If youve ever had much time spent shooting black powder rifles you know about fouling issues and accuracy issues that result from the burnt powder residue / crud that builds up in the bore as fouling builds up can ruin consistent repeatable accuracy.

I've had excellent accuracy and no hint of patch burn or bore fouling in my 54 cal, 58 cal, and 62cal caliber hawken, rifles, but I load 90-110 grains of 2f down the bore, in my 62 caliber hawken, followed by a cotton ball, then a bore size dab,of a soap like lube, in my 54 cal, 58 cal, and 62 cal, rifles and 80 grains of 3f in my 54 and 90 grains of 2f in my 58 cal,

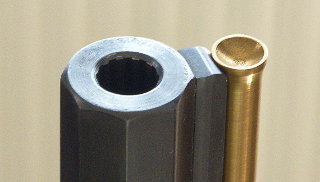

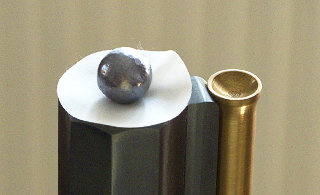

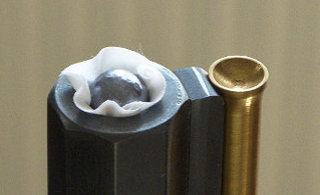

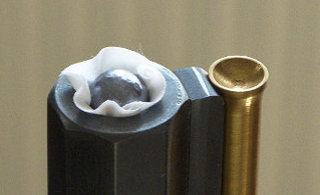

the cotton ball seats firmly over the powder charge, followed by use of a bore size glob of murphys flax soap then a patched ball with the patch having been soaked in flax oil paste

the result is the expanding powder gases compress the column and squeeze out the soap into the rifling and the cotton ball wipes the bore on each shot, the cotton ball keeps the powder dry but the soap paste gets hammered into the cotton ball so it seldom even smokes

use this process and you can shoot dozens of shots between minor bore cleaning, I get 2"-to-2.5" 3 shot groups with iron sites off the bench at 100 yards almost every time at the range, with many good muzzle loaded rifles.

you can use the same process with mini or maxi balls without the greased patch over the dab of grease, thats placed over the cotton ball and get good accuracy, if you prefer those projectiles, and still find the bore remains clean, obviously your rifles twist rate might require a bit of experimentation with loads. (lee makes a nice 500 grain mini for 58 caliber rifles)

http://www.midwayusa.com/product/589474 ... -old-style

many guys don,t realize that the original mini ball partly stabilizes by being distinctly nose heavy / weight forward , just like a styro-foam coffee cup with a couple table spoons of sand in the bottom, if you throw it will always travel bottom forward, and wide open mouth to the rear in the arc it travels, the rifling imparts some spin increasing accuracy, but unlike the newer bullet designs the original mini does not totally depend on that spin to remain point forward, many newer designs are longer and not as nose heavy so they require spin to maintain gyroscopic stability, but if the skirt is deformed as it exits the muzzle, or the mini is not spun by the rifling, any chance of a consistent shot to shot impact point is destroyed

http://www.midwayusa.com/product/460281 ... uctFinding

if you have the correct style rifling and twist rate a mini or maxi ball is an option you might want, to consider, as they pack a good deal more down range energy than a round ball projectile and penetration,

but your rifles rifling twist rate must allow their use to stabilize them or accuracy sucks, do your research homework here.

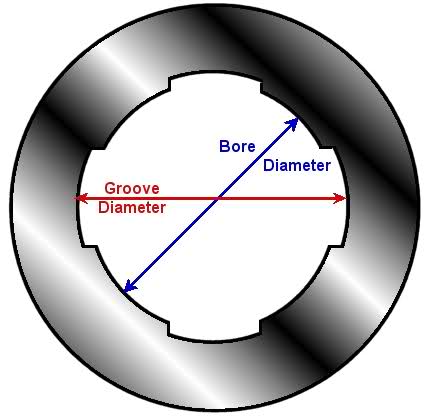

first find your rifles twist rate,

simply mark a line on the cleaning rod,

with it fully down the bore,on the type of cleaning rod,

that allows the rod to spin as its inserted and with drawn,

with a tight fitting patched bore diam brush installed ,

and pull it out watching the mark rotate until exactly one revolution has been made then measure the difference in the length the rod extends from the bore.

if it was 14" out at the start and 40" out at one full revolution, then the twist rates 1 turn in 26"

example,

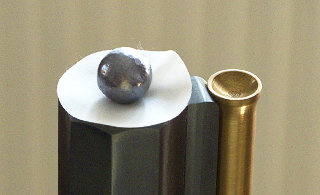

if the maxi ball pictured below is .588 caliber and 1.2" long it would take about a 42" or tighter twist rate to stabilize and 1 turn in 32 would be close to ideal

http://www.bergerbullets.com/twist-rate-calculator/

http://www.midwayusa.com/product/609127 ... hale-style

http://www.midwayusa.com/product/630234 ... -530-grain

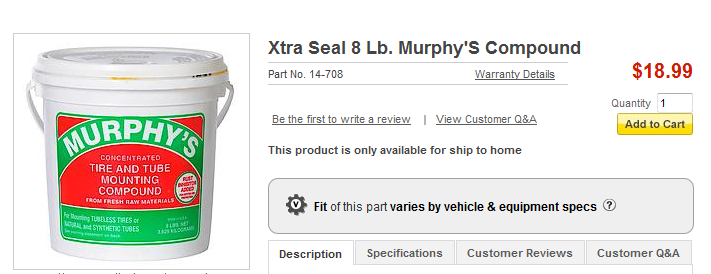

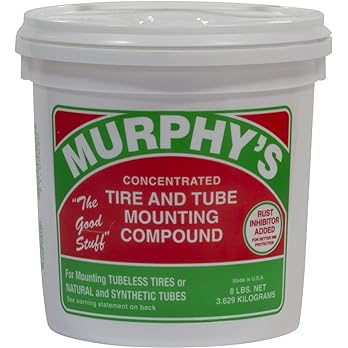

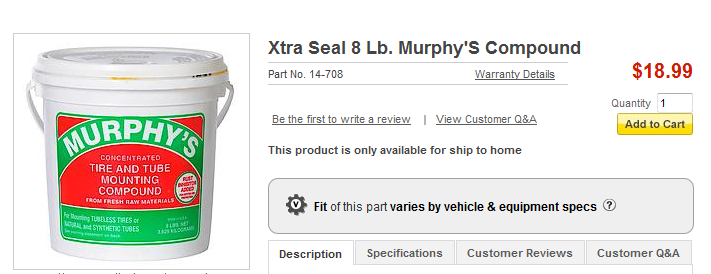

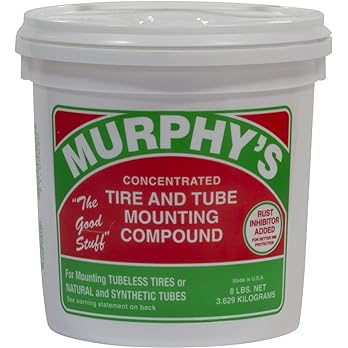

this is the same soap base grease in a larger container and cheaper per pound and easier to locate than the smaller container below

the soap paste is similar to peanut butter or axle grease as it comes out of the can, wet a patch with water and rub a bit into both surfaces to get a well greased patch that makes loading a patched ball fairly easy

the soap paste is similar to peanut butter or axle grease as it comes out of the can, wet a patch with water and rub a bit into both surfaces to get a well greased patch that makes loading a patched ball fairly easy

http://www.colpalcommercial.com/brands.aspx?id=1730

just a bit of info, on hunting loads for larger bore hawkens

when I started out with a muzzle loading rifle I

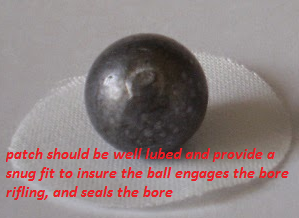

was assured repeatedly by most of the older and supposedly more experienced guys that pure lead balls patched with a properly lubed linen patch were the preferred projectile in my 58 caliber hawken rifle.

but as is my nature I experimented with about every component available, and I tried a dozen different type patches , several dozen lubes and dozens of conical and mini and maxi ball designs in both my 58 and 62 caliber hawken replicas.

what I eventually found is that a bore diam ball cast from wheel weight alloy loaded in a well greased patch of about 1.25" diam, cut from used denim clothe and greased with flax soap paste was the most accurate out to easily 150 yards BUT only if loaded consistently, the same way.

both rifles prefer similar loads of about 90 grains of 2f powder , followed down the bore with a cosmetic cotton ball and a dab of flax soap , then the patched ball seated firmly over the powder charge , the cosmetic cotton ball acts like a seal gasket to prevent the flax soap paste from getting to the powder charge. loaded like that the bore stays fairly clean and powder fouling is minimized.

off a bench rest 2"-2.5" 3 SHOT GROUPS ARE COMMON

SOFTER LEAD BALLS OPEN UP THE GROUP SIZE SLIGHTLY i THINK SOME GET SLIGHTLY DEFORMED DURING THE LOAD PROCESS WHILE THE HARDER WHEEL WEIGHT ALLOY REMAINS FAR MORE RESISTANT TO DEFORMATION.

now Im sure the guys that hunt will point out the round balls from pure lead expand far easier and kill quicker, but in my experience the difference if any is marginal.

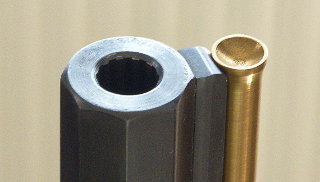

having a slight but concentric and consistent bevel on the rifle bore entrance greatly eases loading and reduces torn patches

THE PATCHED BALL MUST BE CENTERED IN THE LUBED PATCH AND RIFLES BORE WHEN LOADING FOR CONSISTENT ACCURACY!

http://garage.grumpysperformance.com/http:

while some people will think your old fashion or just not putting much thought into it,

a properly patched & lubed round ball has and will continue to be an accurate and useful projectile.

and Id suggest you try it just to check the rifles accuracy and consistency, with that option.

on my 62 cal hawken its shoots about a 2" hundred yard group off a bench rest,

all the other options , I've tried,are closer to 4"-5" groups , probably due to the less popular bore diam.

and slower 1/42 twist rate.

and yes its devastating on the deer Ive shot, so its not likely to be an issue with elk.

as always shot placement and a knowledge of the games anatomy and your judgement is critical.

I've had excellent accuracy and no hint of patch burn or bore fouling in my 54 cal, 58 cal, and 62cal caliber hawken, rifles, but I load 90-110 grains of 2f down the bore, in my 62 caliber hawken, followed by a cotton ball, then a bore size dab,of a soap like lube, in my 54 cal, 58 cal, and 62 cal, rifles and 80 grains of 3f in my 54 and 90 grains of 2f in my 58 cal,

the cotton ball seats firmly over the powder charge, followed by use of a bore size glob of murphys flax soap then a patched ball with the patch having been soaked in flax oil paste

the result is the expanding powder gases compress the column and squeeze out the soap into the rifling and the cotton ball wipes the bore on each shot, the cotton ball keeps the powder dry but the soap paste gets hammered into the cotton ball so it seldom even smokes

use this process and you can shoot dozens of shots between minor bore cleaning, I get 2"-to-2.5" 3 shot groups with iron sites off the bench at 100 yards almost every time at the range, with many good muzzle loaded rifles.

you can use the same process with mini or maxi balls without the greased patch over the dab of grease, thats placed over the cotton ball and get good accuracy, if you prefer those projectiles, and still find the bore remains clean, obviously your rifles twist rate might require a bit of experimentation with loads. (lee makes a nice 500 grain mini for 58 caliber rifles)

http://www.midwayusa.com/product/589474 ... -old-style

many guys don,t realize that the original mini ball partly stabilizes by being distinctly nose heavy / weight forward , just like a styro-foam coffee cup with a couple table spoons of sand in the bottom, if you throw it will always travel bottom forward, and wide open mouth to the rear in the arc it travels, the rifling imparts some spin increasing accuracy, but unlike the newer bullet designs the original mini does not totally depend on that spin to remain point forward, many newer designs are longer and not as nose heavy so they require spin to maintain gyroscopic stability, but if the skirt is deformed as it exits the muzzle, or the mini is not spun by the rifling, any chance of a consistent shot to shot impact point is destroyed

http://www.midwayusa.com/product/460281 ... uctFinding

if you have the correct style rifling and twist rate a mini or maxi ball is an option you might want, to consider, as they pack a good deal more down range energy than a round ball projectile and penetration,

but your rifles rifling twist rate must allow their use to stabilize them or accuracy sucks, do your research homework here.

simply mark a line on the cleaning rod,

with it fully down the bore,on the type of cleaning rod,

that allows the rod to spin as its inserted and with drawn,

with a tight fitting patched bore diam brush installed ,

and pull it out watching the mark rotate until exactly one revolution has been made then measure the difference in the length the rod extends from the bore.

if it was 14" out at the start and 40" out at one full revolution, then the twist rates 1 turn in 26"

example,

if the maxi ball pictured below is .588 caliber and 1.2" long it would take about a 42" or tighter twist rate to stabilize and 1 turn in 32 would be close to ideal

http://www.bergerbullets.com/twist-rate-calculator/

http://www.midwayusa.com/product/609127 ... hale-style

http://www.midwayusa.com/product/630234 ... -530-grain

this is the same soap base grease in a larger container and cheaper per pound and easier to locate than the smaller container below

http://www.colpalcommercial.com/brands.aspx?id=1730

just a bit of info, on hunting loads for larger bore hawkens

when I started out with a muzzle loading rifle I

was assured repeatedly by most of the older and supposedly more experienced guys that pure lead balls patched with a properly lubed linen patch were the preferred projectile in my 58 caliber hawken rifle.

but as is my nature I experimented with about every component available, and I tried a dozen different type patches , several dozen lubes and dozens of conical and mini and maxi ball designs in both my 58 and 62 caliber hawken replicas.

what I eventually found is that a bore diam ball cast from wheel weight alloy loaded in a well greased patch of about 1.25" diam, cut from used denim clothe and greased with flax soap paste was the most accurate out to easily 150 yards BUT only if loaded consistently, the same way.

both rifles prefer similar loads of about 90 grains of 2f powder , followed down the bore with a cosmetic cotton ball and a dab of flax soap , then the patched ball seated firmly over the powder charge , the cosmetic cotton ball acts like a seal gasket to prevent the flax soap paste from getting to the powder charge. loaded like that the bore stays fairly clean and powder fouling is minimized.

off a bench rest 2"-2.5" 3 SHOT GROUPS ARE COMMON

SOFTER LEAD BALLS OPEN UP THE GROUP SIZE SLIGHTLY i THINK SOME GET SLIGHTLY DEFORMED DURING THE LOAD PROCESS WHILE THE HARDER WHEEL WEIGHT ALLOY REMAINS FAR MORE RESISTANT TO DEFORMATION.

now Im sure the guys that hunt will point out the round balls from pure lead expand far easier and kill quicker, but in my experience the difference if any is marginal.

having a slight but concentric and consistent bevel on the rifle bore entrance greatly eases loading and reduces torn patches

THE PATCHED BALL MUST BE CENTERED IN THE LUBED PATCH AND RIFLES BORE WHEN LOADING FOR CONSISTENT ACCURACY!

http://garage.grumpysperformance.com/http:

while some people will think your old fashion or just not putting much thought into it,

a properly patched & lubed round ball has and will continue to be an accurate and useful projectile.

and Id suggest you try it just to check the rifles accuracy and consistency, with that option.

on my 62 cal hawken its shoots about a 2" hundred yard group off a bench rest,

all the other options , I've tried,are closer to 4"-5" groups , probably due to the less popular bore diam.

and slower 1/42 twist rate.

and yes its devastating on the deer Ive shot, so its not likely to be an issue with elk.

as always shot placement and a knowledge of the games anatomy and your judgement is critical.

Last edited by a moderator: