Free Shipping on Orders Over $109 at Summit Racing

Find Parts and Accessories 3/4" tube oil pump pickups KEYWORD and get Free Shipping on Orders Over $109 at Summit Racing!

big block chevy oil pumps - JEGS High Performance

1 million+ parts, 800+ brands-all in-stock at guaranteed best prices. Buy by 11pm & your order ships same-day. Trust JEGS to get it right. Shop now!

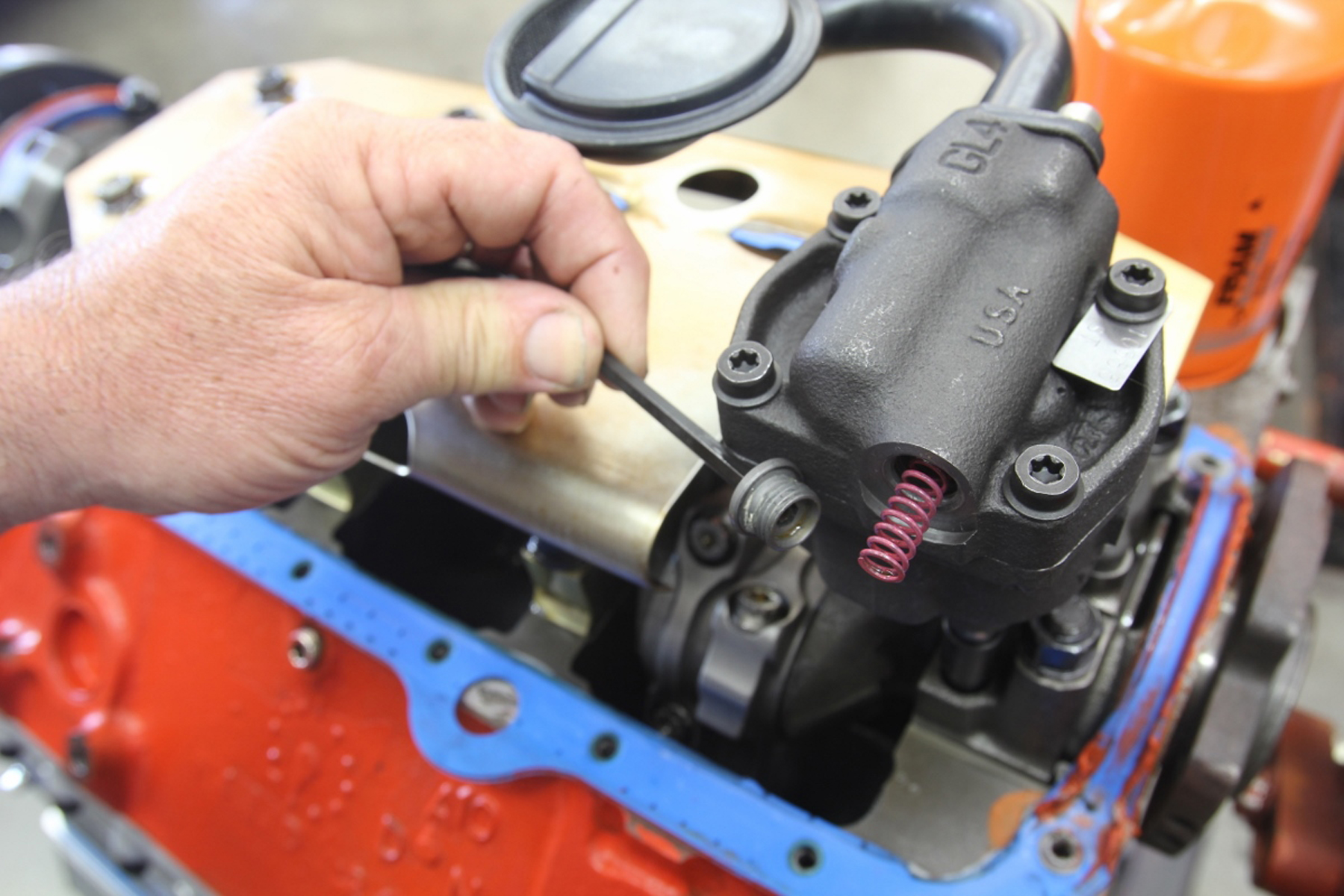

Oil Pump Selection: Is High Pressure Or High Volume Better?

Many feel a high-volume oil pump is a necessity for a high-performance engine. Find out what our professional sources have to say about that.

Rule of thumb is you want a minimum of 12/15 psi oil pressure per 1000 rpm on a healthy Chev small block.

Depending on what type of oil pump you have 15 to 20 psi at idle is normal.

As you say there is a difference in pressure between roller and flat, solid and hydraulic lifter engines.

your oil pump pick-up must be 3/8"-1/2" off the oil pan floor to function correctly

some time spent with a dremel tool ,and you having some skill and knowledge,

can make a decent oil pump flow significantly better.

Oil Pump Springs - Free Shipping on Orders Over $109 at Summit Racing

Find Oil Pump Springs and get Free Shipping on Orders Over $109 at Summit Racing!

CHEVROLET - big block oil pump springs KEYWORD - Free Shipping on Orders Over $109 at Summit Racing

Find CHEVROLET Parts and Accessories big block oil pump springs KEYWORD and get Free Shipping on Orders Over $109 at Summit Racing!

Canton Racing Oil Pump Spring For Big Block Chevy High Pressure 50-75 PSI - 22-180

Canton Racing Oil Pump Spring For Big Block Chevy High Pressure 50-75 PSI - 22-180 A higher pressure bypass spring in an oil pump forces more oil through the engine while a lower pressure spring allows for more oil to be recycled within the pump. This sp

Oil Pump Spring - JEGS High Performance

1 million+ parts, 800+ brands-all in-stock at guaranteed best prices. Buy by 11pm & your order ships same-day. Trust JEGS to get it right. Shop now!

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

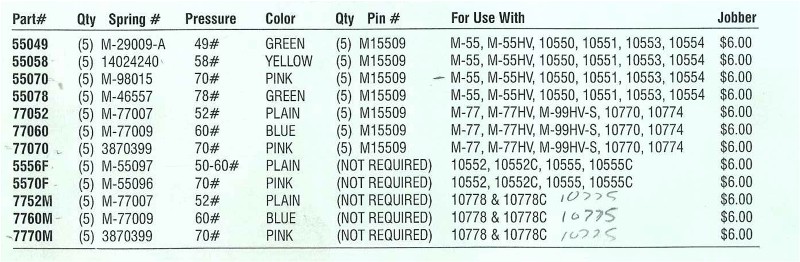

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

Last edited: