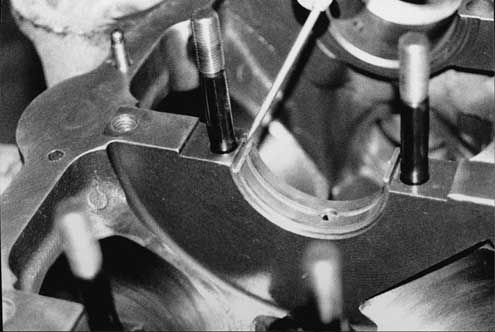

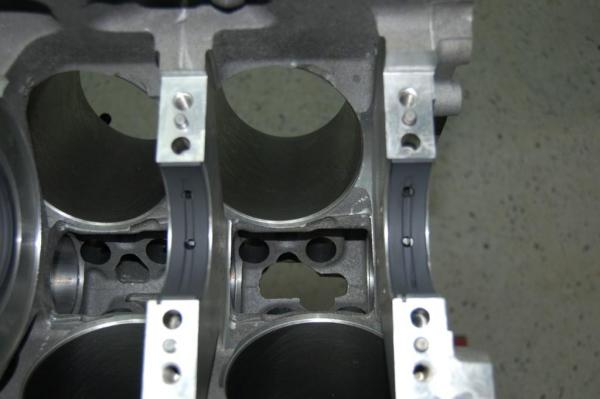

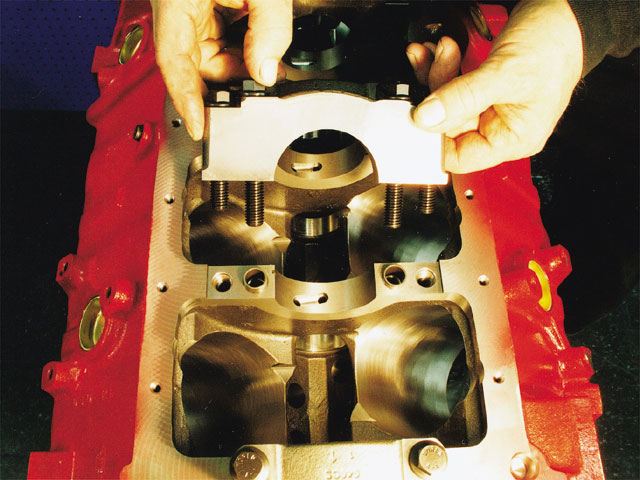

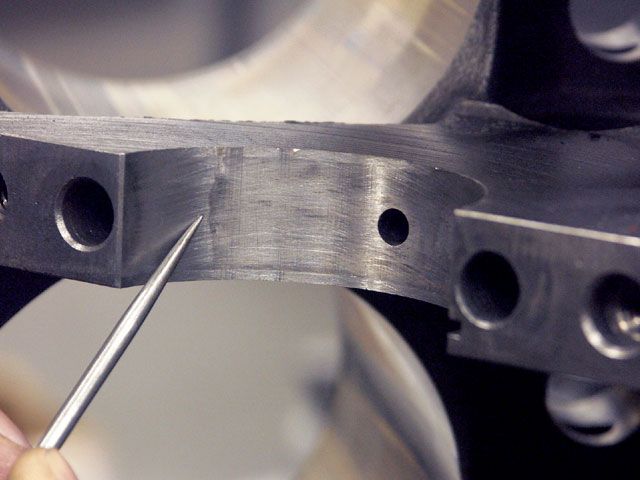

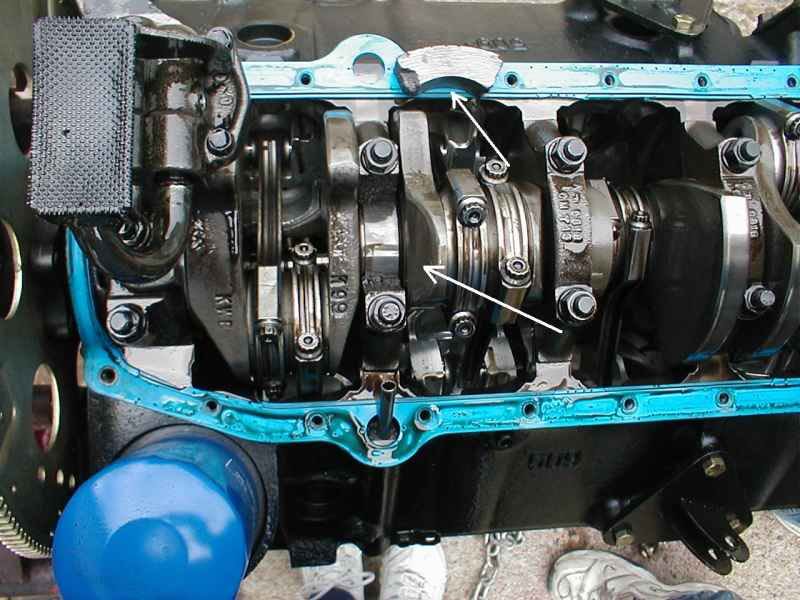

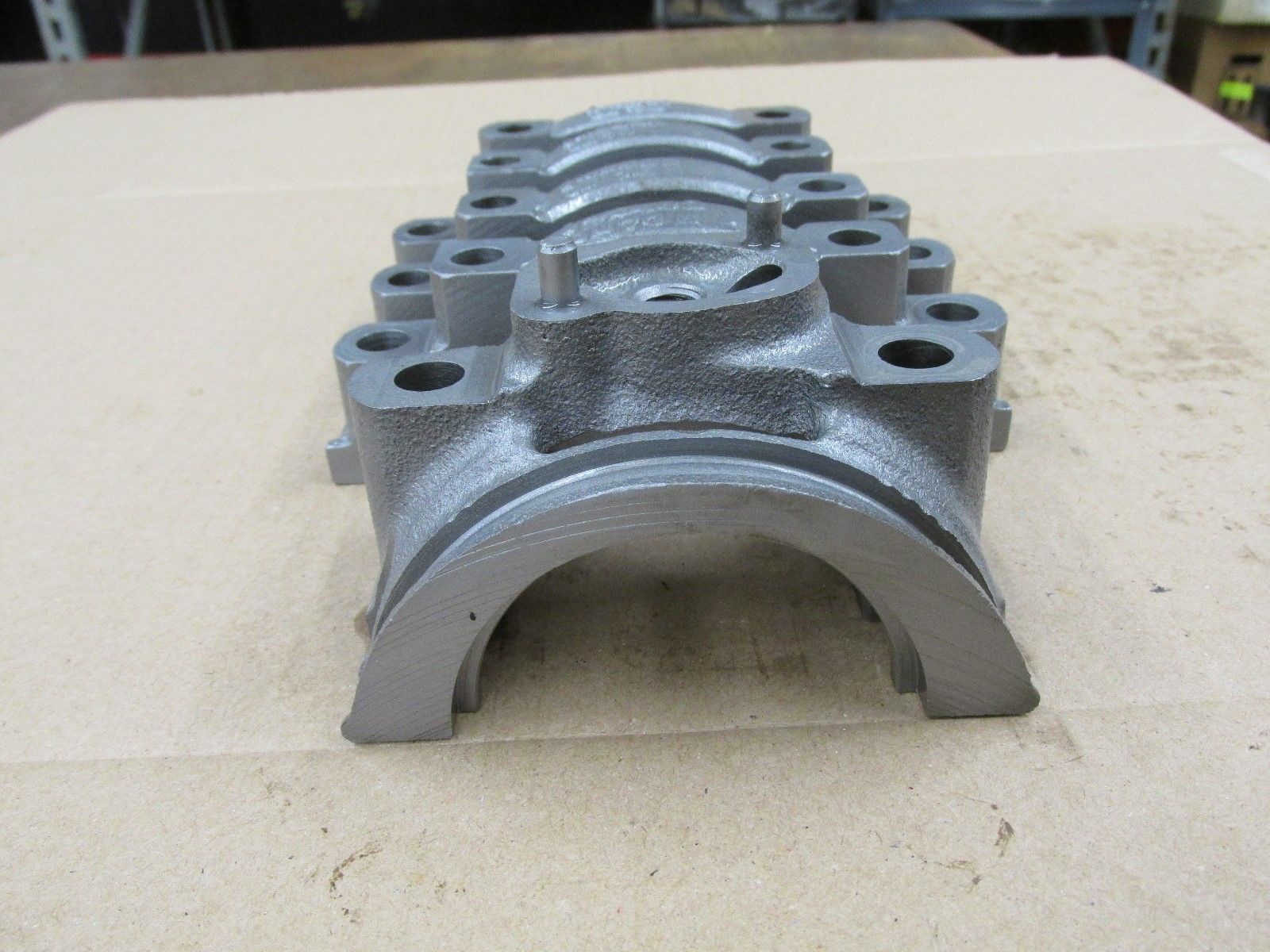

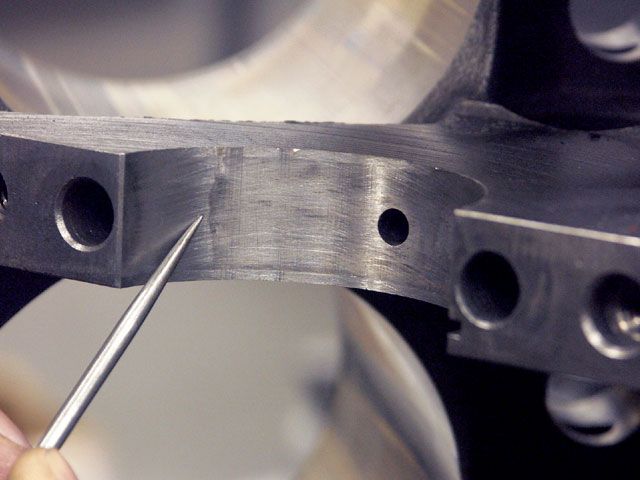

theres several ways to reduce main cap movement, the stock blocks have register notches several thousands of an inch deep and interference fit shoulders that require a solid whack with a mallet and sud thread pressure to seat look at the pictures carefully youll see the main cap lower mating surface sits in a shallow location assuring machined notch

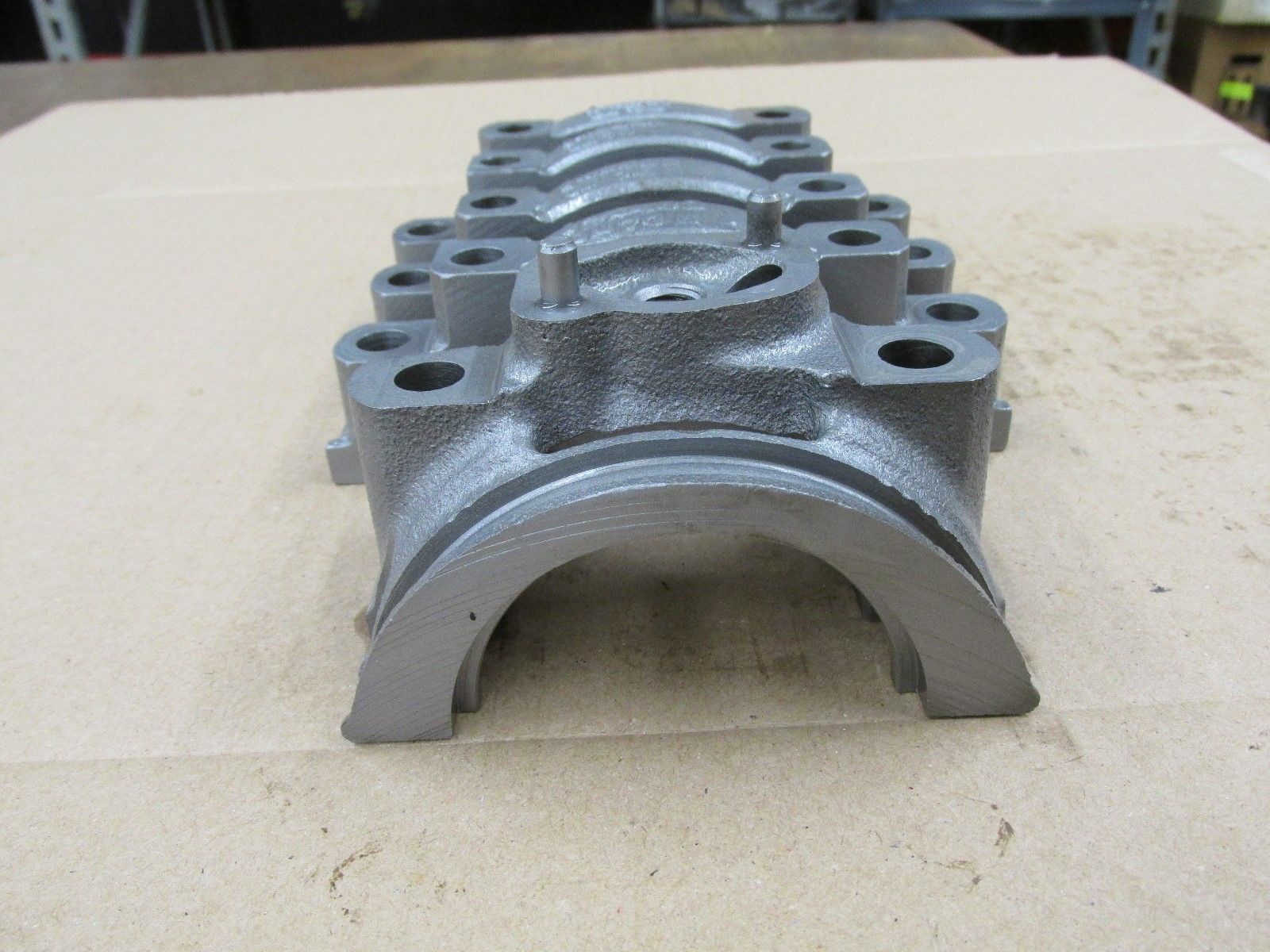

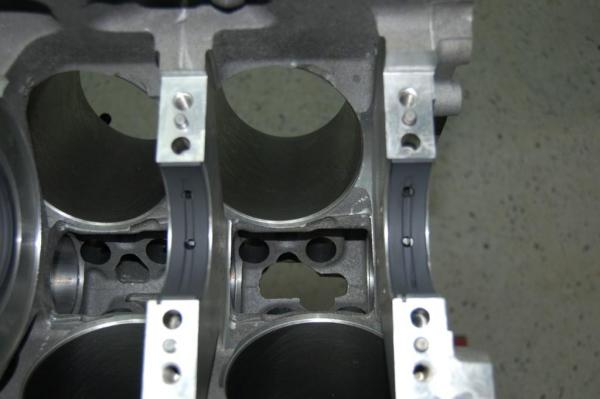

aftermarket blocks like dart have significantly thicker bore walls, main cap webs, decks, can be ordered with splayed and billet main caps

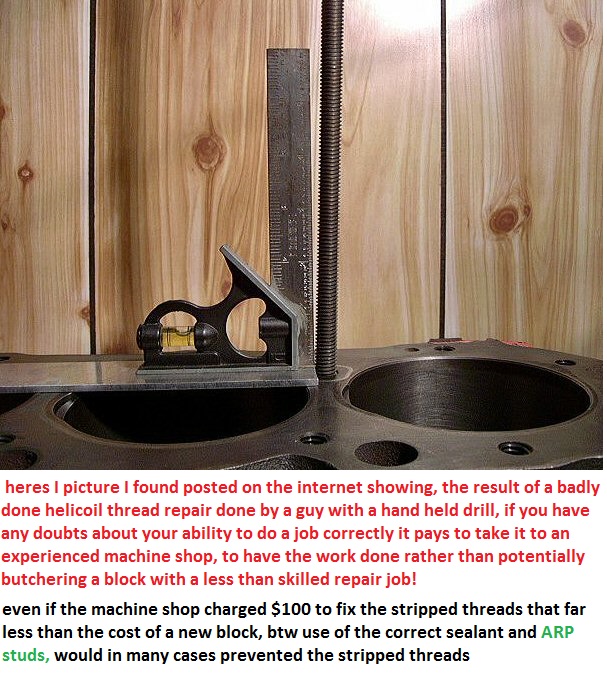

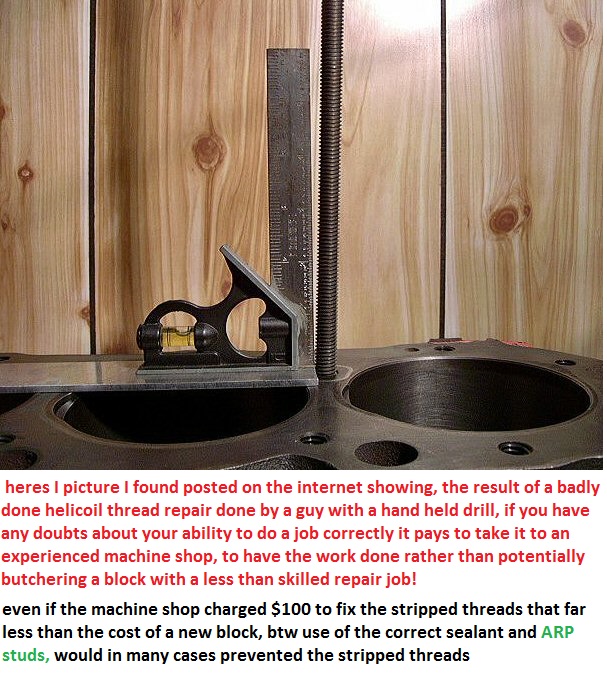

head bolts that show any thread damage should be replaced,

and be aware that NEW ARP studs put far less sress on threads,and are potentially stronger, than using bolts to secure heads to the block

cleaning threads before assembly is always a good idea

READ THRU THESE

viewtopic.php?f=53&t=343&p=419#p419

viewtopic.php?f=53&t=204

glad I could help,

its not all that un-common to find a cracked or damaged main bearing cap on a used or bargain block at a flea market or garage sale.

you obviously can,t use it that way, but replacement main bearing caps you can usually find on EBAY are available from guys that damaged block bore walls extensively or had blocks that can,t be bored any larger, due to excessively thing bore walls etc.

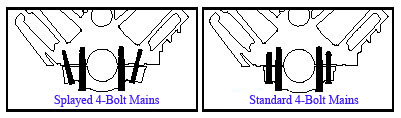

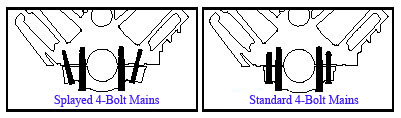

now splayed main caps offer superior strength, but obviously they cost more for your machinist to correctly install (not a great deal more because both will need line hine & index work)

just be sure what you order matches what you need, and be aware youll most likely need to get the replacement rear main cap align honed to get it to fit and the clearances correct to match the existing block its being mated too.

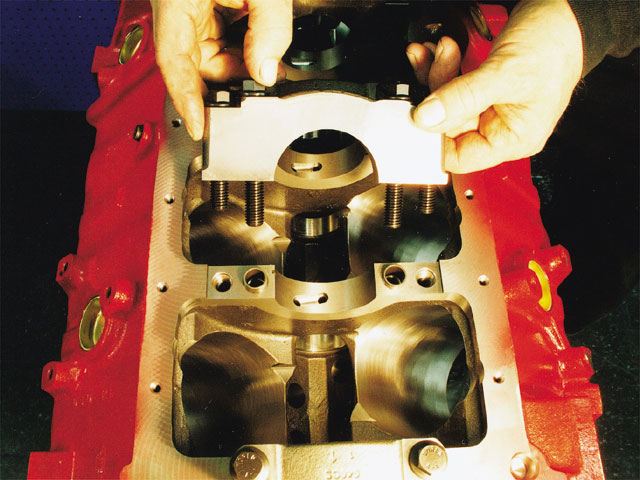

a good machinist that knows what hes doing will have zero issues doing that but its likely to cost a couple hundred bucks between cleaning the block, new cam bearings freeze plugs and line honing the main caps and honing the bores of the cylinders after verifying they are strait and consistent in size and have no taper, and use deck plates while honing the bores, so you may as well order ARP main cap studs that fit a windage tray while your spending the time in the machine shop

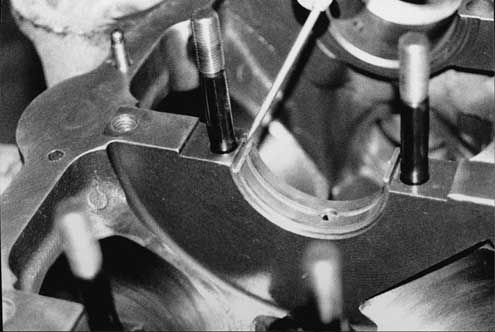

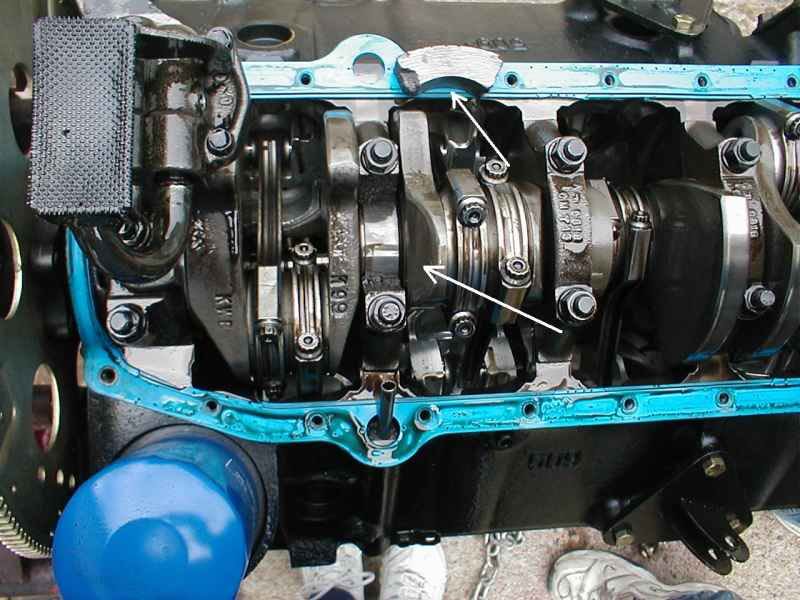

on some engines they insert location dowels that further increase resistance to cap movement like on the block and caps pictured below

Have a block with SPLAYED main cap outer bolts will significantly reduce main cap movement

HOLLOW DOWELS that fit into machined recesses,machined around the inner main cap bolts in slight enlarged main bolt cap and block bolt holes with a slight interference fit that extend about 1/4 into each bolt hole, from the main cap /block parting line, tend to significantly reduce main cap movement

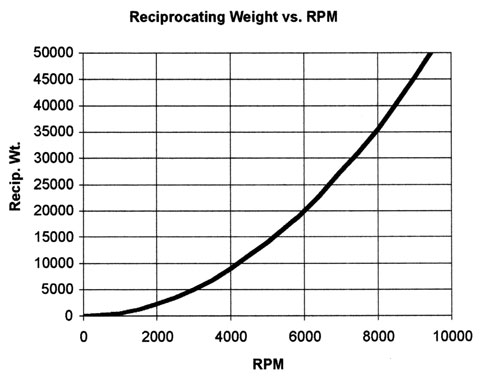

ALLOWING MAIN CAPS TO MOVE< UNDER HIGH LOAD STRESS WILL EVENTUALLY RESULTS IN CRACKED BLOCKS OR MAIN CAPS

keep in mind that main cap STUDS will have the entire threaded length of the main cap stud fully threaded into the block threads BEFORE the clamping force is applied and that the end extending through the main cap will have a finer thread pitch, that will allow a greater clamping force to be applied with identical torque wrench , torque loads

http://www.kylesconverter.com/torque/newton-meters-to-foot--pounds-force

look closely at ARP main studs have one end with course threads matching the O.E.M. block threads and the outer end with finner pitch threads, that use a harden washer and 12 point flange nuts

http://www.autoserviceprofessional....tuds-vs-bolts-and-tips-on-achieving-proper-cl

THE GENERALLY THICKER CASTINGS MADE WITH HIGHER QUALITY MATERIALS IN THE AFTERMARKET BLOCKS LIKE DART, BRODIX SELL ARE EASILY 100%-200% STRONGER THAT O.E.M. CASTINGS IN MOST BLOCKS

http://www.milodon.com/instructions/mai ... d-bolt.pdf

http://www.kennedysdynotune.com/Nitrous ... 20Tips.htm

Introduction:

Two aspects of engine building that relate to nitrous and supercharged use will be discussed. Those that allow the motor to survive under nitrous or supercharger boost and those that enhance performance. General principles are discussed as definitive answers to such FAQ's as "will my motor survive with an xxx shot of nitrous" or with "xxx pounds of boost" are surprisingly hard to answer. There are just too many variables involved to provide general answers to such questions.

Engine Block:

Factory blocks vary all over the map in terms of their basic strength. Different materials are used and designs vary from wimpy to beefy. And for certain motors, the aftermarket provides numerous alternative designs with the same basic architecture. Examples include the GM "Bowtie" blocks and the Ford "R" blocks from the OEM's and the Dart and World Products aftermarket pieces. The main areas to concentrate on are the strength of the cylinder walls and the design and materials used in the main bearing support areas; the caps and webs.

To illustrate these points, let's look a little bit more closely at the venerable small block Chevy, small block Ford, big block Chevy, and the new Gen III small block as well as some other commonly encountered engines.

The original SBC is not a strong design. Priorities of the design were light weight and low cost. The SBC was not designed as a race or even a high performance motor. Designed over 50 years ago the designers lacked the advantages of modern CAD systems. And in addition, much has been learned since then about metallurgy and production techniques. Fortunately, by staying in production for more than 50 years and becoming the darling of the performance community, GM made many changes and the aftermarket became heavily involved. In fact, the performance aftermarket was in a sense created to address the deficiencies of the small block Chevy design!

The two areas of most concern, the cylinder walls and the main bearing support, are two that are compromised by the low weight/low cost design priorities for the SBC. Cylinder walls are thin to save weight (and to promote heat transfer). Nitrous and SC use drastically increases peak cylinder pressures. This can lead to bore distortion with blow-by and loss of power. If the cylinder walls are even thinner due to boring and production tolerances and if a large nitrous shot or high boost is used, cylinder walls may split, which for practical purposes destroys the block. When building a nitrous or blower SBC, this leads to a rule that really applies in principle to all nitrous and blower motors: overbore as little as possible to preserve cylinder wall thickness.

The newer castings (since ~1987) have even thinner cylinders than older motors. And core shift with lack of inspection causes a lot of variation in production block cylinder thickness. If building up newer block, do not go beyond an 0.030-0.040"" overbore and it is preferred to stick with the smallest overbore possible. The huge variety of SBC parts makes it practical to obtain pistons and rings in overbores as small as 0.005", though 0.010" is the most common small overbore size. Older blocks may be ok with larger overbores of up to 0.060". When large overbores are being considered, having the block sonic checked may be well worth your time. Blower and nitrous motors should have AT LEAST 0.200" minimum cylinder wall thickness, and more is better.

Cylinder block fill should be considered if a large overbore must be used or very heavy nitrous use is contemplated. A complete fill makes the block unsuited to anything other than drag strip use. But a 1/2 fill or less provides some added support for the cylinders and can be used on the street. A partially filled block will run hot though. Overheating may occur and an upgraded cooling system using parts such as an electric water pump, high capacity radiator, and a better fan may be needed. Agents that promote heat transfer such as "Water Wetter" are also helpful.

Before starting any expensive block modification, the block should be checked by a competent machine shop for cracks and casting defects such as core shift. Ultimately, if extra displacement is wanted, it should be attained by installing a stroker crank and not by excessive use of the boring bar.

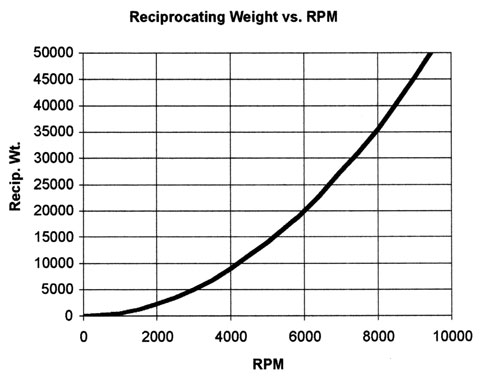

Besides keeping the cylinders as thick as possible, the main cap area also needs attention in the building of a nitrous/SC engine. Stock SBC with 2-bolt caps are adequate for basically stock motors with small amounts of nitrous or boost (in the 100-150hp range). As noted above, block filler will help here also, keeping in mind the potential for overheating that relates to using fill. Block filler will stabilize the crankcase webs and help prevent main cap "movement" under load. The term "movement" refers to a consequence of block flexing and if excessive this will quickly destroy the main bearings and then the crank. Highly modified small blocks will need 4-bolt main bearing caps. The stock iron 4-bolt main caps are a significant upgrade compared to stock 2-bolt caps. They are all that will be needed for typical street or street/strip use. Very highly stressed engines (>250+hp nitrous/>20psi of boost) will benefit from 4-bolt steel caps. Caps with splayed outer bolts offer only a small advantage on stock blocks. Aftermarket blocks, with reinforced webs, will benefit most from the 4-bolt splayed outer bolt steel caps.

An analogous situation exists with respect to the SB Ford. This is an excellent motor in many respects, but the stock Ford small block has significant weaknesses, even more so than the SB Chevy. Most hot rodders consider these blocks as good to only ~500-575hp range depending on the exact combo before the strength of the basic block becomes problematic. Aftermarket main caps, main stud girdles, and block fill are all options for strengthening these motors.

The deficiencies of the stock small blocks have been addressed by both GM, Ford and the aftermarket. For both Fords and Chevys, the factory and the aftermarket produce a variety of heavy duty "race" blocks. These typically are made of stronger alloys, offer thicker cylinder walls, strengthened crankcase webs, upgraded main caps, and thicker deck surfaces. All are quite advantageous when a max-effort motor is being built. In addition to accommodating larger bores, these blocks are often designed to also allow use of longer stroke cranks than their OEM counterparts. The primary downside is cost. Typically, from $1,500 and up depending upon the model chosen. However, these blocks are stronger than even a maximally prepped OEM case. And compared to the cost of fully prepping a production block, the total cost may actually be less if a factory machined race block is selected. Having a stock block fully "blueprinted" is not cheap by any means and no amount of machine work can compensate for the basic deficiencies of the OEM design.

The "new generation" of small block motors are the future of the domestic performance market. Both the Gen III Chevy and the Ford "modular" motor offer significant advances over their traditional predecessors. While most of the advancement has been in the cylinder head area, the "bottom end" and cylinder blocks of these motors also have been improved. These stronger blocks have increased potential for handling high power without resorting to extensive modifications compared to the earlier models. Cylinder wall thickness is still an issue though, so overbore should be kept to a minimum if high boost is contemplated.

Besides the ubiquitous SBC and SBF, there are a huge number of other engines that may be modified by the enthusiast. Each has it's own strengths and weaknesses. Especially in the import market, many seemingly similar car models will have different cylinder blocks, depending on the exact model and year of production. The number of possibilities is so large that it is not possible to generalize in an article of this length. Small domestics also cover a wide range. We suggest you consult us further if you need information about a specific model. The same applies to "exotic" motors such as the Viper and "Triton" V-10's and European models.

Before leaving the subject of cylinder blocks, domestic big blocks deserve a few words. These motors are not currently used as original equipment in cars though they may still be found in light trucks. The big block Chevy in particular is a much stronger piece than its' small block counterpart. The stock BBC can withstand nitrous boost in the 300+hp range with no difficulties due to thick cylinder walls, larger main bearings with thick crankcase webs and strong 4-bolt main caps. As with the small block, both GM and the aftermarket offer "race" versions that are immensely strong though also expensive. It would be very unusual for any street or street/strip big block setup to require a replacement block. But if you want to experiment with huge amounts of nitrous or boost (500hp range) they will be necessary. If very large displacement is needed, an aftermarket block will also be needed.

the crank or block can have the correct bearing clearance but still be slightly bent or the block may be warped and result in the bearing wear , keep in mind main bearing caps can crack or be improperly machined, this is FAR less common on DART AFTERMARKET BLOCKS

RELATED THREADS, you should read CAREFULLY

reading through these threads should be helpful, skipping them WILL COST YOU MONEY AND TIME

http://garage.grumpysperformance.co...bearing-studs-torque-stretch.9409/#post-34241

http://garage.grumpysperformance.co...gine-block-main-cap-movement.6162/#post-19172

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/#post-43984

http://garage.grumpysperformance.com/index.php?threads/splayed-main-caps.1014/#post-16462

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/#post-26892

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-55314

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24723

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://www.jegs.com/i/Dart/301/3277...7&cadevice=c&gclid=CMfnmqaG2tMCFUm1wAodg-4J8A

http://garage.grumpysperformance.co...am-lobe-rod-or-bearings-fail.2919/#post-26455

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

aftermarket blocks like dart have significantly thicker bore walls, main cap webs, decks, can be ordered with splayed and billet main caps

head bolts that show any thread damage should be replaced,

and be aware that NEW ARP studs put far less sress on threads,and are potentially stronger, than using bolts to secure heads to the block

cleaning threads before assembly is always a good idea

READ THRU THESE

viewtopic.php?f=53&t=343&p=419#p419

viewtopic.php?f=53&t=204

glad I could help,

its not all that un-common to find a cracked or damaged main bearing cap on a used or bargain block at a flea market or garage sale.

you obviously can,t use it that way, but replacement main bearing caps you can usually find on EBAY are available from guys that damaged block bore walls extensively or had blocks that can,t be bored any larger, due to excessively thing bore walls etc.

now splayed main caps offer superior strength, but obviously they cost more for your machinist to correctly install (not a great deal more because both will need line hine & index work)

just be sure what you order matches what you need, and be aware youll most likely need to get the replacement rear main cap align honed to get it to fit and the clearances correct to match the existing block its being mated too.

a good machinist that knows what hes doing will have zero issues doing that but its likely to cost a couple hundred bucks between cleaning the block, new cam bearings freeze plugs and line honing the main caps and honing the bores of the cylinders after verifying they are strait and consistent in size and have no taper, and use deck plates while honing the bores, so you may as well order ARP main cap studs that fit a windage tray while your spending the time in the machine shop

on some engines they insert location dowels that further increase resistance to cap movement like on the block and caps pictured below

Have a block with SPLAYED main cap outer bolts will significantly reduce main cap movement

HOLLOW DOWELS that fit into machined recesses,machined around the inner main cap bolts in slight enlarged main bolt cap and block bolt holes with a slight interference fit that extend about 1/4 into each bolt hole, from the main cap /block parting line, tend to significantly reduce main cap movement

ALLOWING MAIN CAPS TO MOVE< UNDER HIGH LOAD STRESS WILL EVENTUALLY RESULTS IN CRACKED BLOCKS OR MAIN CAPS

keep in mind that main cap STUDS will have the entire threaded length of the main cap stud fully threaded into the block threads BEFORE the clamping force is applied and that the end extending through the main cap will have a finer thread pitch, that will allow a greater clamping force to be applied with identical torque wrench , torque loads

read the factory shop manual or connecting rod manufacturers info VERY carefully...FT LBS AND NM ARE NOT THE SAMEARP said:Do I need to re-torque my head bolts or studs?

If you follow the ARP installation instructions, there should be no need to do a re-torque. However, it may be necessary under certain circumstances if the gasket manufacturer’s instructions require it, particularly if a fire ring has been installed. ARP recommends not doing a re-torque on a hot engine.

Do I need lube on my bolts or studs?

We recommend using ARP Ultra-Torque lube to ensure an even, accurate clamp load and to prevent thread galling. This is particularly important for stainless steel fasteners. The lube should be used under the head of the bolt or the bearing surface of the nut and on the threads, unless a thread sealer is used.

Can I use Loctite or any thread locker instead of ARP Ultra-Torque assembly lube?

Yes, you can. Some engine builders use blue Loctite on the stud end that goes into the block. Do NOT use Loctite on the nuts for the head studs or main studs. Always ensure that the threads are clean prior to applying any lube. When using Loctite, make sure you assemble the parts before the Loctite cures. You can use Loctite instead of ARP Ultra-Torque, but do not use them together.

Do I have to use Ultra-Torque?

We spent two years developing ARP Ultra-Torque and we have come up with what we believe to be the ultimate fastener lubricant. All of our torque values are based on using Ultra-Torque. We do not provide torque values for use with any other fastener assembly lubricant (such as motor oil, moly lube, etc.) Use these other lubes at your own risk, as their use may lead to a part or engine failure, for which we are not responsible.

Do the threads of the bolts or studs going into the block need lube?

Yes. On blind holes use a small amount of ARP Ultra-Torque lube on those threads. Additionally, if the studs protrude into a water jacket, you will need to clean the threads in the block to remove all coolant and oil residue. Apply a liberal amount of ARP thread sealer or a high temperature thread sealer.

Are ARP bolts and studs re-usable?

Yes. As long as the fasteners have been installed and torqued correctly, and show no visible signs of damage, they can be re-used. If they show any signs of thread galling or corrosion, they should be replaced. In the case of rod bolts, if any of them have taken a permanent set and have stretched by .001” or longer, you should replace them immediately. See page 29 in the catalog for more detailed information on this critical measurement.

Do I install my studs into the block first?

After test fitting the studs in the block, it is generally easier to remove the studs, put the head gasket and head on the block and install the studs. This will reduce the possibility of damaging the upper threads of the stud and scraping the cylinder mounting holes. If the block has no alignment dowel pins, you can use the stud to align the gasket and head.

Does the chamfer on the inside diameter of the washer go up or down?

The chamfered side of the washer goes up, towards the head of the bolt. The chamfer is there to create clearance for the radius between the bolt shank and the bolt head.

Do the head studs only go in hand, or finger tight?

Yes, cylinder head studs are installed only hand tight. Other than the use of an allen wrench on the hex broached into the end of the stud (to ease installation, not to apply torque), use no tools to seat them in the block. However, it is extremely important to ensure that the studs are fully bottomed out in the hole in the block and not hung up on damaged or corroded threads in the block preventing the stud from being fully seated. This is often indicated when the stud threads extend past the deck surface.

I have heard that some people have had trouble with newly installed cylinder head studs leaking water. How do I make sure I don’t have the same problem with my new ARP head studs?

Prior to installing your new head studs, it is very important that you have clean threads on both the block and the studs. First, clean up all the threads in the block with a thread-cleaning chaser, NOT a regular tap. Thread chasers are designed so that they do not remove material from threads but merely remove debris and corrosion. Make sure you go all the way to the end of the threads in the bottom of the hole. Then clean out all the holes in the block with brake or carburetor cleaner to remove all the debris. Make sure the threads on the new studs are clean. Use a liberal amount of ARP thread sealer, high temp silicone or Loctite to ensure that there will be no air pockets that can cause leaks. Then follow the ARP instructions for installing the fasteners.

Are ARP’s torque recommendations the same as the vehicle manufacturer’s specifications?

Sometimes ARP will recommend using torque specifications that are different than the manufacturer, but not always. Our kits are engineered for specific applications, factoring in the necessary clamp load we’re trying to achieve, material type, block or head material, etc. To achieve our target clamp load, it may be necessary to use a different torque figure than what the factory calls out.

The torque/stretch number listed for my after-market connecting rod is different than what ARP calls out for the same bolt. Which specification do I use?

Refer back to the rod manufacturer and use their torque/stretch value.

What drill size do I need for my wheel studs?

To determine what drill size you need, you will need to know your axle/hub material and the wheel stud knurl diameter. If your axle/hub material is cast iron or steel, your drill size will be 0.005” smaller than the knurl diameter. If your axle/hub material is aluminum, your drill size will be 0.007” less than the knurl diameter. The Wheel Studs section in the catalog, pages 76 & 77, list the knurl diameter size.

What is the difference between ARP2000 and Custom Age 625+ studs?

ARP2000 is an alloy steel that has a tensile strength of 220,000 PSI. Custom Age is an austenitic alloy that has a tensile strength of 260-280,000 PSI, providing a greater clamping force than that of ARP 2000.

Why does L19 material require special handling?

Like most high-strength quench and temper steels, L19 requires special care to avoid hydrogen embrittlement or stress corrosion. The material is easily contaminated and subject to stress corrosion. The parts must be kept well oiled at all times and not exposed to moisture. Wearing gloves while handing L19 parts is a good precaution.

I have heard that the black oxide bolts and studs I get from ARP will eventually rust. Is this true and if it is, can it be prevented?

Yes, the bolts or studs will rust. Black oxide is a conversion coating formed by a chemical reaction with the iron in the metal to form an integral protective surface. It is NOT a permanent coating that has bonded to the surface of the fastener. The black oxide process is a short-term rust preventative only and any part exposed to the atmosphere will show signs of rust in a matter of days. Frequent application of oil to the part will increase corrosion resistance. In addition, the bolt head could be painted with black epoxy primer, followed by semi-flat paint or clear lacquer.

http://www.kylesconverter.com/torque/newton-meters-to-foot--pounds-force

look closely at ARP main studs have one end with course threads matching the O.E.M. block threads and the outer end with finner pitch threads, that use a harden washer and 12 point flange nuts

http://www.autoserviceprofessional....tuds-vs-bolts-and-tips-on-achieving-proper-cl

THE GENERALLY THICKER CASTINGS MADE WITH HIGHER QUALITY MATERIALS IN THE AFTERMARKET BLOCKS LIKE DART, BRODIX SELL ARE EASILY 100%-200% STRONGER THAT O.E.M. CASTINGS IN MOST BLOCKS

http://www.milodon.com/instructions/mai ... d-bolt.pdf

http://www.kennedysdynotune.com/Nitrous ... 20Tips.htm

Introduction:

Two aspects of engine building that relate to nitrous and supercharged use will be discussed. Those that allow the motor to survive under nitrous or supercharger boost and those that enhance performance. General principles are discussed as definitive answers to such FAQ's as "will my motor survive with an xxx shot of nitrous" or with "xxx pounds of boost" are surprisingly hard to answer. There are just too many variables involved to provide general answers to such questions.

Engine Block:

Factory blocks vary all over the map in terms of their basic strength. Different materials are used and designs vary from wimpy to beefy. And for certain motors, the aftermarket provides numerous alternative designs with the same basic architecture. Examples include the GM "Bowtie" blocks and the Ford "R" blocks from the OEM's and the Dart and World Products aftermarket pieces. The main areas to concentrate on are the strength of the cylinder walls and the design and materials used in the main bearing support areas; the caps and webs.

To illustrate these points, let's look a little bit more closely at the venerable small block Chevy, small block Ford, big block Chevy, and the new Gen III small block as well as some other commonly encountered engines.

The original SBC is not a strong design. Priorities of the design were light weight and low cost. The SBC was not designed as a race or even a high performance motor. Designed over 50 years ago the designers lacked the advantages of modern CAD systems. And in addition, much has been learned since then about metallurgy and production techniques. Fortunately, by staying in production for more than 50 years and becoming the darling of the performance community, GM made many changes and the aftermarket became heavily involved. In fact, the performance aftermarket was in a sense created to address the deficiencies of the small block Chevy design!

The two areas of most concern, the cylinder walls and the main bearing support, are two that are compromised by the low weight/low cost design priorities for the SBC. Cylinder walls are thin to save weight (and to promote heat transfer). Nitrous and SC use drastically increases peak cylinder pressures. This can lead to bore distortion with blow-by and loss of power. If the cylinder walls are even thinner due to boring and production tolerances and if a large nitrous shot or high boost is used, cylinder walls may split, which for practical purposes destroys the block. When building a nitrous or blower SBC, this leads to a rule that really applies in principle to all nitrous and blower motors: overbore as little as possible to preserve cylinder wall thickness.

The newer castings (since ~1987) have even thinner cylinders than older motors. And core shift with lack of inspection causes a lot of variation in production block cylinder thickness. If building up newer block, do not go beyond an 0.030-0.040"" overbore and it is preferred to stick with the smallest overbore possible. The huge variety of SBC parts makes it practical to obtain pistons and rings in overbores as small as 0.005", though 0.010" is the most common small overbore size. Older blocks may be ok with larger overbores of up to 0.060". When large overbores are being considered, having the block sonic checked may be well worth your time. Blower and nitrous motors should have AT LEAST 0.200" minimum cylinder wall thickness, and more is better.

Cylinder block fill should be considered if a large overbore must be used or very heavy nitrous use is contemplated. A complete fill makes the block unsuited to anything other than drag strip use. But a 1/2 fill or less provides some added support for the cylinders and can be used on the street. A partially filled block will run hot though. Overheating may occur and an upgraded cooling system using parts such as an electric water pump, high capacity radiator, and a better fan may be needed. Agents that promote heat transfer such as "Water Wetter" are also helpful.

Before starting any expensive block modification, the block should be checked by a competent machine shop for cracks and casting defects such as core shift. Ultimately, if extra displacement is wanted, it should be attained by installing a stroker crank and not by excessive use of the boring bar.

Besides keeping the cylinders as thick as possible, the main cap area also needs attention in the building of a nitrous/SC engine. Stock SBC with 2-bolt caps are adequate for basically stock motors with small amounts of nitrous or boost (in the 100-150hp range). As noted above, block filler will help here also, keeping in mind the potential for overheating that relates to using fill. Block filler will stabilize the crankcase webs and help prevent main cap "movement" under load. The term "movement" refers to a consequence of block flexing and if excessive this will quickly destroy the main bearings and then the crank. Highly modified small blocks will need 4-bolt main bearing caps. The stock iron 4-bolt main caps are a significant upgrade compared to stock 2-bolt caps. They are all that will be needed for typical street or street/strip use. Very highly stressed engines (>250+hp nitrous/>20psi of boost) will benefit from 4-bolt steel caps. Caps with splayed outer bolts offer only a small advantage on stock blocks. Aftermarket blocks, with reinforced webs, will benefit most from the 4-bolt splayed outer bolt steel caps.

An analogous situation exists with respect to the SB Ford. This is an excellent motor in many respects, but the stock Ford small block has significant weaknesses, even more so than the SB Chevy. Most hot rodders consider these blocks as good to only ~500-575hp range depending on the exact combo before the strength of the basic block becomes problematic. Aftermarket main caps, main stud girdles, and block fill are all options for strengthening these motors.

The deficiencies of the stock small blocks have been addressed by both GM, Ford and the aftermarket. For both Fords and Chevys, the factory and the aftermarket produce a variety of heavy duty "race" blocks. These typically are made of stronger alloys, offer thicker cylinder walls, strengthened crankcase webs, upgraded main caps, and thicker deck surfaces. All are quite advantageous when a max-effort motor is being built. In addition to accommodating larger bores, these blocks are often designed to also allow use of longer stroke cranks than their OEM counterparts. The primary downside is cost. Typically, from $1,500 and up depending upon the model chosen. However, these blocks are stronger than even a maximally prepped OEM case. And compared to the cost of fully prepping a production block, the total cost may actually be less if a factory machined race block is selected. Having a stock block fully "blueprinted" is not cheap by any means and no amount of machine work can compensate for the basic deficiencies of the OEM design.

The "new generation" of small block motors are the future of the domestic performance market. Both the Gen III Chevy and the Ford "modular" motor offer significant advances over their traditional predecessors. While most of the advancement has been in the cylinder head area, the "bottom end" and cylinder blocks of these motors also have been improved. These stronger blocks have increased potential for handling high power without resorting to extensive modifications compared to the earlier models. Cylinder wall thickness is still an issue though, so overbore should be kept to a minimum if high boost is contemplated.

Besides the ubiquitous SBC and SBF, there are a huge number of other engines that may be modified by the enthusiast. Each has it's own strengths and weaknesses. Especially in the import market, many seemingly similar car models will have different cylinder blocks, depending on the exact model and year of production. The number of possibilities is so large that it is not possible to generalize in an article of this length. Small domestics also cover a wide range. We suggest you consult us further if you need information about a specific model. The same applies to "exotic" motors such as the Viper and "Triton" V-10's and European models.

Before leaving the subject of cylinder blocks, domestic big blocks deserve a few words. These motors are not currently used as original equipment in cars though they may still be found in light trucks. The big block Chevy in particular is a much stronger piece than its' small block counterpart. The stock BBC can withstand nitrous boost in the 300+hp range with no difficulties due to thick cylinder walls, larger main bearings with thick crankcase webs and strong 4-bolt main caps. As with the small block, both GM and the aftermarket offer "race" versions that are immensely strong though also expensive. It would be very unusual for any street or street/strip big block setup to require a replacement block. But if you want to experiment with huge amounts of nitrous or boost (500hp range) they will be necessary. If very large displacement is needed, an aftermarket block will also be needed.

the crank or block can have the correct bearing clearance but still be slightly bent or the block may be warped and result in the bearing wear , keep in mind main bearing caps can crack or be improperly machined, this is FAR less common on DART AFTERMARKET BLOCKS

RELATED THREADS, you should read CAREFULLY

reading through these threads should be helpful, skipping them WILL COST YOU MONEY AND TIME

http://garage.grumpysperformance.co...bearing-studs-torque-stretch.9409/#post-34241

http://garage.grumpysperformance.co...gine-block-main-cap-movement.6162/#post-19172

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/#post-43984

http://garage.grumpysperformance.com/index.php?threads/splayed-main-caps.1014/#post-16462

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/#post-26892

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-55314

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24723

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://www.jegs.com/i/Dart/301/3277...7&cadevice=c&gclid=CMfnmqaG2tMCFUm1wAodg-4J8A

http://garage.grumpysperformance.co...am-lobe-rod-or-bearings-fail.2919/#post-26455

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

Last edited by a moderator: