I get this question frequently so let me point out a few things

http://garage.grumpysperformance.co...at-manifold-air-temp-sensor.10349/#post-42530

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-25471

http://www.compcams.com/Community/Artic ... 1737510521

http://chevythunder.com/

http://www.superchevy.com/how-to/18459-chevrolet-corvette-c4-tpi-upgrades/

http://garage.grumpysperformance.com/index.php?threads/fuel-injector-resistance-reading.606/

http://garage.grumpysperformance.com/index.php?threads/fuel-line-sizing-return-vs-feed.3067/

http://garage.grumpysperformance.co...ed-a-dual-58mm-throttle-body-on-your-tpi.290/

http://garage.grumpysperformance.com/index.php?threads/throttle-body-size-52mm-vs-58mm.641/

http://garage.grumpysperformance.co...the-throttle-body-coolant-bypass-thing.10544/

http://www.hotrod.com/articles/hrdp-9812-10-common-efi-mistakes/

http://garage.grumpysperformance.co...ocity-vs-intake-runner-sizing.1099/#post-2152

http://mysite.verizon.net/vzezeqah/site ... ystems.pdf

http://www.eecis.udel.edu/~davis/z28/wi ... 21105.html

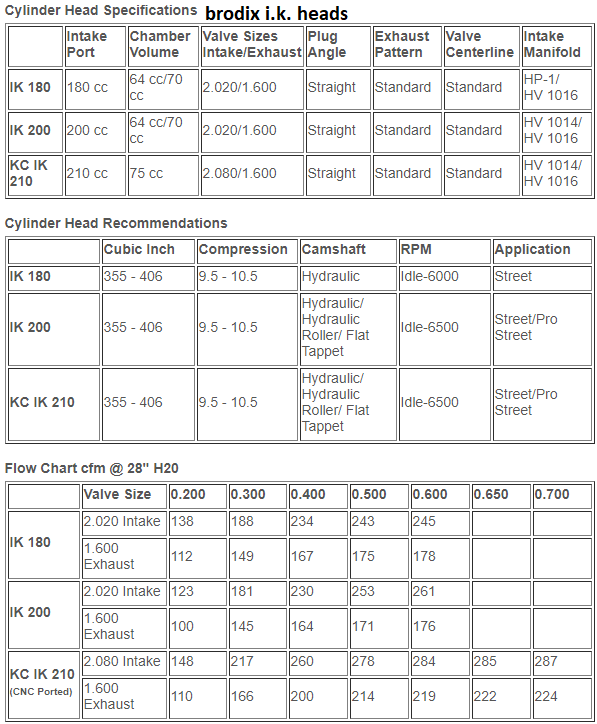

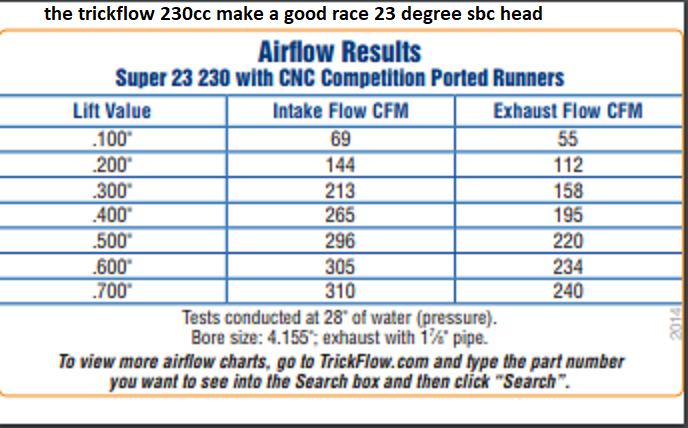

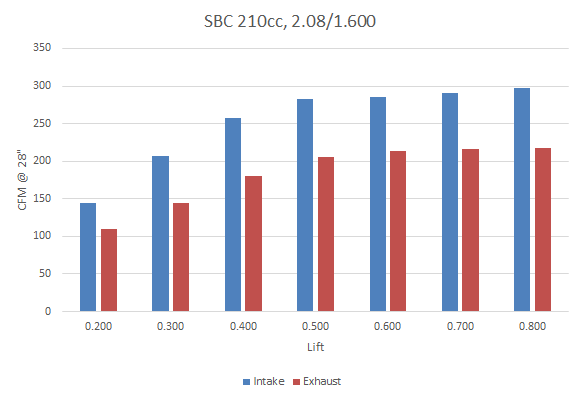

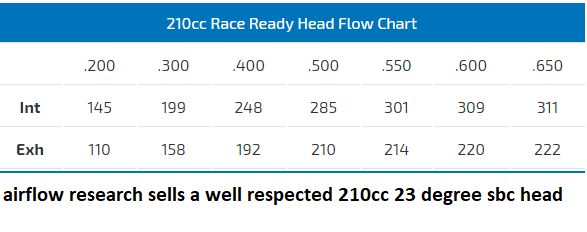

IF you check around on the site theres a good deal more cylinder head , port, and cam, flow data and info on how to match components, if youve got questions please post, as IVE got only about 10% of the info on my hard drives posted currently

the first thing you need to do is step back and decide ,anytime you plan engine upgrades you need to take the SYSTEM approach, as no one component alone will function to its full potential unless matched to other components that are designed to operate at the same rpm, flow and power rates, if your going to swap to far better heads, a larger duration cam, high efficiency & low restriction scavenging exhaust and higher numerically rear gearing , higher compression, possibly larger displacement and a low restriction exhaust so that a huge flow rate on the intake flow increase can be effectively used, or if your basically adding JUST an intake to add some upper rpm flow to a basically stock engine where you don,t intend to do other major mods, the difference in what your trying to do and the results your likely to see will dictate a totally different approach. a simple intake change alone won,t produce outstanding results, its the old (weakest link in the chain deal) even if the intake flow is potentially far better, if the heads and cam won,t allow the intake to flow up to its full potential you won,t see a big change, and too get a noticeable change, all three components need to be upgraded

the most common mistake made by many people is that they fail to look at an engine as an interconnected group of component sub systems and they don,t realize that changes to a single component, no mater how much potential that component has,is not going to allow that component or change in the potential to be realized until all the matched and supporting systems have similar potential.

EXAMPLE ,

the heads may be capable of flowing (x) on a stock engine but with careful selection of a cam with the correct duration and lift, and with a tuned header, and matching valve train mods along with some port and bowl clean-up the resulting improvements can be significantly more impressive.

http://www.jegs.com/webapp/wcs/stores/servlet/topcategory_10001_10002_-1

https://www.ebay.com/itm/Weiand-908...For-Use-With-144-174-Blower-Kits/400669303867

https://www.ebay.com/itm/Weiand-622...r-Small-Block-and-Big-Block-Chev/112273744933

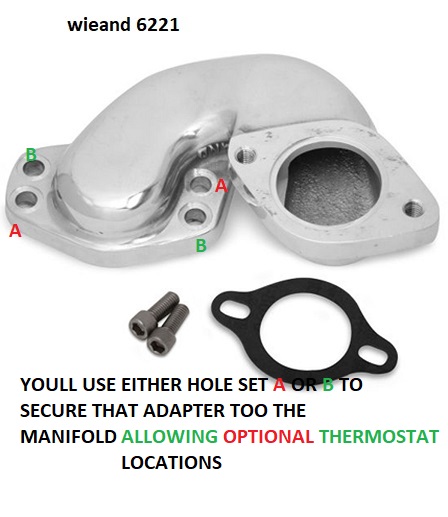

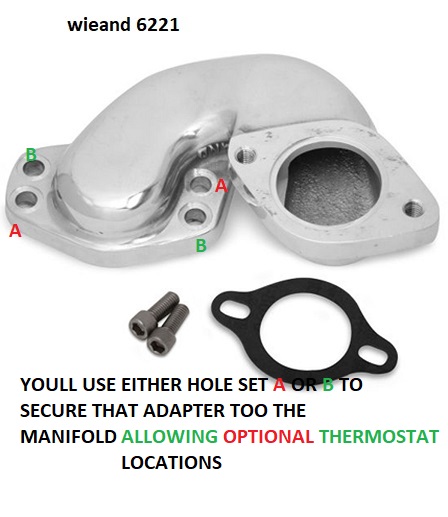

IF YOU HAVE THERMOSTAT TO THROTTLE BODY CLEARANCE ISSUES

Have one to sell? Sell now

Weiand 6221 Offset Thermostat Housing Adapter For Small Block and Big Block Chev

your problem is VERY COMMON, if the throttle body and thermostat housing has a clearance issue on some modified EFI intakes, heres the usual cure

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/

http://garage.grumpysperformance.co...2-bbc-rebuild-but-think-things-through.13604/

http://garage.grumpysperformance.co...t-intake-on-oval-port-heads.13146/#post-69975

use this calculator

http://www.rbracing-rsr.com/runnertorquecalc.html

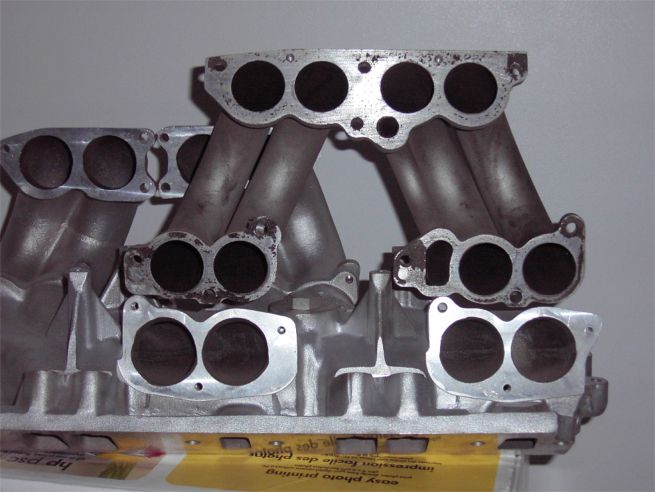

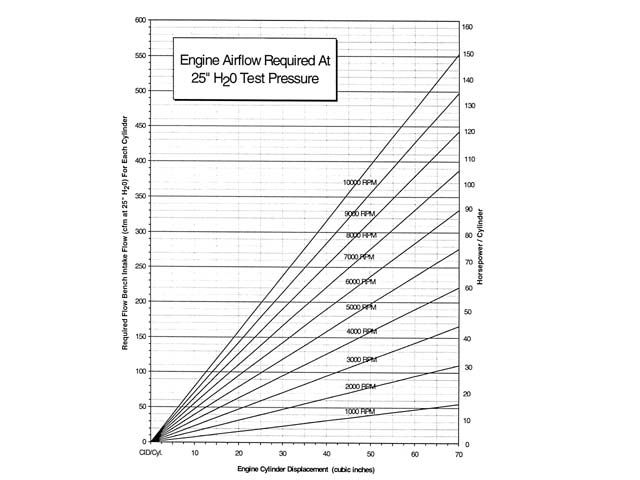

it should open your eyes, the stock TPI runner is optomised for 3400rpm on a 350, with its 1.7 sq inch cross section,swap to, for example the larger FIRST TPI, it jumps to 4800rpm, with its un ported 2.4 sq inch cross section, that alone is worth almost 100 hp is both engines made the same peak 400 ft lbs of torque at there optimum rpm peaks, but your likely to find the larger ports more efficient.

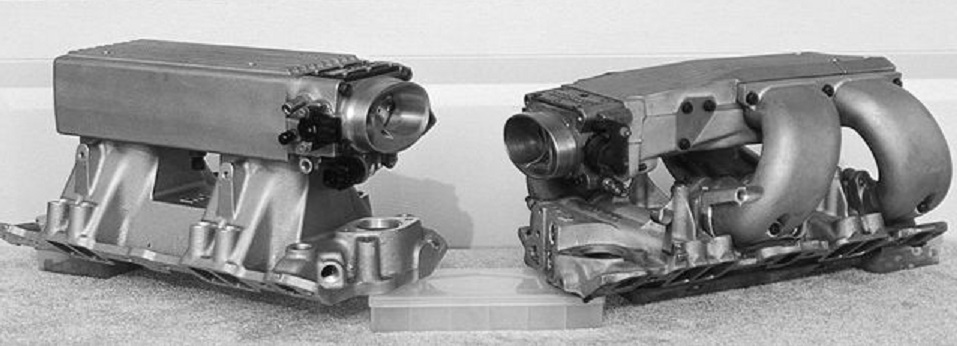

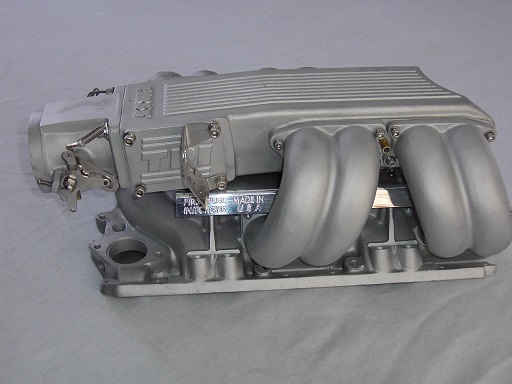

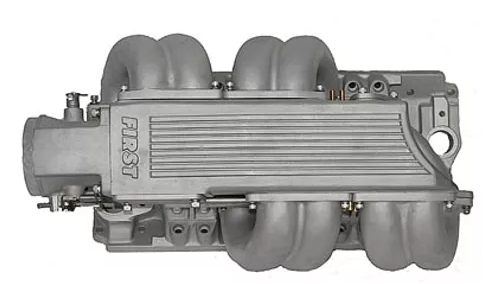

that's one reason the MINI-ram advertises it can make 100 more hp than a TPI, its not that the mini-ram, FIRST,or STEALTHRAM intakes that great, its that THEY ALL allow the engine to breath far higher into the engines upper rpm range where the stock GM TPI has become exceptionally restrictive to flow compared too,the mini-ram, FIRST,or STEALTHRAM intake

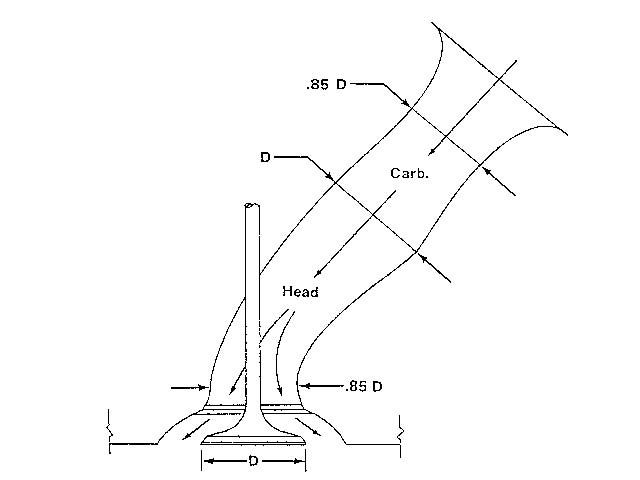

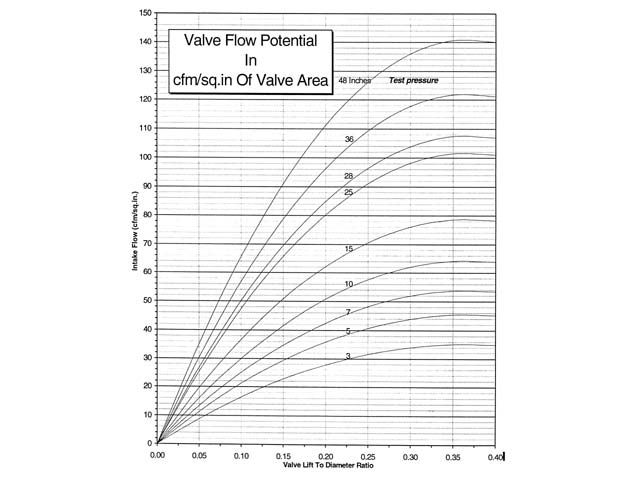

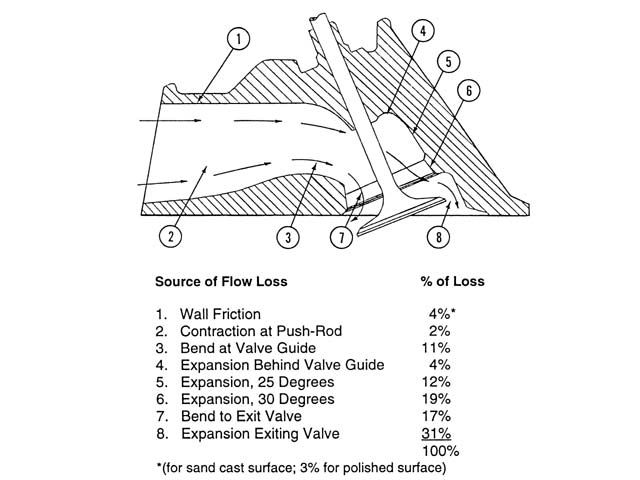

when you combine head flow with intake flow in most cases those measurements were done on the individual components on a flow bench, if the heads flow 200cfm at .500 lift and the intake flows 190cfm that in no way indicates that you'll reach similar numbers with all the components bolted together.

remember your valve is only at full lift (AND THAT'S WELL UNDER .500 with a stock cam) for a very few degrees in the 720 degree repeat cycle, so your very unlikely to even approach those flow numbers, with the stock cam that has about a 195 intake duration, at .050 lift, that's about 27% of the total cycle even if the cam was INSTANTLY fully open and held open for the full 27% of the time, but the truth is its open for a great deal less time at peak flow.

the stock TPI head flow is in the 190cfm-200cfm range, that matches the stock head flow rates,and the stock cam lift.

read thru the posted links theres a good deal of useful info, but keep in mind its a balanced system your after designed to operate in a known rpm range and displacement, its almost always better to increase flow rates and engine displacement, but most components must match, a killer cam designed to operate at 6700rpm won,t work well with heads that effectively become a restriction at 5500rpm, an intake designed to maximize power at 5500rpm should be matched to a cam and heads designed for a similar rpm band and a drive train designed or allow the engine to opperate in that same rpm band 90% of the time.

larger displacements, higher compression ratios and carefully matched components can produce an engine that has impressive torque, excellent durrability and a car thats fun to drive at BOTH the track and on the street!

peak horsepowers nice for bragging but having instantly available massive torque in your cars intended rpm band, matching your trans and gear ratios, is far nicer on the street, and almost as fast or just as fast on the track. keep in mind your cars drive train ,trans stall speed and rear gearing must match the power curve.

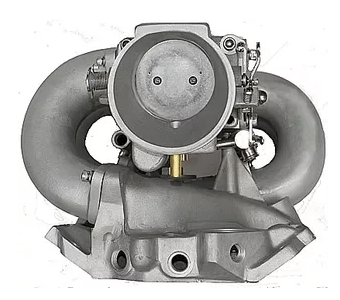

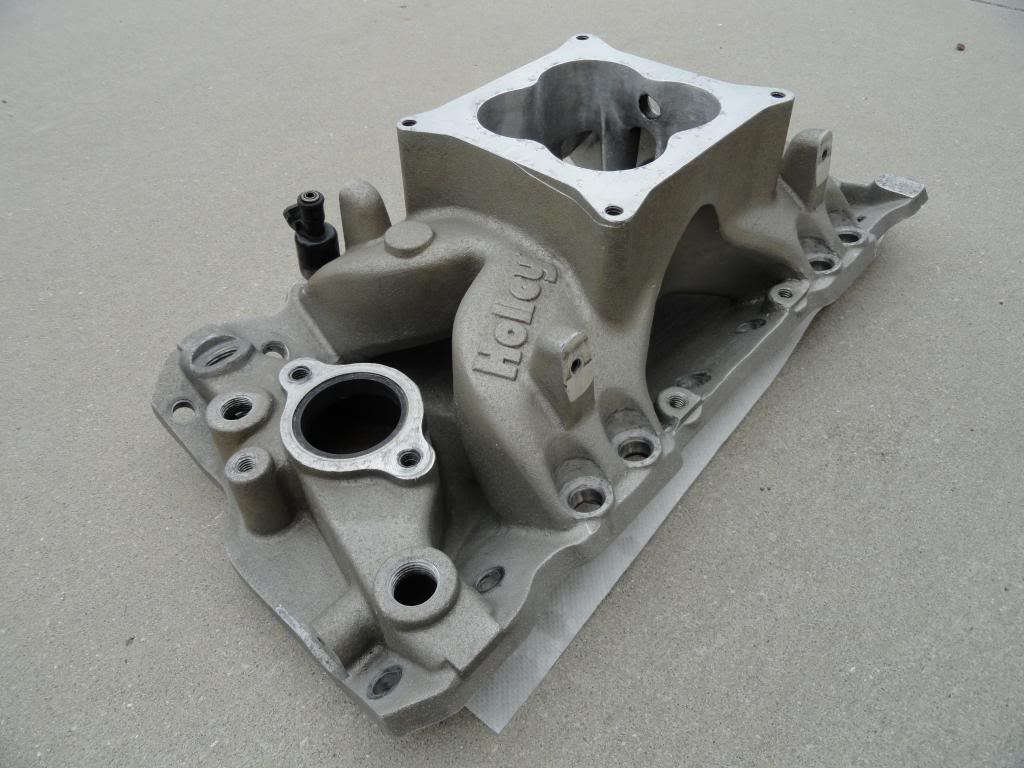

Ive tested a bunch of IMPROVE TPI REPLACEMENT style intakes on my cars, one of the best is the ported HOLLEY STEALTH RAM, but theres CLEARANCE ISSUES on some cars as its 10" tall and a corvette for example has only 9" of hood clearance so a CUSTOM PLENUM or a HOOD SCOOP is MANDATORY TO RUN ONE on a corvette for example !

viewtopic.php?f=52&t=92

the stock TPI intake flow rarely reaches 196cfm

http://dtcc.cz28.com/flow/index.htm

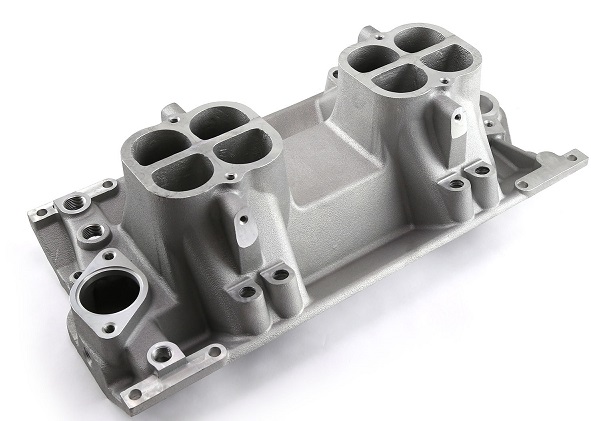

IF your keeping the stock heads and cam , or even just the stock heads and a decent upgraded cam you'll want to keep the basic engine configuration similar to the TPI, in the rpm range and power curve configuration, but you want to add flow to boost the hp, the SUPER RAM, or the FIRST TPI, but keep in mind the results you see won,t reflect the intakes true potential without better heads and a cam with more duration that will allow the heads, intake and cam to flow the necessary air to produce significantly higher power levels.

both those intakes are designed to maximize torque in about the 1800rpm-5800rpm band(depends on porting, heads,displacement, compression, head flow, exhaust scavenging etc.

they will maintain the basic rpm band but at higher flow rates,thus youll have noticably more power without getting into the short block too much,

the mini-ram and stealth ram are both designed to operate a a noticably higher rpm band (about the 3500rpm-6700rpm band) so better heads and higher (3.54:1-3.73:1)rear gear ratios, larger durration cams (usually in the 220-min-to at least 239-245 dur max at .050 lift) range and higher compression ratios become almost mandatory if you want to maximize those intake manifolds potential.

http://stealthram.com/flowcomparison.html

(keep in mind in some cases the intakes are ported and in some cases they were right out of the box)

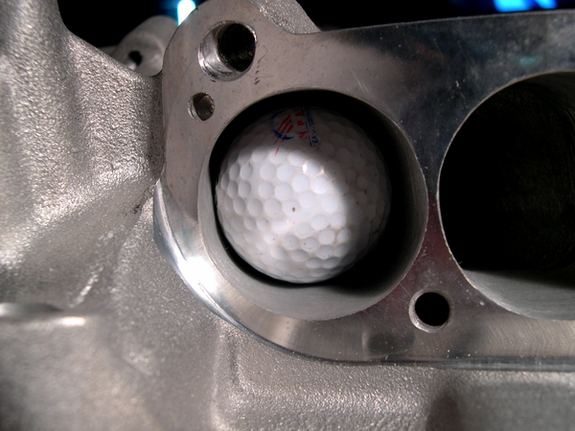

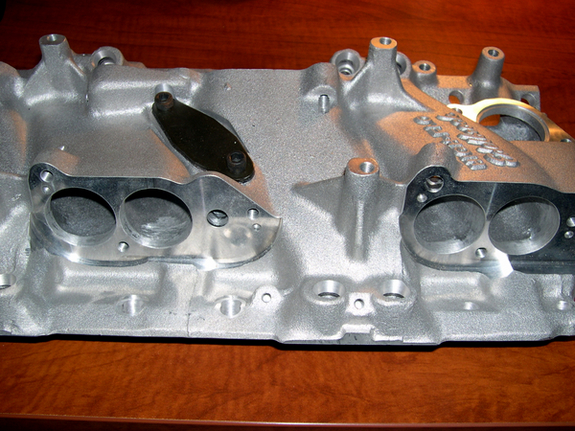

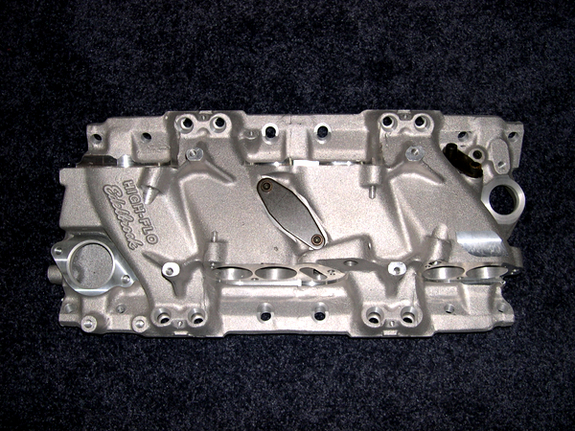

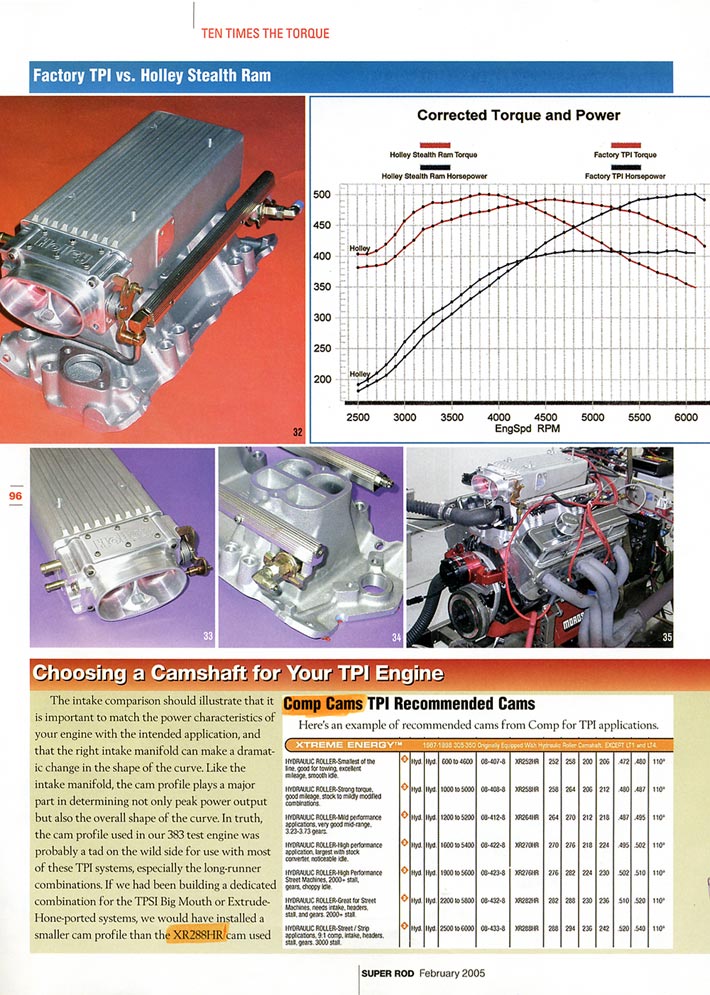

Here's some flow figures, right off the manufactures sites in many cases. Keep in mind the concept of the chains weakest link. It does ABSOLUTELY no good to match a base or runners on a TPI intake that flows 250cfm if the other part flows 200cfm. You'll still only flow 200cfm. The HOLLEY STEALTH RAM FLOWS at 275cfm out of the box,(minor port clean-up work) and can easily reach 300cfm with minor port work. The stock TPI has a hard time flowing 230cfm even with minor port work. Look here. Most of this info is right off the Accel, Holley, Edelbrock, and TPIS sites. Add a little math and the results become much clearer!!!

Intake......runner length .... port in...... out

Stock GM Base----- 6.375"------------- 1.47"------- 1.96x1.20

TPIS base------------6.125"------------- 1.75"------- 2.09x1.28

Accel base-----------6.125"------------- 1.75"---------2.09x1.28

Holley base--------- 6.000" ------------ 2.30â€-------- 1.90x1.23 (2.337 sq inches)

Runners

Stock TPI-------- 7.250"------1.470" round(1.70 sq inches)

SLP -------------- 6.625"------1.600" round (2.01 sq inches)

Accel LTR------- 6.625"------1.615" round (2.05 sq inches)

TPiS-------------- 7.625"------1.660" round (2.168 sq inches)

Mini ram --------3.500â€

stock MRII with 1204 (AFR 195) ports, 58MM - 265 cfm

stock MRII with 1206 (AFR 220) ports, 58MM - 281 cfm

MRII clean-up, 1206 ports, 58MM - 292 cfm

MRII cut, weld, port, etc, 58MM - 321 cfm

LT1 ----------3.000â€

Runners (measured individually)

Stock........................................................................................................................................203.17 cfm

ACCEL.....................................................................................................................................242.02 cfm

Extrude/ACCEL........................................................................................................................275.83 cfm

Super Ram................................................................................................................................289.18 cfm

Intake manifold with 3/8 inch radiused inlet .............................................................................222.45 cfm

Holley stealth ram ………..........................................................................................................275.00 cfm

Stock intake manifold with runner

Stock.........................................................................................................................................198.72 cfm

ACCEL......................................................................................................................................213.52 cfm

Extrude/ACCEL.........................................................................................................................217.11 cfm

Super Ram.................................................................................................................................220.67 cfm

Holley stealth ram ….................................................................................................................275.00 cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.....................................................251.51 cfm

ACCEL Hi-Flow intake manifold with runner Stock...................................................................215.83 cfm

ACCEL......................................................................................................................................232.53 cfm

Extrude/ACCEL.........................................................................................................................243.21 cfm

Super Ram.................................................................................................................................240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.............................275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner.......................................266.94 cfm

Edelbrock Performer RPM manifold (Stock)...............................................................................286.51 cfm

Edelbrock Victor Jr....................................................................................................................275.24 cfm

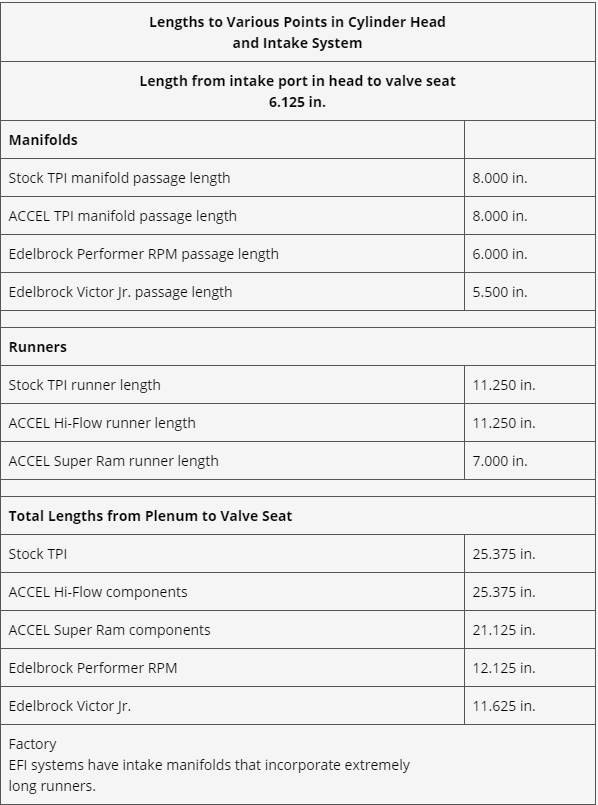

Runner Length

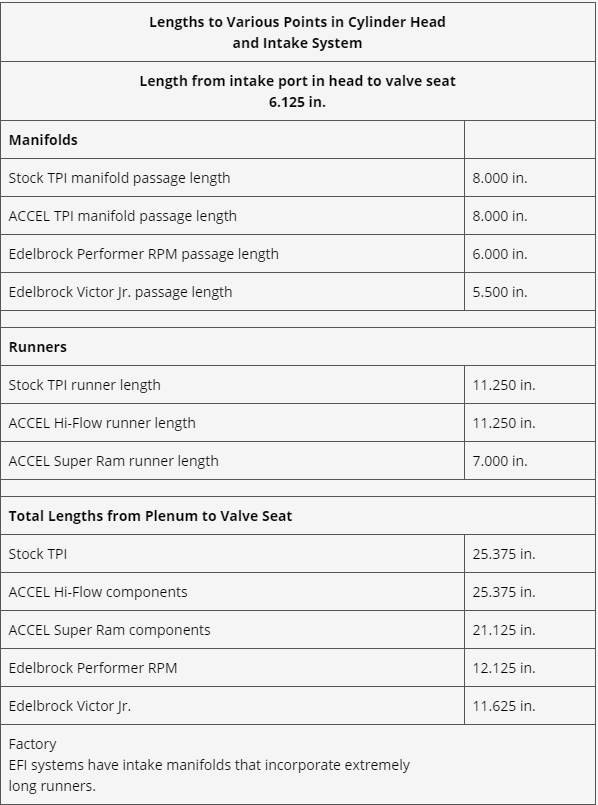

Stock TPI manifold ...................8†...............runners 11.25â€............... cylinder head 6â€.............total 25.25â€

Accel super ram manifold........ 8â€................runners 7.00â€............... cylinder head 6â€............ total 21.00â€

Holley stealth ram manifold .....6.26†................................................. cylinder head 6â€............ total 12.26â€

Edelbrock performer RPM ...........................runners 6.00â€................ cylinder head 6â€............ total 12.00â€

Edelbrock Victor Jr .......................................runners 5.50â€................ cylinder head 6â€............ total 11.50â€

Now playing with the figure in the calculators below, what you'll find is that if your using a 350 size engine as a guide, the tpi runner length is ideal for peak tq 3427rpm and 2700-4000rpm for peak hp.

The Accel Super Ram is ideal for peak tq at 4032rpm and 3300rpm-4800rpm for peak hp.

Holley's Stealth Ram runner length is ideal at 4700 for peak tq and 5618rpm to 6282rpm for peak hp.

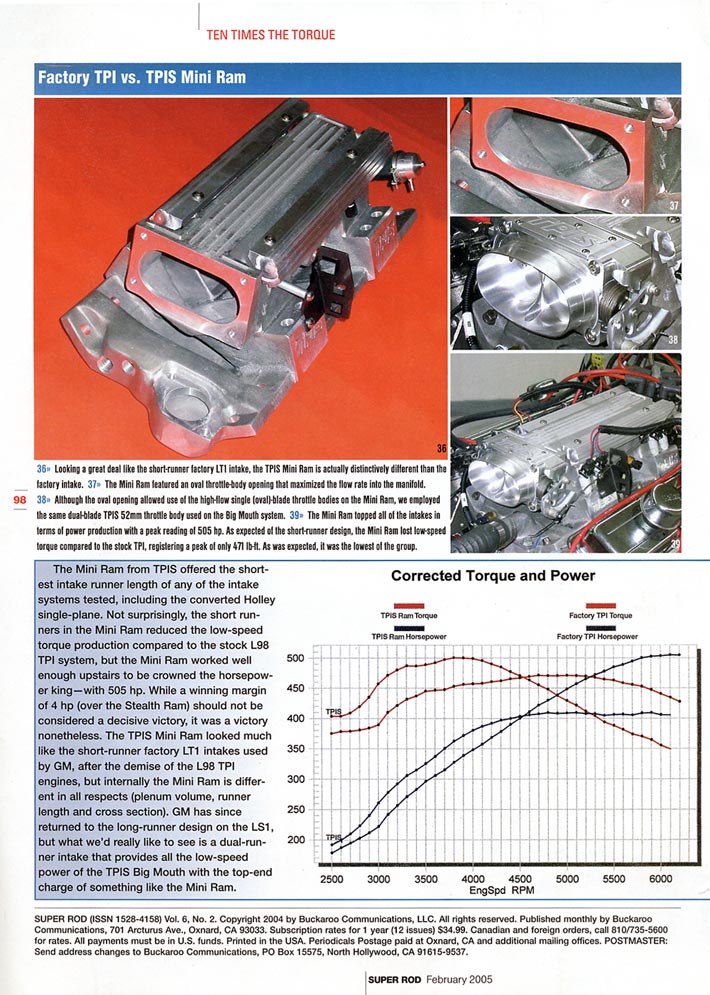

The TPIS Mini Ram and LT1 intakes are ideal for peak tq at about 5200rpm and 7244rpm to 8101rpm for peak hp.

By hp peak, in the above lists, I'M REFERRING TO THE RPM RANGE WHERE combination of cross sectional area MATCHED TO THE plenum to INTAKE valve distance WHERE THE internal AIRFLOW HARMONICS TEND TO INCREASE THE CYLINDER FILLING EFFICIENCY (WHERE THE INTAKE WILL TEND TO PULL THE MOST HP). Now KEEP FIRMLY IN MIND the engines tend to enter valve float and get close to engine red line by 6300-6700rpm depending on your combo. After running all the available combos, I've found a HOLLEY STEALTH RAM has been EXTREMELY EFFECTIVE on several engines tested. CURRENTLY THE STEALTH RAM SEEMS TO

BE THE CHOICE, ESPECIALLY IF MATCHED TO GOOD CYLINDER HEADS AND THE CORRECT

CAM.

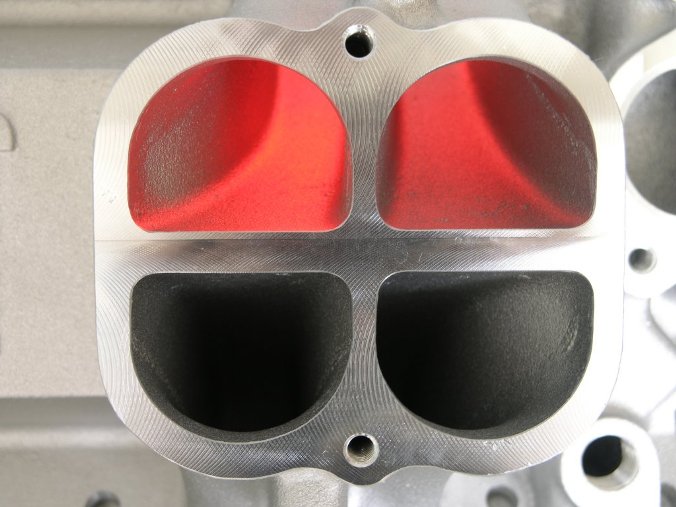

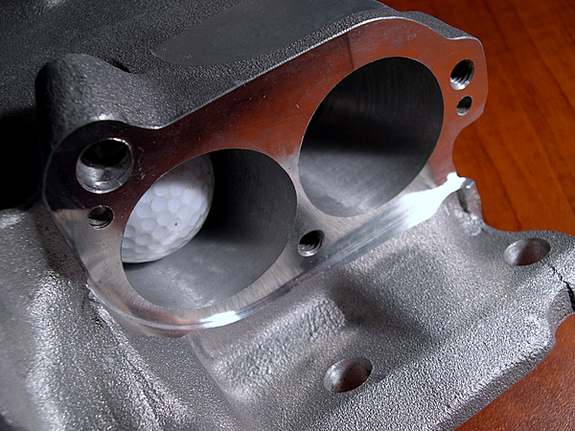

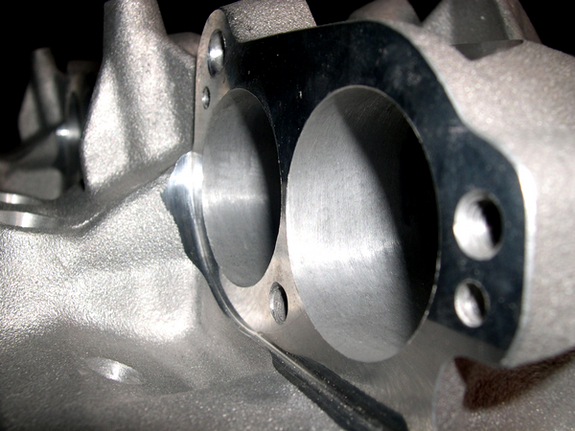

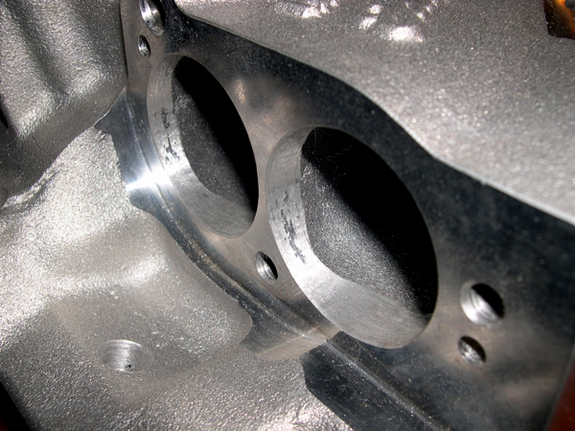

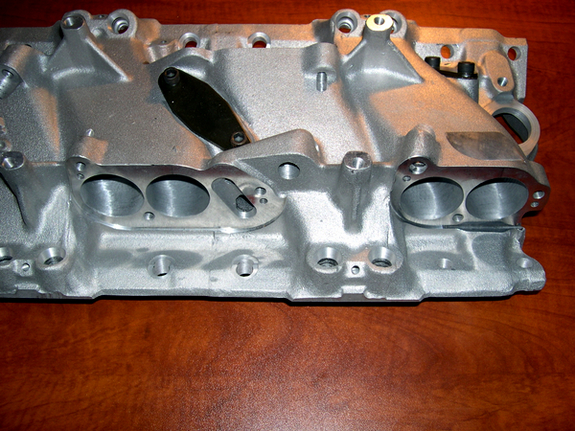

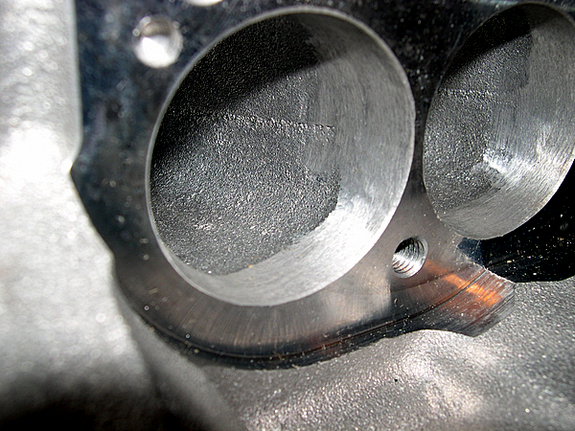

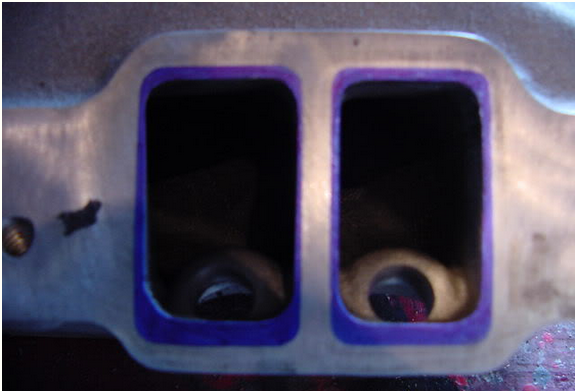

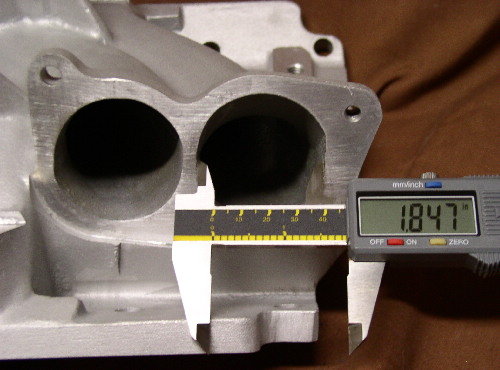

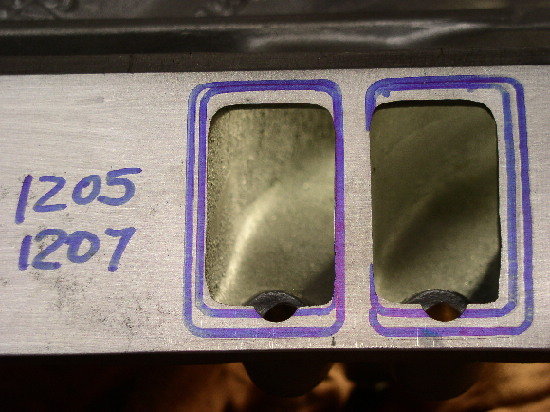

The intake ports on the STEALTHRAM as it comes from HOLLEY. It fits the Felpro #1205 gasket port size.

viewtopic.php?f=55&t=431&p=530#p530

the stock cam is designed for maximium cylinder fill efficiency at no more than 5500rpm

viewtopic.php?f=52&t=133

viewtopic.php?f=52&t=324

viewtopic.php?f=52&t=904

viewtopic.php?f=52&t=1477

the stock stamped rockers are rarely at a full 1.5:1 ratio, in fact 1.45:1 is comon when carefully tested with a dial indicator

viewtopic.php?f=52&t=126

viewtopic.php?f=52&t=553

viewtopic.php?f=71&t=435

viewtopic.php?f=52&t=198

http://garage.grumpysperformance.co...at-manifold-air-temp-sensor.10349/#post-42530

“While I’m this far….?”

I must have said this to myself daily for the past few months & I end up going deeper into my corvette engine. So I need some advice on what I should &/or perhaps not do. My vette is an 89 w/around 72k miles on her. I finally decided to pull her from close to a decade of hibernation to...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-25471

http://www.compcams.com/Community/Artic ... 1737510521

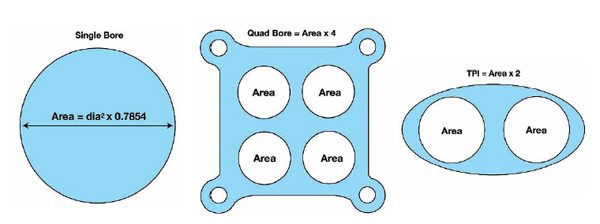

do you need a dual 58mm throttle body on your TPI?

I get asked frequently if installing a larger than the stock 48mm TPI throttle body will significantly help on a corvette engine, Ill save you some reading right off if you want, yes a 58mm can potentially increase hp if your engines highly modified and your still useing a stock 48mm throttle...

garage.grumpysperformance.com

http://chevythunder.com/

http://www.superchevy.com/how-to/18459-chevrolet-corvette-c4-tpi-upgrades/

http://garage.grumpysperformance.com/index.php?threads/fuel-injector-resistance-reading.606/

http://garage.grumpysperformance.com/index.php?threads/fuel-line-sizing-return-vs-feed.3067/

http://garage.grumpysperformance.co...ed-a-dual-58mm-throttle-body-on-your-tpi.290/

http://garage.grumpysperformance.com/index.php?threads/throttle-body-size-52mm-vs-58mm.641/

http://garage.grumpysperformance.co...the-throttle-body-coolant-bypass-thing.10544/

http://www.hotrod.com/articles/hrdp-9812-10-common-efi-mistakes/

http://garage.grumpysperformance.co...ocity-vs-intake-runner-sizing.1099/#post-2152

http://mysite.verizon.net/vzezeqah/site ... ystems.pdf

http://www.eecis.udel.edu/~davis/z28/wi ... 21105.html

IF you check around on the site theres a good deal more cylinder head , port, and cam, flow data and info on how to match components, if youve got questions please post, as IVE got only about 10% of the info on my hard drives posted currently

the first thing you need to do is step back and decide ,anytime you plan engine upgrades you need to take the SYSTEM approach, as no one component alone will function to its full potential unless matched to other components that are designed to operate at the same rpm, flow and power rates, if your going to swap to far better heads, a larger duration cam, high efficiency & low restriction scavenging exhaust and higher numerically rear gearing , higher compression, possibly larger displacement and a low restriction exhaust so that a huge flow rate on the intake flow increase can be effectively used, or if your basically adding JUST an intake to add some upper rpm flow to a basically stock engine where you don,t intend to do other major mods, the difference in what your trying to do and the results your likely to see will dictate a totally different approach. a simple intake change alone won,t produce outstanding results, its the old (weakest link in the chain deal) even if the intake flow is potentially far better, if the heads and cam won,t allow the intake to flow up to its full potential you won,t see a big change, and too get a noticeable change, all three components need to be upgraded

the most common mistake made by many people is that they fail to look at an engine as an interconnected group of component sub systems and they don,t realize that changes to a single component, no mater how much potential that component has,is not going to allow that component or change in the potential to be realized until all the matched and supporting systems have similar potential.

EXAMPLE ,

the heads may be capable of flowing (x) on a stock engine but with careful selection of a cam with the correct duration and lift, and with a tuned header, and matching valve train mods along with some port and bowl clean-up the resulting improvements can be significantly more impressive.

http://www.jegs.com/webapp/wcs/stores/servlet/topcategory_10001_10002_-1

https://www.ebay.com/itm/Weiand-908...For-Use-With-144-174-Blower-Kits/400669303867

https://www.ebay.com/itm/Weiand-622...r-Small-Block-and-Big-Block-Chev/112273744933

IF YOU HAVE THERMOSTAT TO THROTTLE BODY CLEARANCE ISSUES

Have one to sell? Sell now

Weiand 6221 Offset Thermostat Housing Adapter For Small Block and Big Block Chev

your problem is VERY COMMON, if the throttle body and thermostat housing has a clearance issue on some modified EFI intakes, heres the usual cure

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/

http://garage.grumpysperformance.co...2-bbc-rebuild-but-think-things-through.13604/

http://garage.grumpysperformance.co...t-intake-on-oval-port-heads.13146/#post-69975

use this calculator

http://www.rbracing-rsr.com/runnertorquecalc.html

it should open your eyes, the stock TPI runner is optomised for 3400rpm on a 350, with its 1.7 sq inch cross section,swap to, for example the larger FIRST TPI, it jumps to 4800rpm, with its un ported 2.4 sq inch cross section, that alone is worth almost 100 hp is both engines made the same peak 400 ft lbs of torque at there optimum rpm peaks, but your likely to find the larger ports more efficient.

that's one reason the MINI-ram advertises it can make 100 more hp than a TPI, its not that the mini-ram, FIRST,or STEALTHRAM intakes that great, its that THEY ALL allow the engine to breath far higher into the engines upper rpm range where the stock GM TPI has become exceptionally restrictive to flow compared too,the mini-ram, FIRST,or STEALTHRAM intake

when you combine head flow with intake flow in most cases those measurements were done on the individual components on a flow bench, if the heads flow 200cfm at .500 lift and the intake flows 190cfm that in no way indicates that you'll reach similar numbers with all the components bolted together.

remember your valve is only at full lift (AND THAT'S WELL UNDER .500 with a stock cam) for a very few degrees in the 720 degree repeat cycle, so your very unlikely to even approach those flow numbers, with the stock cam that has about a 195 intake duration, at .050 lift, that's about 27% of the total cycle even if the cam was INSTANTLY fully open and held open for the full 27% of the time, but the truth is its open for a great deal less time at peak flow.

the stock TPI head flow is in the 190cfm-200cfm range, that matches the stock head flow rates,and the stock cam lift.

read thru the posted links theres a good deal of useful info, but keep in mind its a balanced system your after designed to operate in a known rpm range and displacement, its almost always better to increase flow rates and engine displacement, but most components must match, a killer cam designed to operate at 6700rpm won,t work well with heads that effectively become a restriction at 5500rpm, an intake designed to maximize power at 5500rpm should be matched to a cam and heads designed for a similar rpm band and a drive train designed or allow the engine to opperate in that same rpm band 90% of the time.

larger displacements, higher compression ratios and carefully matched components can produce an engine that has impressive torque, excellent durrability and a car thats fun to drive at BOTH the track and on the street!

peak horsepowers nice for bragging but having instantly available massive torque in your cars intended rpm band, matching your trans and gear ratios, is far nicer on the street, and almost as fast or just as fast on the track. keep in mind your cars drive train ,trans stall speed and rear gearing must match the power curve.

Ive tested a bunch of IMPROVE TPI REPLACEMENT style intakes on my cars, one of the best is the ported HOLLEY STEALTH RAM, but theres CLEARANCE ISSUES on some cars as its 10" tall and a corvette for example has only 9" of hood clearance so a CUSTOM PLENUM or a HOOD SCOOP is MANDATORY TO RUN ONE on a corvette for example !

viewtopic.php?f=52&t=92

the stock TPI intake flow rarely reaches 196cfm

http://dtcc.cz28.com/flow/index.htm

IF your keeping the stock heads and cam , or even just the stock heads and a decent upgraded cam you'll want to keep the basic engine configuration similar to the TPI, in the rpm range and power curve configuration, but you want to add flow to boost the hp, the SUPER RAM, or the FIRST TPI, but keep in mind the results you see won,t reflect the intakes true potential without better heads and a cam with more duration that will allow the heads, intake and cam to flow the necessary air to produce significantly higher power levels.

both those intakes are designed to maximize torque in about the 1800rpm-5800rpm band(depends on porting, heads,displacement, compression, head flow, exhaust scavenging etc.

they will maintain the basic rpm band but at higher flow rates,thus youll have noticably more power without getting into the short block too much,

the mini-ram and stealth ram are both designed to operate a a noticably higher rpm band (about the 3500rpm-6700rpm band) so better heads and higher (3.54:1-3.73:1)rear gear ratios, larger durration cams (usually in the 220-min-to at least 239-245 dur max at .050 lift) range and higher compression ratios become almost mandatory if you want to maximize those intake manifolds potential.

http://stealthram.com/flowcomparison.html

(keep in mind in some cases the intakes are ported and in some cases they were right out of the box)

Here's some flow figures, right off the manufactures sites in many cases. Keep in mind the concept of the chains weakest link. It does ABSOLUTELY no good to match a base or runners on a TPI intake that flows 250cfm if the other part flows 200cfm. You'll still only flow 200cfm. The HOLLEY STEALTH RAM FLOWS at 275cfm out of the box,(minor port clean-up work) and can easily reach 300cfm with minor port work. The stock TPI has a hard time flowing 230cfm even with minor port work. Look here. Most of this info is right off the Accel, Holley, Edelbrock, and TPIS sites. Add a little math and the results become much clearer!!!

Intake......runner length .... port in...... out

Stock GM Base----- 6.375"------------- 1.47"------- 1.96x1.20

TPIS base------------6.125"------------- 1.75"------- 2.09x1.28

Accel base-----------6.125"------------- 1.75"---------2.09x1.28

Holley base--------- 6.000" ------------ 2.30â€-------- 1.90x1.23 (2.337 sq inches)

Runners

Stock TPI-------- 7.250"------1.470" round(1.70 sq inches)

SLP -------------- 6.625"------1.600" round (2.01 sq inches)

Accel LTR------- 6.625"------1.615" round (2.05 sq inches)

TPiS-------------- 7.625"------1.660" round (2.168 sq inches)

Mini ram --------3.500â€

stock MRII with 1204 (AFR 195) ports, 58MM - 265 cfm

stock MRII with 1206 (AFR 220) ports, 58MM - 281 cfm

MRII clean-up, 1206 ports, 58MM - 292 cfm

MRII cut, weld, port, etc, 58MM - 321 cfm

LT1 ----------3.000â€

Runners (measured individually)

Stock........................................................................................................................................203.17 cfm

ACCEL.....................................................................................................................................242.02 cfm

Extrude/ACCEL........................................................................................................................275.83 cfm

Super Ram................................................................................................................................289.18 cfm

Intake manifold with 3/8 inch radiused inlet .............................................................................222.45 cfm

Holley stealth ram ………..........................................................................................................275.00 cfm

Stock intake manifold with runner

Stock.........................................................................................................................................198.72 cfm

ACCEL......................................................................................................................................213.52 cfm

Extrude/ACCEL.........................................................................................................................217.11 cfm

Super Ram.................................................................................................................................220.67 cfm

Holley stealth ram ….................................................................................................................275.00 cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.....................................................251.51 cfm

ACCEL Hi-Flow intake manifold with runner Stock...................................................................215.83 cfm

ACCEL......................................................................................................................................232.53 cfm

Extrude/ACCEL.........................................................................................................................243.21 cfm

Super Ram.................................................................................................................................240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.............................275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner.......................................266.94 cfm

Edelbrock Performer RPM manifold (Stock)...............................................................................286.51 cfm

Edelbrock Victor Jr....................................................................................................................275.24 cfm

Runner Length

Stock TPI manifold ...................8†...............runners 11.25â€............... cylinder head 6â€.............total 25.25â€

Accel super ram manifold........ 8â€................runners 7.00â€............... cylinder head 6â€............ total 21.00â€

Holley stealth ram manifold .....6.26†................................................. cylinder head 6â€............ total 12.26â€

Edelbrock performer RPM ...........................runners 6.00â€................ cylinder head 6â€............ total 12.00â€

Edelbrock Victor Jr .......................................runners 5.50â€................ cylinder head 6â€............ total 11.50â€

Now playing with the figure in the calculators below, what you'll find is that if your using a 350 size engine as a guide, the tpi runner length is ideal for peak tq 3427rpm and 2700-4000rpm for peak hp.

The Accel Super Ram is ideal for peak tq at 4032rpm and 3300rpm-4800rpm for peak hp.

Holley's Stealth Ram runner length is ideal at 4700 for peak tq and 5618rpm to 6282rpm for peak hp.

The TPIS Mini Ram and LT1 intakes are ideal for peak tq at about 5200rpm and 7244rpm to 8101rpm for peak hp.

By hp peak, in the above lists, I'M REFERRING TO THE RPM RANGE WHERE combination of cross sectional area MATCHED TO THE plenum to INTAKE valve distance WHERE THE internal AIRFLOW HARMONICS TEND TO INCREASE THE CYLINDER FILLING EFFICIENCY (WHERE THE INTAKE WILL TEND TO PULL THE MOST HP). Now KEEP FIRMLY IN MIND the engines tend to enter valve float and get close to engine red line by 6300-6700rpm depending on your combo. After running all the available combos, I've found a HOLLEY STEALTH RAM has been EXTREMELY EFFECTIVE on several engines tested. CURRENTLY THE STEALTH RAM SEEMS TO

BE THE CHOICE, ESPECIALLY IF MATCHED TO GOOD CYLINDER HEADS AND THE CORRECT

CAM.

bytor said:Came across this info while doing some research and thought I'd share.

http://www.hobracing.com/tech/tpi_flow.asp

TPI Intakes and runners

The following airflow tests were performed on the University of Northwestern Ohio's SuperFlow SF600 Flow Bench. All CFM values are corrected for airflow at 28 inches of water. Injector flow rates are flowed at 43.5 PSI on an injector flow bench using test fluid with same density as gasoline.

AirFlow

Stock TPI/LT1 48mm Throttle Body w/o airfoil -- 783.0 cfm

Stock TPI/LT1 48mm Throttle Body w/ airfoil -- 821.9 cfm

TPI/LT1 52mm Throttle Body w/o airfoil -- 848.9 cfm

TPI/LT1 52mm Throttle Body w/ airfoil -- 898.8 cfm

Stock 98 Camaro 3800 II Throttle Body -- 554.3 cfm

Stock TPI Bosch MAF sensor w/ screens -- 517.8 cfm

Stock TPI Bosch MAF sensor w/o screens -- 658.4 cfm

Stock 87 GN 3.8L Turbo AC MAF sensor w/ screen -- 584.2 cfm

Stock 86 2.8L AC 5-wire MAF sensor w/ screen -- 576.2 cfm

Stock 96-up AC 3100 V6 MAF sensor w/ screen -- 616.4 cfm

Stock 96-up AC 3100 V6 MAF sensor w/o screen -- 670.7 cfm

Stock 94-up LT1 MAF Sensor w/o screen -- 719.0 cfm

Stock 85-87 Firebird TPI airbox mid piece -- 499.3 cfm

Stock 4.3/5.0/5.7 2bbl TBI complete -- 574.1 cfm (dry)

Stock 4.3/5.0/5.7 2bbl TBI w/o injectors -- 584.7 cfm

Stock 3800 vin L throttle body w/ screen -- 419.1 cfm

Stock 3800 vin L throttle body w/o screen -- 444.8 cfm

4bbl MPFI Holley Throttle Body -- 1287.6 cfm

Another source sent in these flow numbers

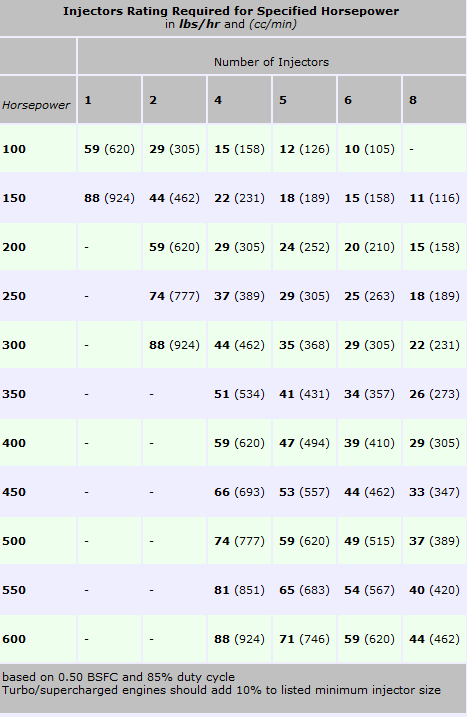

Flow and HP ratings for Throttle-bodies:

Flow (cfm) Max. NA HP

Stock 668 300

Stock w/airfoil 710 350

52MM w/airfoil 835 400

54MM (AS&M) 900 450

58MM 1050 500

TPI Intakes and runners flow rates

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

the stock TPI has a hard time flowing 230cfm even with minor port work, look here

most of this info is right off the accel,holley,edelbrock, and TPIS sites, add a little math and the results become much clearer!!!

Intake....... length ....... port in -- out

Stock GM Base--- 6.375"------ 1.47"- 1.96x1.2

TPiS base------ -6.125"------ 1.75"- 2.09x1.28

Accel base----- -6.125"------ 1.75"- 2.09x1.28

Holley base------- 6” runner 2.3”- 1.9”x 1.23 (2.337 sq inches)

Runners

Stock TPI----- -- 7.250"------1.470" round(1.70 sq inchs)

SLP ----------- - 6.625"------1.600" round (2.01 sq inchs)

Accel LTR------- 6.625"------1.615" round (2.05 sq inchs)

TPiS----------- 7.625"------1.660" round (2.168 sq inchs)

Mini ram -----3.5”

LT1 ----------3”

Runners (measured individually)

Stock....................203.17 cfm

ACCEL................242.02 cfm

Extrude/ACCEL...275.83 cfm

Super Ram............289.18 cfm

Intake manifold with 3/8 inch radiused intlet.............................222.45 cfm

Holley stealth ram ………..275cfm

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

Holley stealth ram …..275cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.........251.51 cfm

ACCEL Hi-Flow intake manifold with runner

Stock....................215.83 cfm

ACCEL................232.53 cfm

Extrude/ACCEL....243.21 cfm

Super Ram............240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet ...............275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner ..............266.94 cfm

Edelbrock Performer RPM manifold (Stock)..........286.51 cfm

Edelbrock Victor Jr. ............275.24 cfm

HOLLEY STEALTH RAM

the HOLLEY STEALTH RAM FLOWS at 275cfm out of the box, and has the potential when matched to the correct heads and cam to totally out flow most other intakes available,can easily reach 300cfm with minor port work and costs much less

Stock…………………………… 275cfm

Ported…………………………..300cfm

Runner lengths

Stock tpi manifold 8” runners 11.25”, cylinder head 6” total 25.25”

Accel super ram manifold 8” runners 7” cylinder head 6” total 21”

Holley stealth ram manifold 6.26” ” cylinder head 6” total 12.26”

Edelbrock performer RPM runners 6” ” cylinder head 6” total 12”

Edelbrock vic jr , runner length 5.5” ” ” cylinder head 6” total 11.5”

Also interesting TPI mods. Not so sure I agree with the one on bumping up the initial timing.

http://www.hobracing.com/tech/tpi_mods.asp

Basic TPI modifications

Friday, May 23, 2014

Basic TPI Mods: by DEBBIES87

There are a few basic mods that should be done to any TPI car, I call these "entry-level" modifications.

1) Cut the air box open without letting air in the engine without going through the air filter & remove the additional plastic piece below the air box to get more air into the engine.

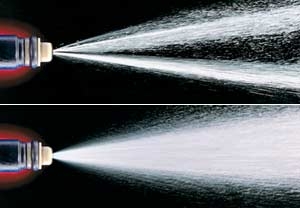

2) Modify the mass air sensor; remove the screens, & and if your brave cut down the fins.

3) Port the plenum (upper intake). There are two small ridges sticking up in the entry-behind the throttle body, remove these. The throttle body openings are already 52mm, so don't go crazy when porting.

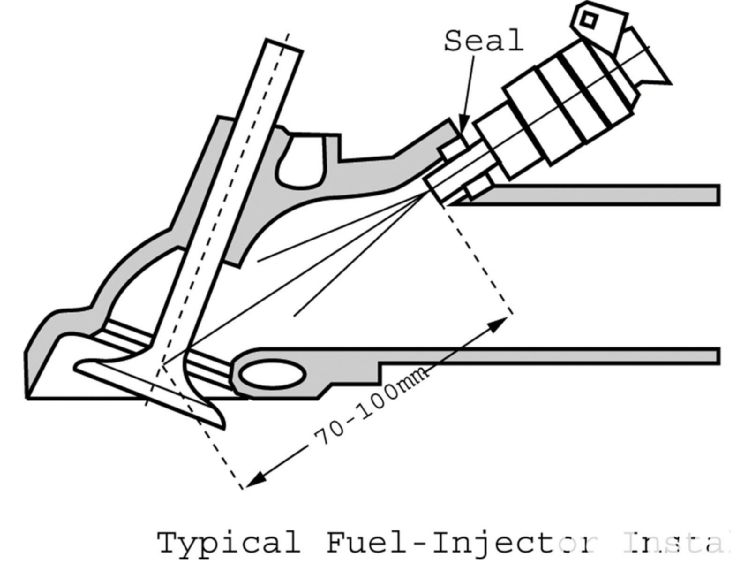

4) While the plenum is off for porting, it is now a good time to get a adjustable fuel pressure regulator & a MAT sensor relocater kit. The Adj. FPR will aid in tuning, and the new MAT sensor will improve throttle response as well. The new LT1 style MAT sensor is placed in the air box instead of the plenum, this allows it to read cooler air and advance the timing accordingly.

5) Advance the base timing to 12-13 degrees. Note: the harmonic balancers on these cars tend to drift with age, adjust timing to where the car still starts good and doesn't detonate.

6) If legal in your area, gut the catalytic converter and remove the smog pump belt (85-87), or run a shorter serpentine belt to bypass the pump (88-92); you will need to remove the smog pump on the 88-92's to reroute the belt properly. Check local smog laws first.

7) On automatic cars, adjust T.V. cable (throttle valve cable), so that the car shifts out between 4200-4500 RPM under wide open throttle. TPI motor power drops off drastically after 4500-4700 RPM, they peak at about 4200-4400 RPM. No need to over-rev these motors.

8) Bypass fan relay to make fans come on manually, or install aftermarket relay to turn on fans sooner.

All together these mods should make the car perform like it should have from the factory, gains should be between .6-.9 tenths of a second from these modifications.

T.V

The intake ports on the STEALTHRAM as it comes from HOLLEY. It fits the Felpro #1205 gasket port size.

viewtopic.php?f=55&t=431&p=530#p530

the stock cam is designed for maximium cylinder fill efficiency at no more than 5500rpm

viewtopic.php?f=52&t=133

viewtopic.php?f=52&t=324

viewtopic.php?f=52&t=904

viewtopic.php?f=52&t=1477

the stock stamped rockers are rarely at a full 1.5:1 ratio, in fact 1.45:1 is comon when carefully tested with a dial indicator

viewtopic.php?f=52&t=126

viewtopic.php?f=52&t=553

viewtopic.php?f=71&t=435

viewtopic.php?f=52&t=198

Last edited by a moderator: