If you've ever had an expensive high quality rifle with a stock that has been damaged ,

and wanted to repair or replace it, you'll know how difficult it is to in many cases find a factory or aftermarket replacement stock.

for many people the factory stocks are long out of production, and no longer available, or horrendously expensive.

many guys just live with the damage , on the original rifles stock, or look for a synthetic, rifle stock replacement, but its not the only route you could potentially take.

keep in mind that synthetic stocks vary a great deal in quality, strength and weight, and the basic design options are limited.

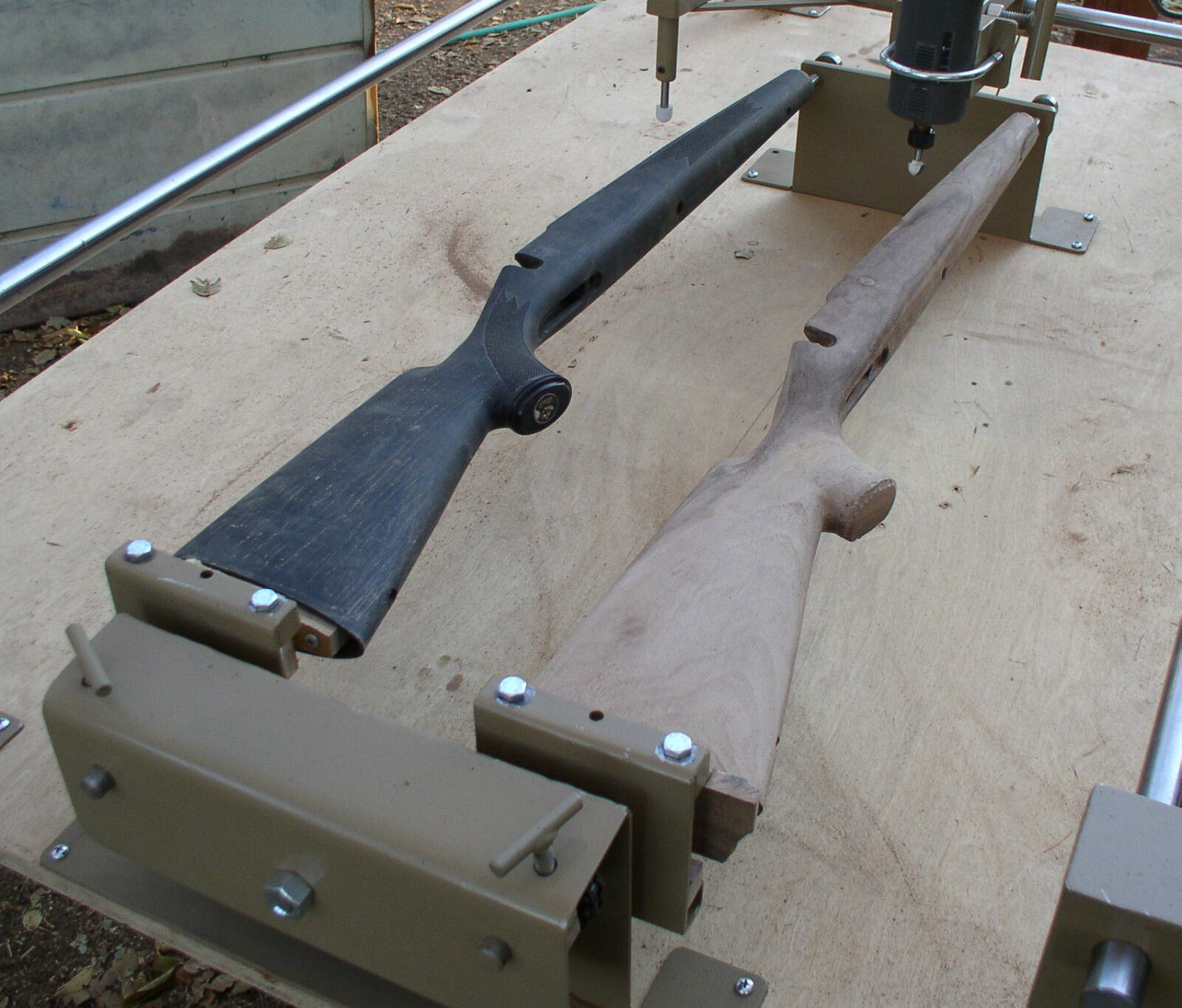

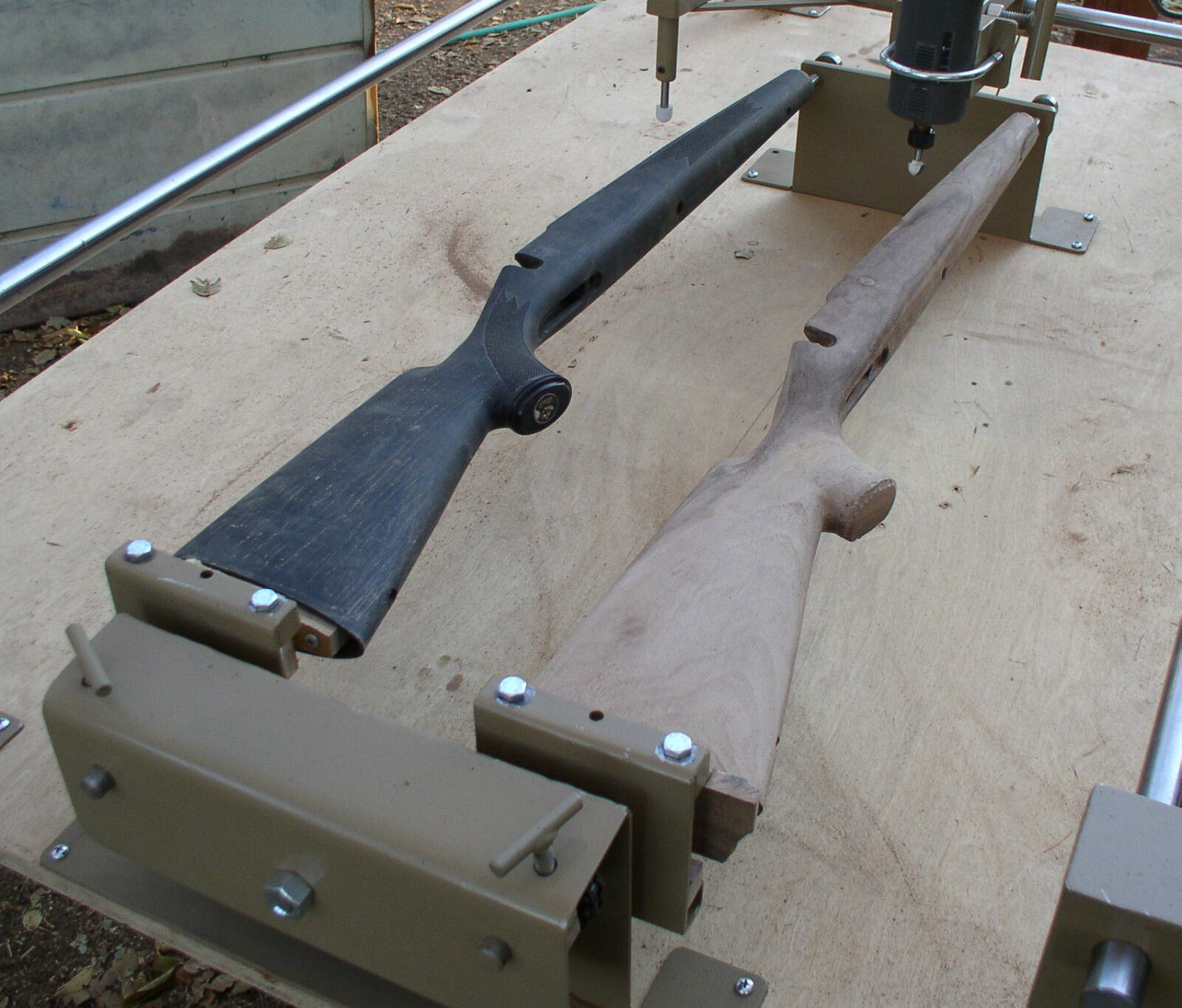

the advantage of using a stock duplication machine is that you can mock up repairs on a damaged original stock and use it as a model to cut a much stronger or modified replacement stock,

you can use bondo, spacers, epoxy, etc, to fabricate a new core with a different contour to use as a pattern to duplicate

to add thickness a cheek comb, or longer or wider grip. or forearm, on the original stock you use as a pattern

and get the new laminated stock you produce with the mods duplicated in a far stronger new stock.

yes , its true, you will still need to do a good deal of bedding on the rifle's action,

and you darn sure will need to provide, options and do more work to get the correct ,

surface finish work before you have a useable rifle stock,

but the options are extensive and this makes the new stock potentially a very nice upgrade.

yeah its true the cost of the machine, the laminated stock blanks,

required accessories, a router, bits that will be required,

and the stock finish related supplies make the stock duplication process potentially cost prohibitive.

if your only going to duplicate a single rifle stock,

but if you were to knock out a dozen or more and sell those even at minimal profit per stock you could rapidly offset,

the potential cost and maybe start having acquisition of the tooling by a gun-shop or range or any serious hobbyist ,

a very attractive option.

just a bit of info,

I was quoted prices in the $340-$400 PER rifle STOCK ,

and a 4-6 month wait on delivery,

when I asked about purchasing replacement factory stocks on Weatherby, Sako and CZ rifle stocks

at those prices it would certainly not take too many stocks duplicated,

to justify the duplication machines purchase price.

(especially once you realize the manufacturers ,

I questioned,

all vendors, stated a 3-6 month wait between the order placed,

and your being force into paying full price up front ,

and maybe delayed or even non-existent production runs)

and the potential of getting a non-returnable stock that may not fit or function,

due to a wide variety of potential reasons.

with a duplication machine you can run off test prototypes using cheap scrap wood test blank cores .

of lets say a basic 2"x 8" lumber with some glued on 1" x8" material,

to check fit ,mods to design, or mods to the fit and user feel for those changes,

before using a more expensive laminated high quality core material.

example

one of my friends machined an adapter that allowed a Remington bolt action.

to use removeable 20 shot m14 magazines,

but he did not want to butcher/modify the original rifle stock to test out,

the use and installation of his magazine adapter ,

he paid a gun-shop that had a stock duplication machine to knock out,

a close too accurate duplicate stock for testing his accessory/adapter,

thus allowing him to keep the original rifle stock unharmed.

EXAMPLE,

one of my friends owned a ITHACA shotgun with a cracked buttstock,

that he could not find used or new at anything like a reasonable cost,

the gun-shop with the duplication machine knocked him out an unfinished core,

using his badly cracked original as a pattern ,

that he refinished for about $120, while thats expensive,

it was far lower in cost than the only other option he was quoted ....

(buying a used ITHACA SHOTGUN to use as a parts gun)

bulletin.accurateshooter.com

bulletin.accurateshooter.com

https://www.ebay.com/itm/143568317701?hash=item216d56ad05:g:yCwAAOSwT5tWKTVD

http://www.rifle-stocks.com/laminated_blanks.htm

https://universalply.com/product/cwp-laminated-blanks/

https://universalply.com/product/cwp-laminated-blanks/

https://www.stockysstocks.com/stocks-by-brand/stocky-s/laminated-woo.html

https://cwp.fi/en/products/cwp-laminated-blanks/

https://www.boydsgunstocks.com/accessories/rifle-blank-sky-laminatea2560

https://richardsmicrofitgunstocks.com/product/laminated-blanks/

https://www.lamnia.com/en/p/37635/h...-blanks-brw-bsw-ggr-camo-single-stock-profile

https://bellandcarlson.com/index.cfm?fuseaction=category.display&category_ID=1038

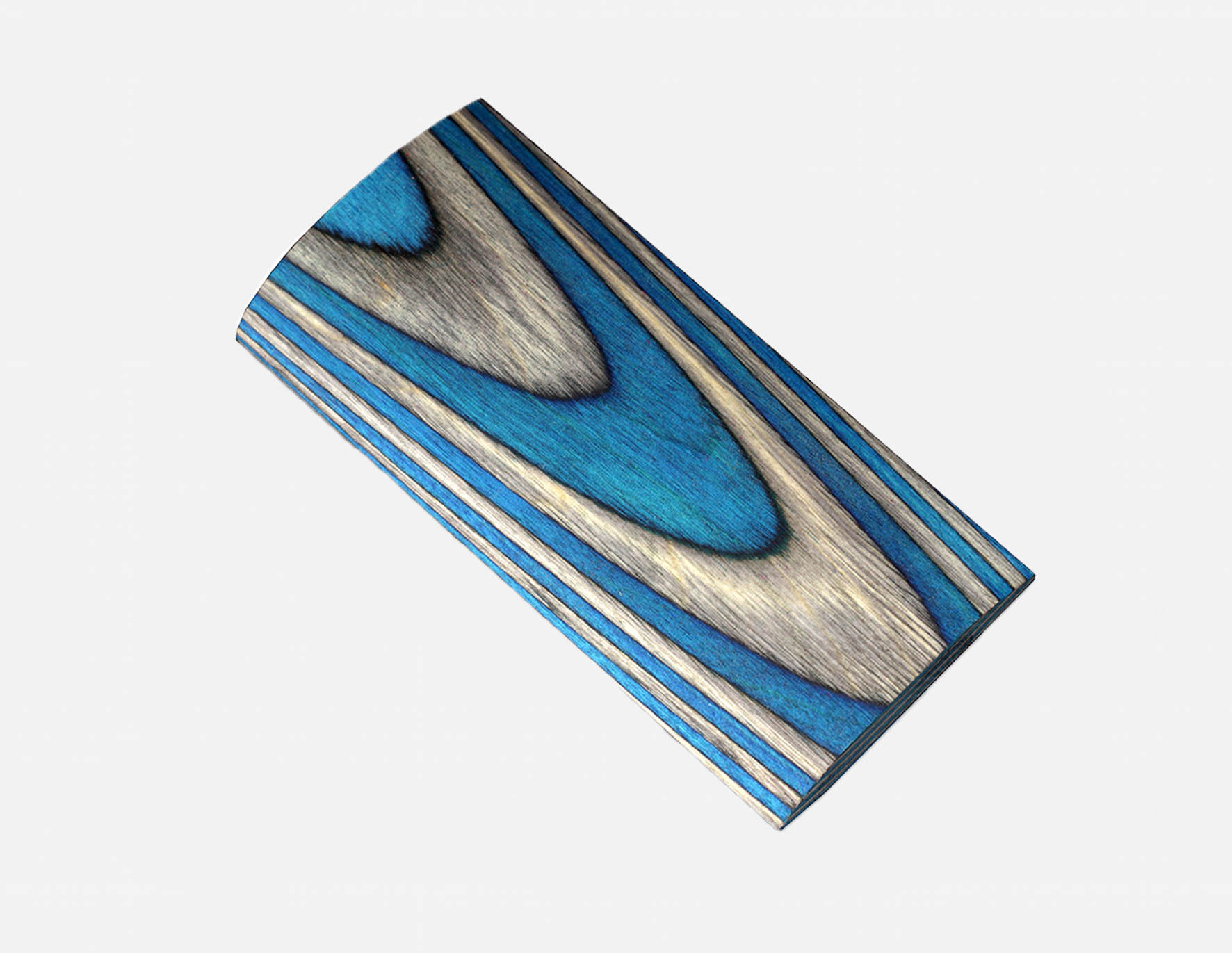

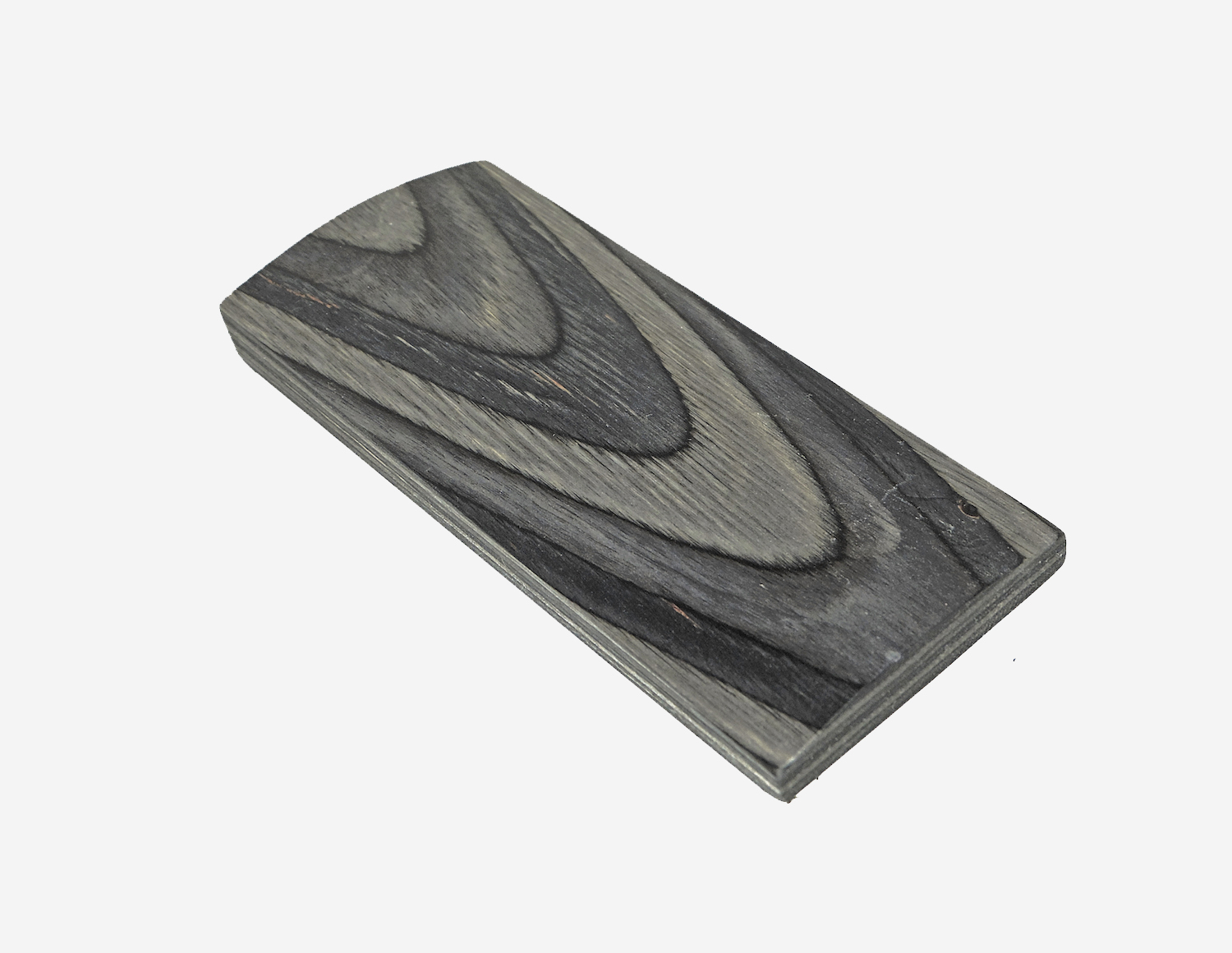

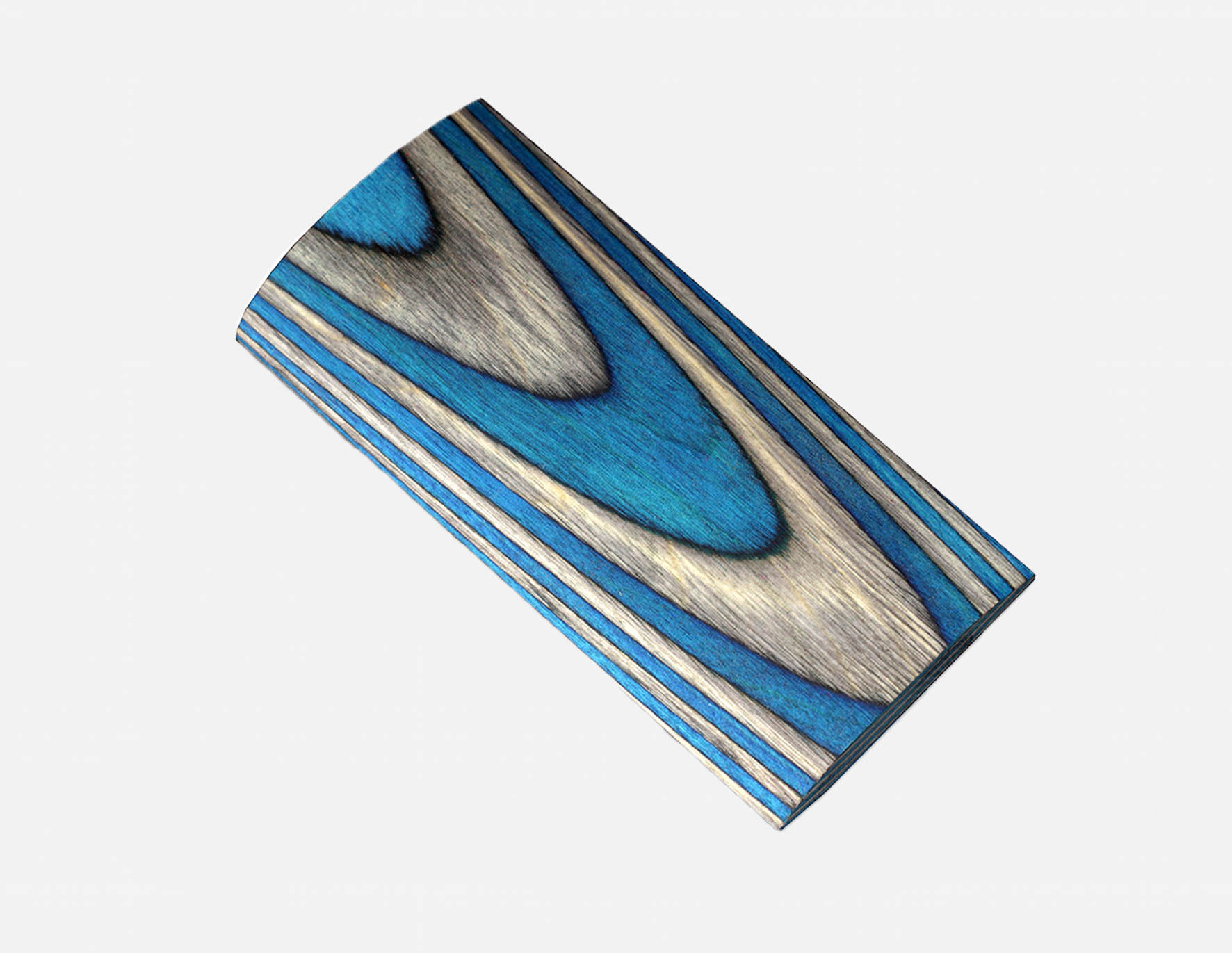

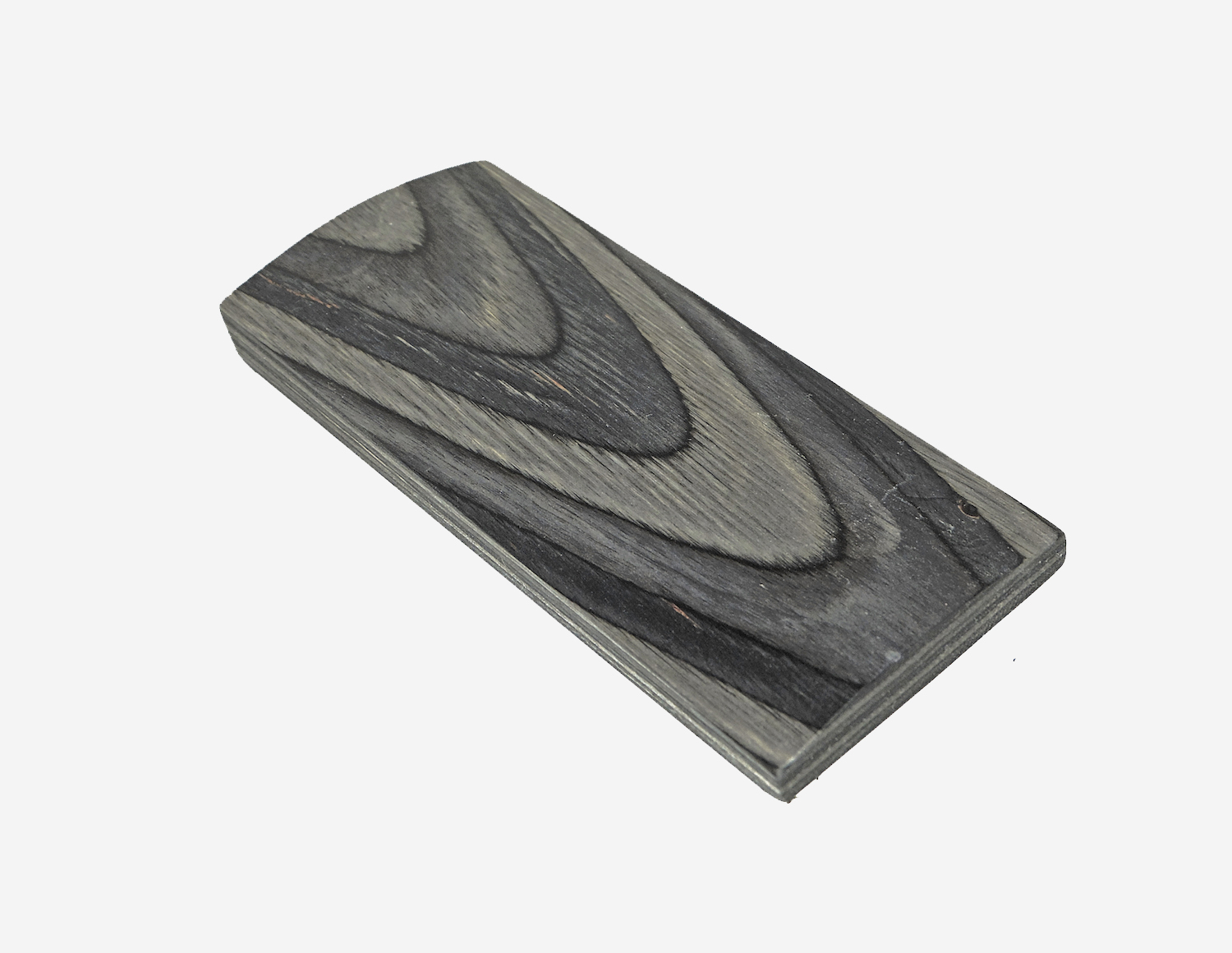

obviously theres non-factory custom color options

and wanted to repair or replace it, you'll know how difficult it is to in many cases find a factory or aftermarket replacement stock.

for many people the factory stocks are long out of production, and no longer available, or horrendously expensive.

many guys just live with the damage , on the original rifles stock, or look for a synthetic, rifle stock replacement, but its not the only route you could potentially take.

keep in mind that synthetic stocks vary a great deal in quality, strength and weight, and the basic design options are limited.

the advantage of using a stock duplication machine is that you can mock up repairs on a damaged original stock and use it as a model to cut a much stronger or modified replacement stock,

you can use bondo, spacers, epoxy, etc, to fabricate a new core with a different contour to use as a pattern to duplicate

to add thickness a cheek comb, or longer or wider grip. or forearm, on the original stock you use as a pattern

and get the new laminated stock you produce with the mods duplicated in a far stronger new stock.

yes , its true, you will still need to do a good deal of bedding on the rifle's action,

and you darn sure will need to provide, options and do more work to get the correct ,

surface finish work before you have a useable rifle stock,

but the options are extensive and this makes the new stock potentially a very nice upgrade.

yeah its true the cost of the machine, the laminated stock blanks,

required accessories, a router, bits that will be required,

and the stock finish related supplies make the stock duplication process potentially cost prohibitive.

if your only going to duplicate a single rifle stock,

but if you were to knock out a dozen or more and sell those even at minimal profit per stock you could rapidly offset,

the potential cost and maybe start having acquisition of the tooling by a gun-shop or range or any serious hobbyist ,

a very attractive option.

just a bit of info,

I was quoted prices in the $340-$400 PER rifle STOCK ,

and a 4-6 month wait on delivery,

when I asked about purchasing replacement factory stocks on Weatherby, Sako and CZ rifle stocks

at those prices it would certainly not take too many stocks duplicated,

to justify the duplication machines purchase price.

(especially once you realize the manufacturers ,

I questioned,

all vendors, stated a 3-6 month wait between the order placed,

and your being force into paying full price up front ,

and maybe delayed or even non-existent production runs)

and the potential of getting a non-returnable stock that may not fit or function,

due to a wide variety of potential reasons.

with a duplication machine you can run off test prototypes using cheap scrap wood test blank cores .

of lets say a basic 2"x 8" lumber with some glued on 1" x8" material,

to check fit ,mods to design, or mods to the fit and user feel for those changes,

before using a more expensive laminated high quality core material.

example

one of my friends machined an adapter that allowed a Remington bolt action.

to use removeable 20 shot m14 magazines,

but he did not want to butcher/modify the original rifle stock to test out,

the use and installation of his magazine adapter ,

he paid a gun-shop that had a stock duplication machine to knock out,

a close too accurate duplicate stock for testing his accessory/adapter,

thus allowing him to keep the original rifle stock unharmed.

EXAMPLE,

one of my friends owned a ITHACA shotgun with a cracked buttstock,

that he could not find used or new at anything like a reasonable cost,

the gun-shop with the duplication machine knocked him out an unfinished core,

using his badly cracked original as a pattern ,

that he refinished for about $120, while thats expensive,

it was far lower in cost than the only other option he was quoted ....

(buying a used ITHACA SHOTGUN to use as a parts gun)

Rifle Stock Carving Duplicator, From Walnut Blank Model One-Gunstock | eBay

Find many great new & used options and get the best deals for Rifle Stock Carving Duplicator, From Walnut Blank Model One-Gunstock at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Watch Stock Duplicator Machine in Action « Daily Bulletin

Production wood rifle stocks, both laminates and hardwoods, are commonly made with stock duplicating machines. Stock duplicators allow a stock-maker to copy a master design faithfully and efficiently. The video below, from Colorado rifle-maker Michael Cuypers, shows a stock duplicator (in...

https://www.ebay.com/itm/143568317701?hash=item216d56ad05:g:yCwAAOSwT5tWKTVD

http://www.rifle-stocks.com/laminated_blanks.htm

https://universalply.com/product/cwp-laminated-blanks/

https://universalply.com/product/cwp-laminated-blanks/

https://www.stockysstocks.com/stocks-by-brand/stocky-s/laminated-woo.html

https://cwp.fi/en/products/cwp-laminated-blanks/

https://www.boydsgunstocks.com/accessories/rifle-blank-sky-laminatea2560

https://richardsmicrofitgunstocks.com/product/laminated-blanks/

https://www.lamnia.com/en/p/37635/h...-blanks-brw-bsw-ggr-camo-single-stock-profile

https://bellandcarlson.com/index.cfm?fuseaction=category.display&category_ID=1038

obviously theres non-factory custom color options

Last edited: