william ritchie

Member

With all that shiney clear coat on it a simple wash will make it ready to show on a weekend?

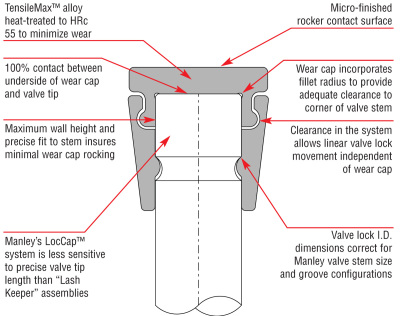

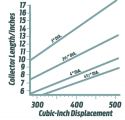

Yes have put allot thought into this for sure. Question for you Grumpy you may know the answer off the top of your head. So the only headers I can find that may fit with my oil pan and angle plugs are Sanderson C12 long tube headers. (Will still need sacrifice factory air for a vintage air system.) My concern is the collector length, I will be running a full exhaust on the car 3" to 3" reducer with O2 bungs into a 3" x pipe into a 3" to 2.5" venturi reducer cone into my 2.5" bola turbo XS mufflers reasonably quiet while keeping performance and flow master tail pipes. As hopefully that gives the exhaust some distance to cool and use the 2.5" exhaust. The Borla Turbo xs mufflers and flow master 2.5 pipes are already mounted under the car. The Sanderson Headers are 1 3/4 diameter runner with a 3" collector but in what I have read the collector length is one of the most important parts of the design as Header collector length should be established so that its volume is at least twice the displacement of one cylinder of the engine in question. This provides an isolation between the header pipes and the atmosphere, ensuring that the collector does not appear as simply more pipe to the exhaust gas slug. - as per MOTORTREND article along with the below diagram. I recall them doing testing on this with Engine Masters series but they have locked those videos away in the subscription only section season 5 episode 16.so far the parts selection appears to very well thought out

Thank you Grumpy you verified what I thought. I may update the rest of the exhaust down the road but right now the budget is being put fully to getting it a driving project. You know projects like this never end.Im not 100% sure what your question is, simply because once you connect the header collector of any ;length to the full 2.5"exhaust the collector length becomes rather un-important, as its back pressure to exhaust gas mass or flow that changes with the displacement and rpms,

generally you'll want a full 3" exhaust from the engine's header collector /exhaust ports to the X pipe at a minimum, only then reduce the dual 2.5" exhaust

building an exhaust system for your car

you might want to read thru these threads and linked info first, yes IM well aware it may take several hours to do so but it will save your many more hours and hundreds of dollars to do it correctly and safely. Id bet 80% of the useful infos in the links and sub-links so take some time and...garage.grumpysperformance.com

is backpressure hurting your combo?

any automotive engine will run best with little or no back pressure on the exhaust system , back pressure ALWAYS tends to reduce the cylinder fill and scavenging efficiency, this is not a guessing game. you can simply measure back pressure in the exhaust every500 rpm from about 3000rpm to where...garage.grumpysperformance.com

(X) or (H) PIPE

INSTALLING AN (X) PIPE IN THE EXHAUST ON A DUAL EXHAUST CAR Magnaflow sells them in stainless: https://www.magnaflow.com/products?partNumber=10782 Dynomax (aluminized): Dynomax 88328: X-Pipe Outer diameter: 3" | JEGS Flowtech (aluminized): Flowtech 53621: FlowTech Exhaust X-Pipe 3" | JEGS...garage.grumpysperformance.com