is the result of the 10%-25% extra gear length

Ive always found the best results from keeping the low rpm pressure , in the 15psi-20psi at hot idle and no more than 65psi at high rpms,is really useful, the volume required depends on the way the engines clearances and oil systems designed or modified ,volume/viscosity/clearances in the approximately stock range works fine in most .oil pressure, will be determined by the difference in RESISTANCE too oil flow volume produced by the pump and the volume exiting the bearing clearances listed below, up to the point where the by-pass piston,held closed by the by-pass spring resistance , of that spring is forced open allowing oil to recirculate thru the pump to the low pressure side, limiting further pressure increases. as the oil temp increases the viscosity tends to decrease, this, lower viscosity or thinner easier to pump hot oil, flows thru the clearances faster,this lowers the resistance to flow thru clearances thus the pressure drops as the resistance to flow decreases

OIL PRESSURE read on the gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but it has zero to do with anything else, if its functioning correctly,During testing the bye-pass circuit in the oil pump should open, allowing high pressure oil to flow back to the feed or low pressure side of the oil pump, and limit oil increases,in pressure too either about 60-65psi or 65-70psi depending on the resistance of the bye-pass spring selected

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

your 55 psi at idle serves no purpose as 15psi-25psi is all thats expected in a new engine with tight clearances using a good 10W30 oil, if your using a higher viscosity than 10w30 its reducing oil flow rates and reducing heat transfer rates, Id suggest using a good 10W30 oil. and use of a 7-8 quart, baffled oil pan and windage tray

the idea that you can 'pump the pan dry" with a high volume oil pump, in a properly set up chevy engine has been proven false dozens of times, thats a myth , oil pumped thru the engine drains back to the sump rapidly in a properly set up engine.that myth been repeated for decades and the reason its gained its supposed verification as fact is simply that guys install a high volume oil pump in the same engine that they just removed a stock oil pump from and find that they reve the engine and the oil pressure starts to go up then tops out or even drops off , the instant and wrong conclusion drawn is that the high volume oil pump sucked the oil pan dry, but what really happened in almost every case was a bit simpler.

high volume oil pumps have a longer body that moves the oil pump pick-up closer to the oil pan floor and if the clearance is not checked and corrected to maintain the required 3/8"-1/2" minimum clearance it severely restricts the flow into the oil pump and pressure drops of as a result of the restriction on the intake side of the oil pump pick-up.

Melling M-77 Melling Oil Pumps | Summit Racing

Free Shipping - Melling Oil Pumps with qualifying orders of $109. Shop Oil Pumps at Summit Racing.

when you inspect the bye-pass piston and spring or replace the oil pumps bye-pass spring, in the oil pump you must be certain it smoothly slides through the internal passage , if it binds it will cause issues with erratic oil pressure

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

keep in mind that as oil temps increase the oil viscosity tends to decrease, thus cold oil, at lets say 70F might cause the oil pressure gauge to read 50 psi at idle but the pressure reading slowly goes down to 25 psi once the oils reached lets say 210F, this is normal and expected

REMEMBER the oil pump bye-pass is designed to limit oil pressure reaching the oil passages in the block,to usually 65psi-75psi max, by opening and re-routing oil from the pressure side of the oil pump to the suction side of the gears one its forced open, this is not the same and has nothing to do with the oil filters oil bye-pass valve,

yes the BYE-PASS IN THE OIL FILTER DOES normally open on cold mornings, or under rapid changes in engine rpms, especially before the heat from the engine lowers the oils effective viscosity, Im fairly sure you have heard or remember hearing advise not to go doing stupid stuff like burn outs in your drive way until the engines reached and maintains operational temps

(usually oil and coolant has reached 190F-215F) well one big reason is that thicker oil viscosity when oils cooler ,takes a good deal more pressure to force thru the filter medium, once the oils fairly hot it flows better, and requires less pressure as it offers less resistance to flow thru the engines clearances and thru the filter, that in turn means that hot oil with its thinner effective viscosity tends to be far less likely to force open the filter bye-pass circuit and that means oil bye-passing the filter medium is far less likely to drag metallic trash held in suspension with it to reach the bearings to cause more rapid wear.the oil filter bye-pass is designed to bye-pass oil to the engine rather than forcing it thru the oil filter any time the pressure on the inlet side of the oil filter is higher than about 10 psi over oil pressure passing thru the oil filter, this in theory prevents the semi clogged oil filter from starving the bearing of oil.but it also means that during rapid rpm changes or before the oils up to operational temps some oil is routed around and past the filter, under the concept that dirty pressurized oil is far superior to no oil reaching the bearings.

MORE USEFUL INFO

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

I like high voluum pumps but I certainly don,t use them IF the engines nearly stock as the standard Z28 SBC pump works fine

"the standard volume pump gears are about 1.2" long the high volume pump gears are about 1.5 inches long (depends on manufacturer)

heres the discriptions right from chevy

12555884

SBC Oil Pump, High Pressure Z28/LT1. Production high-pressure oil pump with 1.20" gears.Will produce 60-70 psi oil pressure. Does not include screen. The pickup tube dia. is 5/8" for this pump.

62.17

the true high voluum pumps like this below are not necessary UNTILL youve done extensive mods that require the expra oil flow voluum

14044872

SBC Oil Pump, High-Volume. This high-volume pump has1.50" long gears.It has approximately 25% more capacity than a production pump at standard pressure. Does not include screen."

http://www.melling.com/Aftermarket/Tech-Tip-Videos

viewtopic.php?f=54&t=2187

ONE VERY COMMON MISTAKE MADE by guys swapping to a high volume oil pump is failure to carefully measure the pick-up to oil pan floor clearances, because the high volume oil pump has longer gears it tends to move the location of the oil pump pick-up lower towards the oil pan floor, if that distance is reduced too less than about 3/8" the common symptom is good oil pressure at idle but rapidly falling pressure as the rpms build as the oil pump intake is restricted significantly, this results in the common MYTH that high volume oil pumps pump the pan dry as rpms increase. when the truth is that its the result of not carefully verifying clearances

the answer to that question of what SMALL BLOCK CHEVY PUMP TO USE, depends on the application and the size of your oil pan, if your using a windage tray, your bearing clearances and a dozen other factors, reading thru the links posted below should be very helpful.

youll seldom have any problem using melling 10552, if its properly installed, in almost any small block, is roughly similar to the old Z28 pump and supplies a bit of extra volume at near stock pressure if you don,t install the optional high pressure spring, that pump should be fine in about 90% of the street strip engine builds

http://www.summitracing.com/parts/mel-10552

related threads to read thru

OIL PUMP MODS

http://www.corvette-restoration.com/res ... ancing.htm

http://www.youtube.com/watch?v=tOiHdIXV ... r_embedded

READ THIS THREAD

small block pumps have 7 tooth gears and 4 bolt covers and don,t provide the smooth oil flow rates the 12 tooth, and 5 bolt cover big block gear pumps provide

In this comparison, you can see the major difference between a high-volume small-block pump gear (left) and the Rat motor gear (right). The Rat motor pump enjoys a larger diameter and more pump teeth that should create a more stable output curve.

every choice you make is a compromise in some area

yes it takes a couple more horsepower to spin a high volume oil pump, at peak rpms, as its doing significantly more work, pushing cooling and lubricating oil flow at a higher volume, but in exchange your getting faster and greater volume of oil flow over the whole rpm range that is slightly more effective at cooling the valve train and bearings, and at start up this tends to reduce wear over time, and in my experience its to your advantage to use a standard volume bbc oil pump in SOME sbc performance applications

remember the oil pump drive only seats in two locations 180 degrees apart but it can be lined up anyplace you want with a 18" long large flat blade screw driver prior to installing the distributor from the top of the engine rather easily before you re-seat the distributor, but as the distributor gear teeth mesh the distributor will turn the rotor about 15 degrees

BTW, , on BIG BLOCKS the oil pumps and oil filter adapters are different due to the block oil filter recess and rear seals being different

GEN 4 or MARK IV

GEN V and VI

Gen V/VI oil filter pad contains two bypass valves, one for the oil filter (A) and one for the oil cooler (B). The filter adapter, which is nothing more than a threaded fitting to mount the filter, has been removed in this photo to show the recessed oil cooler bypass valve. Oil cooler fittings thread into the cooler outlets (C) to the oil cooler and the return (D) from the cooler. If you are not using an oil cooler, you should remove the cooler bypass valve (B) and plug the cooler line holes (C and D) with 1/4-inch NPT pipe plugs. The bypass valves are a light press fit in the block and may be removed by threading a long 3/8-16 bolt into the valve and wiggling it free, which usually damages the valve. That’s okay, because replacement valves are inexpensive and you want to replace the old one with a new bypass valve (GMPP PN 25013759). Note that Gen V/VI rear main caps require an O-ring that fits in a recess in the block (E) to seal oil delivery from the pump.

Read more: http://www.carcraft.com/techarticles/cc ... z2RyXV6xCI

big block vs small block chevy oil pump

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears

your typical big block oil pump has a 5 bolt cover, a 3/4" pick-up tube diameter and the pick-up presses into the pump body , it has the larger more efficient 12 tooth gears and in many cases can be mounted on a small block, but its usually not required

BIG BLOCK CHEVY 5 BOLT cover pump

SBC 4 BOLT COVER OIL PUMP

SBC pumps have 7 tooth gears and BBC pumps generally have 12 tooth gears making the flow more consistent

oil is sucked up the pick-up (or pushed in by the pressure difference, if you need to be technical) into the pump body and swept along the outside walls of the pump,by the rotating gear teeth,and forced thru the pumps pressurized exit port passage in the pump casting, then the pressurized oil is forced thru the rear main cap on the block, fluids are not compressible, so , if the resistance to the oil flow increases, the resulting oil pressure increases until it exceeds the bypass circuit springs resistance, on the bypass circuit piston , this forces open the bypass circuit piston in its bore allowing the excess pressurized oil to bleed back into the low pressure side of the oil pump casting, thru a passage in the oil pump casting designed to limit peak oil pressure,that the spring loaded piston in the pressure relief circuit controls, the flow rate, until the pressure drops below the oil pumps pressure relief spring resistance , when the spring forces the passage to close as the small piston on the spring closes the pressure relief passage acting as a valve, that controls and limits peak pressure.

the pumps secured to the rear main cap with a stud or bolt and its indexed with the twin pins,in the rear main cap, that fit the holes in the pump casting.

the pumps spun with a drive shaft that connects the distributor gear and cam gear interface

the by-pass circuit has no effect on oil pressure other than to control the peak pressure, that can be reached before the circuit opens and limits further increases, installing a stiffer spring only delays the circuit opening point until a higher pressure is reached and has zero effect on the oil pressure up to that point in the pressure curve. a common problem is guys failing to remove the spring & piston assembly prior to brazing the oil pump pick-up onto the pump casting as the heat can anneal the spring temper reducing its resistance, thus reducing the pumps peak pressure or failing to clean and oil and properly re-assemble the oil pumps by-pass circuit components which can result in the piston binding in its bore and not allowing the by-pass circuit to open and function at all.

in years past it was fairly common to use a small washer to shim the by-pass spring to add a few extra pounds of resistance before the circuit opened, if done correctly this worked but it was common for guys to screw it up and its not advisable to go that route, as stiffer springs designed for the job are cheap and easy to install.

I,d also point out that while oil pressures over 60 psi are certainly easily reached they provide little or no improvement in lubrication, you need to try to maintain a minimum of about 10-15 psi per 1000rpm and Ive generally found a 20-25 psi at hot idle and 60-65 psi at peak rpms to be ideal.

the oil pump pumps oil out this exit passage to the main cap

heres the matching rear main cap surface

below you can see the inlet and outlet for the pressure relief passage in the big block oil pump(remember big block pumps have the pick-up in the main pump body while sbc pick-ups are mounted into the pump cover plate)

look at the picture below, the restrictive stock O.E.M. pickup if placed to close to the oil pan floor becomes a HUGE restriction to oil flow rates

you should NEVER shim an oil pumps pressure relief spring

back in the 1950s-1960s it was common to pull the pressure relief spring retaining pin in the oil pump that retains the pressure relief spring and insert a washer , between the pin and spring to add pressure to the spring, thus forcing the pump to build more pressure before the relief valve opened, this was before properly designed higher pressure springs were available, this could be done but it frequently caused problems

as it reduces the clearances and may cause spring coil stacking before the pressure valve opens fully,it may prevent the piston that pressure relief spring holds from moving back down its bore far enough to allow it to open the by-pass passage, that shim behind the spring causes a reduction of distance it can travel to open the oil pressure release, valve or allow return oil flow through that passage allowing the pressure on the high pressure side of the oil pump from bleeding off back into the intakes low pressure intake side of the oil pump, the oil pump relief springs come in several resistance strength levels, but extensive testing has shown no increased bearing protection at pressure levels exceeding 65 psi, higher strength pressure relief springs,

just increase engine rotational resistance

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

(1)

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

there are oil pump testers available commercially or if your mechanically inclined you can fabricate one with reasonable care, after a bit of measuring and purchasing a gauge

http://cvrproducts.com/oil-pressure-test-kit/

one point I should mention is that if you manage to wipe out a lifter and cam lobe, much of the the metallic trash is ALWAYS sucked thru the oil pump gears and its frequently packed into the pressure relief ports significantly reducing oil pump efficiency, so at a minimum it will require dis-assembly and careful inspection and cleaning and, if run awhile before you detect the problem, usually replacement

keep in mind fluids like oil, are not compressible the resistance to flow increases as the pump is turned simply because the oil flow exiting the oil pump is flowing through the bearing clearances thus the oil flow exiting the oil pump is being restricted, if the engine was rotating the restriction too oil flow is reduced.

if the oil pumps pressure relief valve opens as designed max resistance is limited to the pump producing flow rates that will build until resistance to that flow volume reaches about 60 psi, when the pressure relief valve opens recirculating additional oil flow back to the low pressure side of the oil pump.

remember volume increases as rpms increase up to the point where the relief valve opens limiting pump flow.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/page-2#post-75256

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/#post-68205

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

VS AROUND IT INTO THE BLOCKS OIL PASSAGES,

oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter,

down through the case and filter element and up through the central hollow screw retention stud,

into the blocks oil passages, if the resistance too flow is too great,

the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

theres a great deal more info in these threads & links

http://www.chevyhiperformance.com/techa ... index.html

http://www.livermoreperformance.com/gm_oil_acc.html

http://www.enginebuildermag.com/2012/07/performance-oil-systems/

http://www.hotrod.com/articles/ccrp-0911-small-block-chevy-oil-pumps/

http://www.enginebuildermag.com/2008/10/oil-pumps/

http://garage.grumpysperformance.co...high-volume-high-press-or-both-oil-pump.2294/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://www.superchevy.com/how-to/148-0506-lubrication-systems

http://www.onallcylinders.com/2014/10/23/oil-well-choosing-proper-pressure-volume-oil-pump/

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=1800&p=5526&hilit=brazed#p5526

viewtopic.php?f=50&t=382&p=467&hilit=MAIN+CAPS%E2%80%A6#p467

Last edited by a moderator: