IT should be rather obvious that a great deal of the info you need to build a really efficient engine combo is easily calculated if you know just a few basics about what you want to build and the enviroment or power band its expected to operate in,but obviously is not! AND YES EVERY PART CHOICE EFFECTS YOUR RESULTS

your at the point in your engine build where you need to select an intake manifold and carburetor.

https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=6-522

https://www.holley.com/products/fue...s_and_components/needle_and_seats/parts/6-522

https://behrents.com/parts/holley-needle-and-seat-assembly-6-522.asp

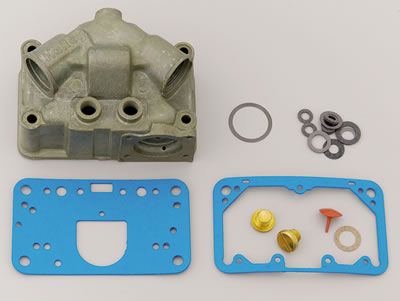

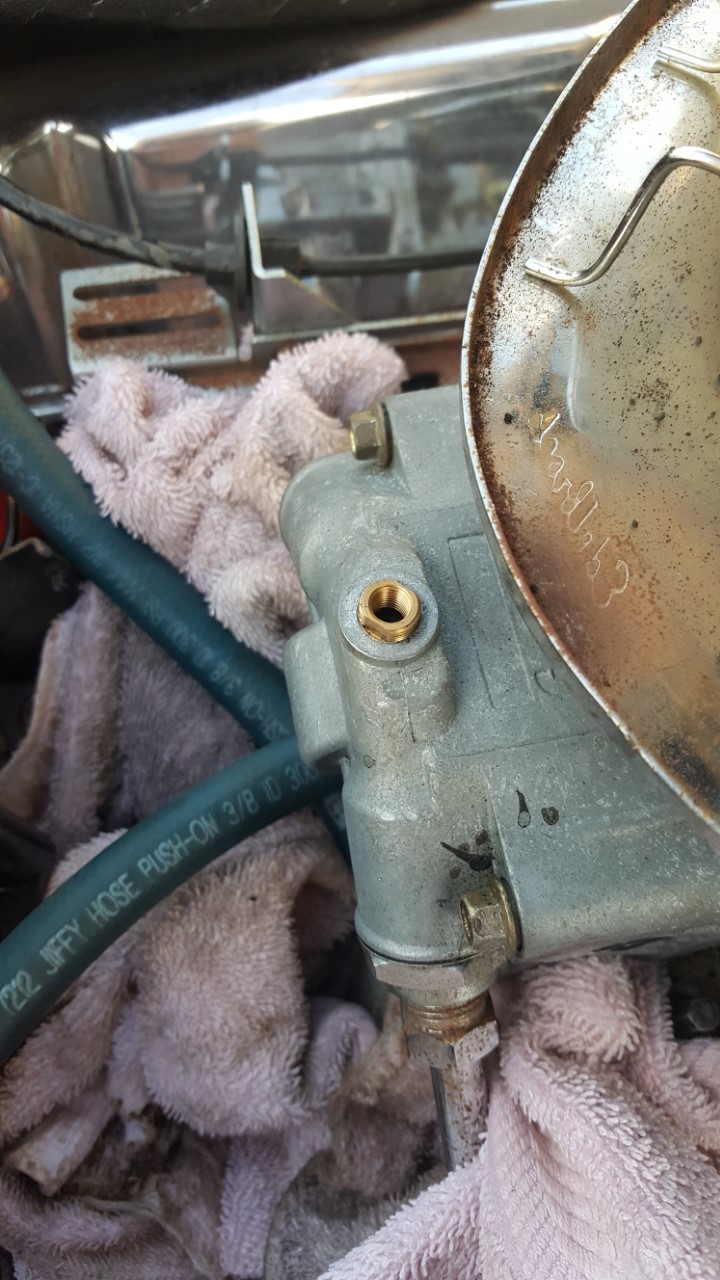

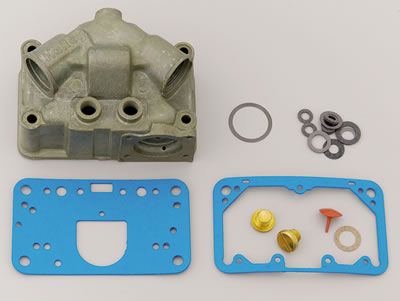

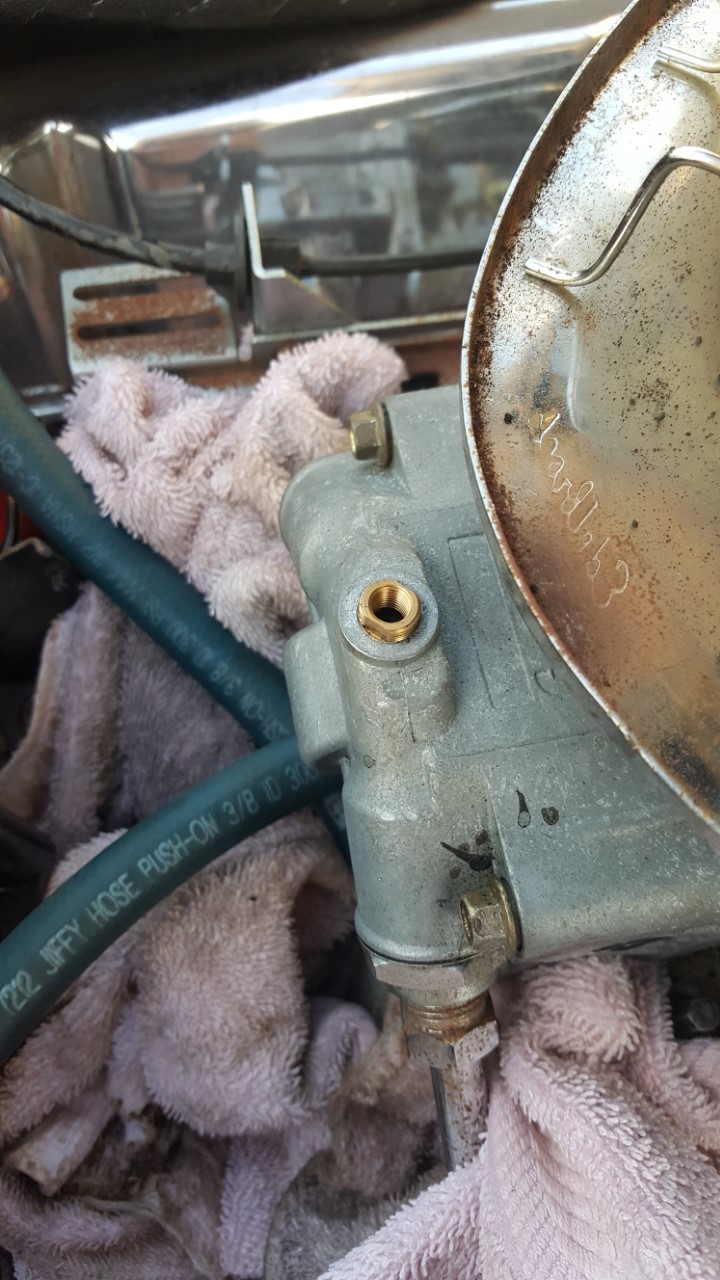

Holley 6-522 Viton Inlet Needle

($20-$30 a pair depending on source new)

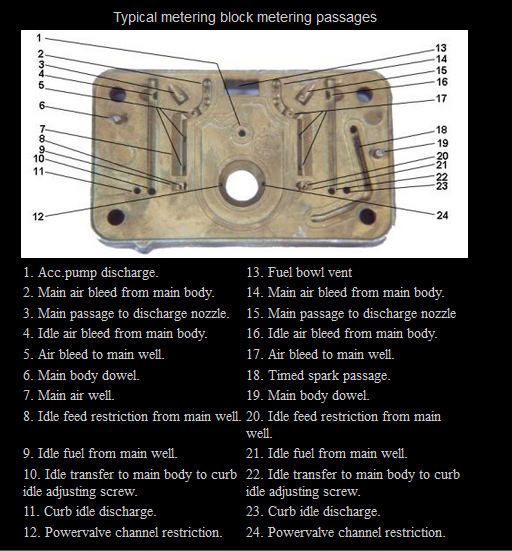

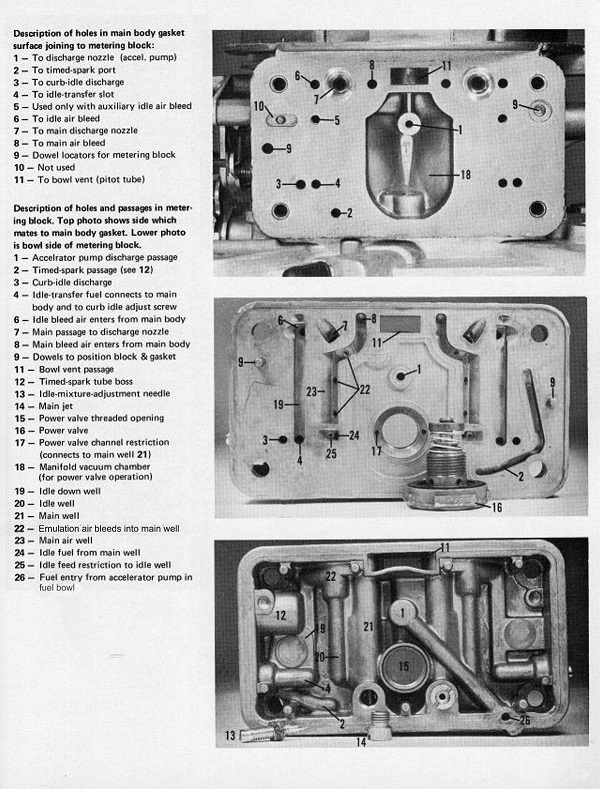

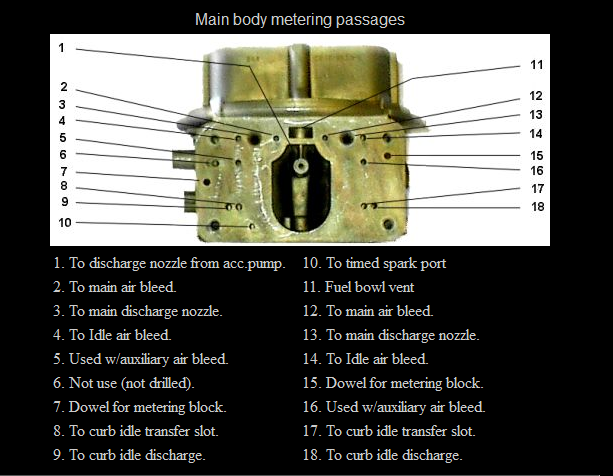

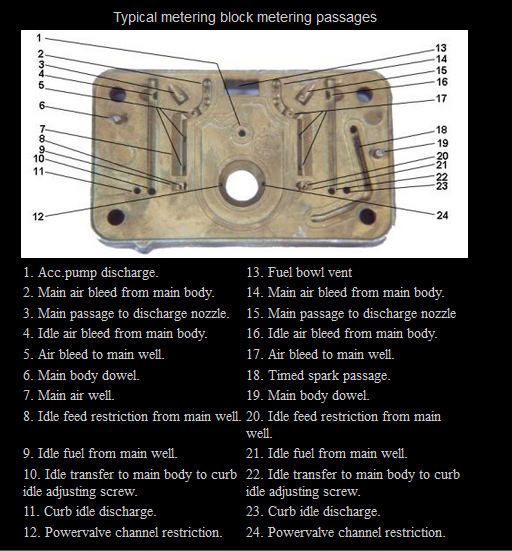

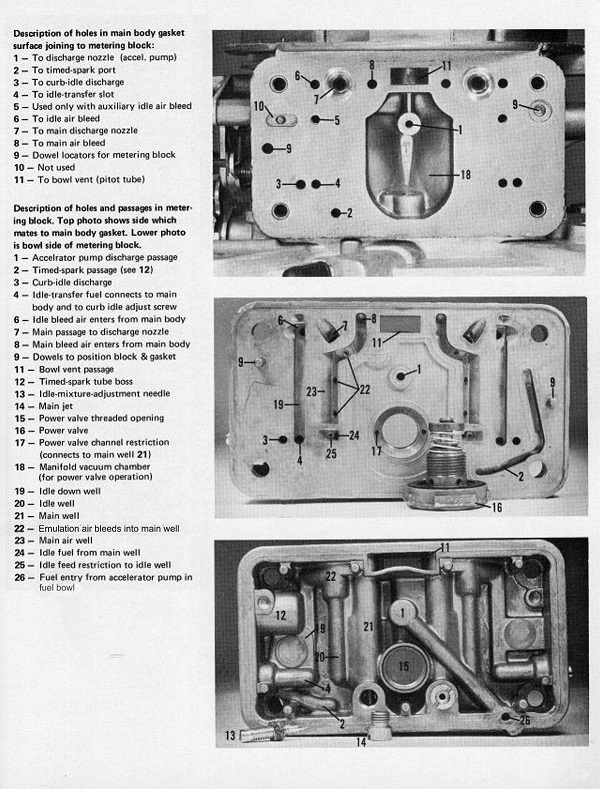

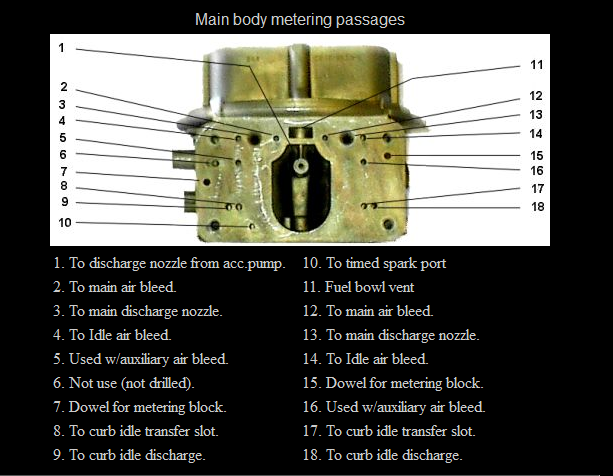

keep in mind theres lots of small passages that can get clogged and theres several different fuel bowl gaskets, these vary by manufacturer and carb model, so be sure you use the correct gasket on the meter block and fuel bowl, if you leave debris in the fuel bowl or use the wrong gaskets they can block passages and the carb won,t function

AS ALWAYS YOUR GOING TO MISS A TON OF INFO IF YOU SKIP THE SUB LINKS

you know from the experience of dozens of guys that a 750cfm carburetor will work, reasonably well so you purchased one, but what intake type should you use? lets use some calculators to find out!

but what intake manifold do you need, single plane or dual plane?

I can tell you from experience that is RARE for a single plane intake to produce better AVERAGE power than a dual plane unless the cam duration exceeds about 240 degrees @ .050 lift AND the peak engine rpm exceeds 6500rpm

the basic operating range of most dual plane intakes on most 327 and larger SBC engines is about 1500rpm-6500rpm, while most single plane intakes are designed to operate in the 4000rpm-7000rpm power band but obviously increasing the engines displacement increases the air flow speeds thru the ports, the single planes shorter more direct port runner design, will flow slightly more air but it requires higher rpms to maintain the air flow rates needed for effective air flow inertia to effectively fill the cylinders, keep in mind this has a big effect on the rpm range that the cylinder heads and intake will work best in,but doesn,t necessarily indicate the power level your going to be producing, as smaller port head can produce impressive power in the rpm band they are designed to operate in, your usually working against restrictions,

as for example

your valve train components might limit you to 6300rpm, but your cylinder heads might easily allow your engine to spin 7000rpm and still produce good power with a different cam, or your cylinder heads could be restricting power but the intake and cam could easily operate at a higher average rpm range.

its up to the engine builder to match the power and rpm limitations of components used to allow maximum efficient within the restrictions

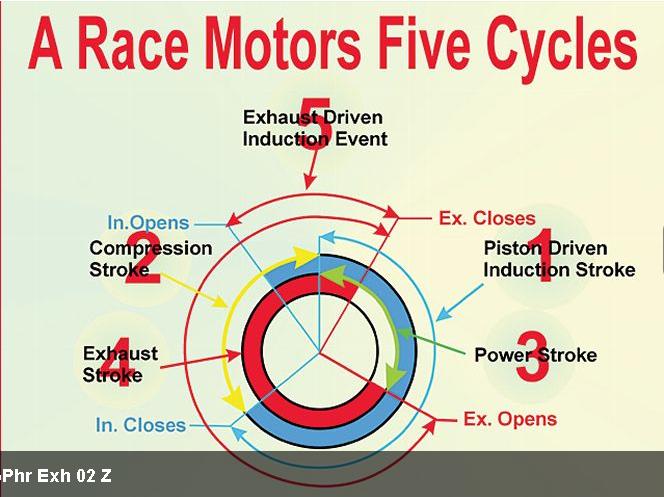

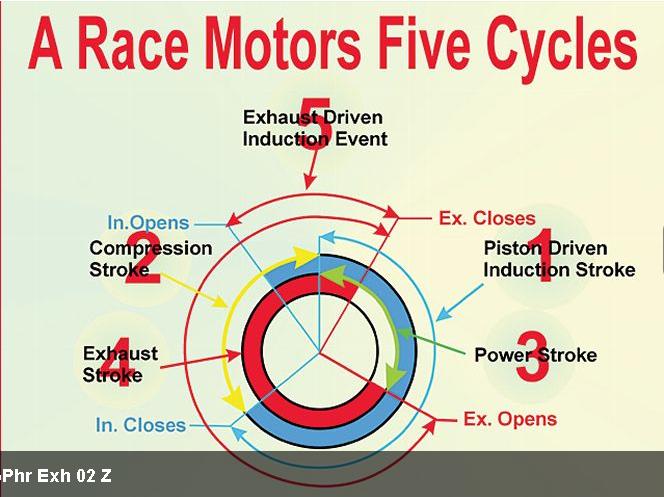

A CORRECTLY TUNED SET OF HEADERS , MATCHED TO A CORRECTLY DESIGNED CAM TIMING HAS A SIGNIFICANT EFFECT ON INTAKE FLOW AND CYLINDER SCAVENGING EFFICIENCY, EXHAUST SCAVENGING CAN BE 5 TIMES STRONGER THAN THE PISTON, MOVEMENT INDUCED NEGATIVE PRESSURE (VACUUM) IN THE INTAKE RUNNERS

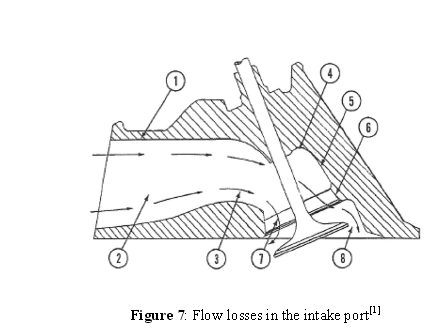

you will need to match both the port cross sectional area and length to the cam timing , while taking into consideration the engine displacement and intended operational power band to select the correct intake manifold design.

Im assuming you know a good bit of info and are concentrating on selecting an intake to match parts you already have, but obviously you can calculate almost any thing you need to know if you just know the engine displacement, port size and cam timing.

lets look at this a bit, lets take for example a rather common 383 that we want to build to operate up to 6300 rpm, where we have found the hydraulic lifters don,t allow you to keep control of the valves, on your previously built 383 or 350,so you know a bit of useful info, now lets say you are using better heads on this engine build, youll need to know your cylinder heads cross sectional area and the valve size and lift, because those factors will effect max port flow rates and port stall speeds.

OK first step, you know the engine won,t rev with the current cam and intake past 6300rpm, but will that be true with the new engine?

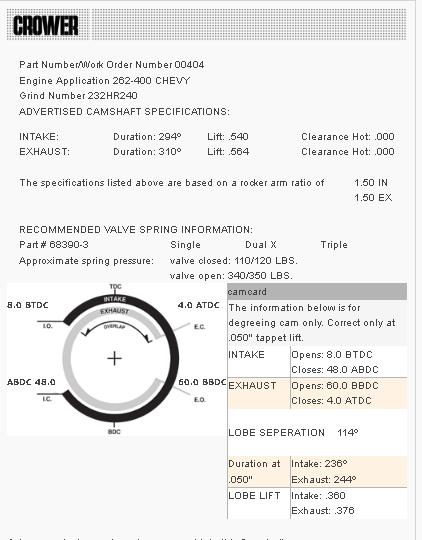

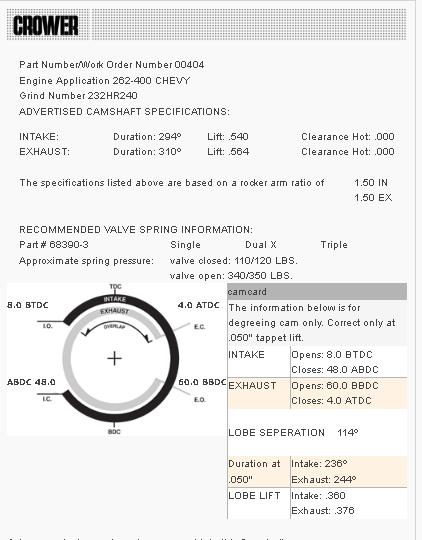

HERES THE HYDRAULIC ROLLER CAM YOUR RE-USING

a simple calculation shows that at max valve lift the curtain area of the valve is larger than the runner cross sectional area so the cams unlikely to be a huge limiting factor in the combos ability to make power, but its duration maximizes the power in the upper mid range not peak power.

its not horsepower, its the stress on the valve train, that makes a rocker stud girdle and its increased rigidity useful,

and thats more closely related to average stress levels, RPM and VALVE SPRING LOAD RATES

any time your occasionally exceeding 6000rpm or getting close too 330 lbs of open valve load rate Id strongly suggest screw in rocker studs

any time your intentionally exceeding 6000rpm and exceeding 350 lbs of open valve spring rate a rocker stud girdle might be a good idea.

and if your regularly exceeding 6500rpm and 400 lbs of open valve spring load rate its use is going to become almost mandatory

http://www.summitracing.com/parts/pro-66950

http://www.summitracing.com/parts/sum-141010

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

OK lets assume you measure your cylinder heads intake ports and you find they have a 2.2 sq inch cross sectional area at the smallest point

(BTW I CAN ASSURE YOU that if you want better PEAK POWER NUMBERS swapping to a cylinder head that flows at least 280 cfm and has at LEAST a 2.6 sq inch cross sectional area would boost peak power

you use a a calculator and find that peak torque should occur near 4100 rpm, WITH THE CAM AND WITH THOSE 2.2 SQ INCH PORT HEADS , and that ideal runner length should be about 20" long

peak torque 4100rpm

http://www.rbracing-rsr.com/runnertorquecalc.html

IDEAL RUNNER LENGTH 20"

http://www.wallaceracing.com/runnertorquecalc.php

PORT STALL =6300rpm

http://www.wallaceracing.com/chokepoint.php

port velocity near 600fps PEAK

http://www.wallaceracing.com/lpv.php

FROM THE CALCULATED INFO it should be rather obvious that the longer runners in a dual plane intake and the basic operational range all point to a dual plane intake as being the best match, but its fairly close,if the peak torque was about 900rpm higher and the port stall was above 7000rpm,or higher, the balance point would more than likely favor the single plane intake, remember the single plane intake runners tend to be larger effectively reducing flow restriction.

http://www.summitracing.com/parts/EDL-7501/

this intakes great between about 1500rpm and about 6300rpm. but really likes to have a bit better cam and head flow than stock, or your not going to get nearly its full potential benefits and of course a low restriction exhaust and headers

http://www.summitracing.com/expertadvic ... Calculator

http://www.summitracing.com/parts/HLY-300-110/

this intakes great on a SBC between about 3700rpm and about 6800rpm IF YOU HAVE THE HEADS AND CAM TO USE THE FLOW POTENTIAL,On a non-supercharged engine, but its pretty much wasted with out a decent cam with at least 240 dur at .050 lift, and at least 10:1 minimum compression, and killer heads,that flow at least 250cfm at .500 lift OR with a supercharger with killer heads that flow at least 250cfm at .500 lift and a decent cam with at least 230 dur. at .050 lift and of course a low restriction exhaust and headers, but if you have an engine combo that does spend a great deal of its operational life in the 3800rpm-7000rpm power band you might want to look at it

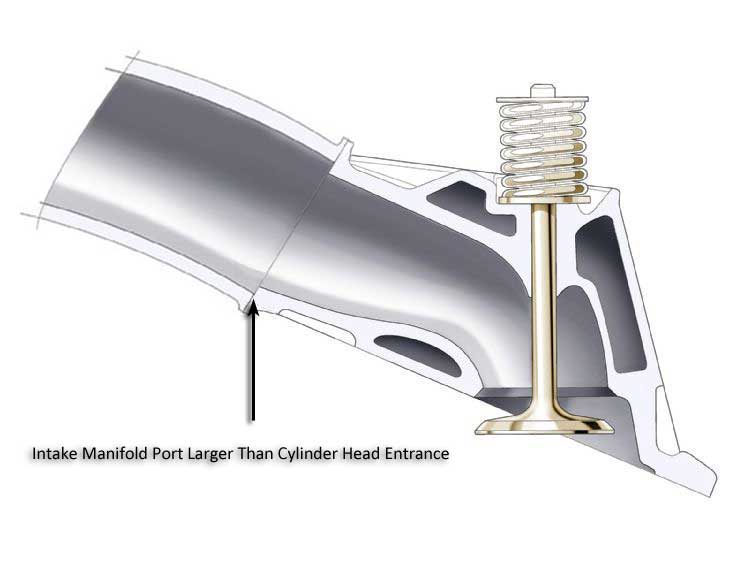

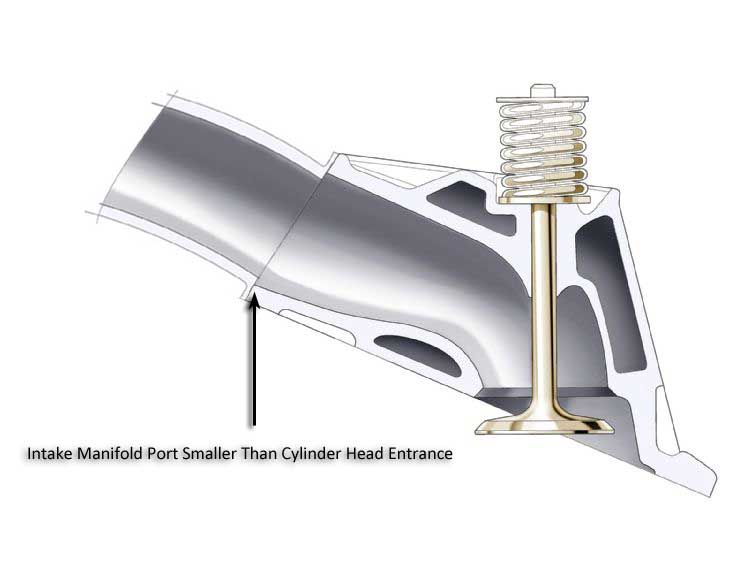

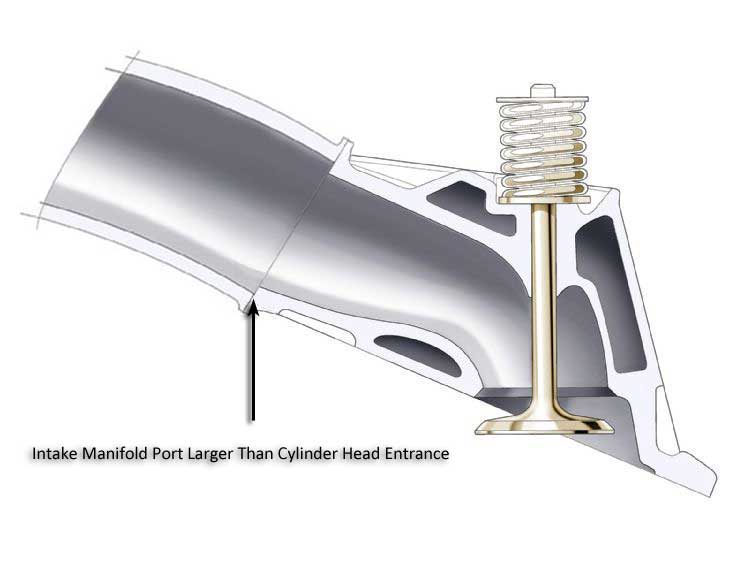

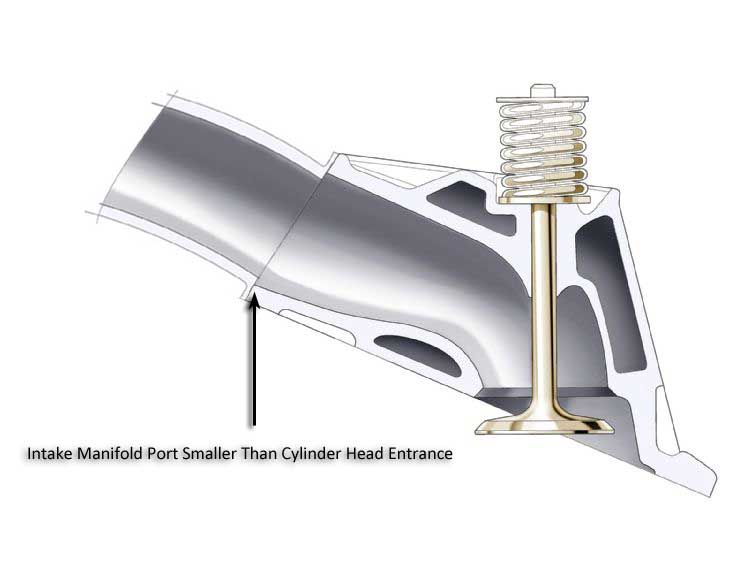

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

SINGLE PLANE INTAKE DIMENSIONS (you can learn a great deal by actually measuring INTAKE ports and runners ETC.)

http://www.edelbrock.com/automotive_new ... ions.shtml

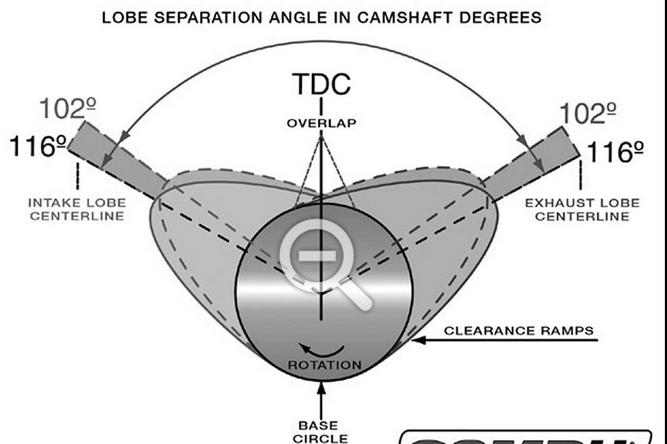

combining the info posted a 383 sbc has 47.8 cubic inches per cylinder divided by 2.02=23.7 on the chart above, so youll find cams in the correct duration range having a tight 105-108 lSA most efficient at filling the cylinders in many combos,

lets say we build a 496 big block with 2.19" intake valves,

496 divided by 8=62 cubic inches per cylinder, divided by 2.19=28.3. now look at the chart! you find youll need a rather tight 101-103 LSA

RELATED THREADS YOU SHOULD READ THRU

viewtopic.php?f=55&t=624

viewtopic.php?f=55&t=5378

http://www.wallaceracing.com/camcalc.php

viewtopic.php?f=55&t=2614&p=7114&hilit=tpis+runner#p7114

http://mysite.verizon.net/vzezeqah/site ... ystems.pdf

http://rehermorrison.com/tech-talk-70-a ... low-bench/

http://www.csgnetwork.com/automotiveconverters.html

anything you can do , to increase horse power with a tunnel ram,

can be duplicated and in most cases significantly improved with a stack injection set up.

your at the point in your engine build where you need to select an intake manifold and carburetor.

https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=6-522

https://www.holley.com/products/fue...s_and_components/needle_and_seats/parts/6-522

https://behrents.com/parts/holley-needle-and-seat-assembly-6-522.asp

Holley 6-522 Viton Inlet Needle

($20-$30 a pair depending on source new)

keep in mind theres lots of small passages that can get clogged and theres several different fuel bowl gaskets, these vary by manufacturer and carb model, so be sure you use the correct gasket on the meter block and fuel bowl, if you leave debris in the fuel bowl or use the wrong gaskets they can block passages and the carb won,t function

AS ALWAYS YOUR GOING TO MISS A TON OF INFO IF YOU SKIP THE SUB LINKS

you know from the experience of dozens of guys that a 750cfm carburetor will work, reasonably well so you purchased one, but what intake type should you use? lets use some calculators to find out!

but what intake manifold do you need, single plane or dual plane?

I can tell you from experience that is RARE for a single plane intake to produce better AVERAGE power than a dual plane unless the cam duration exceeds about 240 degrees @ .050 lift AND the peak engine rpm exceeds 6500rpm

the basic operating range of most dual plane intakes on most 327 and larger SBC engines is about 1500rpm-6500rpm, while most single plane intakes are designed to operate in the 4000rpm-7000rpm power band but obviously increasing the engines displacement increases the air flow speeds thru the ports, the single planes shorter more direct port runner design, will flow slightly more air but it requires higher rpms to maintain the air flow rates needed for effective air flow inertia to effectively fill the cylinders, keep in mind this has a big effect on the rpm range that the cylinder heads and intake will work best in,but doesn,t necessarily indicate the power level your going to be producing, as smaller port head can produce impressive power in the rpm band they are designed to operate in, your usually working against restrictions,

as for example

your valve train components might limit you to 6300rpm, but your cylinder heads might easily allow your engine to spin 7000rpm and still produce good power with a different cam, or your cylinder heads could be restricting power but the intake and cam could easily operate at a higher average rpm range.

its up to the engine builder to match the power and rpm limitations of components used to allow maximum efficient within the restrictions

A CORRECTLY TUNED SET OF HEADERS , MATCHED TO A CORRECTLY DESIGNED CAM TIMING HAS A SIGNIFICANT EFFECT ON INTAKE FLOW AND CYLINDER SCAVENGING EFFICIENCY, EXHAUST SCAVENGING CAN BE 5 TIMES STRONGER THAN THE PISTON, MOVEMENT INDUCED NEGATIVE PRESSURE (VACUUM) IN THE INTAKE RUNNERS

you will need to match both the port cross sectional area and length to the cam timing , while taking into consideration the engine displacement and intended operational power band to select the correct intake manifold design.

Im assuming you know a good bit of info and are concentrating on selecting an intake to match parts you already have, but obviously you can calculate almost any thing you need to know if you just know the engine displacement, port size and cam timing.

lets look at this a bit, lets take for example a rather common 383 that we want to build to operate up to 6300 rpm, where we have found the hydraulic lifters don,t allow you to keep control of the valves, on your previously built 383 or 350,so you know a bit of useful info, now lets say you are using better heads on this engine build, youll need to know your cylinder heads cross sectional area and the valve size and lift, because those factors will effect max port flow rates and port stall speeds.

OK first step, you know the engine won,t rev with the current cam and intake past 6300rpm, but will that be true with the new engine?

HERES THE HYDRAULIC ROLLER CAM YOUR RE-USING

a simple calculation shows that at max valve lift the curtain area of the valve is larger than the runner cross sectional area so the cams unlikely to be a huge limiting factor in the combos ability to make power, but its duration maximizes the power in the upper mid range not peak power.

its not horsepower, its the stress on the valve train, that makes a rocker stud girdle and its increased rigidity useful,

and thats more closely related to average stress levels, RPM and VALVE SPRING LOAD RATES

any time your occasionally exceeding 6000rpm or getting close too 330 lbs of open valve load rate Id strongly suggest screw in rocker studs

any time your intentionally exceeding 6000rpm and exceeding 350 lbs of open valve spring rate a rocker stud girdle might be a good idea.

and if your regularly exceeding 6500rpm and 400 lbs of open valve spring load rate its use is going to become almost mandatory

http://www.summitracing.com/parts/pro-66950

http://www.summitracing.com/parts/sum-141010

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

OK lets assume you measure your cylinder heads intake ports and you find they have a 2.2 sq inch cross sectional area at the smallest point

(BTW I CAN ASSURE YOU that if you want better PEAK POWER NUMBERS swapping to a cylinder head that flows at least 280 cfm and has at LEAST a 2.6 sq inch cross sectional area would boost peak power

you use a a calculator and find that peak torque should occur near 4100 rpm, WITH THE CAM AND WITH THOSE 2.2 SQ INCH PORT HEADS , and that ideal runner length should be about 20" long

peak torque 4100rpm

http://www.rbracing-rsr.com/runnertorquecalc.html

IDEAL RUNNER LENGTH 20"

http://www.wallaceracing.com/runnertorquecalc.php

PORT STALL =6300rpm

http://www.wallaceracing.com/chokepoint.php

port velocity near 600fps PEAK

http://www.wallaceracing.com/lpv.php

FROM THE CALCULATED INFO it should be rather obvious that the longer runners in a dual plane intake and the basic operational range all point to a dual plane intake as being the best match, but its fairly close,if the peak torque was about 900rpm higher and the port stall was above 7000rpm,or higher, the balance point would more than likely favor the single plane intake, remember the single plane intake runners tend to be larger effectively reducing flow restriction.

http://www.summitracing.com/parts/EDL-7501/

this intakes great between about 1500rpm and about 6300rpm. but really likes to have a bit better cam and head flow than stock, or your not going to get nearly its full potential benefits and of course a low restriction exhaust and headers

http://www.summitracing.com/expertadvic ... Calculator

http://www.summitracing.com/parts/HLY-300-110/

this intakes great on a SBC between about 3700rpm and about 6800rpm IF YOU HAVE THE HEADS AND CAM TO USE THE FLOW POTENTIAL,On a non-supercharged engine, but its pretty much wasted with out a decent cam with at least 240 dur at .050 lift, and at least 10:1 minimum compression, and killer heads,that flow at least 250cfm at .500 lift OR with a supercharger with killer heads that flow at least 250cfm at .500 lift and a decent cam with at least 230 dur. at .050 lift and of course a low restriction exhaust and headers, but if you have an engine combo that does spend a great deal of its operational life in the 3800rpm-7000rpm power band you might want to look at it

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

SINGLE PLANE INTAKE DIMENSIONS (you can learn a great deal by actually measuring INTAKE ports and runners ETC.)

http://www.edelbrock.com/automotive_new ... ions.shtml

combining the info posted a 383 sbc has 47.8 cubic inches per cylinder divided by 2.02=23.7 on the chart above, so youll find cams in the correct duration range having a tight 105-108 lSA most efficient at filling the cylinders in many combos,

lets say we build a 496 big block with 2.19" intake valves,

496 divided by 8=62 cubic inches per cylinder, divided by 2.19=28.3. now look at the chart! you find youll need a rather tight 101-103 LSA

RELATED THREADS YOU SHOULD READ THRU

viewtopic.php?f=55&t=624

viewtopic.php?f=55&t=5378

http://www.wallaceracing.com/camcalc.php

viewtopic.php?f=55&t=2614&p=7114&hilit=tpis+runner#p7114

http://mysite.verizon.net/vzezeqah/site ... ystems.pdf

http://rehermorrison.com/tech-talk-70-a ... low-bench/

http://www.csgnetwork.com/automotiveconverters.html

anything you can do , to increase horse power with a tunnel ram,

can be duplicated and in most cases significantly improved with a stack injection set up.

Last edited by a moderator: