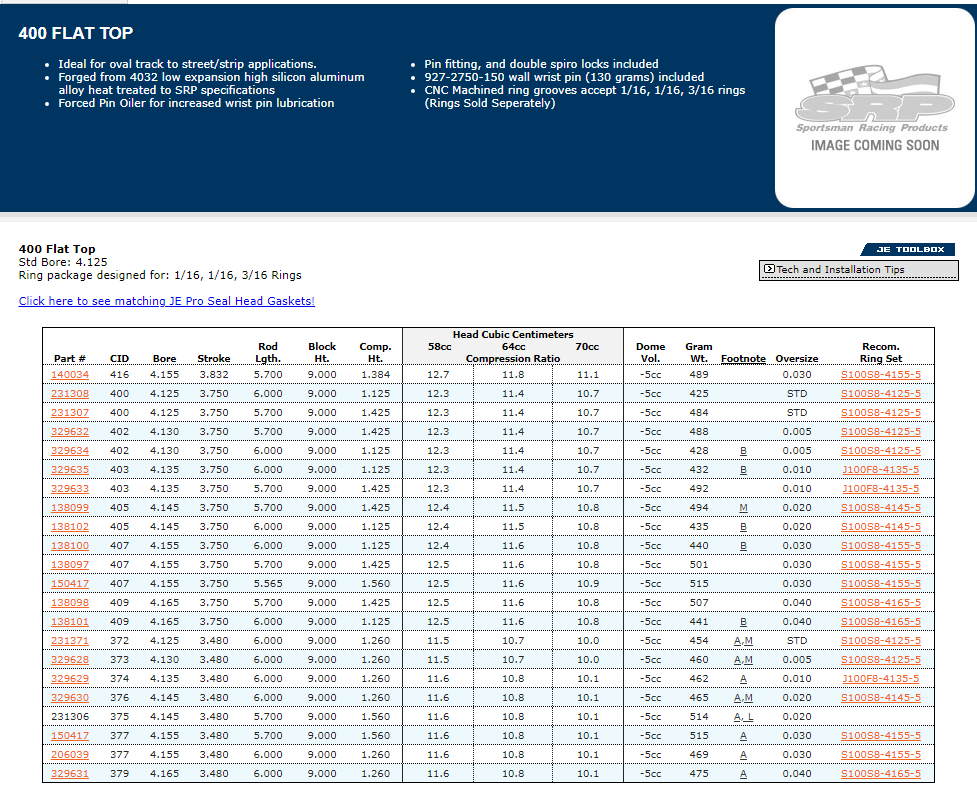

Sonic Checking Your Block

Author Andy Finkbeiner

Photos Ron Valera

Modern technology is great for us hot rodders. A few years ago, you practically needed a top security clearance before you could get your hands on technology like this. Now you can whip out the VISA card and order yourself a sonic checker like the one shown above.

Sonic checking is a fairly common term in the engine building business but many people might not fully understand just what it is all about. When the engine builder asks if you want to spend another $75 to have the block sonic checked, some people might think he is just trying to get more money from you. Actually, the engine builder is probably trying to save you from wasting a lot of money on a block that might not be any good. After all, most of the engine blocks in our musclecars are at least 30 years old now and have been through a lot.

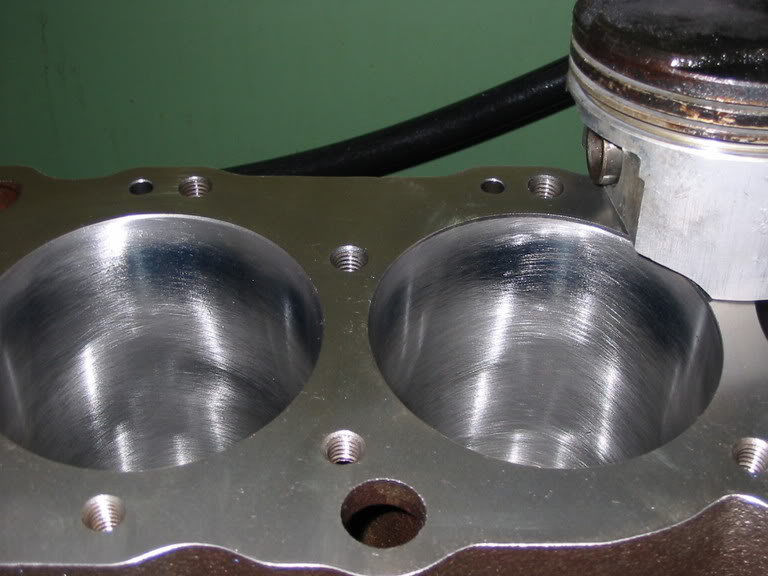

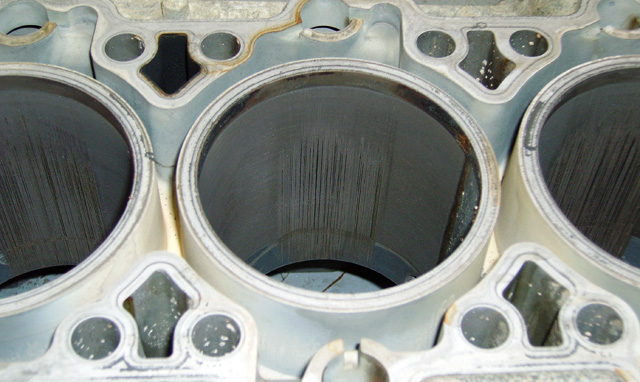

Sonic checking is a method for measuring material thickness when you only have access to one side of the part. For instance, if you want to know how thick a cylinder wall in an engine will be, you would have to cut a hole in the wall in order to use a pair of calipers. The sonic checker is able to measure the thickness by sending out a sound wave and then measuring the time that it takes for the sound wave to get to the other side of the wall. Modern electronics allow this complicated task to be accomplished in a hand held device.

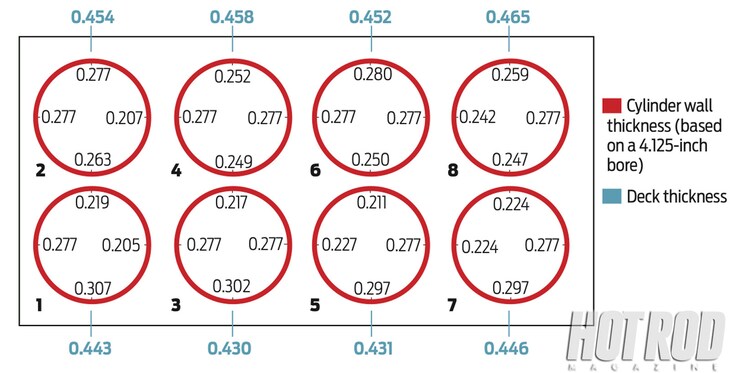

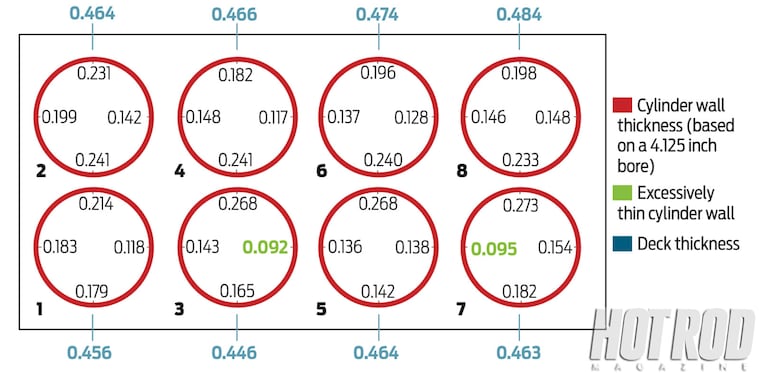

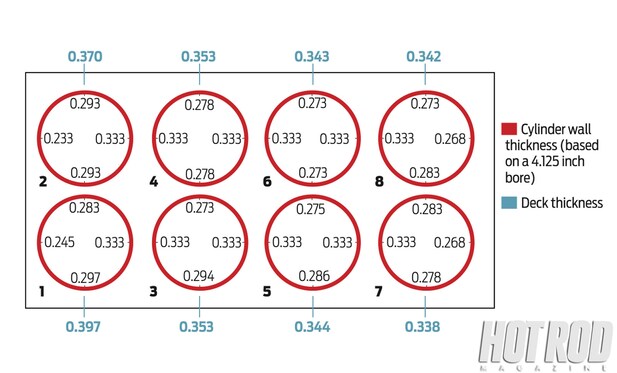

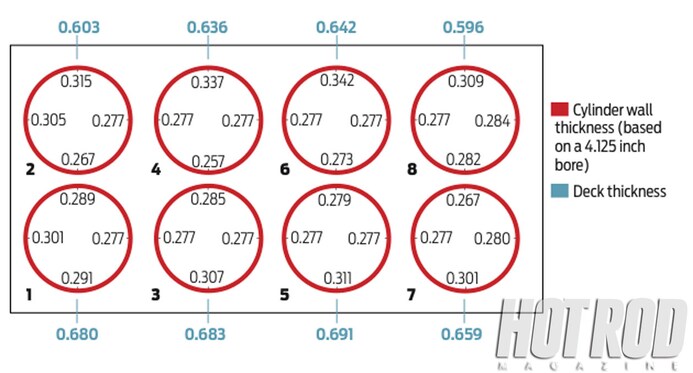

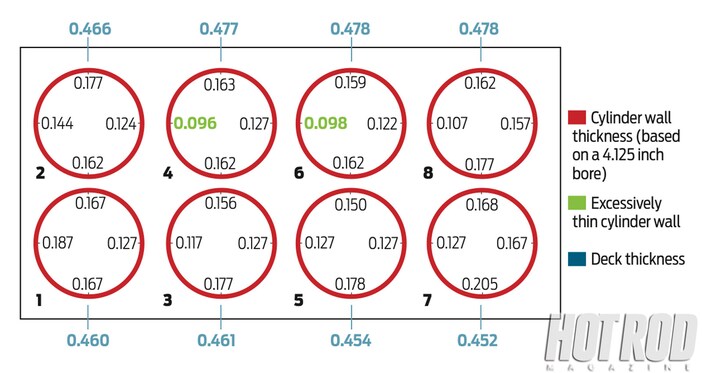

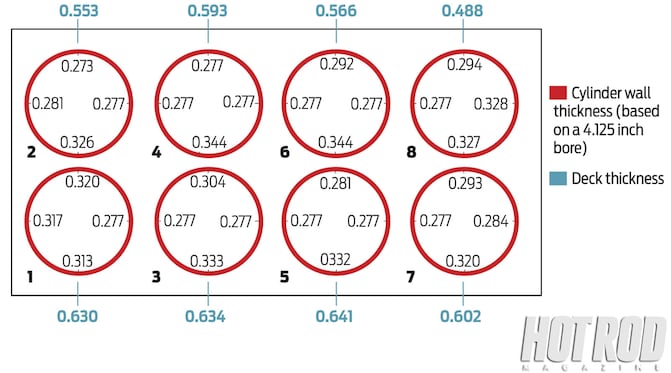

How thick the cylinder walls need to be is a fairly difficult question to answer but we do have some clues. Most production V8 blocks have cylinder wall thicknesses that range from 0.090 to .250 thick. Ford motors tend to be the thinnest while some Chevy blocks are the thickest. The thickness of the cylinder wall becomes more important as you start to make more horsepower, so a block that works in a passenger car application might not be suited for Winston Cup duty. If you can find a production block that is at least 0.200 thick on all cylinder wall thrust surfaces you’ve found a good one. Walls that thick should be good for at least 500 or 600 horsepower. If you’re going to be making more power than that then it is probably best to step up to a factory race block. Typically the race blocks are designed to maintain a 0.250 thick cylinder wall at the maximum overbore. They might start out with a wall thickness close to 0.400 as delivered.

Here is the sonic checker from Dakota Ultrasonics. This unit sells for $990 and is designed to be used for various automotive tasks. It can measure thicknesses from 0.025 to 20 inches in a variety of materials but is especially good at measuring cast materials.

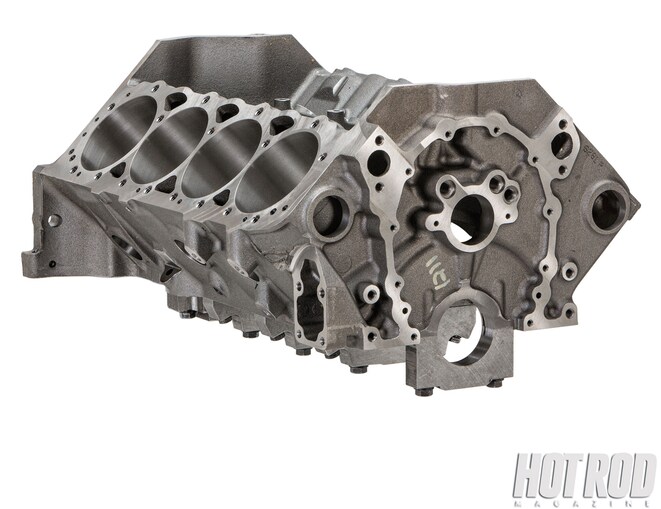

Here is where you really need a sonic checker! Nine engine blocks to choose from but which one is the best? A sonic checker allows you to examine each block for core shift and casting flaws. Obviously, what you want to do is to pick the block with the least amount of core shift. Minimum core shift will be indicated by having fairly consistent thickness measurements for each cylinder.

Contact Information:

Dakota Ultrasonics

1650B Mansfield Street

Santa Cruz, CA 95062

(831) 465-8585

HotRodBlockTests_Pg06.jpg79.5 KB · Views: 553

HotRodBlockTests_Pg06.jpg79.5 KB · Views: 553 HotRodBlockTests_Pg05.jpg60.9 KB · Views: 553

HotRodBlockTests_Pg05.jpg60.9 KB · Views: 553 HotRodBlockTests_Pg04.jpg70.1 KB · Views: 553

HotRodBlockTests_Pg04.jpg70.1 KB · Views: 553 HotRodBlockTests_Pg03.jpg76.5 KB · Views: 553

HotRodBlockTests_Pg03.jpg76.5 KB · Views: 553 HotRodBlockTests_Pg02.jpg84.8 KB · Views: 553

HotRodBlockTests_Pg02.jpg84.8 KB · Views: 553 HotRodBlockTests_Pg01.jpg78.6 KB · Views: 552

HotRodBlockTests_Pg01.jpg78.6 KB · Views: 552 SonicTest01_800x600.jpg94.3 KB · Views: 552

SonicTest01_800x600.jpg94.3 KB · Views: 552