You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oil system mods that help

- Thread starter grumpyvette

- Start date

that if you limit the lifter valley drain back volume it helps reduce the friction or resistance caused by falling oil around the crank has on the rapidly spinning crank assembly.

you look at the potential sources for oil flow dropping around the spinning crank assembly and its rather obvious any oil drain back reduction from the lifter valley is not being significantly reduced by installing vent tubes, as the oil spraying off all the cam, rotating assembly bearings, lifter,bores, is unaffected, and much of the valve train oil flows to the rear of the blocks lifter valley to drain near the oil pump/distributor so a properly designed baffled oil pan and windage tray assembly will do you more good here, I've yet to see a dyno showing gains from vent tube use vs, but a well designed windage tray can get you a couple extra horsepower near peak rpms , but far more importantly it helps keep the majority of the oil around the oil pump pick-up.

there are many oil leakage points(100) in a standard Chevy V8 engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

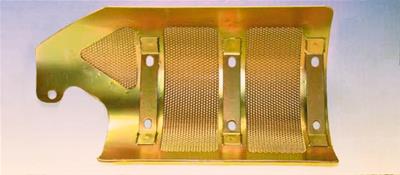

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

your 55 psi at idle serves no purpose as 15psi-25psi is all that's expected in a new engine with tight clearances using a good 10W30 oil, if your using a higher viscosity than 10w30 its reducing oil flow rates and reducing heat transfer rates, Id suggest using a good 10W30 or lighter viscosity oil. and use of a 7-8 quart, baffled oil pan and windage tray

Last edited:

whats a windage tray do?

"OK GRUMPYVETTE< I have dumb question? What is a windage tray and whats it for?" windage trays don,t provide a huge boost in horse power, the purpose is mostly in providing much improved oil control, thus they can, if properly designed provide a much more consistent oil supply, and enhanced...

garage.grumpysperformance.com

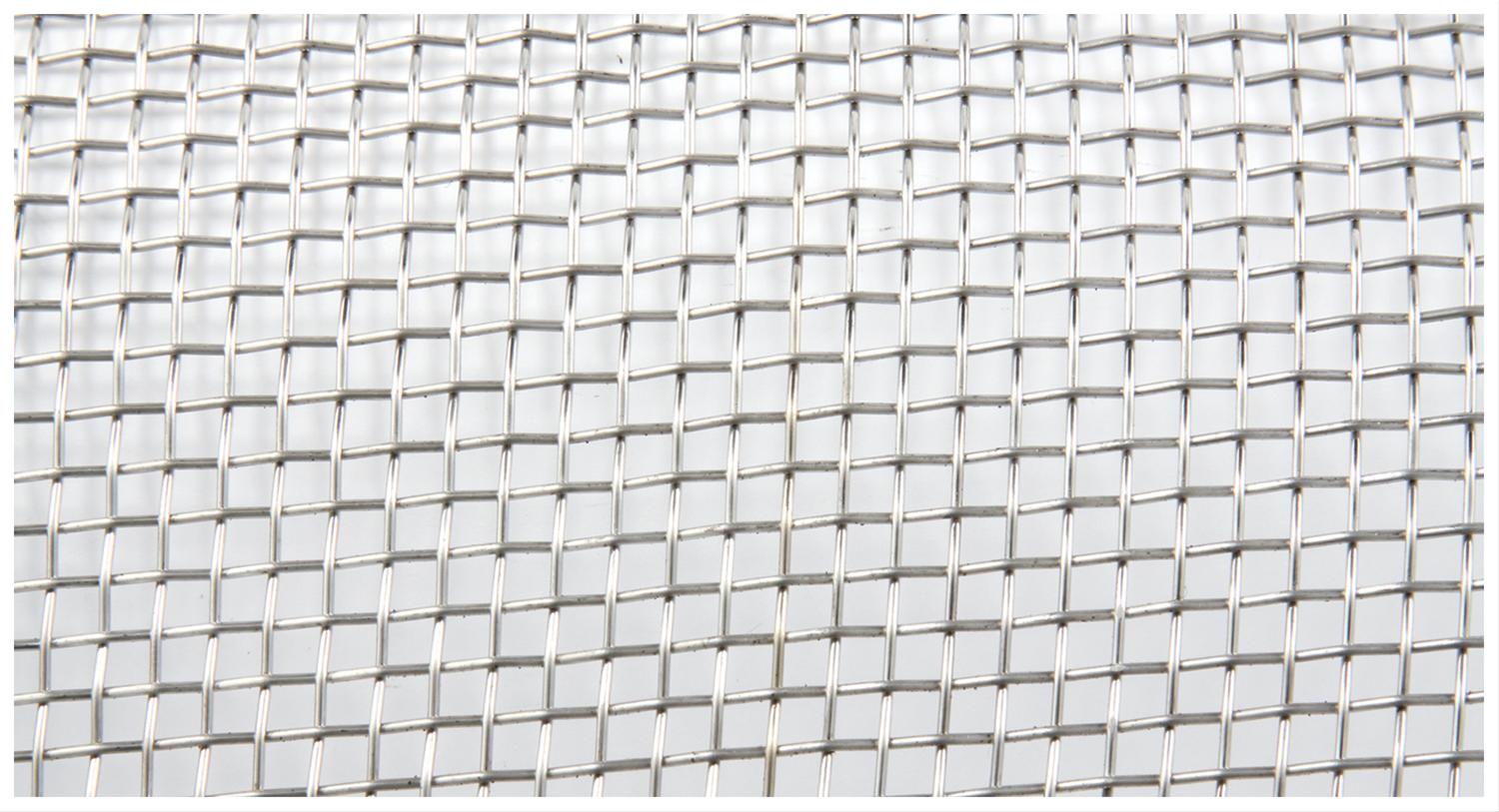

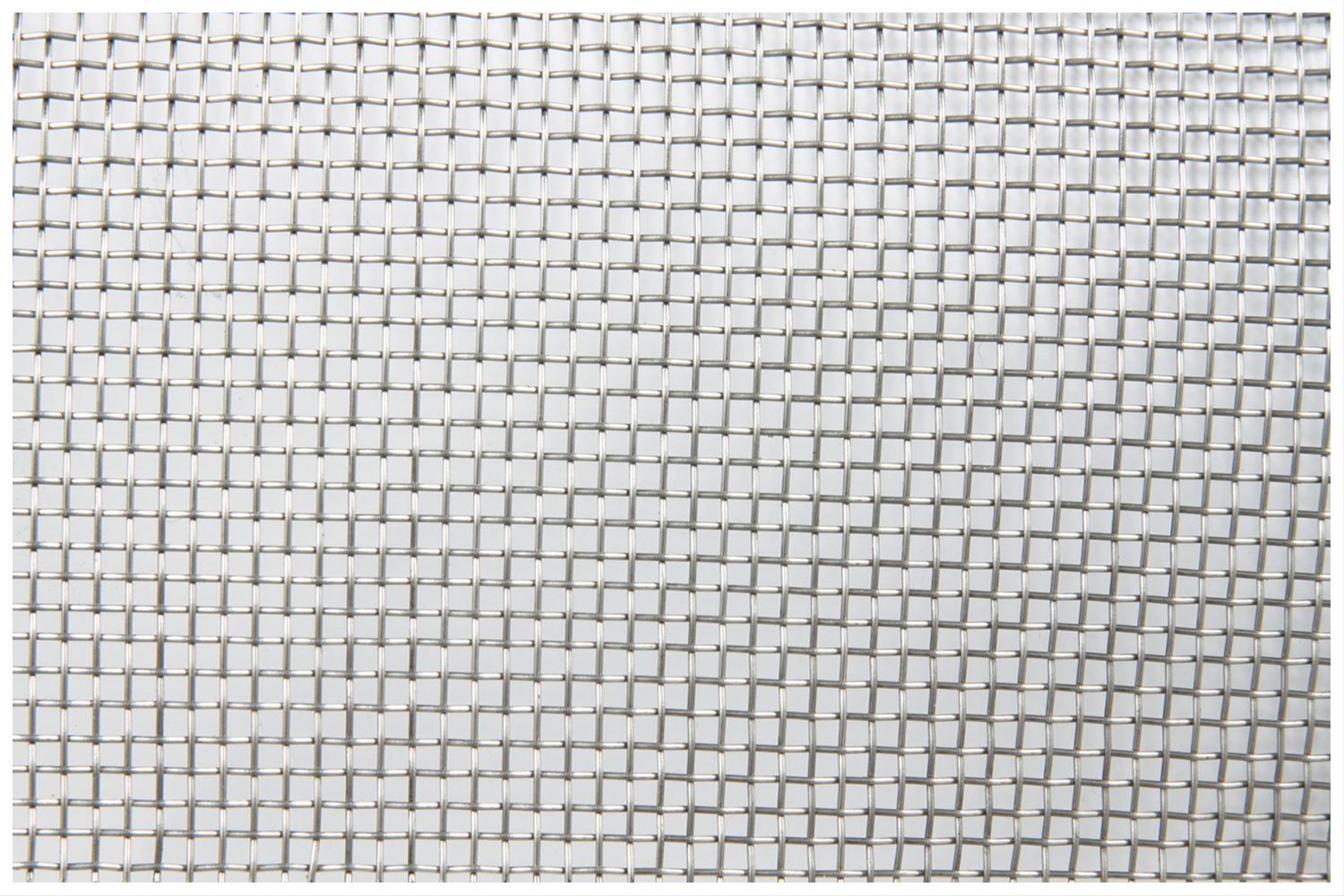

the screen used in the lifter gallery in the picture is in my opinion much too small/fine,

as it will tend to slow or restrict oil flow rates back to the oil pan.

the larger screen linked below will still catch most metallic crap/debris

yet not restrict return oil flow rates, as the holes are about a 10th inch square openings

Ive generally used hardware stainless screen epoxied over oil drain holes, and ceramic magnets to limit broken valve train debris reaching the lower crank case

Allstar Performance ALL22260 Allstar Performance Stainless Wire Screens | Summit Racing

Free Shipping - Allstar Performance Stainless Wire Screens with qualifying orders of $109. Shop Wire Screens at Summit Racing.

Last edited: