OK you've decided you can,t live without a killer 383 sbc,

you need to select the parts and you want to build an engine you can be proud of,

the first question is whats your budget look like,

quickly followed by what will you be using the engine for,

and do you have the drive train to match that engines power curve.

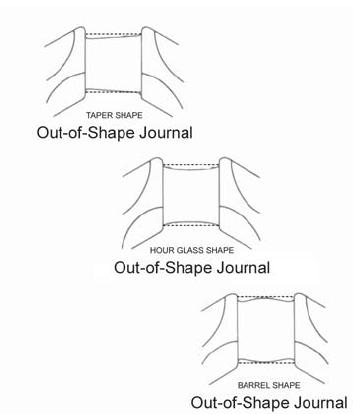

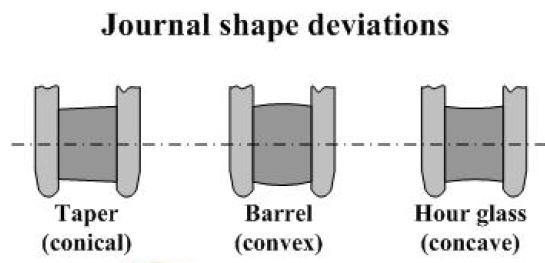

be sure you, measure EACH bore and EACH piston,

(CORRECTLY with the proper tools in the way the tool and piston manufacturers suggested)

and number them on an engine build sheet indicating the bore and piston diam.

from large to smallest on each and install them on each cylinder to get the most consistent piston to bore clearance's

yes the difference may only be a few ten thousands if the bores are machined correctly, but you'll get the best results , most consistent lubrication, best durability and less heat build up that might result in detonation issues that way. its the little things that add up to making a good durable engine assembly,

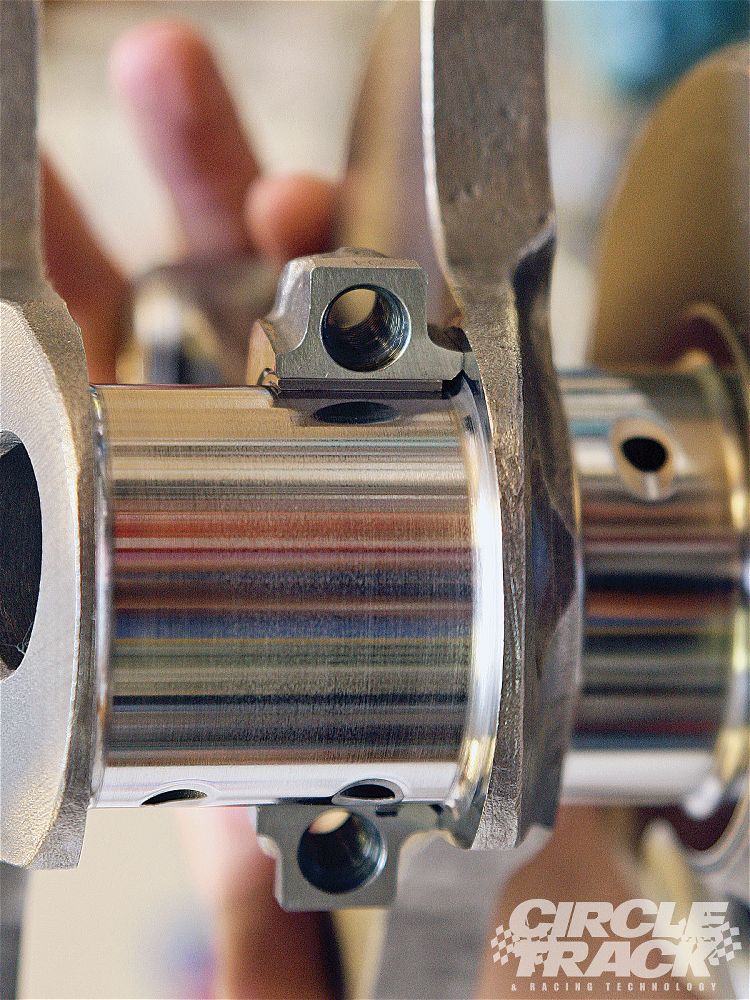

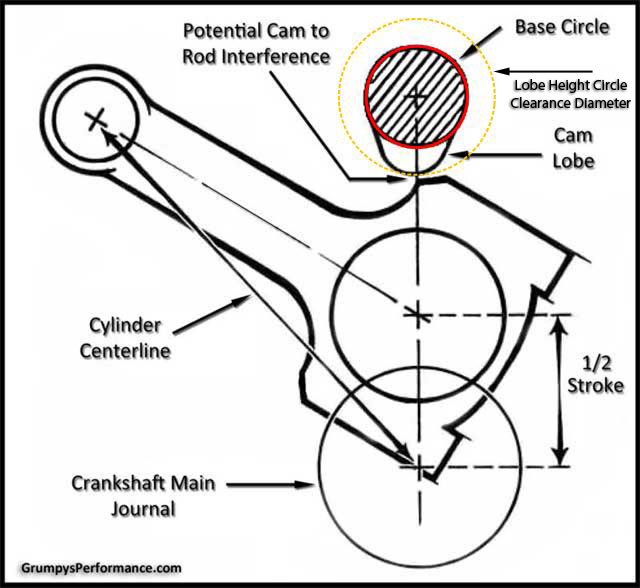

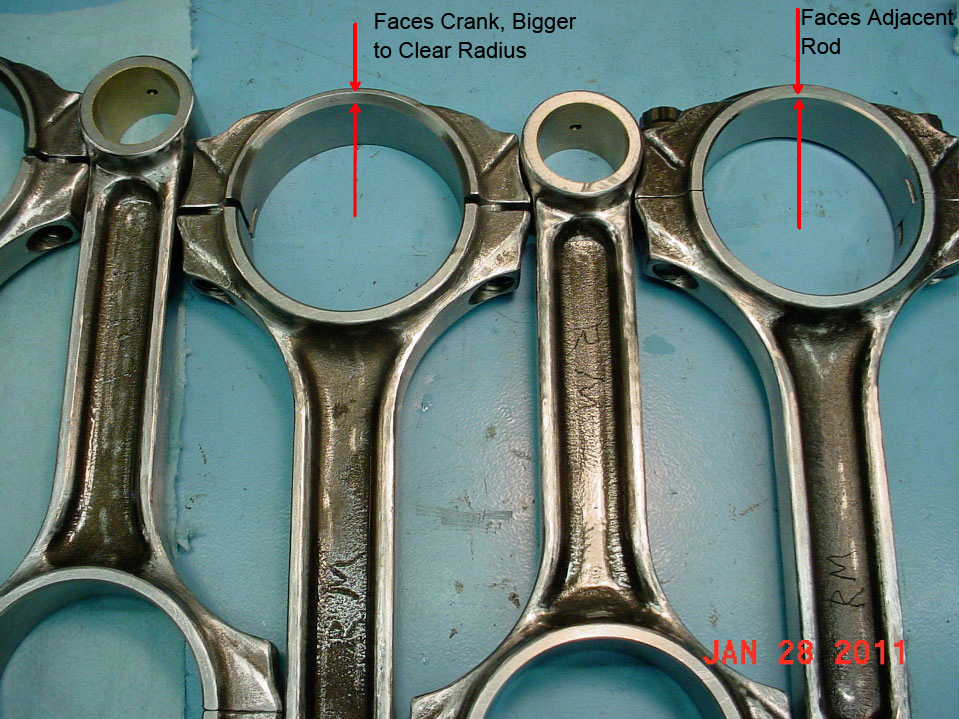

BTW check rod orientation, so the beveled sides don't fact the adjacent rods, and check the bearing clearances with plasti guage

every part you choose is a compromise , and may require changes,

that cost you in time, money or performance to some degree,

and almost every part will require a bit of fitting or clearance work,

or adjustment to fit and function to get the best results

if it drops out of the package and bolts together as it drops out of the package,

its almost certain its not functional to nearly its full potential

your job is to think things through carefully and make sure parts fit and function to their full potential,

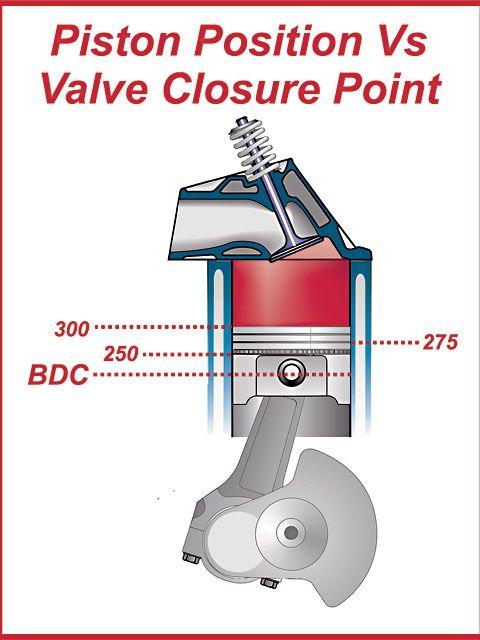

little things like checking piston ring end gap, verifying bearing clearances, and ccing the heads and checking piston to valve clearance, degreeing in the cam and verifying the valve train geometry, polishing combustion chambers, getting a decent 3 angle valve job,verifying the piston to bore clearance, MATTER's

and theres that P.I.T.A. FACT that building an engine to produce impressive PEAK POWER,

you can brag about to your buddies almost always results in an engine with less than ideal street drive-ability,

especially if you want good gas mileage or like to cruise at 2000 rpm

every choice you make is a compromise in some area,

if you want massive low and mid rpm torque and instant re responsiveness, in your engine your very likely to be trading those characteristics at the expense of high peak horse power, if you want bragging rights and impressive power your very likely to pay a price in less than ideal manors in traffic and loss of low rpm power , theres EASILY A POTENTIAL OF 80-120 HORSEPOWER DIFFERENCE IN YOUR SELECTION OF HEADS CAM AND COMPRESSION RATIO ALONE

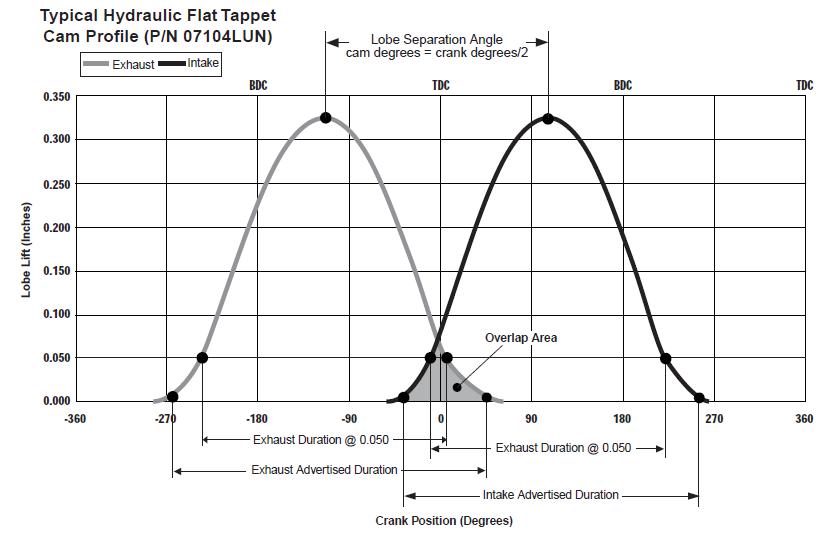

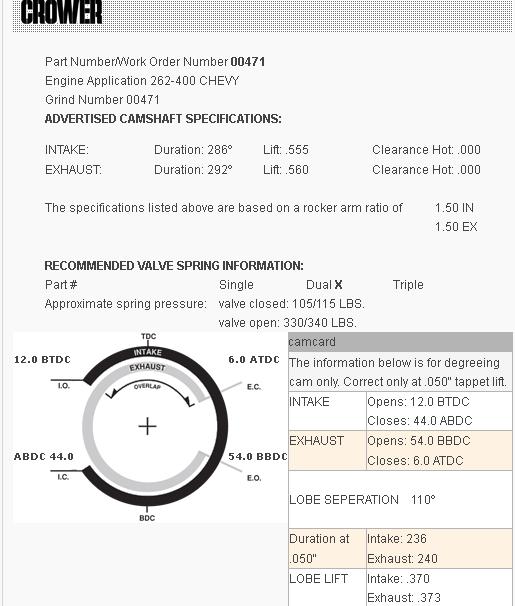

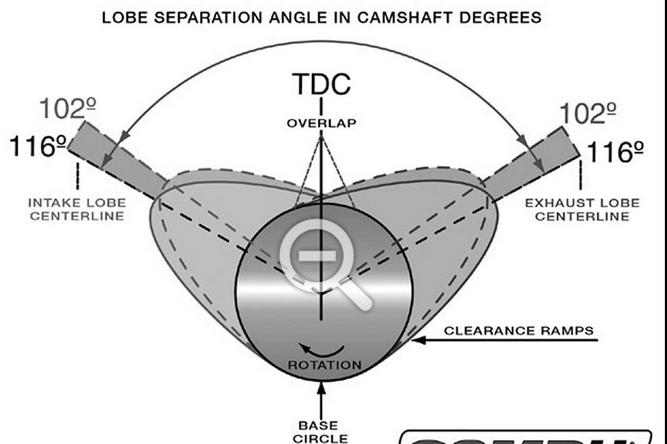

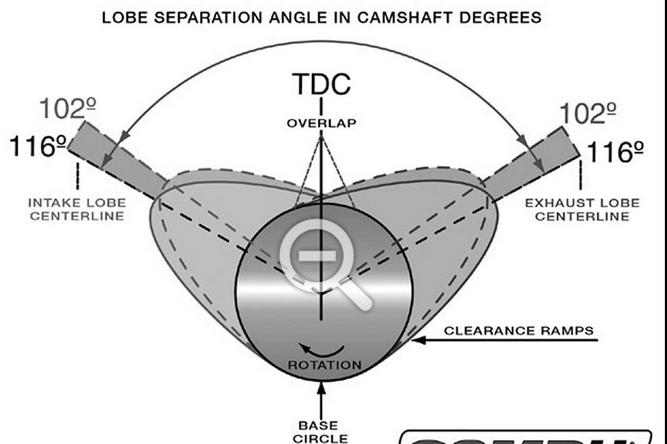

wider LSA smooths out the idle but it reduces overlap, the increased overlap tends to allow cylinder fill at a bit higher rpm and it also tends to kill off a bit of low rpm torque

http://www.chevytech.com/2c40o8.html

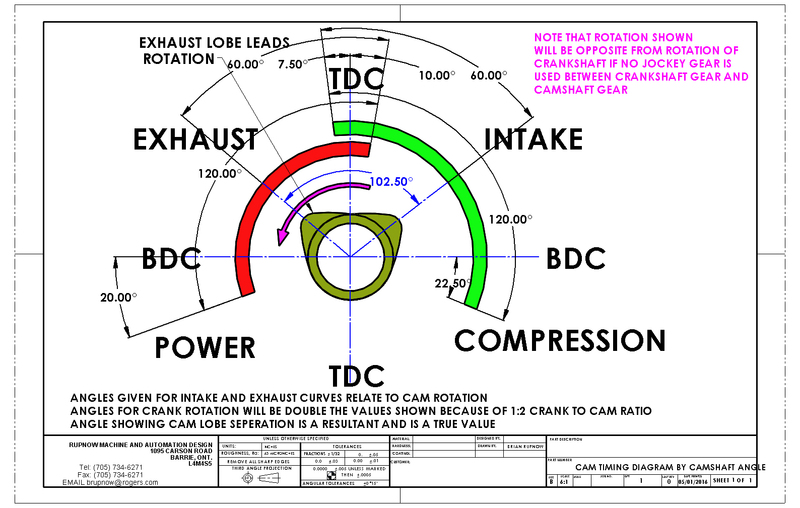

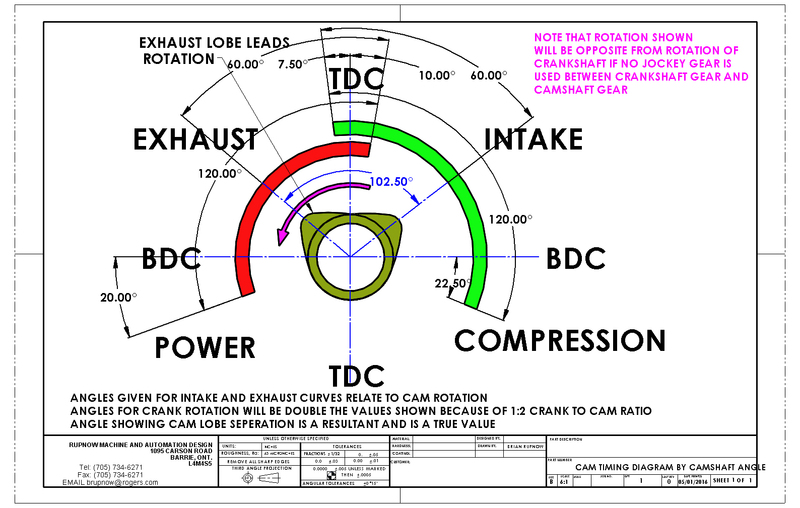

The following tables illustrate how variations in lobe separation angle and cam

timing will effect the behavior of the engine in which the camshaft is installed.

EFFECTS OF ALTERING CAMSHAFT TIMING

Advancing.......................................... Retarding

Begins Intake Event Sooner................. Delays Intake Closing Event

Open Intake Valve Sooner ........................Keeps Intake Valve Open Later

Builds More Low-End Torque................. Builds More High-RPM Power

Decrease Piston-Intake Valve Clearance Increase Piston-Intake Valve Clearance

Increase Piston-Exhaust Valve Clearance Decrease Piston-Exhaust Valve Clearance

you would be foolish to ignore the available info, in these links

http://www.camquest.com/

http://www.hotrod.com/how-to/engine/ccrp-0808-383-stroker-small-block-chevy/

http://www.strokerengine.com/SBCHeadsFlow.html

search.php?search_id=active_topics

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55571

http://www.technovelocity.com/chevyhack ... cation.htm

http://www.chevyhiperformance.com/techa ... ine_build/

if your building a sbc street/strip engine every component works a part of a total system, your always restricted by the weakest link in the chain, or the biggest restriction, and with engines its air flow rates, fuel/air ratios,cylinder scavenging,ignition advance curve and compression that determine a great deal of your potential power.

REMEMBER A MANUAL TRANSMISSION ALLOWS YOU A GREAT DEAL MORE FLEXIBILITY IN CAM SELECTION

keep in mind you need to think thru the combo as a package where all parts selected must complement each other and be designed to operate in approximately the same basic rpm band and flow and effectively burn and use the pressure generated from similar amounts of fuel/air mix.

one very common mistake is selecting a cam duration,that exceeds or limits the engines rpm band, a rear gear ratio,thats not matched to the intended power band,or selecting a compression ratio or set of heads that can,t operate with the other components in the same power band efficiently

the best heads matched to a restrictive intake or the wrong cam will result in a DOG just as surely as a great intake and crappy heads with low compression, or any of a few dozen other miss-matched parts.

I think most of us have run into a great many similar choices, between buying tools and auto parts,

its simply the result of a limited budget ,in most cases,

and most of us make a few mistakes ,

but as long as you keep the goal of building the car in mind you'll do ok.

after you gain experience there's both engineering and art involved in the process,

you'll generally start with a goal, you've envisioned for your car, reality and physics will provide some of the limitations, you'll be limited to a budget and at times by your access too tools and limited by your skills and knowledge, youll generally start,by simply making a very detailed list of the components you want too use ,to upgrade and modify the car to gain the performance and look of the car, and once you have that list of components, and being forced by going back through that detailed, list and doing the required math too verify you have selected the correct matching parts, and when you find you have to change a few components you go back, change the list and again revue the math, most of us start out without the required knowledge to accurately match parts and your goal.

yet this process forces you to do some research into what you can reasonably accomplish with the tools and skills you have and the realization that you may need to acquire both skills and more tools as you proceed. as you read through most of the builds listed and discussed on this web site,

youll eventually see a strong trend, towards what I and many other knowledgeable engine builders have been forced over time into recognizing.

the trend is simply that only engines built for max long term durability and max torque in the useful rpm range are making any financial sense.

as Ive stated many times, you have to finish a race to win it! and your never going to build a client base ,

if the engines you build make killer power on a dyno but need rebuilding in a couple months time.

theres several threads on builds here on this web site, and a great deal of time and research is devoted to extended durability, cooling and lubrication ,

and carefully selecting components, and machine work done, designed for max strength, for the dollars spent!

I used to ask guys

"would you prefer to build an engine that if you keep it well tuned and change the oil regularly,

will most likely still be running in 10-12 years, without changing major components, or

would you rather have an additional 25-30 hp,and need a rebuild every 3-6 years,

but have a much better chance it won,t last half that time span....

especially in a muscle car driven on the street,

where either engine choice will destroy street tires effortlessly,

and get you a ticket effortlessly for speeding any time you get stupid?"

READ THIS LINKED INFO

Change Cam - Gain 78 HP ..... "article on page 22, in the magazine" [Best of Tech /Winter 2003]

A few years ago there were claims by a magazine of adding 78 horsepower to a wimpy 8.6:1 compression-ed 355 sbc equipped w/"the usual hot rodding parts" headers, 750 Speed Demon carb, Edelbrock Performer RPM Air-Gap intake, 2.02/1.60 Summit aluminum heads, MSD, ect.

Just using an Erson TQ40 cam kit [218/228@.050 duration][.472 valve lift, w/1.5:1 rockers]

instead of the stock small block Chevy [195/202 duration] factory type [.390/.410 lift] camshaft ...

Using this Erson TQ40 cam, it showed gaining a maximum of 78 hp @ 5,600 RPM = [403 hp/maximum] .....

and gaining 20 pounds of torque, @ 4,400 RPM = [418# torque/maximum] over the stock low lift camshaft.

Oddly enough, from 2,000-to-3,900 RPM, results were [-1 horsepower] and [-4 pounds of torque].

Average gains from 2,000-to-5,900 RPM, were 44 horsepower & 35 pounds of torque .....

This Erson TQ40 cam showed gaining 78 hp & 78 pounds of torque, from about 4,000-to-5,900 RPM.

now 78 hp gain looks impressive but if you retained the stock rear gear and converter youll spend very little time in the 4000rpm-6000rpm power band so a cam like that won,t produce nearly the gains, in performance you might expect without making the matching drive train mods so the engine operates mostly in the new higher average power band, it makes little difference if your engine makes 100 more hp if it makes it only in an rpm band you seldom reach or use!.

if you want the car to run decent you need to significantly increase the air flow rates,and feed the required fuel to maintain the correct f/a ratio and that requires much better flowing heads,much better flowing intake and a cam with more lift and duration and a higher stall speed converter and a 3.54:1-or- 3.73:1 rear gear ratio

a cam that will move the intended power range high enough to make that intended power curve is required , but planing where in the rpm range that power curve is strongest is your first decision,..... all the components selected must match,that intended power curve, and the cam, compression ratio and head flow need to match that combos goal, you can build a good street combo with massive torque in the rpm range you normally drive, (usually 1800rpm-4500rpm, on most street cars) for use on the street or you can build a race engine with far better peak power (up in the (4500rpm-6500rpm range) but it won,t be nearly as much fun to drive at low rpms or on the street, in fact its only going to work great on a dyno or where you can drive while keeping the engine rpms in the 4500-6500 range in most cases

keep in mind if your gearing keeps the engine rpms in the 1500rpm-5500rpm range and the transmission shifts at 5500rpm under wide open throttle like most nearly stock engines do its rather useless to cam the engine or use heads designed to maximize power in the 5500-700rpm range

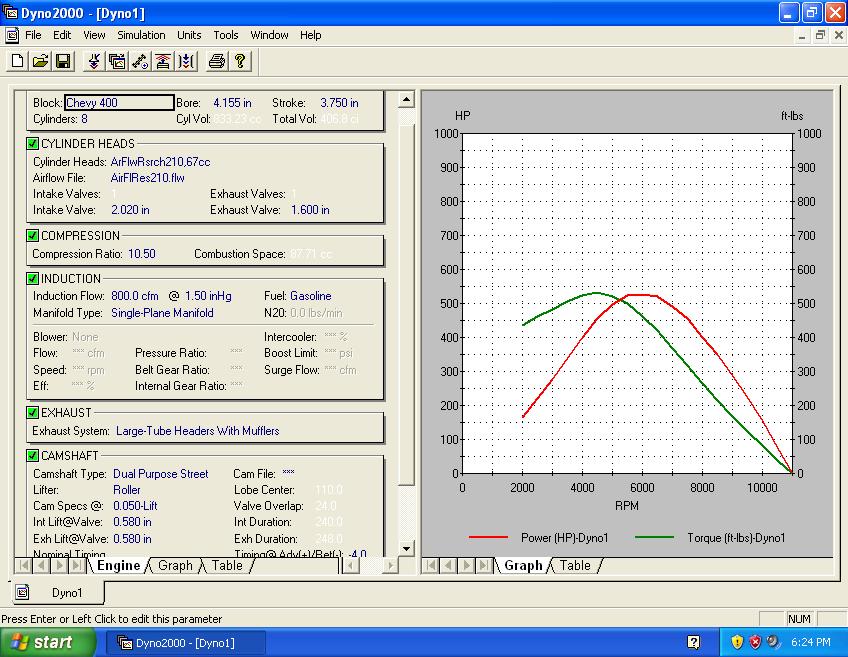

put your info into this program, don,t exaggerate or lie, just input what you really have top work with

http://www.camquest.com/

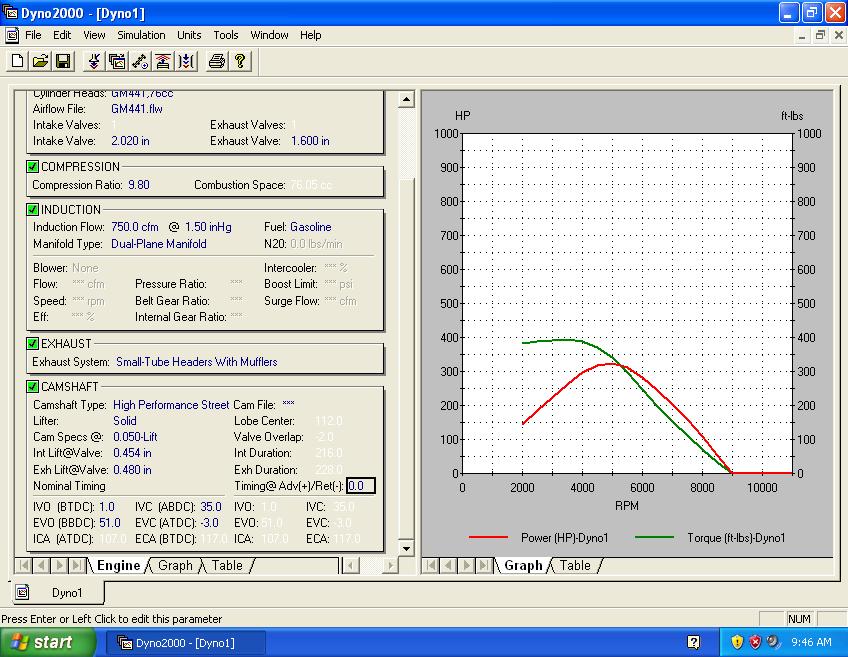

a typical sbc makes about 1.1 ft lb of torque per cubic inch of displacement

your torque curve depends mostly on your engines displacement,compression,head, & intake flow and cam timing

the formula for hp is torque times rpm divided by 5252=hp

a higher torque peak generally increases power

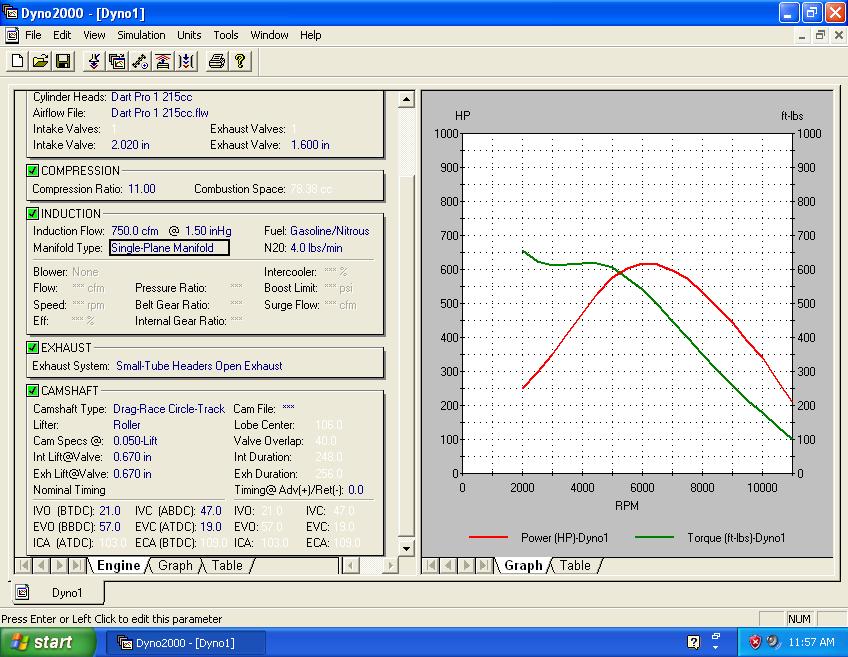

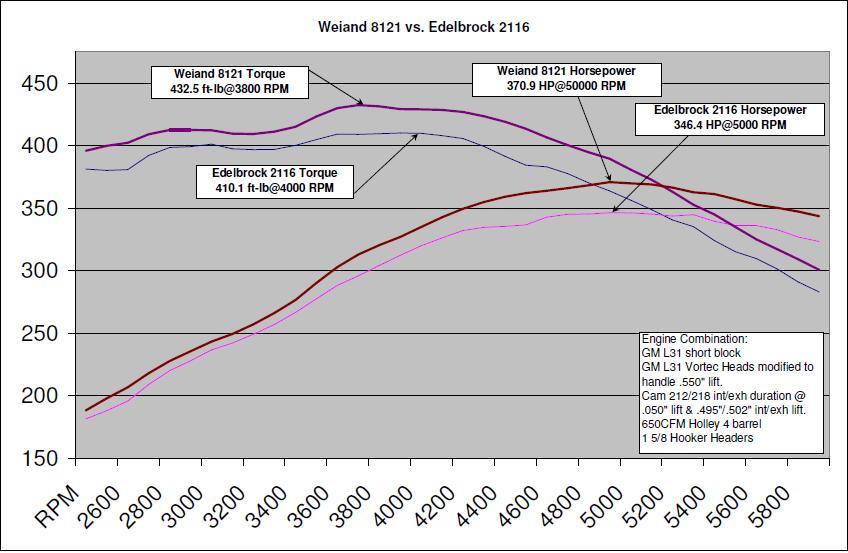

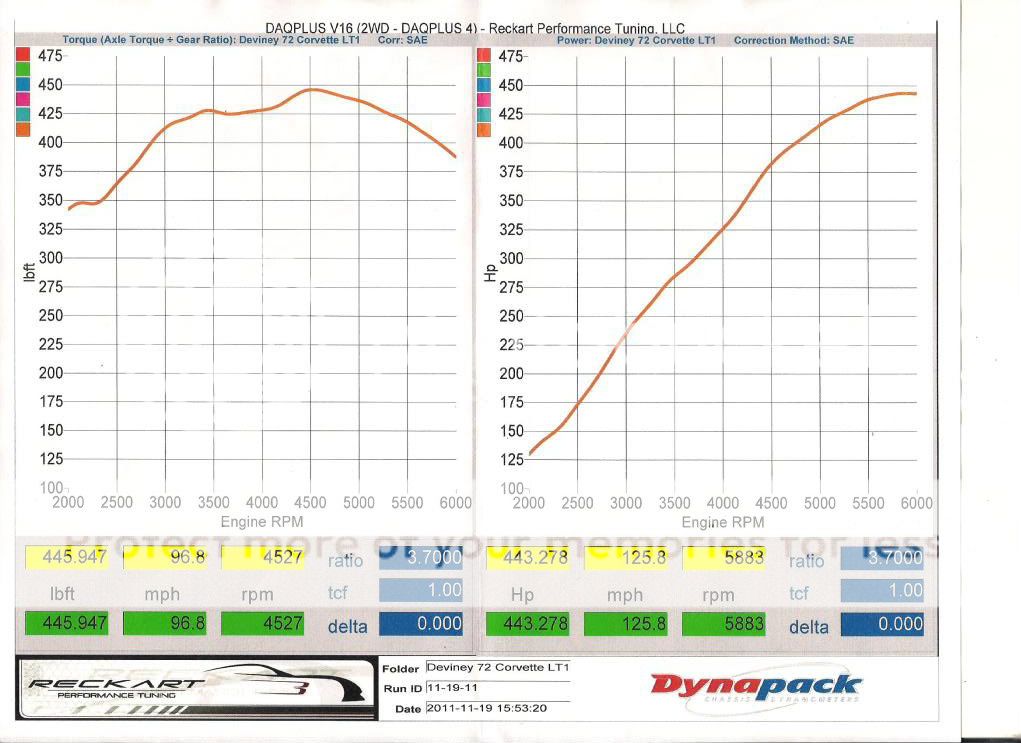

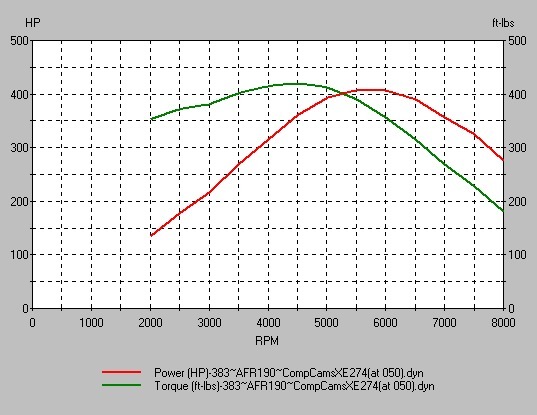

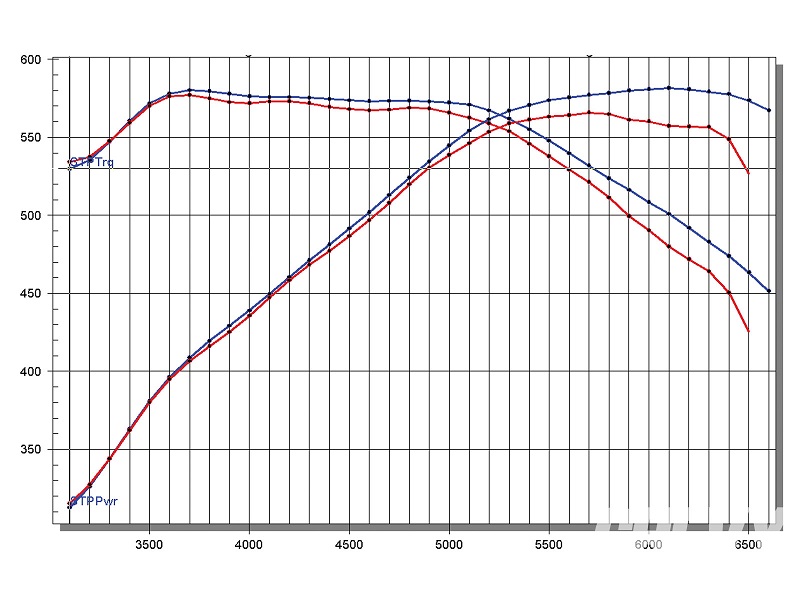

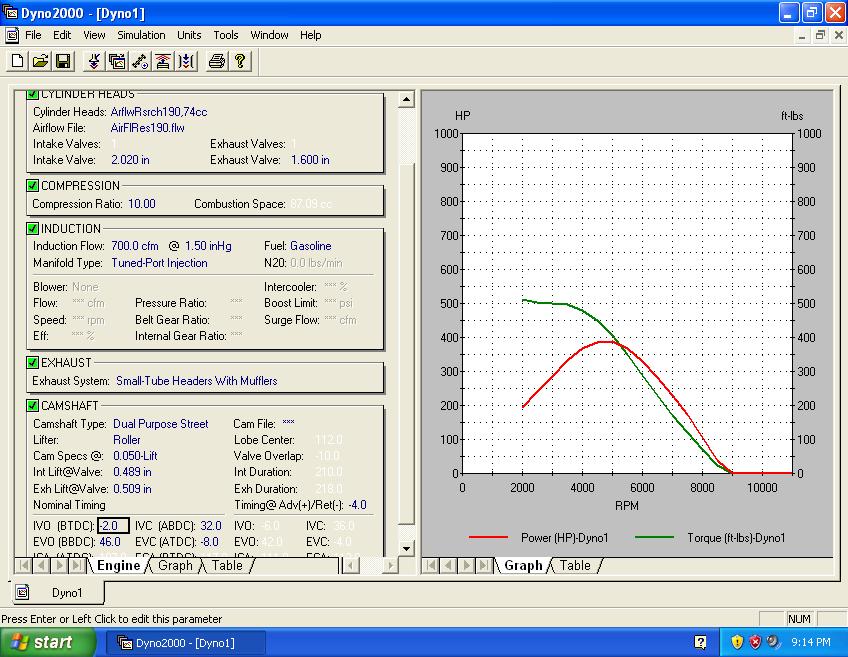

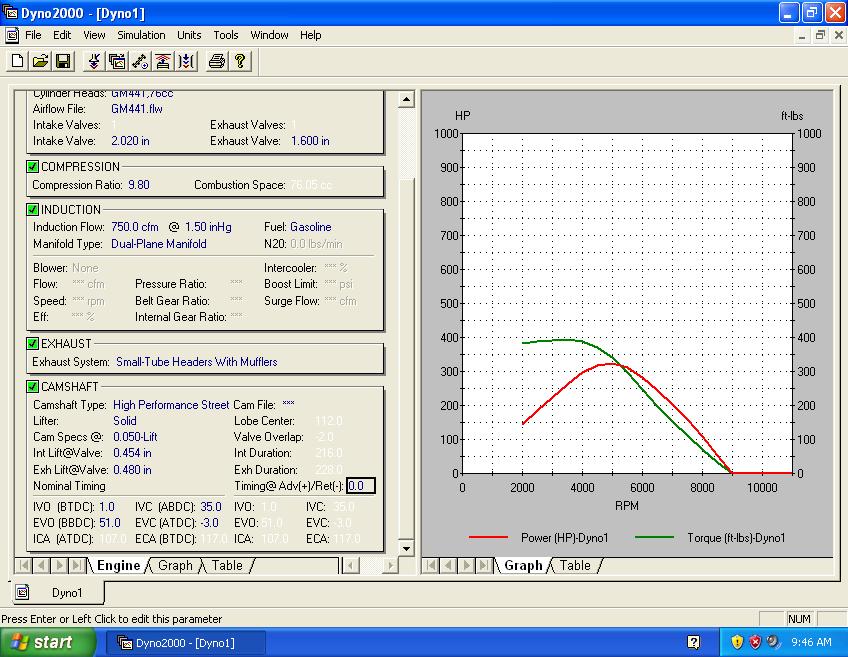

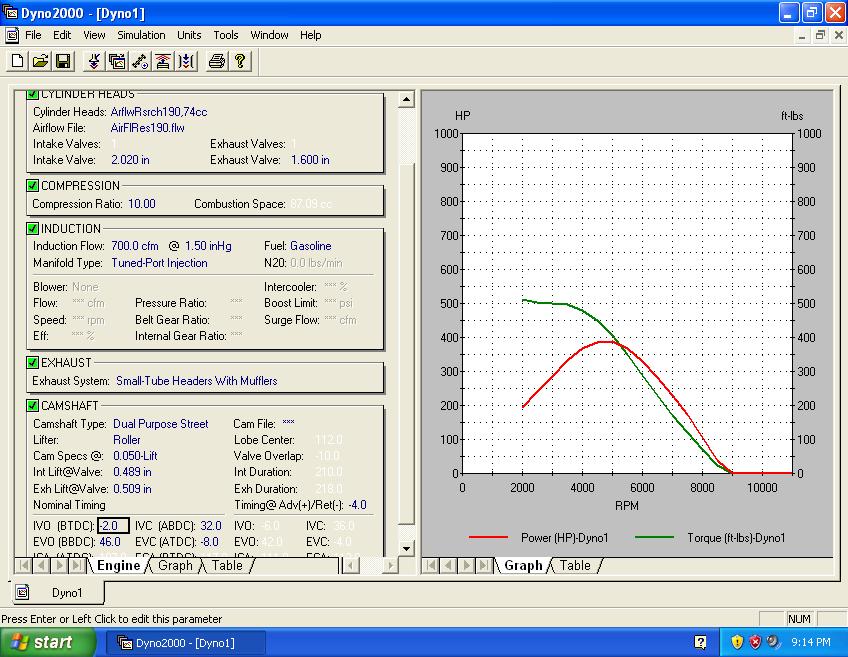

this is a very typical dyno chart from an engine with stock heads a mild cam and stock exhaust and intake, as all components are designed for max low and mid rpm torque, you can easily move the peak hp and torque number higher , with larger head ports cam duration, better intake and less restrictive headers and exhaust but doing so tends to reduce the off idle responsiveness and torque, as every choice is a compromise in some area.

example

400 ft lbs at 3500rpm=267hp

400 ft lbs at 5500rpm=419hp

400 ft lbs at 6500rpm=495hp

you'll want to run about 10:1 cpr on the street to maximize performance, because on pump gas thats about the max you can use, but the cam selected effects the dynamic compression ratio so you can use a bit more compression with a longer duration cam and a bit less with a lower duration,

heads that flow about 250cfm or more at .500 lift are going to be a huge asset, but the port cross sectional area will tend to vary based on where you want peak hp,

if your going for an aggressive combo a bit more on the race end of the scale but a compromise to keep it semi-street-able, you'll usually need a 3.54:1-3.73:1 rear gear and a manual transmission or a 2700rpm-3000rpm stall converter to maximize acceleration, with a cam that's designed to maximize power in the 3000rpm-6300rpm band

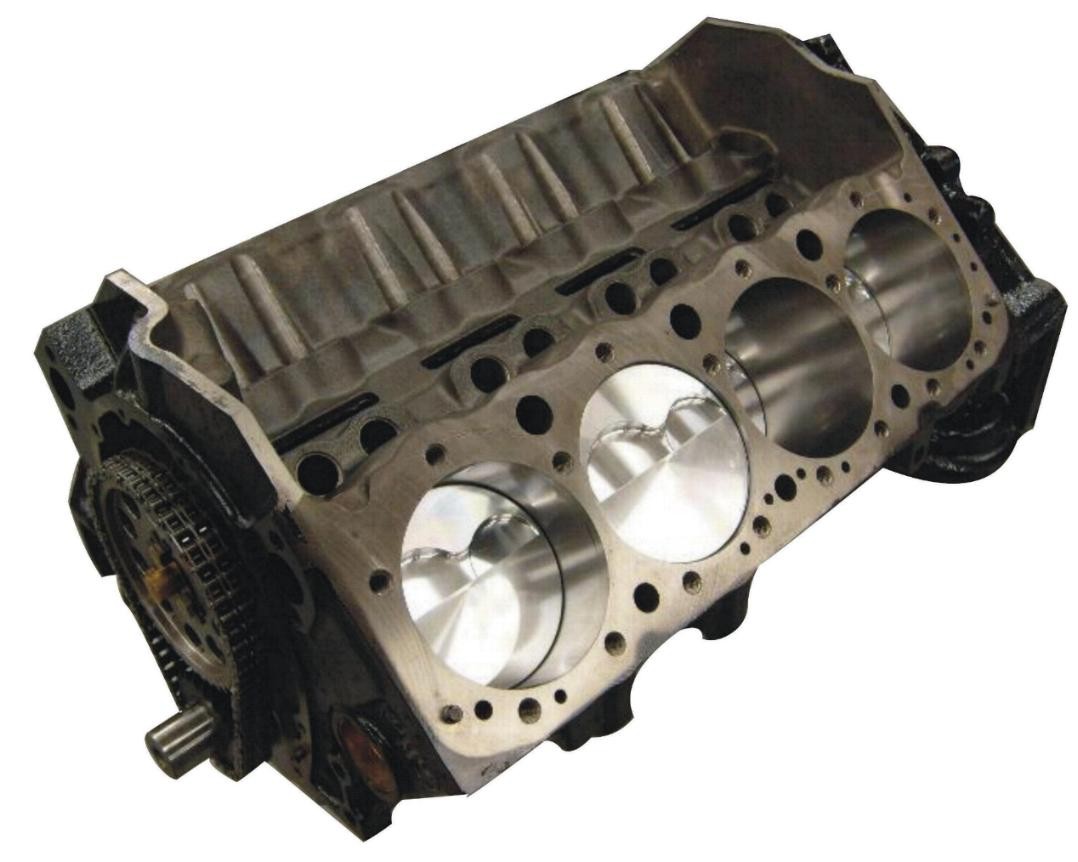

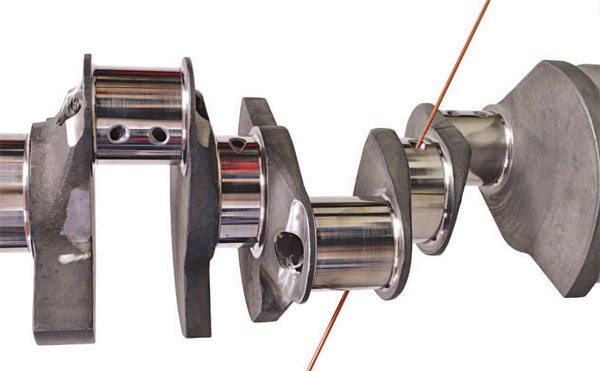

personally if I was building as hot street combo, Id select a complete rotating assembly with matched components,from a single supplier, it will tend to avoid problems or finger pointing if parts don,t match and fit, specifically say you want those components and balanced, a good scat cast STEEL 9000 balanced crank and 5.7" connecting rods with 7/16" rod bolts,and forged pistons, do the research and make sure you get match and balanced parts

If it was a street and race combo ID also specify INTERNAL BALANCE and 4340 forged rotating parts

YOU CAN LEARN A GREAT DEAL, ABOUT COMBOS THAT WORK, IF YOU READ THRU ALL THE LINKS AND SUB LINKED INFO BELOW, YES IM FULLY AWARE IT WILL TAKE SOME EFFORT AND TIME, IT WILL ALSO SAVE YOU WEEKS OF WASTED EFFORT AND HUNDREDS OF DOLLARS

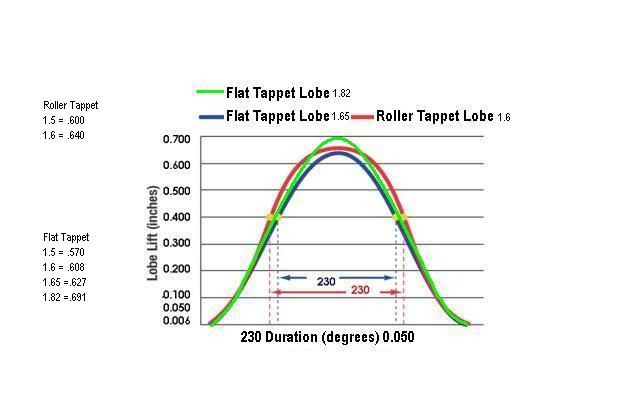

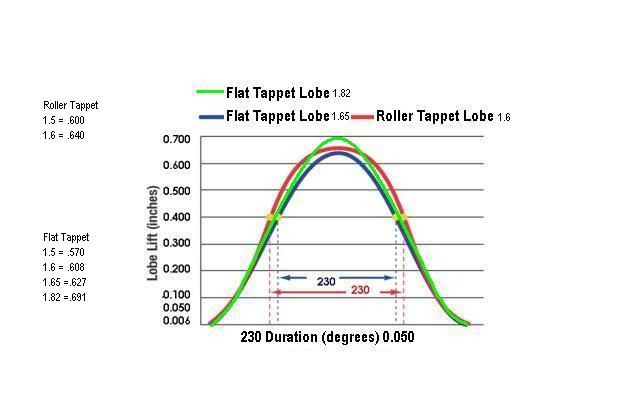

notice its right where the roller cams lobe design maximized the extra air flow potential that is the most effective flow area during the whole valve flow curve

and yes it frequently helps to match a roller cam to roller rockers as the reduced friction further helps the engines durability and ability to easily cope with faster valve train component acceleration, that tends to reduce heat and wear.

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches, thus it makes a great deal of sense to push the valve lift a bit over .500, and have an intake port that is at least 3.2 square inches in cross sectional area, if you want to maximize flow on a 2.02" intake valve

BTW I JUST TOOK THE TIME TO RE_READ THIS THREAD< ITS A VIRTUAL CLASS IN ENGINE ASSEMBLY THAT SHOULD BE READ BY EVERY LAST MEMBER

http://www.themotorbookstore.com/resmchstvi.html

this is exceptionally useful for newer guys

the fact that peak lift is not where you gain the vast majority of the ports airflow potential

think about the math a bit , at 6000 rpm, the valve is going from seat to full lift and back to its seat,3000 times a minute, thats 50 time's a second

but that 50 times a second includes the full 360 degree rotation, peak lift rarely lasts more than 40 degrees of that rotation, or about 1/10th of that time.so how much air flow can occur in 1 /500th of a second the valves are near peak lift

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.com/index.php?threads/valve-seat-angles-and-air-flow.8460/

http://www.hioutput.com/tech/343hp/343hp.html

(if your stuck using restrictive heads, follow this build and use much of what can be used as its designed to maximize restrictive heads)

keep in mind you have a great deal of options,in parts that can be used,and your selection will have a huge effect on where in the rpm range you make the best power, and making 1.1-up to-1.4 horsepower per cubic inch is not that difficult, with the correct parts.

if you read thru the links and sub links youll find many tips and combos

http://www.hotrod.com/techarticles/383c ... ock_build/

http://www.airflowresearch.com/articles ... 5/A-P1.htm

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.airflowresearch.com/articles ... 1/A-P1.htm

http://www.airflowresearch.com/articles ... A16-P1.htm

http://www.circletrack.com/tipstricks/4 ... index.html

http://airflowresearch.com/articles/article115/A-P1.htm

http://airflowresearch.com/articles/art ... A27-P1.htm

http://airflowresearch.com/articles/article085/A-P1.htm

http://vexer.com/automotive-tools/1-4-m ... calculator

BUY A FEW BOOKS ON ENGINE REBUILDING AND PROPER ENGINE ASSEMBLY

AND READ THROGH THEM CAREFULLY,

ITS MONEY VERY WELL SPENT!

example

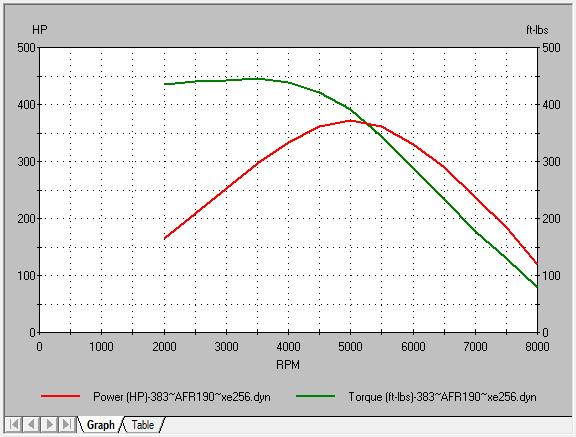

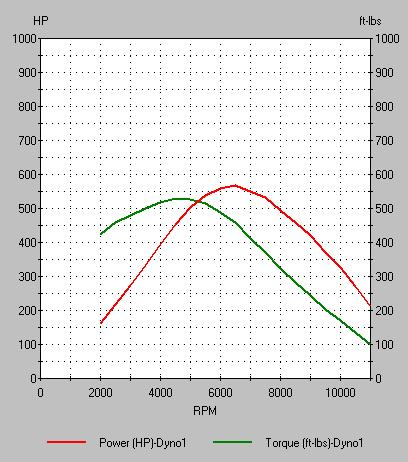

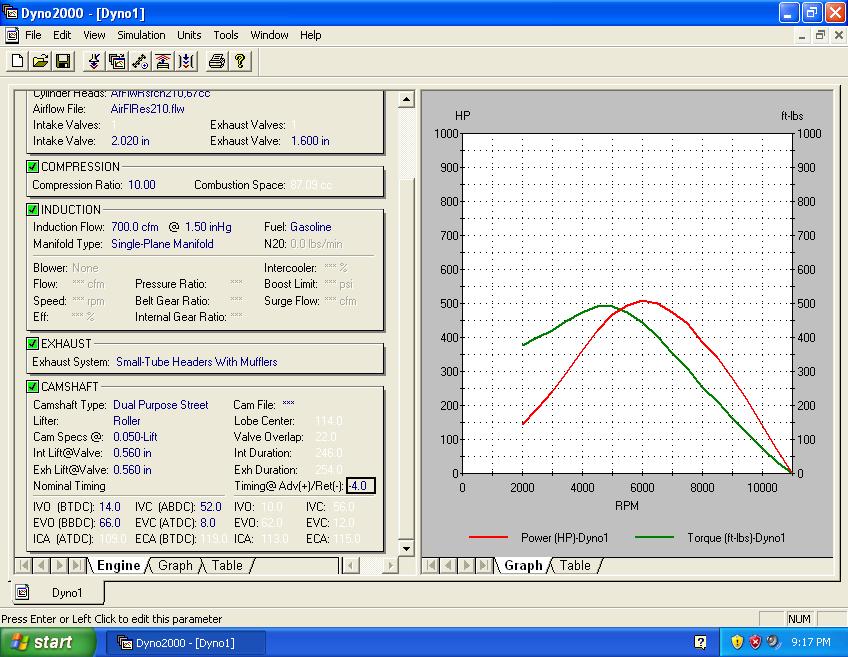

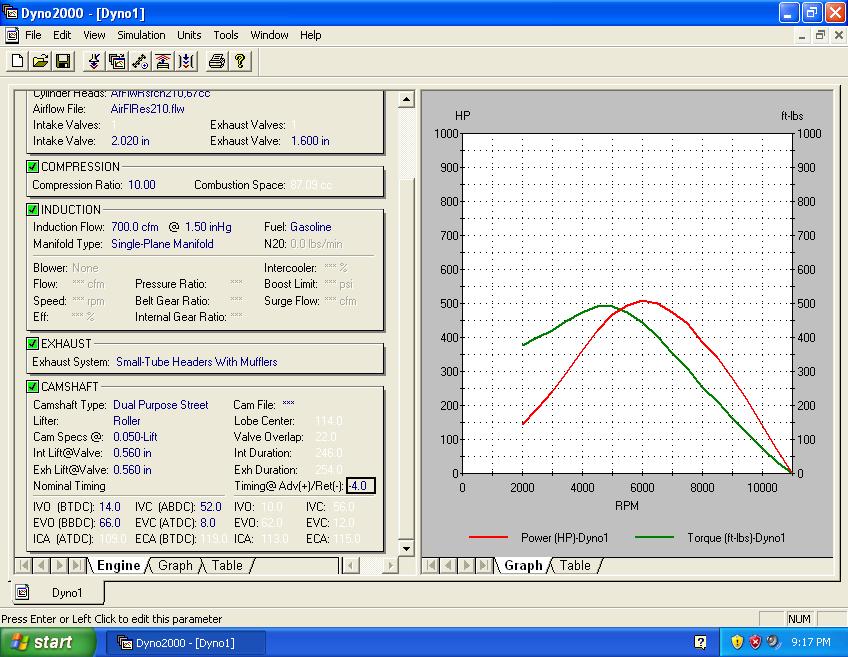

here posted below are two 383s on dyno software with different heads cams and intakes almost everything else is similar,

look at the differences in torque and peak hp that the changes made in

BOTH the low range (1500rpm-4500rpm) (noticeably more low rpm torque)

and the upper or peak hp, (4500rpm-6500rpm) (a good deal more peak hp)

KEEP IN MIND THE STOCK AUTOMATIC TRANSMISSIONS GOING TO SHIFT AT ABOUT 5000RPM OR LOWER,AND STOCK REAR GEARS ARE EFFECTIVELY PREVENTING YOU FROM USING THE WILDER CAMS POWER IF THE DRIVE TRAIN IS NOT MODIFIED TO FUNCTION IN THAT HIGHER RPM BAND, REMEMBER SELECTING COMPONENTS TO MATCH THE INTENDED POWER BAND IS CRITICAL

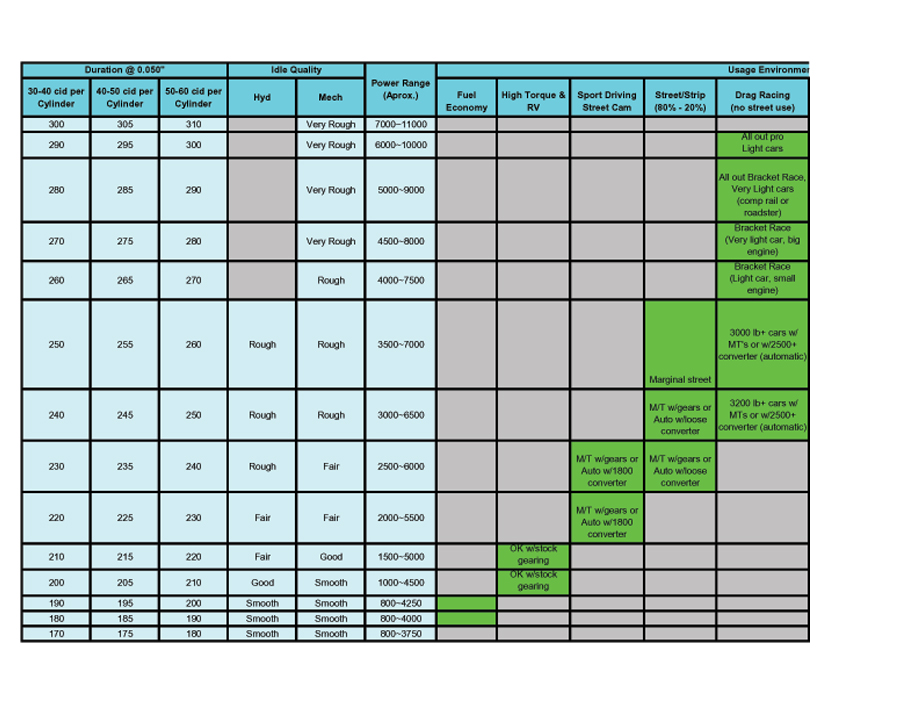

heres a chart I found that I don,t fully agree with, I think its a bit conservative, by about 3%-5% on the required cam duration ,required to avoid detonation with todays crappy octane fuel, but it at least gives you a base to work from, but Id suggest selecting a bit more duration

why not call crane,

1-866-388-5120

crower,1-619.661.6477

erson,1-800-641-7920

lunati 1-662-892-1500

and

isky 323.770.0930

and talk to the tec support guys about what they suggest but DON,T mention anything any other cam manufacturer suggests during the conversations, just present the info on the parts used in that combo, rear gear ratio, compression, etc and see what they suggest, then make up your mind.

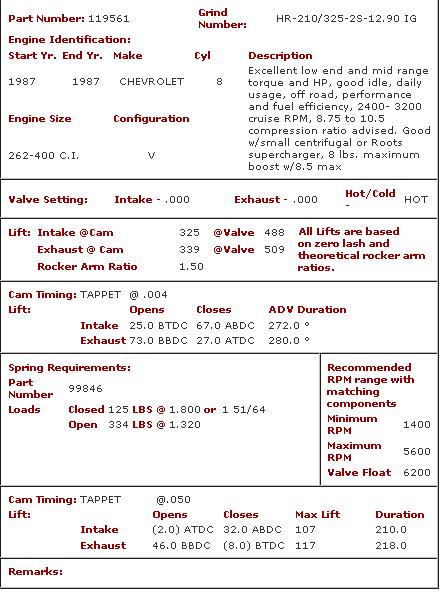

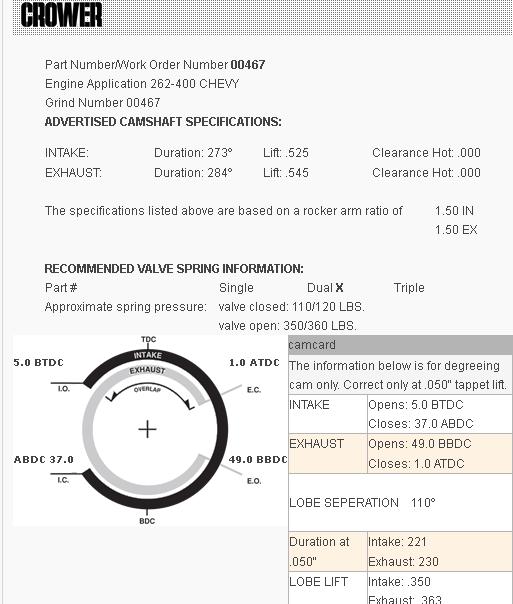

190cc heads tpi, mild cam (crane 119561)

Volumetric Efficiency: Is calculated by dividing the mass of air inducted into the cylinder between IVO and IVC divided by the mass of air that would fill the cylinder at atmospheric pressure (with the piston at BDC). Typical values range from 0.6 to 1.2, or 60% to 120%. Peak torque always occurs at the engine speed that produced the highest volumetric efficiency.

keep in mind as rpms increase so do port speeds and volumetric efficiency UP TO A POINT, WHERE THE TIME LIMITATION TO FILL AND SCAVENGE the cylinder limits power

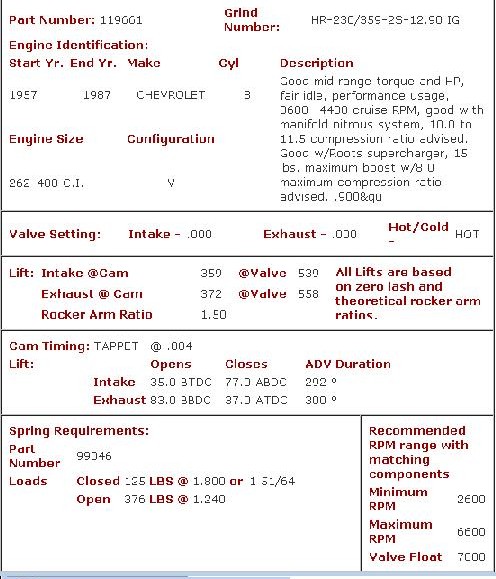

210cc heads single plane intake wilder cam (CRANE 119601)

if your building a 383 sbc these links and sub links will help

SAFE piston speeds are best restricted to 4000fpm for stock components and 4500fpm for the better common aftermarket components

if your serious about building a performance engine you might want to consider a BBC over a SBC

you can generally expect to get between 1.0 to 1.3 ft lbs per cubic inch of displacement and 1.0 to 1.3 horsepower per cubic inch of displacement on your average street/strip daily driver SBC or BBC engine build

how the big block and small block engines differ. The answer is not only in displacement. A small block Chevy motor can be stroked and bored to over 400 ci . it comes down to bore centers. and much stronger OEM blocks and generally better flowing heads, The small block has bore centers spaced 4.4 inches apart. On the big block, those centers are at 4.84 inches.

as a general rule you can build a 396-402 BBC that can outperform a 400 SBC, you'll have a difficult time finding SBC heads that flow more than 310 cfm at a decent price, but many BBC heads flow in excess of 350 cfm, especially if mildly ported and aftermarket BBC heads that flow over 400 cfm are available

keep in mind your basic BBC With more metal separating the bores, there's extra space for cooling galleries and added potential for boring-out. Further, more metal means a stronger block. cranks and rods and the basic BBC block are significantly stronger than the average OEM sbc parts, If you're looking for big horsepower from your muscle car motor, a big block might be the way to go.

read these threads

http://www.trickflow.com/articles/dynod ... _heads.asp

http://www.brodix.com/heads/tonydyno.html

http://airflowresearch.com/articles/article085/A-P1.htm

http://airflowresearch.com/articles/article031/A-P1.htm

http://airflowresearch.com/articles/article096/A-P1.htm

IF your building a stroker big block,combo,you might find info here in the thread below and its sub links useful

keep in mind the 383 small block has become almost the standard its basically the 350 with a 1/4" stroker crank and a slight .030 over bore,to clean up and wear in the 350s bore

in the similar manor a 454 big block with a .030--.060 over bore and a 1/4" stroker crank assembly is used to build a 489-496 big block version

you need to select the parts and you want to build an engine you can be proud of,

the first question is whats your budget look like,

quickly followed by what will you be using the engine for,

and do you have the drive train to match that engines power curve.

be sure you, measure EACH bore and EACH piston,

(CORRECTLY with the proper tools in the way the tool and piston manufacturers suggested)

and number them on an engine build sheet indicating the bore and piston diam.

from large to smallest on each and install them on each cylinder to get the most consistent piston to bore clearance's

yes the difference may only be a few ten thousands if the bores are machined correctly, but you'll get the best results , most consistent lubrication, best durability and less heat build up that might result in detonation issues that way. its the little things that add up to making a good durable engine assembly,

BTW check rod orientation, so the beveled sides don't fact the adjacent rods, and check the bearing clearances with plasti guage

every part you choose is a compromise , and may require changes,

that cost you in time, money or performance to some degree,

and almost every part will require a bit of fitting or clearance work,

or adjustment to fit and function to get the best results

if it drops out of the package and bolts together as it drops out of the package,

its almost certain its not functional to nearly its full potential

your job is to think things through carefully and make sure parts fit and function to their full potential,

little things like checking piston ring end gap, verifying bearing clearances, and ccing the heads and checking piston to valve clearance, degreeing in the cam and verifying the valve train geometry, polishing combustion chambers, getting a decent 3 angle valve job,verifying the piston to bore clearance, MATTER's

and theres that P.I.T.A. FACT that building an engine to produce impressive PEAK POWER,

you can brag about to your buddies almost always results in an engine with less than ideal street drive-ability,

especially if you want good gas mileage or like to cruise at 2000 rpm

every choice you make is a compromise in some area,

if you want massive low and mid rpm torque and instant re responsiveness, in your engine your very likely to be trading those characteristics at the expense of high peak horse power, if you want bragging rights and impressive power your very likely to pay a price in less than ideal manors in traffic and loss of low rpm power , theres EASILY A POTENTIAL OF 80-120 HORSEPOWER DIFFERENCE IN YOUR SELECTION OF HEADS CAM AND COMPRESSION RATIO ALONE

wider LSA smooths out the idle but it reduces overlap, the increased overlap tends to allow cylinder fill at a bit higher rpm and it also tends to kill off a bit of low rpm torque

http://www.chevytech.com/2c40o8.html

The following tables illustrate how variations in lobe separation angle and cam

timing will effect the behavior of the engine in which the camshaft is installed.

EFFECTS OF ALTERING CAMSHAFT TIMING

Advancing.......................................... Retarding

Begins Intake Event Sooner................. Delays Intake Closing Event

Open Intake Valve Sooner ........................Keeps Intake Valve Open Later

Builds More Low-End Torque................. Builds More High-RPM Power

Decrease Piston-Intake Valve Clearance Increase Piston-Intake Valve Clearance

Increase Piston-Exhaust Valve Clearance Decrease Piston-Exhaust Valve Clearance

what to look for in a "GOOD" engine combo

I got asked , "what makes a GOOD vs A poor engine combo?" and without getting into specific combos , too deeply, lets look at that question like with most performance parts and applications the critical part of the build, is generally in selecting the correct components for that particular...

garage.grumpysperformance.com

http://www.camquest.com/

http://www.hotrod.com/how-to/engine/ccrp-0808-383-stroker-small-block-chevy/

http://www.strokerengine.com/SBCHeadsFlow.html

search.php?search_id=active_topics

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55571

http://www.technovelocity.com/chevyhack ... cation.htm

http://www.chevyhiperformance.com/techa ... ine_build/

if your building a sbc street/strip engine every component works a part of a total system, your always restricted by the weakest link in the chain, or the biggest restriction, and with engines its air flow rates, fuel/air ratios,cylinder scavenging,ignition advance curve and compression that determine a great deal of your potential power.

REMEMBER A MANUAL TRANSMISSION ALLOWS YOU A GREAT DEAL MORE FLEXIBILITY IN CAM SELECTION

keep in mind you need to think thru the combo as a package where all parts selected must complement each other and be designed to operate in approximately the same basic rpm band and flow and effectively burn and use the pressure generated from similar amounts of fuel/air mix.

one very common mistake is selecting a cam duration,that exceeds or limits the engines rpm band, a rear gear ratio,thats not matched to the intended power band,or selecting a compression ratio or set of heads that can,t operate with the other components in the same power band efficiently

the best heads matched to a restrictive intake or the wrong cam will result in a DOG just as surely as a great intake and crappy heads with low compression, or any of a few dozen other miss-matched parts.

I think most of us have run into a great many similar choices, between buying tools and auto parts,

its simply the result of a limited budget ,in most cases,

and most of us make a few mistakes ,

but as long as you keep the goal of building the car in mind you'll do ok.

after you gain experience there's both engineering and art involved in the process,

you'll generally start with a goal, you've envisioned for your car, reality and physics will provide some of the limitations, you'll be limited to a budget and at times by your access too tools and limited by your skills and knowledge, youll generally start,by simply making a very detailed list of the components you want too use ,to upgrade and modify the car to gain the performance and look of the car, and once you have that list of components, and being forced by going back through that detailed, list and doing the required math too verify you have selected the correct matching parts, and when you find you have to change a few components you go back, change the list and again revue the math, most of us start out without the required knowledge to accurately match parts and your goal.

yet this process forces you to do some research into what you can reasonably accomplish with the tools and skills you have and the realization that you may need to acquire both skills and more tools as you proceed. as you read through most of the builds listed and discussed on this web site,

youll eventually see a strong trend, towards what I and many other knowledgeable engine builders have been forced over time into recognizing.

the trend is simply that only engines built for max long term durability and max torque in the useful rpm range are making any financial sense.

as Ive stated many times, you have to finish a race to win it! and your never going to build a client base ,

if the engines you build make killer power on a dyno but need rebuilding in a couple months time.

theres several threads on builds here on this web site, and a great deal of time and research is devoted to extended durability, cooling and lubrication ,

and carefully selecting components, and machine work done, designed for max strength, for the dollars spent!

I used to ask guys

"would you prefer to build an engine that if you keep it well tuned and change the oil regularly,

will most likely still be running in 10-12 years, without changing major components, or

would you rather have an additional 25-30 hp,and need a rebuild every 3-6 years,

but have a much better chance it won,t last half that time span....

especially in a muscle car driven on the street,

where either engine choice will destroy street tires effortlessly,

and get you a ticket effortlessly for speeding any time you get stupid?"

READ THIS LINKED INFO

Change Cam - Gain 78 HP ..... "article on page 22, in the magazine" [Best of Tech /Winter 2003]

A few years ago there were claims by a magazine of adding 78 horsepower to a wimpy 8.6:1 compression-ed 355 sbc equipped w/"the usual hot rodding parts" headers, 750 Speed Demon carb, Edelbrock Performer RPM Air-Gap intake, 2.02/1.60 Summit aluminum heads, MSD, ect.

Just using an Erson TQ40 cam kit [218/228@.050 duration][.472 valve lift, w/1.5:1 rockers]

instead of the stock small block Chevy [195/202 duration] factory type [.390/.410 lift] camshaft ...

Using this Erson TQ40 cam, it showed gaining a maximum of 78 hp @ 5,600 RPM = [403 hp/maximum] .....

and gaining 20 pounds of torque, @ 4,400 RPM = [418# torque/maximum] over the stock low lift camshaft.

Oddly enough, from 2,000-to-3,900 RPM, results were [-1 horsepower] and [-4 pounds of torque].

Average gains from 2,000-to-5,900 RPM, were 44 horsepower & 35 pounds of torque .....

This Erson TQ40 cam showed gaining 78 hp & 78 pounds of torque, from about 4,000-to-5,900 RPM.

now 78 hp gain looks impressive but if you retained the stock rear gear and converter youll spend very little time in the 4000rpm-6000rpm power band so a cam like that won,t produce nearly the gains, in performance you might expect without making the matching drive train mods so the engine operates mostly in the new higher average power band, it makes little difference if your engine makes 100 more hp if it makes it only in an rpm band you seldom reach or use!.

if you want the car to run decent you need to significantly increase the air flow rates,and feed the required fuel to maintain the correct f/a ratio and that requires much better flowing heads,much better flowing intake and a cam with more lift and duration and a higher stall speed converter and a 3.54:1-or- 3.73:1 rear gear ratio

a cam that will move the intended power range high enough to make that intended power curve is required , but planing where in the rpm range that power curve is strongest is your first decision,..... all the components selected must match,that intended power curve, and the cam, compression ratio and head flow need to match that combos goal, you can build a good street combo with massive torque in the rpm range you normally drive, (usually 1800rpm-4500rpm, on most street cars) for use on the street or you can build a race engine with far better peak power (up in the (4500rpm-6500rpm range) but it won,t be nearly as much fun to drive at low rpms or on the street, in fact its only going to work great on a dyno or where you can drive while keeping the engine rpms in the 4500-6500 range in most cases

keep in mind if your gearing keeps the engine rpms in the 1500rpm-5500rpm range and the transmission shifts at 5500rpm under wide open throttle like most nearly stock engines do its rather useless to cam the engine or use heads designed to maximize power in the 5500-700rpm range

put your info into this program, don,t exaggerate or lie, just input what you really have top work with

http://www.camquest.com/

a typical sbc makes about 1.1 ft lb of torque per cubic inch of displacement

your torque curve depends mostly on your engines displacement,compression,head, & intake flow and cam timing

the formula for hp is torque times rpm divided by 5252=hp

a higher torque peak generally increases power

this is a very typical dyno chart from an engine with stock heads a mild cam and stock exhaust and intake, as all components are designed for max low and mid rpm torque, you can easily move the peak hp and torque number higher , with larger head ports cam duration, better intake and less restrictive headers and exhaust but doing so tends to reduce the off idle responsiveness and torque, as every choice is a compromise in some area.

example

400 ft lbs at 3500rpm=267hp

400 ft lbs at 5500rpm=419hp

400 ft lbs at 6500rpm=495hp

you'll want to run about 10:1 cpr on the street to maximize performance, because on pump gas thats about the max you can use, but the cam selected effects the dynamic compression ratio so you can use a bit more compression with a longer duration cam and a bit less with a lower duration,

heads that flow about 250cfm or more at .500 lift are going to be a huge asset, but the port cross sectional area will tend to vary based on where you want peak hp,

if your going for an aggressive combo a bit more on the race end of the scale but a compromise to keep it semi-street-able, you'll usually need a 3.54:1-3.73:1 rear gear and a manual transmission or a 2700rpm-3000rpm stall converter to maximize acceleration, with a cam that's designed to maximize power in the 3000rpm-6300rpm band

personally if I was building as hot street combo, Id select a complete rotating assembly with matched components,from a single supplier, it will tend to avoid problems or finger pointing if parts don,t match and fit, specifically say you want those components and balanced, a good scat cast STEEL 9000 balanced crank and 5.7" connecting rods with 7/16" rod bolts,and forged pistons, do the research and make sure you get match and balanced parts

If it was a street and race combo ID also specify INTERNAL BALANCE and 4340 forged rotating parts

YOU CAN LEARN A GREAT DEAL, ABOUT COMBOS THAT WORK, IF YOU READ THRU ALL THE LINKS AND SUB LINKED INFO BELOW, YES IM FULLY AWARE IT WILL TAKE SOME EFFORT AND TIME, IT WILL ALSO SAVE YOU WEEKS OF WASTED EFFORT AND HUNDREDS OF DOLLARS

notice its right where the roller cams lobe design maximized the extra air flow potential that is the most effective flow area during the whole valve flow curve

and yes it frequently helps to match a roller cam to roller rockers as the reduced friction further helps the engines durability and ability to easily cope with faster valve train component acceleration, that tends to reduce heat and wear.

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches, thus it makes a great deal of sense to push the valve lift a bit over .500, and have an intake port that is at least 3.2 square inches in cross sectional area, if you want to maximize flow on a 2.02" intake valve

BTW I JUST TOOK THE TIME TO RE_READ THIS THREAD< ITS A VIRTUAL CLASS IN ENGINE ASSEMBLY THAT SHOULD BE READ BY EVERY LAST MEMBER

http://www.themotorbookstore.com/resmchstvi.html

this is exceptionally useful for newer guys

the fact that peak lift is not where you gain the vast majority of the ports airflow potential

think about the math a bit , at 6000 rpm, the valve is going from seat to full lift and back to its seat,3000 times a minute, thats 50 time's a second

but that 50 times a second includes the full 360 degree rotation, peak lift rarely lasts more than 40 degrees of that rotation, or about 1/10th of that time.so how much air flow can occur in 1 /500th of a second the valves are near peak lift

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.com/index.php?threads/valve-seat-angles-and-air-flow.8460/

http://www.hioutput.com/tech/343hp/343hp.html

(if your stuck using restrictive heads, follow this build and use much of what can be used as its designed to maximize restrictive heads)

keep in mind you have a great deal of options,in parts that can be used,and your selection will have a huge effect on where in the rpm range you make the best power, and making 1.1-up to-1.4 horsepower per cubic inch is not that difficult, with the correct parts.

if you read thru the links and sub links youll find many tips and combos

http://www.hotrod.com/techarticles/383c ... ock_build/

http://www.airflowresearch.com/articles ... 5/A-P1.htm

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.airflowresearch.com/articles ... 1/A-P1.htm

http://www.airflowresearch.com/articles ... A16-P1.htm

http://www.circletrack.com/tipstricks/4 ... index.html

http://airflowresearch.com/articles/article115/A-P1.htm

http://airflowresearch.com/articles/art ... A27-P1.htm

http://airflowresearch.com/articles/article085/A-P1.htm

http://vexer.com/automotive-tools/1-4-m ... calculator

BUY A FEW BOOKS ON ENGINE REBUILDING AND PROPER ENGINE ASSEMBLY

AND READ THROGH THEM CAREFULLY,

ITS MONEY VERY WELL SPENT!

example

here posted below are two 383s on dyno software with different heads cams and intakes almost everything else is similar,

look at the differences in torque and peak hp that the changes made in

BOTH the low range (1500rpm-4500rpm) (noticeably more low rpm torque)

and the upper or peak hp, (4500rpm-6500rpm) (a good deal more peak hp)

KEEP IN MIND THE STOCK AUTOMATIC TRANSMISSIONS GOING TO SHIFT AT ABOUT 5000RPM OR LOWER,AND STOCK REAR GEARS ARE EFFECTIVELY PREVENTING YOU FROM USING THE WILDER CAMS POWER IF THE DRIVE TRAIN IS NOT MODIFIED TO FUNCTION IN THAT HIGHER RPM BAND, REMEMBER SELECTING COMPONENTS TO MATCH THE INTENDED POWER BAND IS CRITICAL

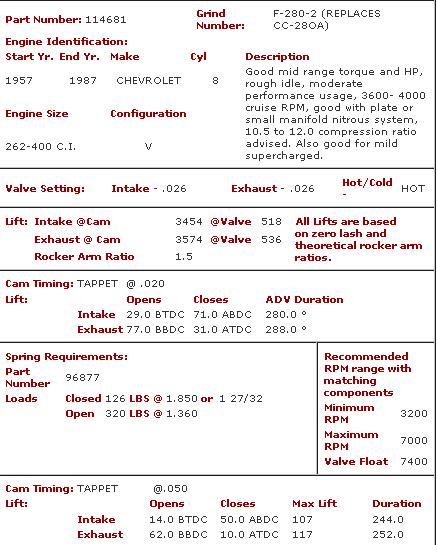

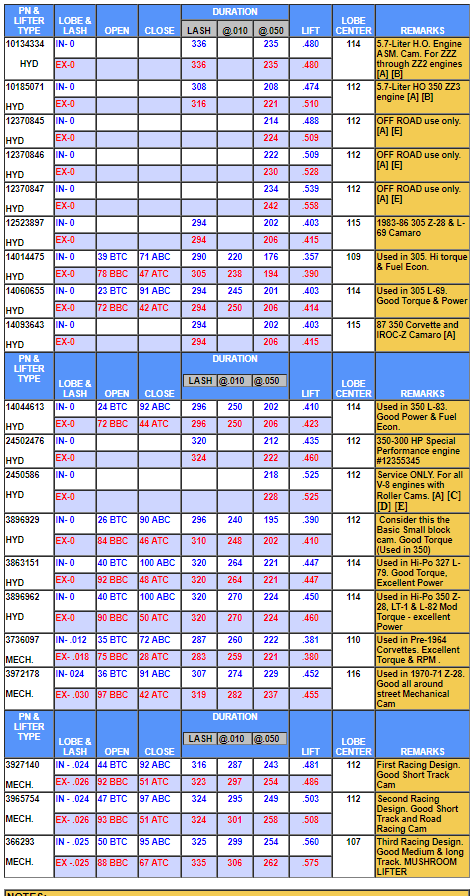

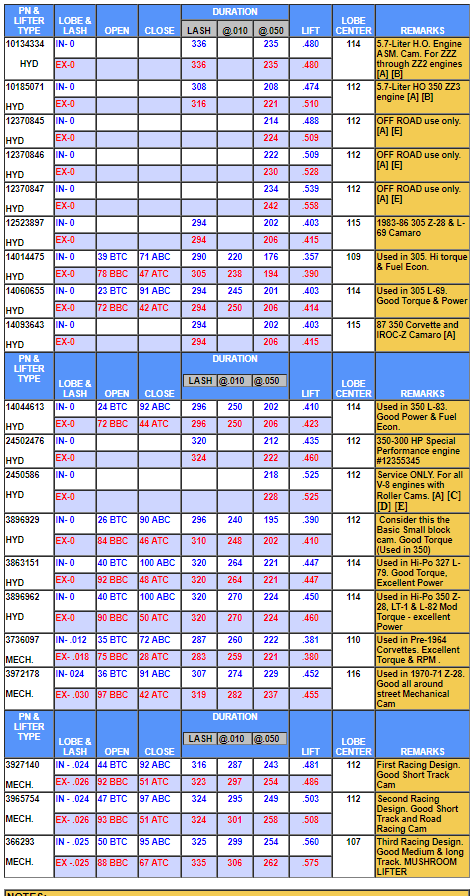

heres a chart I found that I don,t fully agree with, I think its a bit conservative, by about 3%-5% on the required cam duration ,required to avoid detonation with todays crappy octane fuel, but it at least gives you a base to work from, but Id suggest selecting a bit more duration

why not call crane,

1-866-388-5120

crower,1-619.661.6477

erson,1-800-641-7920

lunati 1-662-892-1500

and

isky 323.770.0930

and talk to the tec support guys about what they suggest but DON,T mention anything any other cam manufacturer suggests during the conversations, just present the info on the parts used in that combo, rear gear ratio, compression, etc and see what they suggest, then make up your mind.

190cc heads tpi, mild cam (crane 119561)

Volumetric Efficiency: Is calculated by dividing the mass of air inducted into the cylinder between IVO and IVC divided by the mass of air that would fill the cylinder at atmospheric pressure (with the piston at BDC). Typical values range from 0.6 to 1.2, or 60% to 120%. Peak torque always occurs at the engine speed that produced the highest volumetric efficiency.

keep in mind as rpms increase so do port speeds and volumetric efficiency UP TO A POINT, WHERE THE TIME LIMITATION TO FILL AND SCAVENGE the cylinder limits power

210cc heads single plane intake wilder cam (CRANE 119601)

if your building a 383 sbc these links and sub links will help

SAFE piston speeds are best restricted to 4000fpm for stock components and 4500fpm for the better common aftermarket components

if your serious about building a performance engine you might want to consider a BBC over a SBC

you can generally expect to get between 1.0 to 1.3 ft lbs per cubic inch of displacement and 1.0 to 1.3 horsepower per cubic inch of displacement on your average street/strip daily driver SBC or BBC engine build

how the big block and small block engines differ. The answer is not only in displacement. A small block Chevy motor can be stroked and bored to over 400 ci . it comes down to bore centers. and much stronger OEM blocks and generally better flowing heads, The small block has bore centers spaced 4.4 inches apart. On the big block, those centers are at 4.84 inches.

as a general rule you can build a 396-402 BBC that can outperform a 400 SBC, you'll have a difficult time finding SBC heads that flow more than 310 cfm at a decent price, but many BBC heads flow in excess of 350 cfm, especially if mildly ported and aftermarket BBC heads that flow over 400 cfm are available

keep in mind your basic BBC With more metal separating the bores, there's extra space for cooling galleries and added potential for boring-out. Further, more metal means a stronger block. cranks and rods and the basic BBC block are significantly stronger than the average OEM sbc parts, If you're looking for big horsepower from your muscle car motor, a big block might be the way to go.

read these threads

http://www.trickflow.com/articles/dynod ... _heads.asp

http://www.brodix.com/heads/tonydyno.html

http://airflowresearch.com/articles/article085/A-P1.htm

http://airflowresearch.com/articles/article031/A-P1.htm

http://airflowresearch.com/articles/article096/A-P1.htm

IF your building a stroker big block,combo,you might find info here in the thread below and its sub links useful

keep in mind the 383 small block has become almost the standard its basically the 350 with a 1/4" stroker crank and a slight .030 over bore,to clean up and wear in the 350s bore

in the similar manor a 454 big block with a .030--.060 over bore and a 1/4" stroker crank assembly is used to build a 489-496 big block version

Last edited by a moderator: