{quote]Carl Hinkson

ptsSnordoe8Jgu155e21 i la5h93:u8mPac4cu2tM0nt t4 ·

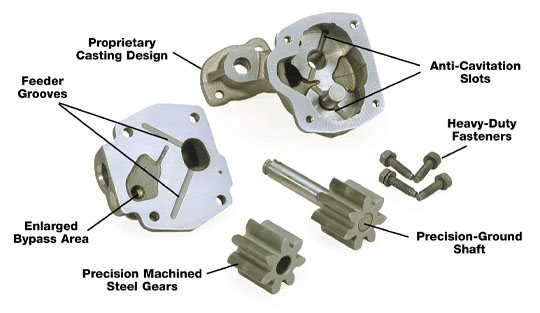

The 383 I dynoed with high oil pressure using the 10552 ST oil pump was exactly what I thought was the problem. The bypass valve was to long and not exposing the complete bypass hole. I also have another engine with the same pump same problem.

I don't understand why I have to there home work for them. They told me not to take the pump apart it would void the warranty. I said really.

I have used probably 35 10552 pumps with zero problems. Now they said the 10552 ST they did change the cover HMMMMM

Here is a link to the dyno run

https://www.facebook.com/cncblocks.northeast/posts/pfbid0CWMCC5tUE7H6txU83MSpjAoU8FzbTU3S2kHjCUGtFtAoZSEQEPaEeG165yXwCig7l

[/quote]

ANY time you don't get the expected results from a part you install,

ID suggest you stop and take the time and effort to inspect and find out WHY?

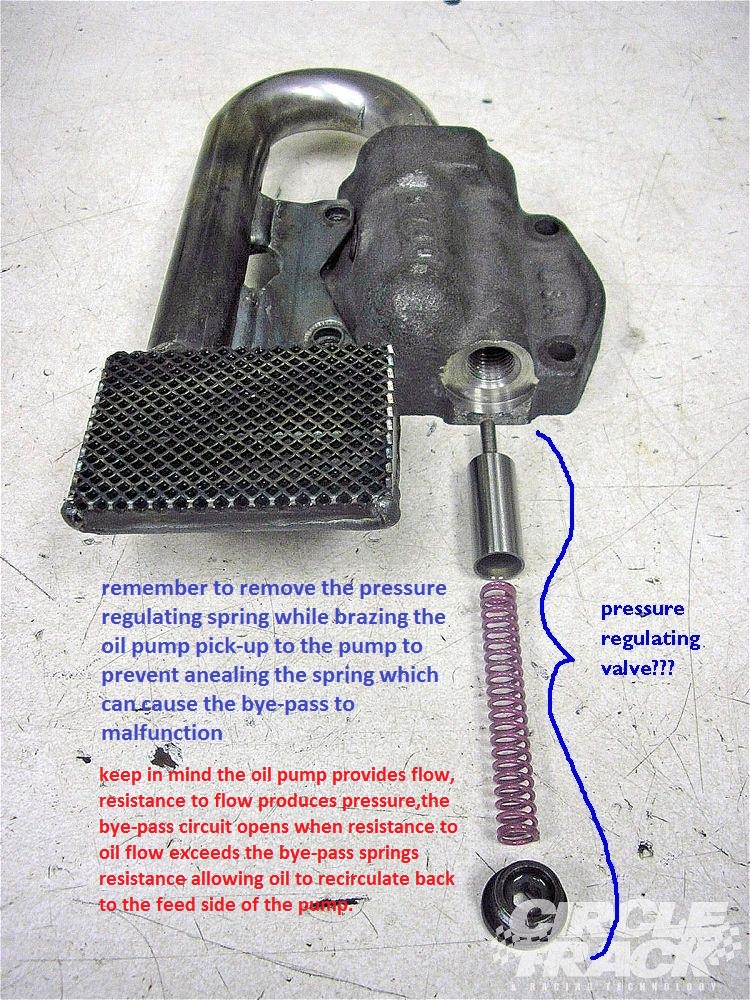

Id have to point out that if your oil pump spring stacks or binds,

you should either replace it with a shorter spring, that allows more clearance, one that fits inside that oil pump slide valve

or remove a few coils to gain the required clearance to allow the oil pressure bye-pass passage to fully open and be exposed to allow full oil flow, the linked picture shows the relief valve piston is not moving enough to fully open the bye-pass oil passage, IF you have that issue be sure the oil pump spring and spacers allow the full clearance, SPRING SPACERS are not generally required.

or remove a few coils to gain the required clearance to allow the oil pressure bye-pass passage to fully open and be exposed to allow full oil flow, the linked picture shows the relief valve piston is not moving enough to fully open the bye-pass oil passage, IF you have that issue be sure the oil pump spring and spacers allow the full clearance, SPRING SPACERS are not generally required.keep in mind that spring only regulates the max pressure , shortening it will have a minimal effect.

some oil pumps have an adjustable depth, threaded plug or roll pin, retaining the spring on the back end, of the oil pressure relief pistons passage, and spring passage.

its the attention to details and checking clearance etc. and time and care taken,

that makes the difference between a barely or average functional ,

and a rather exceptional engine build, yes the urge to get it running is strong,

but getting it done correctly is the goal

there are oil pump testers available commercially or if your mechanically inclined you can fabricate one with reasonable care, after a bit of measuring and purchasing a pressure gauge,

I mounted the gauge and plate I fabricated from a plate of scrap 5/8" thick aluminum plate thats 3" wide and 5" long I mount the pump to and use an air ratchet to/under the lid of a 50 cal ammo can and use that as a oil reservoir the oil pump sits in while testing

a drive shaft with a socket welded to it extends above the lid of the oil and pump tested in the 50 cal ammo can.

http://cvrproducts.com/oil-pressure-test-kit/

Testing High Volume Vs Standard Chevy Oil Pumps

after reading all the posted info , you would more than likely avoid or skip the related links, so I posted them at the beginning so you at least realize, theres much more and useful info available https://www.cpperformance.com/products/Engine_Parts/valve-spring-oiler.htm btw if you don,t want...

garage.grumpysperformance.com

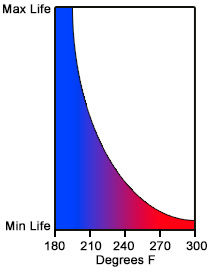

how your oil pumps pressure bye-pass circuit works,

theres seems to be a lot of mis-information about , how the oil pump regulates its pressure curve, and the related subject of shimming oil pump springs and how your oil pumps pressure bye-pass circuit works. PRESSURE, that you see displayed on the oil pressure gauge is a measure of the...

garage.grumpysperformance.com

Oil pump priming

I have attempted to prime and pre oil the system in my 355 build using the tool shown on Grumpy's stickys but am not sure if all is as it should be. The filter was filled pre installation and the balance of the 5 quarts of oil poured into the lifter valley. The tool in inserted and run with a...

garage.grumpysperformance.com

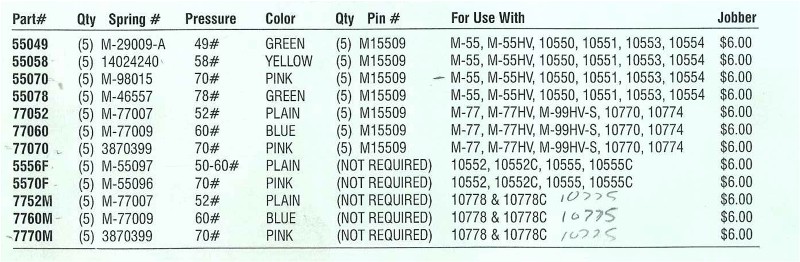

YEAH YOU WILL OCASIONALLY SEE OIL PUMPS SHIPPED WITH SPACERS THAT SHOULD NOT BE INSTALLED

I REMEMBER RICK HAD THAT HAPPEN TO HIM!

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

the small end of the spring seats inside the slide valve the larger diam. end seats against the retaining pin in the outer pump passage, so you only cut the link/coils from the smaller diameter end of the spring

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

(1)

Last edited: