Block-400 dart shp block. 4.125 STD bore, honed to .003" piston to wall clearance. Line honed, decked .005, oil feed restrictor in last right lifter bore. Scott Foxwell modification. No extra clearancing required. 350 main journal

Heads- profiler 210, 70cc combustion chamber. Gasket matched to felpro 1205. Minor bowl blending and spark plugs and threads smoothed in combustion chamber. 150lb on seat, AFR adjustable guideplates, rocker geometry was all over the place with the guideplates and studs I bought them with.

176-2170P-04-93 part number

134-3603 ARP head bolts with stainless outer bolts, step torqued. I liked the dart head bolt holes. No issues with water leaks, the bolts don't go into water passages.

Felpro 1003 gaskets. Quench height a tad over .043"

Harland sharp 1.6 rockers, arp 7/16 studs. I didn't care for the supplied guide plates or the 3/8 studs. Rocker geometry sucked. Each morel 5372 lifters received 1 turn of preload due to noise complaints. Lifter bore clearance was .015-.016. I lightly honed a few of the lifter bores. Took awhile to get oil out of all the rockers when priming, but it finally got there. Trick flow 7.1" pushrods I believe, don't quote me on the length. I started out with 7.20" and swipe pattern wasn't what I liked.

Intake is Edelbrock proflo 3, 4150 flange. Initially I unbolted the throttle body and ran with an AED 950hp, ran great with that and a hei distributor I had. Pulled carb and distributor out and put in the supplied small cap Edelbrock distributor. Inital timing to 12 degree btdc. Wired everything to the stand. Excellent grounding was a priority. Not that bad of an install. I did change the 29lb injectors to 35lb pico style injectors from Edelbrock. The included tuner can do 29lb or 35lb depending on the tune you choose. I had around 10mmhg vacuum with the AED setup. 11mmhg or so at 800rpm after firing up with the proflo 3. Doing the setup and Bluetooth connection to tablet was easy. Fuel pump is Carter 7psi 140gph, it runs to a edeEdelbr fuel command pump that has a reservoir and kicks it up to 58 psi for the injectors.

Plugs are autolite 3923 with FireWire spark plug wires. Coil is a msd blaster canister coil, nothing fancy. You can run a cdi box with this setup. I'm not. I did have to put a wire with a diode from starter wire into 12v hot, as it want to go to around 10v when cranking from the other supplied 12v switched wire. Pistons are wiesco forged slugs, 2 valve relief, -5cc relief. Smoothed edges, 1/16 mahle plasma moly ring pack. Top gap .022" 2nd gap .023, STD tension oil ring. Oil rings are super tight going in, I called mahle and they said it was normal. Once I popped them in they were good. .003 skirt clearances. I lightly oiled rings pistons with MMO. Pistons did require oil ring spacer, pin clearances were good, .010" higher compression height ordered, no reason to deck block excessively, spirolocks hold them on to a scat 6" pro competition style rod with ARP 7/16/ bolts. All ends were weight matched. Pistons were weight matched.

Crank is scat 4340. 350 main journal. I ordered the block with 350 mains for less heat/stress on bearings and I can later use a 350 crank if I want.

Balanced to 1gm, internal front and rear. Pioneer 872023 neutral 8" balancer, aluminum cover with comp cam button and lock. Cloyes

9-3500TX9,

I would have used retainer plate, but forgot to order step-nose camshaft...my fault

Clevite H bearings, clearances were spot on, I did lightly sand thrust and bevel for extra oiling like Rick did.

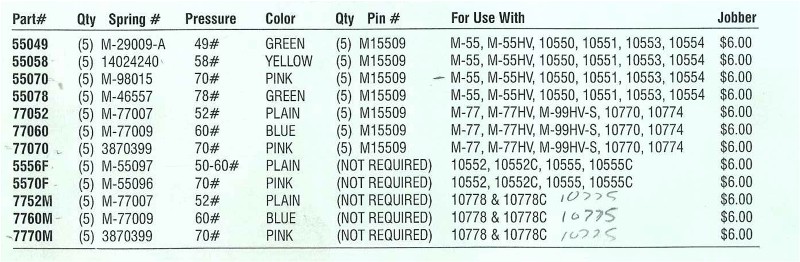

Oil pump is melling 10552. 10% increase volume. Used their supplied oil pump driveshaft. Clearances were good. I need to address too much pressure.... pressure relief issues or spring issues. It didn't have any spacers, I'm questioning whether I may have installed the spring backwards. It's possible. Melling pickup which was a bolt on gasket style 3/4 inlet. Using a moroso pan with a 8.25" sump, scraper and baffled with built in windage tray. No clearance issues with splayed caps. Milodon one piece gasket with thick front and 80-85 passenger dipstick. A few dabs of grey rtv in corners. Milodon gasket had nice anticrush washers and fit really well. I like it so far. Hays billet neutral flywheel. 4-speed car. Installed an oilrite non-magnetic pilot bushing before I put crankshaft in. Just used my press.

Camshaft is a Straub hyd roller. Duration @.050 233/240, duration @ .004 292/299, lobe lift with 1.5" rockers .547/.516, I used 1.6 intake and exhaust. Centerline intake/exhaust 104/112, LSA 108. Timing events at .050" verified with degree wheel and solid lifter were Intake: open 12.5°, close at 40.5°, exhaust open @ 52°, close at 8°. 20.5° overlap. Great sound. Lopes really nicely even with the EFI. Excellent throttle response. It has 3° advance ground in it. I installed it straight up after verifying events.

I used a cvf sepentine kit with lwp. 150amp Alt, new power steering pump. All black powder coated. I will have to clearance the alt. Bracket. You can't get the lower radiator hose on easily, I can't imagine trying to do it in the car or on the side of the road. Too tight. Aluminum front cover, nothing special, moroso pointer for 8" balancer. ARP balancer bolt.

I'm trying the summit brand motor mounts. They seem fine, black poly mount.

Runs well, timing is at 35°, AFR are still being messed with. No signs of detonation with 93 octane. Dynamic compression calculation was really high, not sure. Don't remember the value. Runs around 195°. Has to be over 170° for EFI self learning. 192° thermostat. Using electric fan on the stand.

Block got high temp magnets in the lifter valley and pan, and I coated valley with glyptal paint I had left over. I'm sure I'm leaving something out. I followed a lot of Rick's build. Super helpful info. Thanks to all of you for your input. Super helpful wealth of information here.