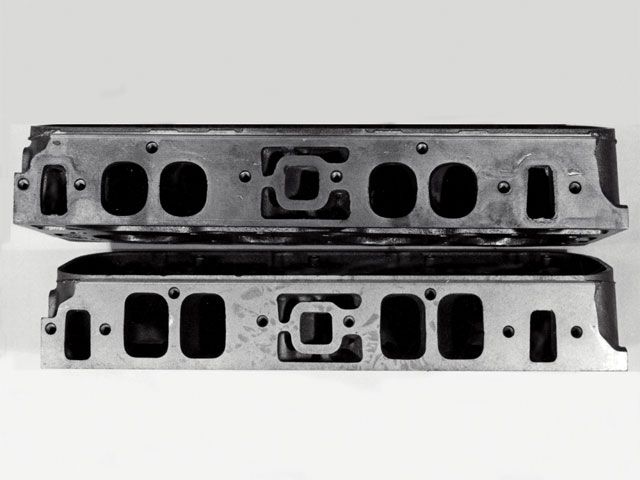

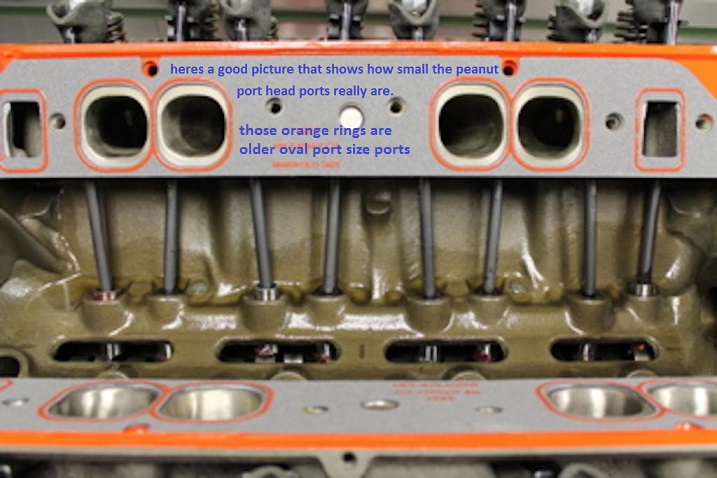

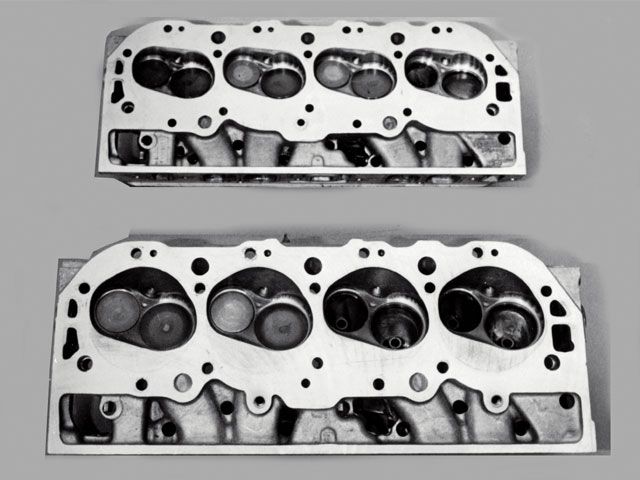

most of us have heard this issue discussed for decades, back in the late 1960s everyone wanted the larger rectangle port performance heads and when the high performance 427-454 chevy engines were produced they all had rectangle port heads, but as guys experimented its been found that theres a whole lot more factors that come into play in engine component selection , than the old ,rectangle or oval port, debate which is a non-issue based on mis-information.

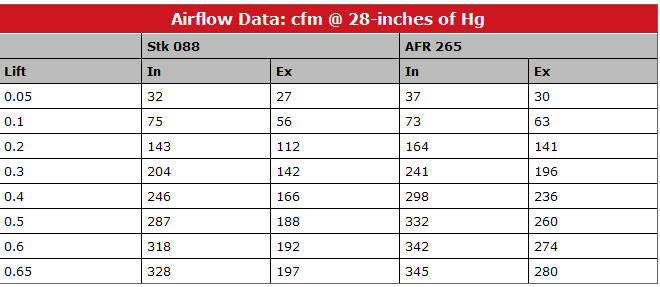

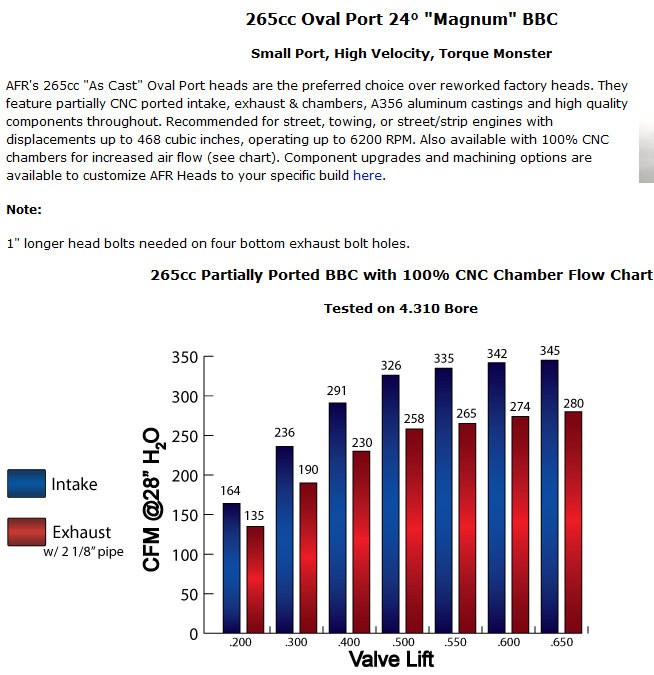

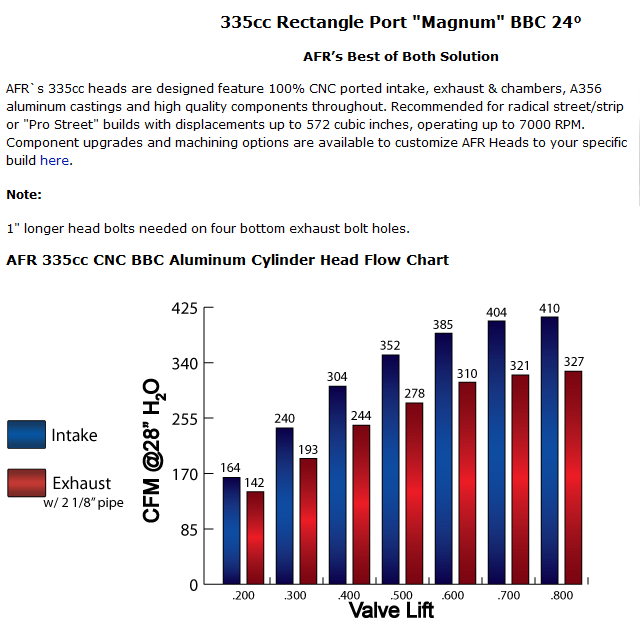

as a general guide oval port heads with 260cc-290cc ports tend to best match the 396-454-500 cubic inch and smaller displacement engines that will be operated in the 2000rpm-6000rpm power band, naturally the larger displacement combos will have higher average port speeds and reach port stall at a lower rpm where the cylinder heads cross sectional area becomes a limiting factor in how well the engine can fill its cylinders,and depending on the particular application,oval ports can still be a valid choice on larger combos but generally by the time your displacements in the 496- 540 cid range youll be looking at a 315cc-335cc port size or larger, in most cases if you intend to spin the engine into the rpm ban that maximizes it power potential.

but be aware the intake manifold,design and intake runner length and cross section, engine compression ratio, cam lift and duration, drive train gearing,and exhaust scavenging all have a significant effect on the results youll see.

The truth is that its the application, the cylinder heads will be used on that determines which head design is superior, and the relationship between the port cross sectional area , valve size, curtain area,and the engines cam timing, compression ratio, displacement and intended rpm band , and rear gearing that will have a huge effect on your parts selection.

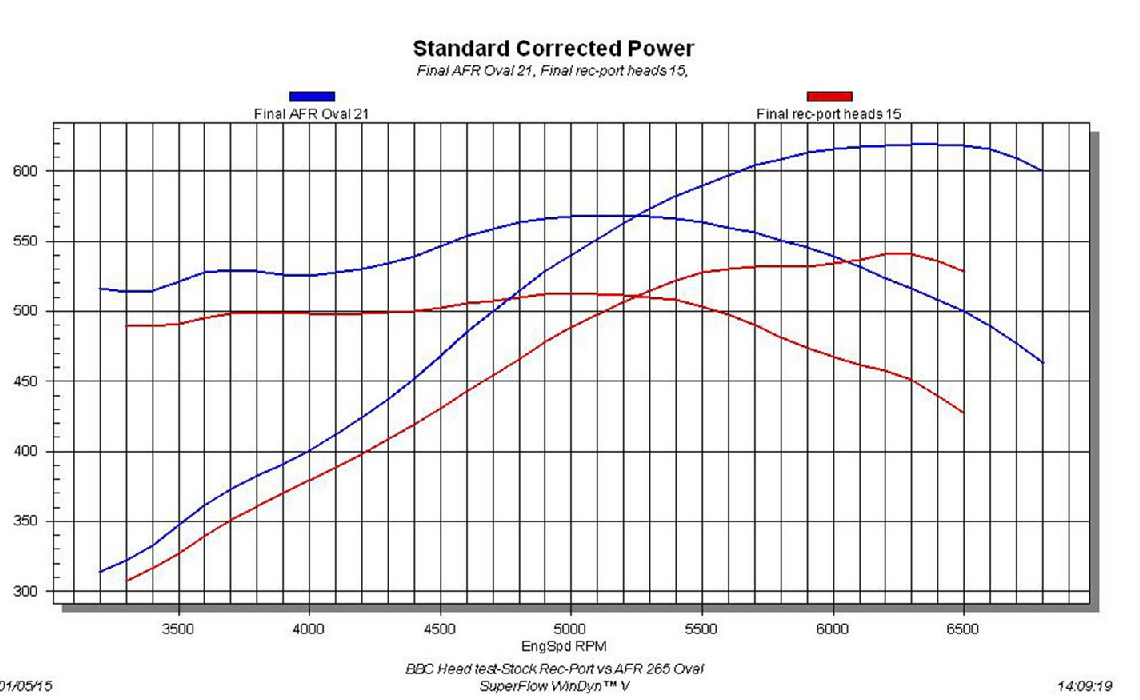

if you have a basically stock 396-427 in your street driven muscle car, that you just stuck a hydraulic or mild solid lifter performance cam,into with an aftermarket intake ,expecting to have built a great deal of horse power, yet you stuck with the stock drive train and gearing and maybe added headers but kept the stock exhaust , in the car youll generally find oval port heads, are going to produce the best torque curve, because they keep

thats not going to be the case if you built a serious race combo and gear the car to spend most of its time in the 4000rpm-7000rpm power band, like a 13:1 compression 496 stroker big block engine and a cam with .700 lift with about 255 at .050 lift or more duration, simply because the stock or smaller port oval port cylinder heads will be nearly hopeless at supplying the required air flow that the displacement and cam timing can potentially require.

look thru the links there are calculators links to allow you to accurately calculate the correct port length and cross sectional areas,

this is NOT a GUESSING GAME the correct combo is fairly easy to accurately CALCULATE

FINDING A DECENT BBC CAM ON A TIGHT LSA , THAT BREATHES WELL AND GIVES THAT OLD SCHOOL RUMBLE AT IDLE,CAN BE A PROBLEM AT TIMES< HERES A FEW

http://www.claysmithcams.com/big-block-chevy-11/

viewtopic.php?f=52&t=148&p=34936&hilit=calculate+port+stall#p34936

viewtopic.php?f=52&t=8460

viewtopic.php?f=69&t=5123

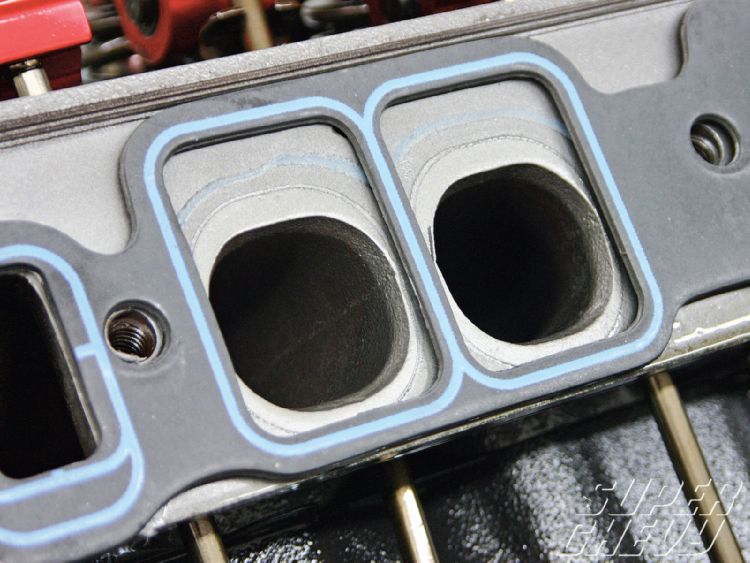

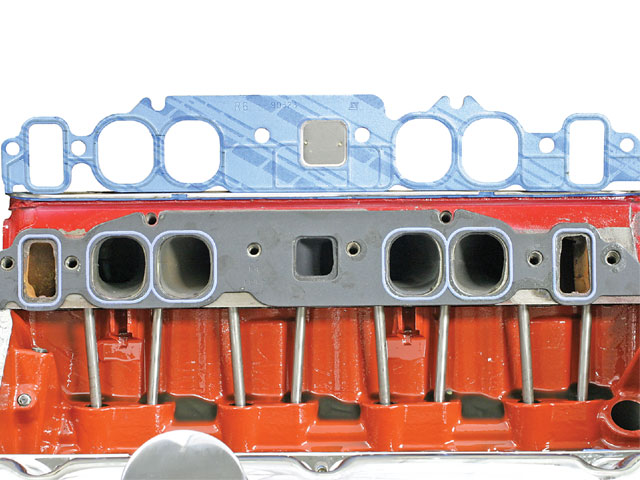

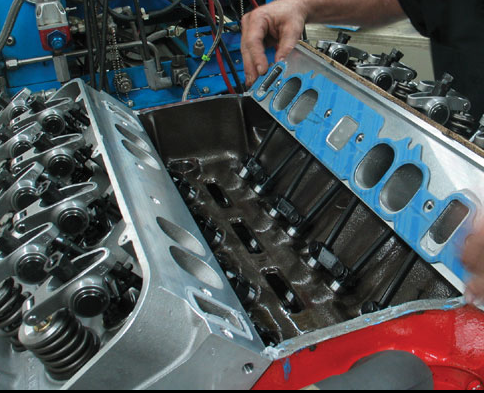

most intakes require gasket matching to maximize the flow potential

simply open the ports to match and transition too the heads and blend back any change in cross sectional area up the runners at least an inch or more

don,t forget the plenum and runner entrance needs smoothing

http://www.carcraft.com/techarticles/cc ... lock_test/

http://airflowresearch.com/articles/art ... /A-P3.html

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/max-rpm2.php

and yes theres also OPEN AND CLOSED CHAMBER DESIGNS

READ THRU THE LINKS AND SUB LINKS

viewtopic.php?f=52&t=796

viewtopic.php?f=52&t=333

viewtopic.php?f=55&t=624&p=11495&hilit=port+area#p11495

http://users.erols.com/srweiss/tablehdc.htm

viewtopic.php?f=52&t=410

viewtopic.php?f=52&t=319

viewtopic.php?f=52&t=148

viewtopic.php?f=52&t=4564

viewtopic.php?f=52&t=1563

viewtopic.php?f=52&t=2956

ID suggest you select from heads from these sources

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333

as a general guide oval port heads with 260cc-290cc ports tend to best match the 396-454-500 cubic inch and smaller displacement engines that will be operated in the 2000rpm-6000rpm power band, naturally the larger displacement combos will have higher average port speeds and reach port stall at a lower rpm where the cylinder heads cross sectional area becomes a limiting factor in how well the engine can fill its cylinders,and depending on the particular application,oval ports can still be a valid choice on larger combos but generally by the time your displacements in the 496- 540 cid range youll be looking at a 315cc-335cc port size or larger, in most cases if you intend to spin the engine into the rpm ban that maximizes it power potential.

but be aware the intake manifold,design and intake runner length and cross section, engine compression ratio, cam lift and duration, drive train gearing,and exhaust scavenging all have a significant effect on the results youll see.

The truth is that its the application, the cylinder heads will be used on that determines which head design is superior, and the relationship between the port cross sectional area , valve size, curtain area,and the engines cam timing, compression ratio, displacement and intended rpm band , and rear gearing that will have a huge effect on your parts selection.

if you have a basically stock 396-427 in your street driven muscle car, that you just stuck a hydraulic or mild solid lifter performance cam,into with an aftermarket intake ,expecting to have built a great deal of horse power, yet you stuck with the stock drive train and gearing and maybe added headers but kept the stock exhaust , in the car youll generally find oval port heads, are going to produce the best torque curve, because they keep

thats not going to be the case if you built a serious race combo and gear the car to spend most of its time in the 4000rpm-7000rpm power band, like a 13:1 compression 496 stroker big block engine and a cam with .700 lift with about 255 at .050 lift or more duration, simply because the stock or smaller port oval port cylinder heads will be nearly hopeless at supplying the required air flow that the displacement and cam timing can potentially require.

look thru the links there are calculators links to allow you to accurately calculate the correct port length and cross sectional areas,

this is NOT a GUESSING GAME the correct combo is fairly easy to accurately CALCULATE

FINDING A DECENT BBC CAM ON A TIGHT LSA , THAT BREATHES WELL AND GIVES THAT OLD SCHOOL RUMBLE AT IDLE,CAN BE A PROBLEM AT TIMES< HERES A FEW

http://www.claysmithcams.com/big-block-chevy-11/

viewtopic.php?f=52&t=148&p=34936&hilit=calculate+port+stall#p34936

viewtopic.php?f=52&t=8460

viewtopic.php?f=69&t=5123

most intakes require gasket matching to maximize the flow potential

simply open the ports to match and transition too the heads and blend back any change in cross sectional area up the runners at least an inch or more

don,t forget the plenum and runner entrance needs smoothing

http://www.carcraft.com/techarticles/cc ... lock_test/

http://airflowresearch.com/articles/art ... /A-P3.html

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/max-rpm2.php

and yes theres also OPEN AND CLOSED CHAMBER DESIGNS

READ THRU THE LINKS AND SUB LINKS

viewtopic.php?f=52&t=796

viewtopic.php?f=52&t=333

viewtopic.php?f=55&t=624&p=11495&hilit=port+area#p11495

http://users.erols.com/srweiss/tablehdc.htm

viewtopic.php?f=52&t=410

viewtopic.php?f=52&t=319

viewtopic.php?f=52&t=148

viewtopic.php?f=52&t=4564

viewtopic.php?f=52&t=1563

viewtopic.php?f=52&t=2956

ID suggest you select from heads from these sources

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333

Last edited by a moderator: