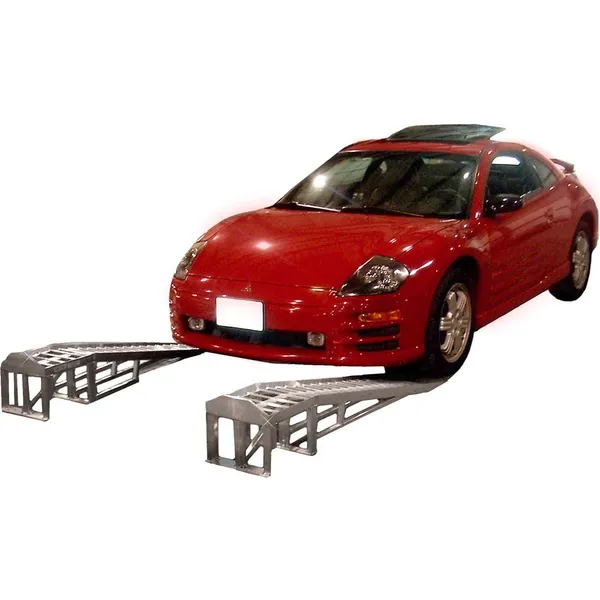

your average auto store ramps ,(especially the cheap stamped steel versions)are dangerous and won,t allow the corvettes low approach angle to drive up on them, get the tires centered off/center and they frequently bend or tip, the RINO RAMPS work ok, but are FAR from high enough or stabilize enough for serious work, and they tend to skid as you try to roll up on them occasionally

http://www.kwik-lift.com/gallery.html

if you have the cash the KWIK-LIFT RAMPS ARE GREAT,

the question comes up about how you use a two post AUTO lift with a low car with limited side clearance, or side pipe exhaust, like my brother-in-laws corvette,where the lift arms would damage the exhaust as the cars lifted, unless pad extenders are used, but theres not enough clearance the way the car sits on the tires,

yes I do it all the time with my brother in laws 74 big block corvette,(below an early picture before we added the lower panels)

you simply need to drive the car up on 4 short doubled tapered, sections of 2" x 10" board to provide the required clearance for the arms with extended pads to reach the frame, thus preventing damage to the side pipes, it helps if you mark the location for the spacer ramps , on the shop floor where the ramps and tires need to be located.

theres also adapter plates that can be used with two post lifts

we simply made 4 cheap wood low height ramps we place them where the corvettes tires need to be and swing the lifts control arms well out of the way while the corvette drives onto the ramps, once the cars sitting up about 4" higher than normal on the four mini ramps we swing the arms in, under the car, add the pad extenders and lift the car , and yes you reverse the process to let the car down, so marking the ramp locations on the shop floor helps if you need to move them while you have the car up on the lift.

http://www.discountramps.com/roll-ups.htm

heres some better options

http://www.chapmanenterprise.com/jack_rabbit.html

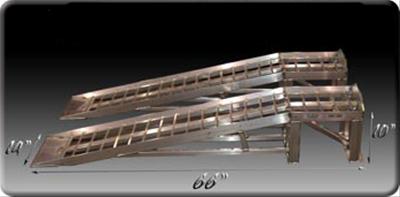

look closely at the details on these ramps, you could buy those or weld up something similar at reasonable cost and with custom dimensions

http://www.raceramps.com/store/shopexd.asp?id=62

much better but not nearly high enought for serious work

http://www.discountramps.com/sports_car_ramps.htm

http://www.summitracing.com/parts/rrr-ml-1066

http://www.discountramps.com/low_profile_car_ramp.htm

much better but not nearly high enought for serious work

but still too low

http://www.kwiklift.com/

http://www.kwiklift.com/

excellent but expensive

http://www.chapmanenterprise.com/products.html

these are made to YOUR specs if you want them custom

keep in mind if youve got a spare weekend and a few hundred dollars worth of alluminum or steel and a decent welder , you can build a fantastic set of heavy duty ramps

listed from decent... too great but expensive

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=K1297

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907312

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=43550

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=500526

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907324

ive got these last two in the shop

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907321

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=K1419-5

welders may seem expensive, but they rapidly pay for themselfs

then theres lifts if you save up and have the room, frankly I can,t believe I wated as long as I did to purchase one now that I have one in the shop

http://www.digitalcorvettes.com/forums/showthread.php?t=80368

if you have a set of rhino ramps and a corvette , you could do what a buddy did in his shop,

you could purchase a sheet of 3/4" plywood and have them cut it into (4) 8 foot long sections,

glue and screw them together off set so there's about 6" on both ends sticking out longer on each end

he bolted with 1/4 1.25" bolts and fender washers a section of thick rubber mat ,

so he had about 18" long and 12" wide sections of mat on each end this allows you to have a much more gradual ramp angle and the car won't cause the ramp to move because the mat, is squeezed between the ,mat and adjacent surfaces on both the floor and over the rhino ramps

yes he added two short sections of 2" x 12" boards under the ramp he screwed in as support braces with the top angled to match the incline angle at the 2.5 ft and 6 ft locations

yeah it sounds like work and its not real cheap to do but it worked as it provided him with ramps he felt helped a great deal, btw he also found

if he placed a 3 foot section of 2"x12" board against the shop back wall, and used that to keep the rhino ramps from moving as the car was driven up on the ramps it helped a good deal, of course you need to space the ramps to match the cars wheel base and it helps if you have a helper guide your car tire center line up on the ramps

OK first you DON,T raise a vette one corner at a time! you drive it up on the ramps to get clearance for the jack then slide the floor jack under the center of the front (CROSS MEMBER) and lift the front and place BOTH front 12 ton jack stands, under the frame , wide spaced, then the angle allows you to either use a second floor jack or move the front floor jack to the rear of the vette, and lift the whole back and place both REAR 12 ton jack stands, on the rear frame. now personally I usually leave the rear jack stands and the jack holding the rear up ,and the 12 ton jack stands on the front with the tires hanging just above the ramps, that way theres almost no chance the vette can fall, even if some component were to fail.

Ill ALSO point out I have and have always used two floor jacks, twin rino ramps and 4 12 ton jack stand WHEN I was under the corvette as I don,t want to be doing bench presses with a vette!

IF YOU SELLECT TO USE JACK STANDS, youll need a decent floor jack,

ive got two that are now discontinued

this replaced it at sears, they seem to be getting made less quality lately, Ive had mine for 12 years plus with zero problems, you want a 20" minimum lift and a 4 ton rated jack

BTW ALL the aluminum jacks Ive seen are JUNK so far

http://www.sears.com/shc/s/p_10153_...TOOL&subcat=Lift+Equipment&BV_UseBVCookie=Yes

http://www.corvettegadgetman.com/products3.html

you can BUY a jack adapter from this guy for your C4 to lift the rear or if you own a WELDER like I keep advising, you can fabricate an adapter for less thats even better

I would not take some of the 2 and three ton jacks I see advertized at auto parts stores home FOR FREE! they are DANGERIOUS JUNK!

BUY A DECENT 20" lift 4 ton rated HYDROLIC floor jack and decent 12 ton jack stands, youll wonder HOW you got along without them after a few years, EVERY SISSORS jack Ive seen is a cheap emergency only tire change tool for the trunk,an accident looking for a location and victim,

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

theres few things that harbor freight sells that are good quality, but IVe had 6 of these in nearly constant use for many years in the shop and they are an exception. I CAN HIGHLY RECOMMEND BUYING AT LEAST 4, AS THEY ARE SIGNIFICANTLY MORE STABILE THAN THE AVERAGE and MUCH SMALLER 3 & 6 TON RATED STANDS most auto parts stores sell.

and on the first notch they are exactly the correct height for clearance under the corvette to do clutch, brake, u-joint replacements ETC. and most other work that youll generally do........remember WORK on a flat level concrete surface if you can and use all 4 or 6 12 ton jack stands to fully and securely support the car, you can,t bench press the car if it falls and larege, stabile ,serious jack stands go a LOOOOOOONG way to keeping your butt safe under the car, and yes, before you ask, even thought I have a lift I frequently use those 12 ton jack stands......an EXCELLENT ADDITION TO YOUR SHOP TOOLS.

IVE USED 12 ton JACK STANDS for MANY YEARS, they are FAR SAFER than your average auto parts store crap stands, I can,t BELIEVEsome of the total CRAP Ive seen guys use and trust to support a car, remember guys YOUR LIKELY to be CRIPPLED OR DEAD IF the car falls on your butt, USE DECENT STANDS, I now have a two post lift but the jack stands still get used because at times your going to leave the car up for a few days and your not generally going to want to tie up the lift that long, nor is it any advantage over the jack stands for some things

BTW I was asked how to install those 12 ton jacks

I generally drive the front wheels of the car up on two rhino car ramps Ive screwed to a sheet of 3/4" plywood base at the correct spacing ,that I attached a rubber base to to prevent skidding first to get clearance , this adds about 1.25" to the normal ramp height , then use both 3-4 ton, (I forget which but they are sears better floor jacks )with my sons help or some one else, after I instruct them, too lift the rear smoothly and evenly to the height necessary to place the two rear stands on the frame so I dont twist the body,while the fronts already up on the ramps so the angles not to extreme, once thats done both floor jacks get relocated and the fronts lifted from both sides evenly and the front jack stands are placed, I use the first height notch on the 12 ton jacks, I occasionally place two more 12 ton stands mid frame after that and use a roller creaper from the front or rear to access under the car, I try only to work on LEVEL CONCRETE and I try to shake the car to make sure its sturdy before getting under it.

the 12 tons stands are a P.I.T.A. to install if you need to do it in stages so I developed that system to get the corvette up to a 20" or so height smoothly and easily in that way.

http://www.kwik-lift.com/gallery.html

if you have the cash the KWIK-LIFT RAMPS ARE GREAT,

the question comes up about how you use a two post AUTO lift with a low car with limited side clearance, or side pipe exhaust, like my brother-in-laws corvette,where the lift arms would damage the exhaust as the cars lifted, unless pad extenders are used, but theres not enough clearance the way the car sits on the tires,

yes I do it all the time with my brother in laws 74 big block corvette,(below an early picture before we added the lower panels)

you simply need to drive the car up on 4 short doubled tapered, sections of 2" x 10" board to provide the required clearance for the arms with extended pads to reach the frame, thus preventing damage to the side pipes, it helps if you mark the location for the spacer ramps , on the shop floor where the ramps and tires need to be located.

theres also adapter plates that can be used with two post lifts

we simply made 4 cheap wood low height ramps we place them where the corvettes tires need to be and swing the lifts control arms well out of the way while the corvette drives onto the ramps, once the cars sitting up about 4" higher than normal on the four mini ramps we swing the arms in, under the car, add the pad extenders and lift the car , and yes you reverse the process to let the car down, so marking the ramp locations on the shop floor helps if you need to move them while you have the car up on the lift.

http://www.discountramps.com/roll-ups.htm

heres some better options

http://www.chapmanenterprise.com/jack_rabbit.html

look closely at the details on these ramps, you could buy those or weld up something similar at reasonable cost and with custom dimensions

http://www.raceramps.com/store/shopexd.asp?id=62

much better but not nearly high enought for serious work

http://www.discountramps.com/sports_car_ramps.htm

http://www.summitracing.com/parts/rrr-ml-1066

http://www.discountramps.com/low_profile_car_ramp.htm

much better but not nearly high enought for serious work

but still too low

http://www.kwiklift.com/

http://www.kwiklift.com/

excellent but expensive

http://www.chapmanenterprise.com/products.html

these are made to YOUR specs if you want them custom

keep in mind if youve got a spare weekend and a few hundred dollars worth of alluminum or steel and a decent welder , you can build a fantastic set of heavy duty ramps

listed from decent... too great but expensive

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=K1297

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907312

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=43550

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=500526

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907324

ive got these last two in the shop

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=907321

http://www.welders-direct.com/merchant2/merchant.mv?Screen=PROD&Store_Code=WD&Product_Code=K1419-5

welders may seem expensive, but they rapidly pay for themselfs

then theres lifts if you save up and have the room, frankly I can,t believe I wated as long as I did to purchase one now that I have one in the shop

http://www.digitalcorvettes.com/forums/showthread.php?t=80368

if you have a set of rhino ramps and a corvette , you could do what a buddy did in his shop,

you could purchase a sheet of 3/4" plywood and have them cut it into (4) 8 foot long sections,

glue and screw them together off set so there's about 6" on both ends sticking out longer on each end

he bolted with 1/4 1.25" bolts and fender washers a section of thick rubber mat ,

so he had about 18" long and 12" wide sections of mat on each end this allows you to have a much more gradual ramp angle and the car won't cause the ramp to move because the mat, is squeezed between the ,mat and adjacent surfaces on both the floor and over the rhino ramps

yes he added two short sections of 2" x 12" boards under the ramp he screwed in as support braces with the top angled to match the incline angle at the 2.5 ft and 6 ft locations

yeah it sounds like work and its not real cheap to do but it worked as it provided him with ramps he felt helped a great deal, btw he also found

if he placed a 3 foot section of 2"x12" board against the shop back wall, and used that to keep the rhino ramps from moving as the car was driven up on the ramps it helped a good deal, of course you need to space the ramps to match the cars wheel base and it helps if you have a helper guide your car tire center line up on the ramps

OK first you DON,T raise a vette one corner at a time! you drive it up on the ramps to get clearance for the jack then slide the floor jack under the center of the front (CROSS MEMBER) and lift the front and place BOTH front 12 ton jack stands, under the frame , wide spaced, then the angle allows you to either use a second floor jack or move the front floor jack to the rear of the vette, and lift the whole back and place both REAR 12 ton jack stands, on the rear frame. now personally I usually leave the rear jack stands and the jack holding the rear up ,and the 12 ton jack stands on the front with the tires hanging just above the ramps, that way theres almost no chance the vette can fall, even if some component were to fail.

Ill ALSO point out I have and have always used two floor jacks, twin rino ramps and 4 12 ton jack stand WHEN I was under the corvette as I don,t want to be doing bench presses with a vette!

IF YOU SELLECT TO USE JACK STANDS, youll need a decent floor jack,

ive got two that are now discontinued

this replaced it at sears, they seem to be getting made less quality lately, Ive had mine for 12 years plus with zero problems, you want a 20" minimum lift and a 4 ton rated jack

BTW ALL the aluminum jacks Ive seen are JUNK so far

http://www.sears.com/shc/s/p_10153_...TOOL&subcat=Lift+Equipment&BV_UseBVCookie=Yes

http://www.corvettegadgetman.com/products3.html

you can BUY a jack adapter from this guy for your C4 to lift the rear or if you own a WELDER like I keep advising, you can fabricate an adapter for less thats even better

I would not take some of the 2 and three ton jacks I see advertized at auto parts stores home FOR FREE! they are DANGERIOUS JUNK!

BUY A DECENT 20" lift 4 ton rated HYDROLIC floor jack and decent 12 ton jack stands, youll wonder HOW you got along without them after a few years, EVERY SISSORS jack Ive seen is a cheap emergency only tire change tool for the trunk,an accident looking for a location and victim,

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

theres few things that harbor freight sells that are good quality, but IVe had 6 of these in nearly constant use for many years in the shop and they are an exception. I CAN HIGHLY RECOMMEND BUYING AT LEAST 4, AS THEY ARE SIGNIFICANTLY MORE STABILE THAN THE AVERAGE and MUCH SMALLER 3 & 6 TON RATED STANDS most auto parts stores sell.

and on the first notch they are exactly the correct height for clearance under the corvette to do clutch, brake, u-joint replacements ETC. and most other work that youll generally do........remember WORK on a flat level concrete surface if you can and use all 4 or 6 12 ton jack stands to fully and securely support the car, you can,t bench press the car if it falls and larege, stabile ,serious jack stands go a LOOOOOOONG way to keeping your butt safe under the car, and yes, before you ask, even thought I have a lift I frequently use those 12 ton jack stands......an EXCELLENT ADDITION TO YOUR SHOP TOOLS.

IVE USED 12 ton JACK STANDS for MANY YEARS, they are FAR SAFER than your average auto parts store crap stands, I can,t BELIEVEsome of the total CRAP Ive seen guys use and trust to support a car, remember guys YOUR LIKELY to be CRIPPLED OR DEAD IF the car falls on your butt, USE DECENT STANDS, I now have a two post lift but the jack stands still get used because at times your going to leave the car up for a few days and your not generally going to want to tie up the lift that long, nor is it any advantage over the jack stands for some things

BTW I was asked how to install those 12 ton jacks

I generally drive the front wheels of the car up on two rhino car ramps Ive screwed to a sheet of 3/4" plywood base at the correct spacing ,that I attached a rubber base to to prevent skidding first to get clearance , this adds about 1.25" to the normal ramp height , then use both 3-4 ton, (I forget which but they are sears better floor jacks )with my sons help or some one else, after I instruct them, too lift the rear smoothly and evenly to the height necessary to place the two rear stands on the frame so I dont twist the body,while the fronts already up on the ramps so the angles not to extreme, once thats done both floor jacks get relocated and the fronts lifted from both sides evenly and the front jack stands are placed, I use the first height notch on the 12 ton jacks, I occasionally place two more 12 ton stands mid frame after that and use a roller creaper from the front or rear to access under the car, I try only to work on LEVEL CONCRETE and I try to shake the car to make sure its sturdy before getting under it.

the 12 tons stands are a P.I.T.A. to install if you need to do it in stages so I developed that system to get the corvette up to a 20" or so height smoothly and easily in that way.

Last edited by a moderator: