aluminum or steel rocker arms?

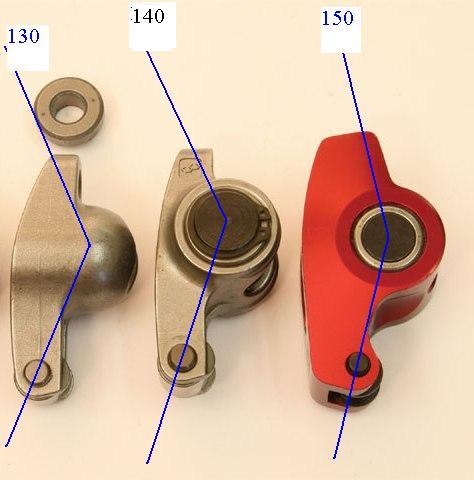

well the first issue most guys look at is the rather obvious weight difference,between the two materials, but remember the size of the rocker trunnion and circumference of the rocker bearing does matter in the load carry capacity, and tendency to wear as does the bearing surface area, and its ability to dissipate heat, and the materials reciprocating mass. because as the weight of the valve train goes up the ability of the valve train, to rapidly respond to changes in rpm decreases due to inertial loads.

the truth is that steel is significantly stronger than aluminum and has noticeably higher wear resistance for the same material thickness, but steel is also heavier.

Elastic modulus

Steel at 210 GPa, has three times the elastic modulus compared to aluminum's 70 GPa. Steel has three times the elastic modulus as aluminum. Related to stamping performance, aluminum will possess higher springback than mild steels. Even compared to high strength steels, strength level to strength level, aluminum will still possess higher springback.

Advantage: Steel

Fatigue

Aluminum fatigue performance is less than ½ that of steel. This is a very important advantage for steel in terms of vehicle life durability. Automotive steel grades also possess an endurance limit. From testing, it was found that structural aluminum grades (5XXX series) will not reach an endurance limit, but continually degrade at higher cycles. The following figure indicates this pictorially:

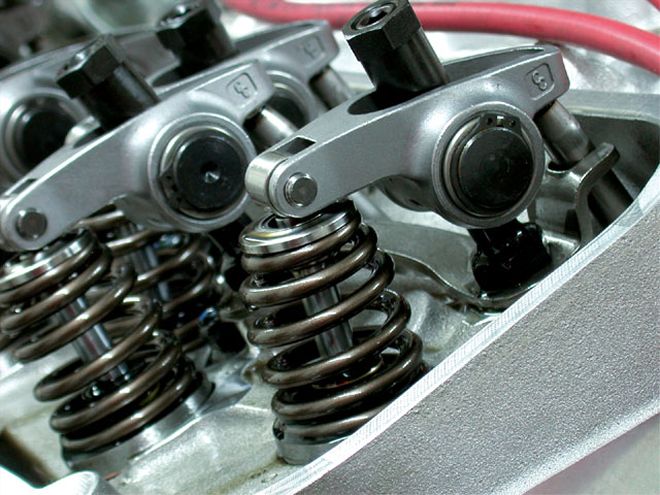

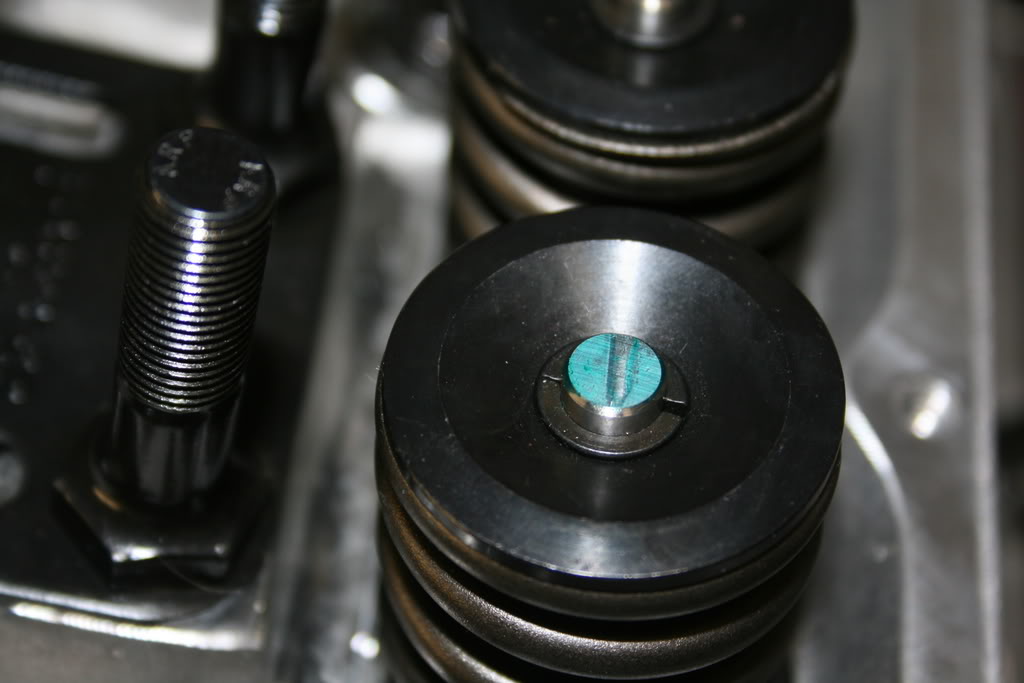

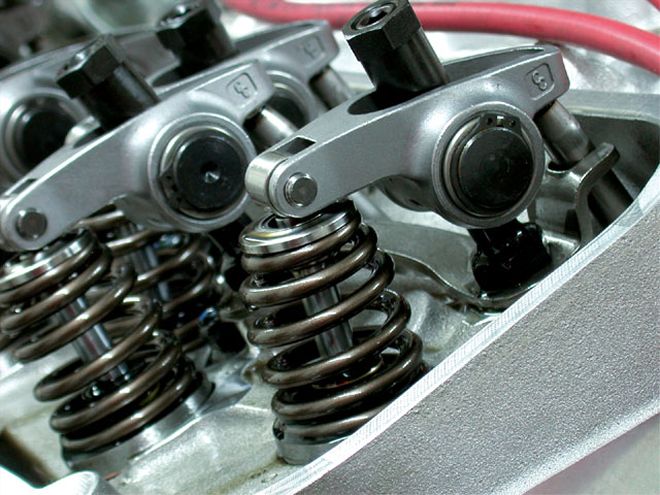

IF the roller tip of a roller rocker arm is doing it's job the way it is supposed to then the wipe pattern across the valve tip is of little consequence as long as it remains away from the edge of the valve stem, as its designed too reduce friction, but its not the roller tip moving accross the valve tip that produces most of the friction,its the roller bearing on the trunnion where , the rocker studs are thru the bearing,that handle easily 95% of the friction, ."

now obviously you can design thinner and stiffer components from steel, of a given thickness than an equally thick aluminum component strength level so theres a balance or compromise thats made, you can make far stronger steel components of a similar thickness or thinner steel components having about equal strength to the thicker aluminum component.

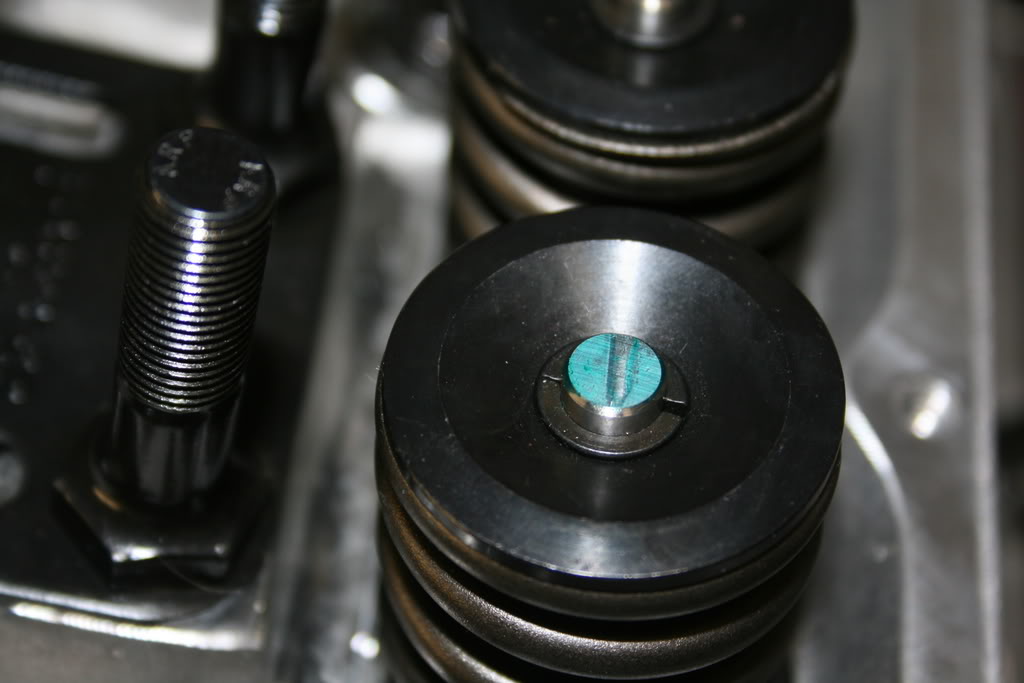

it should also be obvious that the QUALITY of the bearings and CHOICE of MATERIALS and care taken during manufacture has a huge effect on the durability of the finished product.

as a rough average depending on alloy used you can assume aluminum will weigh about 35% less than steel of the same component dimensions

Surprisingly, the steel chrome moly steel rockers can be actually lighter from the valve spring's point of view.

Even though the steel rockers may have more overall weight, they can have less bulk further from the fulcrum (pivot point) than aluminum rockers. Therefore they have a lower "polar moment" of inertia and change their rocking direction with slightly less effort. remember the bearing axle or trunion can be larger and the bearing surface larger, with a steel rocker because the part of the rocker rotating around it can be made thinner and still maintain the same or greater resistance to deflection under high pressure loads, this is important because increased bearing diameter can provide significantly more strength and that center axle does not rotate or add inertial mass so its not slowing the valve train down.

IF YOUR REALLY PAYING ATTENTION youll generally find the center axle and bearing size in the better steel rockers is significantly larger and more durable in the steel rockers vs the aluminum, because the rocker body on the steel rocker can be made about 30% thinner yet still be stronger

as long as you select good quality name brand roller rockers you can usually depend on steel rockers having a significant strength and durability advantage and aluminum having a slight rpm advantage due to lower mass resisting inertial loads, this gives a couple of hundred rpm advantage, at best in some engines,less in most, but below a valve float limitations.

Steel also does not fatigue nearly as fast, over as many load cycles like aluminum does. thats why aluminum rockers are usually changed out after 30K-50K miles as an expendable item like belts and hoses but steel rockers can be rebuilt with new roller bearings

aluminum will eventually fail, in most cases simply because they will eventually fatigue faster. That is simply due to the repeated heat and stress cycling of the aluminum. Comp Cams, CROWER and several other sources make a stainless rocker or shaft rockers that actually have less rotational weight than your average aluminum rocker. The resistance to metal fatigue properties of the properly heat treated stainless create a much longer expected lifespan because it is not affected by heat and stress cycles nearly as much.

both materials have their strong points, and if your looking for the lightest weight rockers aluminum seems to be the obvious choice ,and steel rockers can be made thinner so clearance issues with other valve train components tend to be less common that with the thicker aluminum rockers, but its not just the total rockers weight but the reciprocating weight, and rigidity of the lifter,push-rod, and retainer and valve string loads that must be considered and the distance that weight is from the pivot point that matters to some extent to your valve train,, its the total inertial, loads that will effect your upper rpm valve train stability , and upper rpm limits

a good aluminum roller rocker design like the ERSON EXTREME ROCKERS provides you with a few extra rpm due to the lighter weight, and its a great choice for a weekend toy that gets run hard but sees low mileage

but for long term durability Id select the newer comp steel rockers for a street strip application

stamped rockers are cheap and dependable but decent roller rockers will frequently allow the engine to run at reduced friction loads, 10-15 hp gains are easily available, and in some cases even more is available especially with higher spring loads or a higher than stock rocker ratio.

Ive suggested these newer comp cams rockers on several builds as Ive seen good results

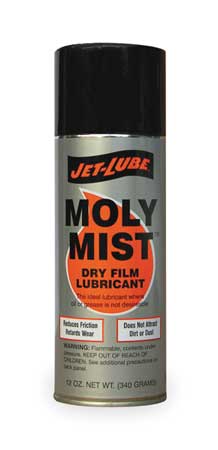

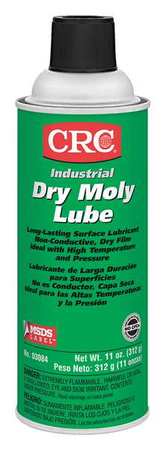

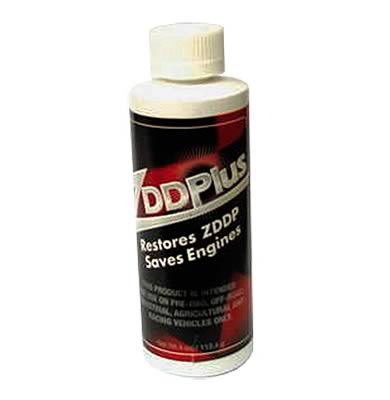

pre-spraying all bearing and valve train components with a moly based spray, helps embed micro moly lubricants in the metallic surface micro fissures , a good paste lube like cranes assembly lube over the spray surface helps insure a good lubricant surface coating, that is far stronger than just the ZINC and PHOSPHATES in oil

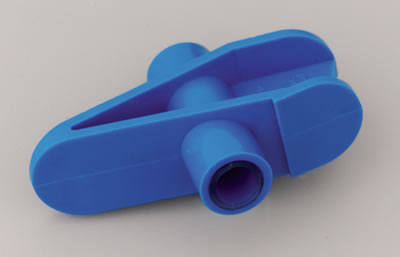

Proper push rod length is absolutely critical for peak performance—minimizing bent or broken valve stems, guide wear, and energy-wasting valve side-loading friction.

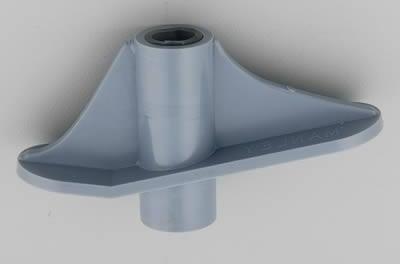

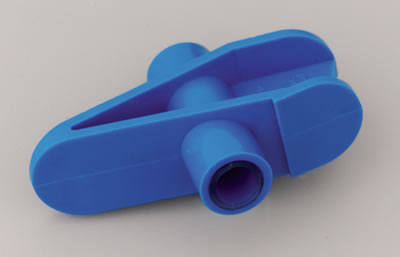

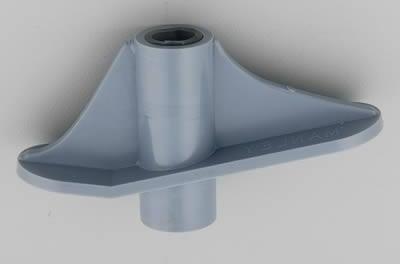

With the lifter located on the round base circle, position the Push Rod length Checker (make sure you have the Checker with the proper diameter hole) over the stud. Ideally the Checker should contact the top of the push rod and the valve tip evenly at the same moment, should the Checker contact the push rod first, measure the gap between the front of the checker and the valve tip, and purchase a shorter push rod of the correct length. Should the Checker contact the valve tip first, measure the gap between the back of the Checker and the top of the push rod, and purchase a longer push rod

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

http://www.summitracing.com/parts/CCA-1601-16/

READ THESE RELATED LINKS VERY CAREFULLY

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-54232

some roller rocker too retainer combo clearance issues cause problems easily solved with beehive springs and smaller retainer diameters

look through this thread

http://garage.grumpysperformance.com/index.php?threads/two-loose-valve-locks.9687/#post-47884

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://www.popularhotrodding.com/engine ... ewall.html

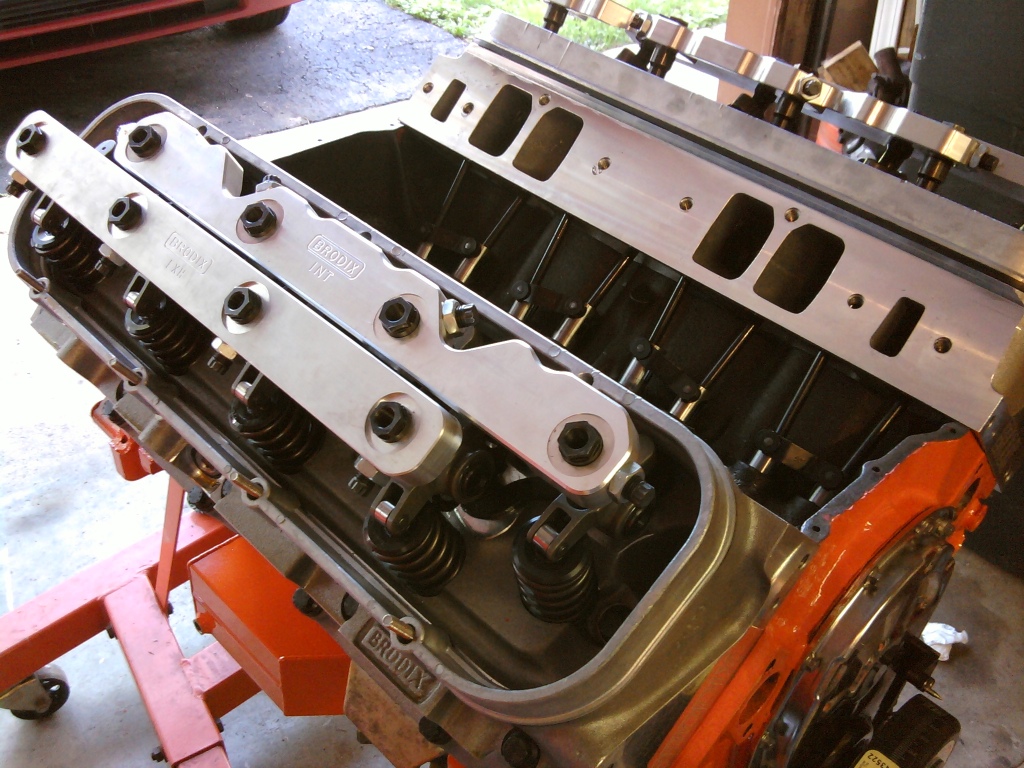

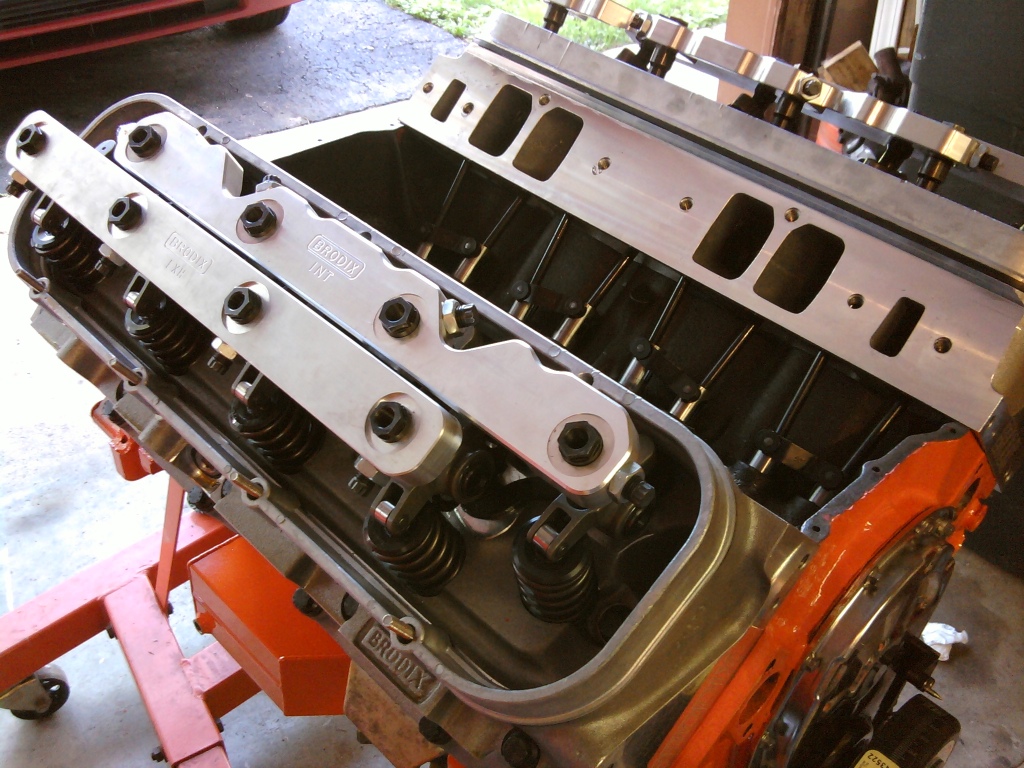

STUD GIRDLES ADD A GREAT DEAL OF RIGIDITY TO THE VALVE TRAIN

the older comp chrome moly rockers work well but on some applications had clearance issues with spring retainers

Ive used the previous or older design comp cams steel rockers on lots of engines with good results, that the newer design has recently replaced, the older design with the advantage of having a slightly stronger and lighter design and having more retainer to rocker clearance, btw lash caps on the valve stems can be used to increase clearance in some cases, if your having that problem but their use, may require longer push-rods

http://www.summitracing.com/parts/CRN-9 ... N-99421-16

remember the object is to maintain the proper valve train geometry, to have minimal side loads , and the roller rockers lower friction resulting in low heat as well as maintaining the lighter valve train, with the new components

but Ive also used these two rockers

ERSON extreme duty

http://www.pbm-erson.com/store.php?catId=24

which Ive used for dozens of engines over many years with ZERO FAILURES so far, just be aware that the extreme duty rockers are ,a more robust design that the standard ERSON rockers which I don,t recommend

READ THIS LINK!

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

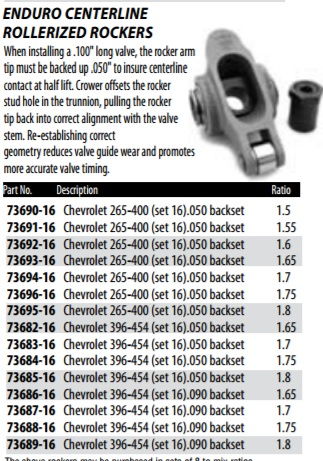

and the CROWER stainless ROCKERS

http://www.jegs.com/i/Crower/258/73670-16/10002/-1

theres ARE big differences in the quality of the metal and hardness, look closely at the PROCOMP Chinese rockers above, notice the tip of the rockers axle, its obviously been flared,like a rivet indicating a fairly soft metal, rather than forced into place with an interference fit like the comp cams rockers they try to duplicate

BTW if your thinking about getting those stamped steel, roller tip rockers , DON,T!!, they have a tendency to fail, and they don,t handle high spring pressures well, and they don,t reduce friction much so they are basically a (FEEL AND LOOK GOOD" part that doesn,t do much constructively

Because, easily 90% PLUS of the friction in the valve train is NOT on the contact between rocker arm tip and the valve stem, so swapping to a roller tip on a rocker provides negligible benefits in friction reduction.

you can buy decent quality full roller rockers, for well under $250-$350

and roller tip rockers commonly cost 1/2 or more of that making the full rollers a much better option

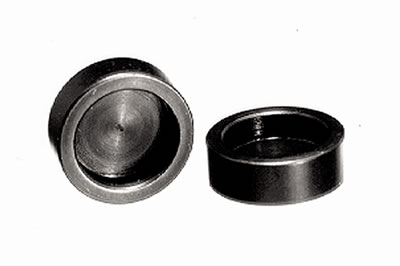

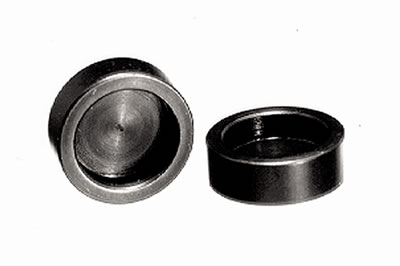

obviously valve float and improper lash clearance can cause problems but in some cases, lash caps can reduce wear

in most cases when you see valve tip damage like this its the result of valve float or a weak valve spring , in many cases youll need to swap to a higher spring load rate and new springs to prevent or reduce this damage

read these threads

viewtopic.php?f=52&t=2632&p=6790&hilit=louis+rocker#p6790

http://www.circletrack.com/techarticles ... index.html

viewtopic.php?f=52&t=3009&p=7985&hilit=roller+rocker#p7985

viewtopic.php?f=44&t=737&p=1034&hilit=louis+rocker#p1034

viewtopic.php?f=52&t=198&hilit=louis+rocker

viewtopic.php?f=52&t=181&p=215&hilit=louis+rocker#p215

viewtopic.php?f=52&t=2746&p=7513&hilit=rocker+stud#p7513

http://www.americanmachinetools.com/ten ... rength.htm

http://www.ami.ac.uk/courses/topics/0123_mpm/index.html

http://www.lunatipower.com/Tech/Valvetr ... metry.aspx

Pushrod Too Long: Notice how the pattern is wide, and shifted to the exhaust side of the valve tip

Pushrod Too Short: Notice how the pattern is wide, and shifted to the intake side of the valve tip.

Pushrod Length Correct: Notice how the pattern is narrow and is centered on the valve tip.

viewtopic.php?f=44&t=2839&p=7344&hilit=adjustable+guide#p7344

viewtopic.php?f=52&t=126&hilit=louis+rocker

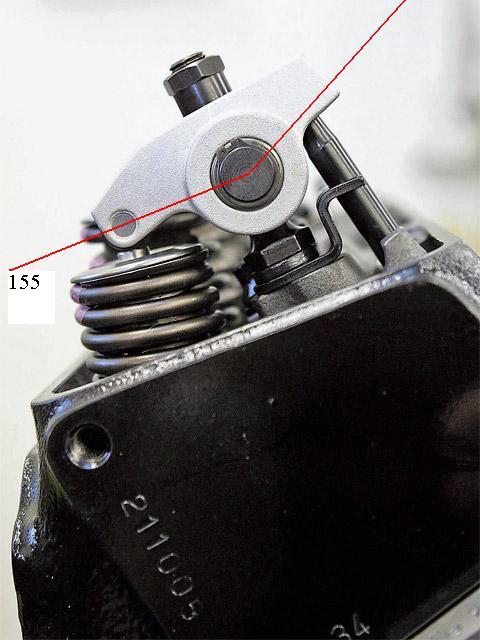

pictured above you see the last rocked badly out of alignment with the valve center line,

a good example why you need adjustable guide plates, this rocker if left too run off center like this, on the valve stem tip , will quickly destroy the valve guide and rocker

and you may need too use the correct adjustable guide plates when you find the push-rod alignment is in need of minor tweaking to get the clearance and geometry correct,

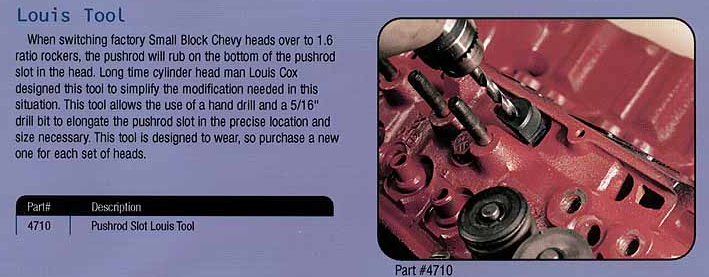

don,t forget as many guys do, that swapping to a higher ratio rocker changes the push-rod rocker geometry,and clearances, the heads and rockers used obviously effect the required clearance, but you'll usually want at least 60 thousands clearance on the push rods to slot measurements and you'll want to rotate the engine thru two complete revolutions while verifying that clearance, while watching the push-rod geometry as it changes as the rockers move thru their arcsand may require a different length push-rods.

using a louis tool, this tool is a GUIDE /tool for use with a high quality DRILL,its made of HARDENED STEEL that FORCES the DRILL BIT to drill thru the head to correctly lengthen the pushrod slot for increased clearance, they usually come WITH INSTRUCTIONS AND THE NECESSARY DRILL

well the first issue most guys look at is the rather obvious weight difference,between the two materials, but remember the size of the rocker trunnion and circumference of the rocker bearing does matter in the load carry capacity, and tendency to wear as does the bearing surface area, and its ability to dissipate heat, and the materials reciprocating mass. because as the weight of the valve train goes up the ability of the valve train, to rapidly respond to changes in rpm decreases due to inertial loads.

the truth is that steel is significantly stronger than aluminum and has noticeably higher wear resistance for the same material thickness, but steel is also heavier.

Elastic modulus

Steel at 210 GPa, has three times the elastic modulus compared to aluminum's 70 GPa. Steel has three times the elastic modulus as aluminum. Related to stamping performance, aluminum will possess higher springback than mild steels. Even compared to high strength steels, strength level to strength level, aluminum will still possess higher springback.

Advantage: Steel

Fatigue

Aluminum fatigue performance is less than ½ that of steel. This is a very important advantage for steel in terms of vehicle life durability. Automotive steel grades also possess an endurance limit. From testing, it was found that structural aluminum grades (5XXX series) will not reach an endurance limit, but continually degrade at higher cycles. The following figure indicates this pictorially:

IF the roller tip of a roller rocker arm is doing it's job the way it is supposed to then the wipe pattern across the valve tip is of little consequence as long as it remains away from the edge of the valve stem, as its designed too reduce friction, but its not the roller tip moving accross the valve tip that produces most of the friction,its the roller bearing on the trunnion where , the rocker studs are thru the bearing,that handle easily 95% of the friction, ."

now obviously you can design thinner and stiffer components from steel, of a given thickness than an equally thick aluminum component strength level so theres a balance or compromise thats made, you can make far stronger steel components of a similar thickness or thinner steel components having about equal strength to the thicker aluminum component.

it should also be obvious that the QUALITY of the bearings and CHOICE of MATERIALS and care taken during manufacture has a huge effect on the durability of the finished product.

as a rough average depending on alloy used you can assume aluminum will weigh about 35% less than steel of the same component dimensions

Surprisingly, the steel chrome moly steel rockers can be actually lighter from the valve spring's point of view.

Even though the steel rockers may have more overall weight, they can have less bulk further from the fulcrum (pivot point) than aluminum rockers. Therefore they have a lower "polar moment" of inertia and change their rocking direction with slightly less effort. remember the bearing axle or trunion can be larger and the bearing surface larger, with a steel rocker because the part of the rocker rotating around it can be made thinner and still maintain the same or greater resistance to deflection under high pressure loads, this is important because increased bearing diameter can provide significantly more strength and that center axle does not rotate or add inertial mass so its not slowing the valve train down.

Steel has what is called a fatigue limit. If you keep the stress in a steel part below a known critical level, that you can design the parts for, you can flex it indefinitely and it will never break. Only when you exceed the fatigue limit do you have a problem. If you exceed it slightly, you weaken the metal and effectively lower the limit. You can still flex it indefinitely without breakage so long as you keep it under the new fatigue limit.

Aluminum has no fatigue limit. That might sound good, but it's not. What it really means is that no matter how little you stress aluminum, if you cycle it enough times, it is going to fail. There is no "keep it under this point and you'll be safe," failure is guaranteed, the question is simply a matter of when it will fail.

IF YOUR REALLY PAYING ATTENTION youll generally find the center axle and bearing size in the better steel rockers is significantly larger and more durable in the steel rockers vs the aluminum, because the rocker body on the steel rocker can be made about 30% thinner yet still be stronger

as long as you select good quality name brand roller rockers you can usually depend on steel rockers having a significant strength and durability advantage and aluminum having a slight rpm advantage due to lower mass resisting inertial loads, this gives a couple of hundred rpm advantage, at best in some engines,less in most, but below a valve float limitations.

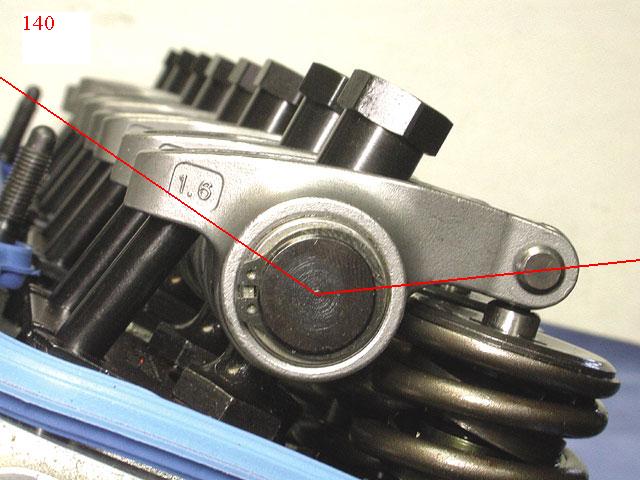

thinking about putting roller rockers on my 327.

IM seriously considering/ thinking about putting roller rockers on my 327.do i have room to put 1.6 ratio or just stay with 1.5s http://garage.grumpysperformance.com/index.php?threads/louis-tool-swapping-to-1-6-1-ratio-rockers.14761/...

garage.grumpysperformance.com

Steel also does not fatigue nearly as fast, over as many load cycles like aluminum does. thats why aluminum rockers are usually changed out after 30K-50K miles as an expendable item like belts and hoses but steel rockers can be rebuilt with new roller bearings

aluminum will eventually fail, in most cases simply because they will eventually fatigue faster. That is simply due to the repeated heat and stress cycling of the aluminum. Comp Cams, CROWER and several other sources make a stainless rocker or shaft rockers that actually have less rotational weight than your average aluminum rocker. The resistance to metal fatigue properties of the properly heat treated stainless create a much longer expected lifespan because it is not affected by heat and stress cycles nearly as much.

both materials have their strong points, and if your looking for the lightest weight rockers aluminum seems to be the obvious choice ,and steel rockers can be made thinner so clearance issues with other valve train components tend to be less common that with the thicker aluminum rockers, but its not just the total rockers weight but the reciprocating weight, and rigidity of the lifter,push-rod, and retainer and valve string loads that must be considered and the distance that weight is from the pivot point that matters to some extent to your valve train,, its the total inertial, loads that will effect your upper rpm valve train stability , and upper rpm limits

a good aluminum roller rocker design like the ERSON EXTREME ROCKERS provides you with a few extra rpm due to the lighter weight, and its a great choice for a weekend toy that gets run hard but sees low mileage

but for long term durability Id select the newer comp steel rockers for a street strip application

stamped rockers are cheap and dependable but decent roller rockers will frequently allow the engine to run at reduced friction loads, 10-15 hp gains are easily available, and in some cases even more is available especially with higher spring loads or a higher than stock rocker ratio.

Ive suggested these newer comp cams rockers on several builds as Ive seen good results

pre-spraying all bearing and valve train components with a moly based spray, helps embed micro moly lubricants in the metallic surface micro fissures , a good paste lube like cranes assembly lube over the spray surface helps insure a good lubricant surface coating, that is far stronger than just the ZINC and PHOSPHATES in oil

Proper push rod length is absolutely critical for peak performance—minimizing bent or broken valve stems, guide wear, and energy-wasting valve side-loading friction.

With the lifter located on the round base circle, position the Push Rod length Checker (make sure you have the Checker with the proper diameter hole) over the stud. Ideally the Checker should contact the top of the push rod and the valve tip evenly at the same moment, should the Checker contact the push rod first, measure the gap between the front of the checker and the valve tip, and purchase a shorter push rod of the correct length. Should the Checker contact the valve tip first, measure the gap between the back of the Checker and the top of the push rod, and purchase a longer push rod

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

http://www.summitracing.com/parts/CCA-1601-16/

READ THESE RELATED LINKS VERY CAREFULLY

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-54232

some roller rocker too retainer combo clearance issues cause problems easily solved with beehive springs and smaller retainer diameters

look through this thread

http://garage.grumpysperformance.com/index.php?threads/two-loose-valve-locks.9687/#post-47884

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://www.popularhotrodding.com/engine ... ewall.html

STUD GIRDLES ADD A GREAT DEAL OF RIGIDITY TO THE VALVE TRAIN

the older comp chrome moly rockers work well but on some applications had clearance issues with spring retainers

Ive used the previous or older design comp cams steel rockers on lots of engines with good results, that the newer design has recently replaced, the older design with the advantage of having a slightly stronger and lighter design and having more retainer to rocker clearance, btw lash caps on the valve stems can be used to increase clearance in some cases, if your having that problem but their use, may require longer push-rods

http://www.summitracing.com/parts/CRN-9 ... N-99421-16

remember the object is to maintain the proper valve train geometry, to have minimal side loads , and the roller rockers lower friction resulting in low heat as well as maintaining the lighter valve train, with the new components

but Ive also used these two rockers

ERSON extreme duty

http://www.pbm-erson.com/store.php?catId=24

which Ive used for dozens of engines over many years with ZERO FAILURES so far, just be aware that the extreme duty rockers are ,a more robust design that the standard ERSON rockers which I don,t recommend

READ THIS LINK!

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

and the CROWER stainless ROCKERS

http://www.jegs.com/i/Crower/258/73670-16/10002/-1

theres ARE big differences in the quality of the metal and hardness, look closely at the PROCOMP Chinese rockers above, notice the tip of the rockers axle, its obviously been flared,like a rivet indicating a fairly soft metal, rather than forced into place with an interference fit like the comp cams rockers they try to duplicate

BTW if your thinking about getting those stamped steel, roller tip rockers , DON,T!!, they have a tendency to fail, and they don,t handle high spring pressures well, and they don,t reduce friction much so they are basically a (FEEL AND LOOK GOOD" part that doesn,t do much constructively

Because, easily 90% PLUS of the friction in the valve train is NOT on the contact between rocker arm tip and the valve stem, so swapping to a roller tip on a rocker provides negligible benefits in friction reduction.

you can buy decent quality full roller rockers, for well under $250-$350

and roller tip rockers commonly cost 1/2 or more of that making the full rollers a much better option

obviously valve float and improper lash clearance can cause problems but in some cases, lash caps can reduce wear

in most cases when you see valve tip damage like this its the result of valve float or a weak valve spring , in many cases youll need to swap to a higher spring load rate and new springs to prevent or reduce this damage

read these threads

viewtopic.php?f=52&t=2632&p=6790&hilit=louis+rocker#p6790

http://www.circletrack.com/techarticles ... index.html

viewtopic.php?f=52&t=3009&p=7985&hilit=roller+rocker#p7985

viewtopic.php?f=44&t=737&p=1034&hilit=louis+rocker#p1034

viewtopic.php?f=52&t=198&hilit=louis+rocker

viewtopic.php?f=52&t=181&p=215&hilit=louis+rocker#p215

viewtopic.php?f=52&t=2746&p=7513&hilit=rocker+stud#p7513

http://www.americanmachinetools.com/ten ... rength.htm

http://www.ami.ac.uk/courses/topics/0123_mpm/index.html

http://www.lunatipower.com/Tech/Valvetr ... metry.aspx

Pushrod Too Long: Notice how the pattern is wide, and shifted to the exhaust side of the valve tip

Pushrod Too Short: Notice how the pattern is wide, and shifted to the intake side of the valve tip.

Pushrod Length Correct: Notice how the pattern is narrow and is centered on the valve tip.

viewtopic.php?f=44&t=2839&p=7344&hilit=adjustable+guide#p7344

viewtopic.php?f=52&t=126&hilit=louis+rocker

pictured above you see the last rocked badly out of alignment with the valve center line,

a good example why you need adjustable guide plates, this rocker if left too run off center like this, on the valve stem tip , will quickly destroy the valve guide and rocker

and you may need too use the correct adjustable guide plates when you find the push-rod alignment is in need of minor tweaking to get the clearance and geometry correct,

don,t forget as many guys do, that swapping to a higher ratio rocker changes the push-rod rocker geometry,and clearances, the heads and rockers used obviously effect the required clearance, but you'll usually want at least 60 thousands clearance on the push rods to slot measurements and you'll want to rotate the engine thru two complete revolutions while verifying that clearance, while watching the push-rod geometry as it changes as the rockers move thru their arcsand may require a different length push-rods.

using a louis tool, this tool is a GUIDE /tool for use with a high quality DRILL,its made of HARDENED STEEL that FORCES the DRILL BIT to drill thru the head to correctly lengthen the pushrod slot for increased clearance, they usually come WITH INSTRUCTIONS AND THE NECESSARY DRILL

Last edited by a moderator: