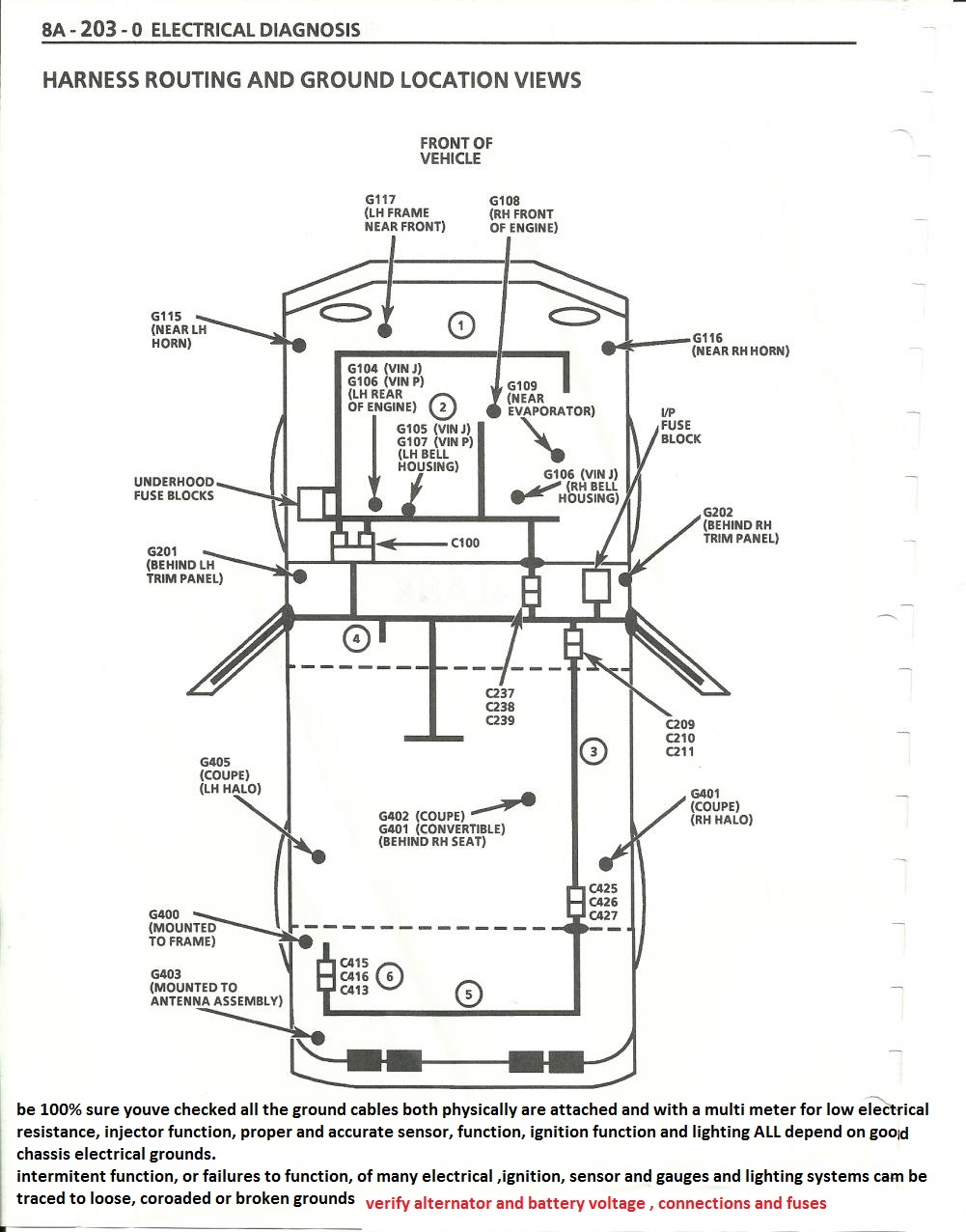

logically think things thru and verify each possibility , one of the local guys stopped by with his 1996 corvette, His complaint was that it had and intermittent ignition miss he was having a difficult time locating.

so I pull trouble codes and it says that were having ignition miss fire as expected, I got out my old out of date now code scanner, and IR thermometer,

http://www.professionalequipment.com/xq/ASP/ProductID.3461/id.22/subID.177/qx/default.htm

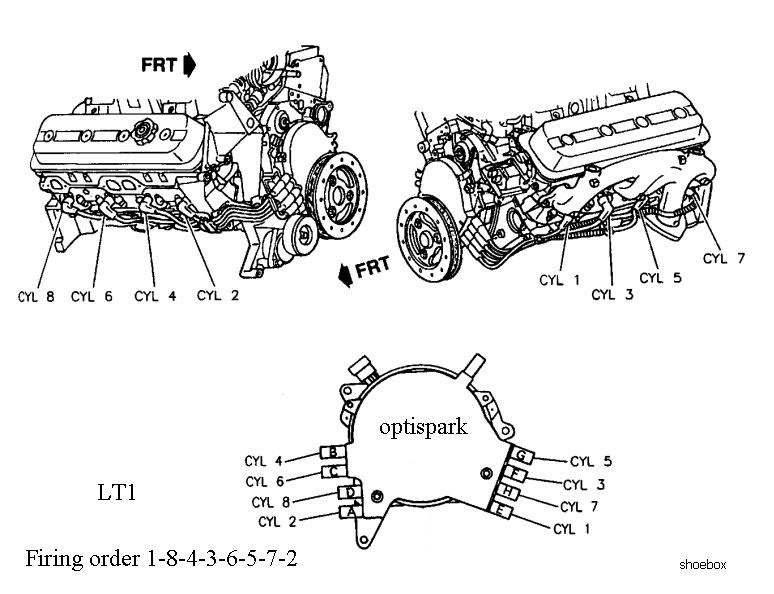

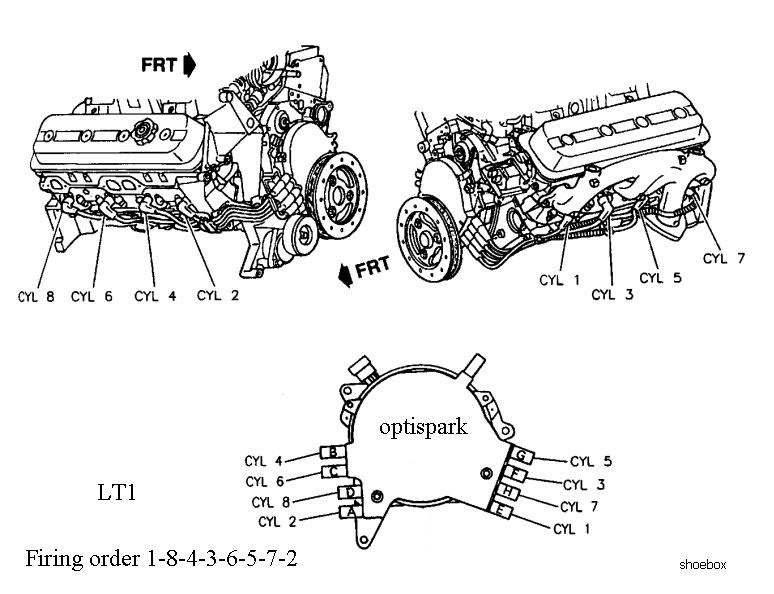

AutoXray EZ-Scan 6000 and its shows two plugs are causing 99% of the miss fires, #4, and #6 , looking in the shop manual,a quick check with the IR gun shows those cylinders running much cooler at about 250F vs 470F on the other 6 exhaust ports

I noticed something about those two cylinders , they are positioned on the opti-ignition side by side, so I asked if there had been any repair or upgrade work done recently and found that the water pump had been recently replaced, so with that info and after checking the ignition wire connections on the plug ends were good I went and put the car up on the lift and not totally unexpectedly found the #4, and #6 plug wire connections on the opti-crap ignition were loose. they must of gotten loose during the water pump replacement process, and after driving the car the connections got even looser over time. see a bit of logical progression , in tracking down the cause led me too the likely cause.

.lets start with a break-down of the OBDII fault code

1. the first character identifies the related system

P=power train

B=body

C=chassis

U= unspecified

2. the second character identifies if the fault code, is genetic or manufacturer specific. a generic code is the same on all OBDII vehicles, regardless of manufacturer

..a manufacturer-specific code is used by only that car maker

0=generic

1= manufacturer specific.

3.the third character denotes the specific system

1=emissions/fuel-air

2=injector circuit

3=ignition or missfire

4=emission control

5=vehical speed and idle control

6=computer and out put circuit

7= transmission

8=transmission control

the fourth and fifth digit relate to the area where the fault/trouble occurs

example code p0303

p==power train

0==generic

3=missfire

the last two 03 indicate cylinder # 3 is miss firing

p0301=cylinder #1

p0302=cylinder #2

p0303=cylinder #3

p0304=cylinder #4

p0305=cylinder #5

p0306=cylinder #6

p0307=cylinder #7

p0308=cylinder #8

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.com/index.php?threads/basic-trouble-shooting-on-the-c4.302/

http://garage.grumpysperformance.com/index.php?threads/efi-and-scan-tool-software-links.469/

so I pull trouble codes and it says that were having ignition miss fire as expected, I got out my old out of date now code scanner, and IR thermometer,

http://www.professionalequipment.com/xq/ASP/ProductID.3461/id.22/subID.177/qx/default.htm

AutoXray EZ-Scan 6000 and its shows two plugs are causing 99% of the miss fires, #4, and #6 , looking in the shop manual,a quick check with the IR gun shows those cylinders running much cooler at about 250F vs 470F on the other 6 exhaust ports

I noticed something about those two cylinders , they are positioned on the opti-ignition side by side, so I asked if there had been any repair or upgrade work done recently and found that the water pump had been recently replaced, so with that info and after checking the ignition wire connections on the plug ends were good I went and put the car up on the lift and not totally unexpectedly found the #4, and #6 plug wire connections on the opti-crap ignition were loose. they must of gotten loose during the water pump replacement process, and after driving the car the connections got even looser over time. see a bit of logical progression , in tracking down the cause led me too the likely cause.

.lets start with a break-down of the OBDII fault code

1. the first character identifies the related system

P=power train

B=body

C=chassis

U= unspecified

2. the second character identifies if the fault code, is genetic or manufacturer specific. a generic code is the same on all OBDII vehicles, regardless of manufacturer

..a manufacturer-specific code is used by only that car maker

0=generic

1= manufacturer specific.

3.the third character denotes the specific system

1=emissions/fuel-air

2=injector circuit

3=ignition or missfire

4=emission control

5=vehical speed and idle control

6=computer and out put circuit

7= transmission

8=transmission control

the fourth and fifth digit relate to the area where the fault/trouble occurs

example code p0303

p==power train

0==generic

3=missfire

the last two 03 indicate cylinder # 3 is miss firing

p0301=cylinder #1

p0302=cylinder #2

p0303=cylinder #3

p0304=cylinder #4

p0305=cylinder #5

p0306=cylinder #6

p0307=cylinder #7

p0308=cylinder #8

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.com/index.php?threads/basic-trouble-shooting-on-the-c4.302/

http://garage.grumpysperformance.com/index.php?threads/efi-and-scan-tool-software-links.469/

Last edited: