hello gang...

So here I am with my fully rebuilt '69 LM1 which by the way is running fantastic. Smooth as silk, engine is steady as a rock at idle, and you can feel the power even though I haven't jumped on it (because I'm still breaking it in). I got to this point because of a lot of solid advise from folks on here...thank you. Especially Grumpyvette who gave a lot of good and well thought out advice.

So after all that, there's one thing bugging me. The oil pump seems to be "noisy". Now Grumpy if you're reading this know I've already been to your forum and read the links on pump noise and that it shouldn't really have any, causes etc. So let me first qualify "noise".

As the engine runs, you can here a whirling almost like a belt driven accessory or gear whine but its quiet enough that you'd never notice if you weren't looking for things (new engine, after all). Using a stethoscope I confirmed it is loudest at the sump end of the pan. The stethoscope defined it better to be a little more of a sound you would expect from two gears meshing. Once the engine is at operating temp it becomes undetectable to the ear.

The pump is a new Melling M155 with the stock (58#) relief spring. I used Mellings steel-coupling drive shaft and confirmed it to be the correct one for the block. I opened the pump and measured everything inside for clearence and all was good, and I put assy lube on the gears and then primed the pump with oil before install. There is lots of distributor to drive shaft clearance, with the disty fully installed I can pull the rotor up almost 3/16", if anything it may be too much clearance. Finally the pan was clearanced to the pump, the pickup was set 1/2" pff the bottom of the pan including accounting for the felpro 1-pc gasket. When I drill-primed the engine, I thought the pump was on the loud side but other than volume, no unusual sounds, and it spun without any kind of binding. Oil pressure is great and consistant. I'm running Brad Penn Grade 1 10W30

I feel like I've done everything right, but it feels wrong that I should be able to hear it at all with the engine running. Before the rebuild I never heard the oil pump. But then again that pump was 48 years old with 130K miles on it and God knows how clean the oil may or may not have been before I got it, or how much wear it may have had. But the M155 is a higher flow pump (but not HV - those things are taller and need a different pan, and would be too much for my stock rebuild with stock bearing clearances) so maybe being new + higher flow, it makes more noise.

Finally, I called Melling and they said "oh yeah, don't worry about it". But its the oil pump, and a new engine. Of course I'm going to worry. Its what I do best in the absence of sound facts.

So tell me, am I being paranoid?

update...since this is bugging the heck out of me, and since I know its oil-pump related, the easiest and least effort check is to pull the disty (On a '69 Impala, you can't drop the pan without more or less pulling the motor. Some books will tell say you can jack it up and put wood blocks under the mount, but in reality the tranny will hit the floor before you can get that far..._

So disty out and on the bench. First observation, the shaft has a full 1/8 inch slack back/forth between the washer and the gear. So that's probably what you mean by shims, not the intake shims but gear shims to take up the slack. Book says it should be .005 - .007. Wear pattern on the disty gear is just south of centre so I'll bet it "floats" with engine RPM and will no doubt impact timing etc. Wondering if that's the noise, when oil is cold it will take more effort to turn the pump and shove the disty shaft upward and when it warms up it will lay back down. Even if its not the cause, I need to fix it.

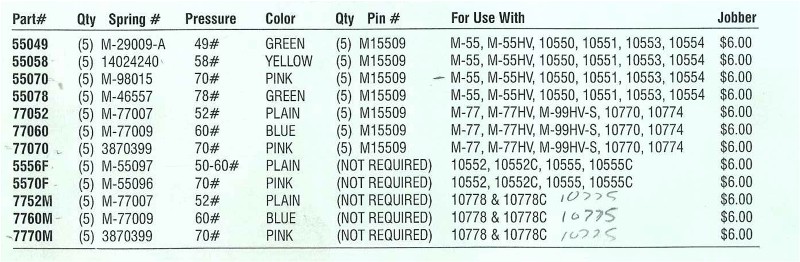

GM Small Block Performance Pumps

10550

High volume performance upgrade for M-55HV.

25% increase in volume over stock oil pump.

The 10550 housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide. Uses 5/8” press in screen.

10551

High volume performance upgrade for M155HV.

25% increase in volume over stock oil pump.

The 10551 housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide. Uses 3/4” press in screen.

10552

High volume performance oil pump.

10% increase in volume over stock oil pump.

The 10552 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and phosphate coated.

Includes intermediate shaft with steel guide. Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571.

10552C (Anti-Cavitation)

10552CHigh volume performance oil pump.

10% increase in volume over stock oil pump.

Same as the 10552 with the addition of grooves machined in the body and cover. The grooves reduce cavitation effects in high RPM applications.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

Using this oil pump will reduce pressure at idle.

The 10552C uses the high pressure spring only.

Racing Applications Only.

Patent No. 5,810,571.

10553

10553High pressure performance upgrade for M-55 & M-55A.

Standard volume oil pump.

The 10553 housing and cover are CNC machined and phosphate coated.

Manufactured with pink spring installed for higher pressure (M-55A).

To change pump to lower pressure (M-55) install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10553 uses a 5/8” press in screen.

10554

Performance upgrade for M155. Standard volume oil pump.

The 10554 housing and cover are CNC machined and manganese phosphate coated.

Manufactured with pink spring installed for higher pressure.

To change pump to lower pressure install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10554 uses a 3/4” press in screen.

10555

High Volume performance upgrade for the 10550 oil pump.

25% increase in volume over stock oil pump.

The 10555 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and manganese phosphate coated.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571

10555C (Anti-Cavitation)

High volume performance upgrade for the 10550 oil pump.

25% increase in volume over stock oil pump.

Same as the 10555 with the addition of grooves machined in the body and cover. The grooves reduce cavitation effects in high RPM applications.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

Using this oil pump will reduce pressure at idle.

The 10555C uses the high pressure spring only.

Racing Applications Only.

Patent No. 5,810,571

10990

High volume performance upgrade for the M-99HV-S.

Increase in volume of 25% over stock oil pump.

The 10990 is a Big Block style oil pump made to fit the Small Block applications.

The drive and idler shafts have been extended to allow for additional support in the cover. Additional support eliminates dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

The relief valve has a screw-in plug instead of a pin.

The housing and cover are CNC machined and phosphate coated.

An additional spring, the original stock replacement is supplied which will reduce bypass pressure if needed.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Patent No. 5,810,571.

10990C (Anti-Cavitation)

High volume performance upgrade for the M-99HV-S.

Increase in volume of 25% over stock oil pump.

The same as the 10990 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571.

GM B.B. Performance Pumps

10770

High volume performance upgrade for M-77HV.

25% increase in volume over stock pump.

The housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

10774

10774Standard volume performance upgrade for M-77.

The housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

10778

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The drive shaft has been manufactured from chrome-moly steel.

The drive and idler shafts have been extended to allow for additional support in the cover. Additional support eliminates dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

The relief valve has a screw-in plug instead of a pin.

The housing and cover are CNC machined and phosphate coated.

An additional spring, the original stock replacement is supplied which will reduce bypass pressure if needed.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Patent No. 5,810,571.

10778C (Anti-Cavitation)

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The same as the 10778 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571

RELATED INFO

viewtopic.php?f=54&t=6479&p=20555&hilit=testing+pump#p20555

viewtopic.php?f=54&t=2598

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/page-2#post-75256

viewtopic.php?f=54&t=8735&p=30834&hilit=test+pump#p30834

I've built hundreds of engines over the last 50 years and I can,t remember a single issue with oil pumps making excessive noise,

posting a video with a sound track would help,

as obviously I can,t hear the noise on a web site.

as always it will require an isolate and test procedure,

too locate and verify the exact source of the noise.

I would have temporarily swapped oil pumps as a test ,

too see if the issue was with the oil pump or else ware

since you stated you checked the oil pump end to plate clearance,

Id be looking into the distributor to cam gear wear,

Id check to verify the oil pump pick-up is not loose,

touching thee oil pan,or windage tray,etc.

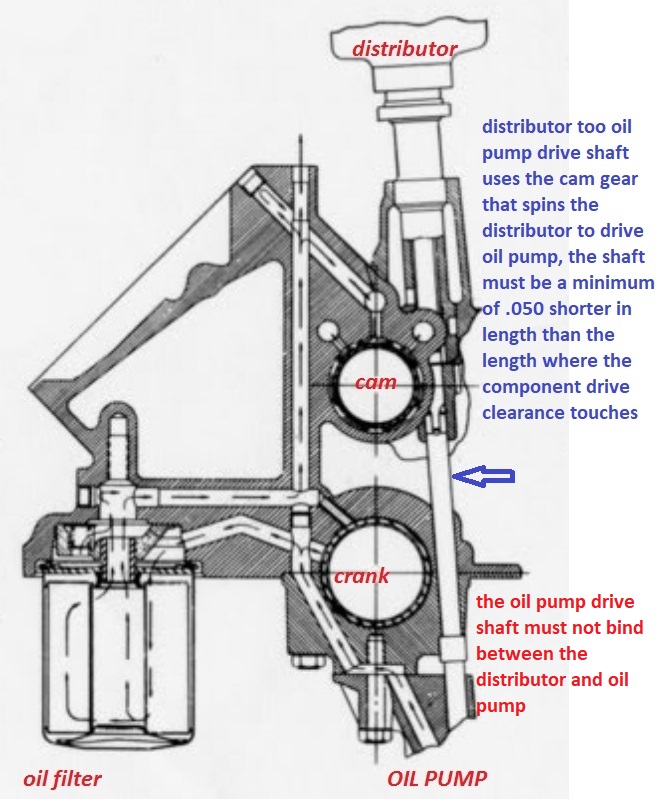

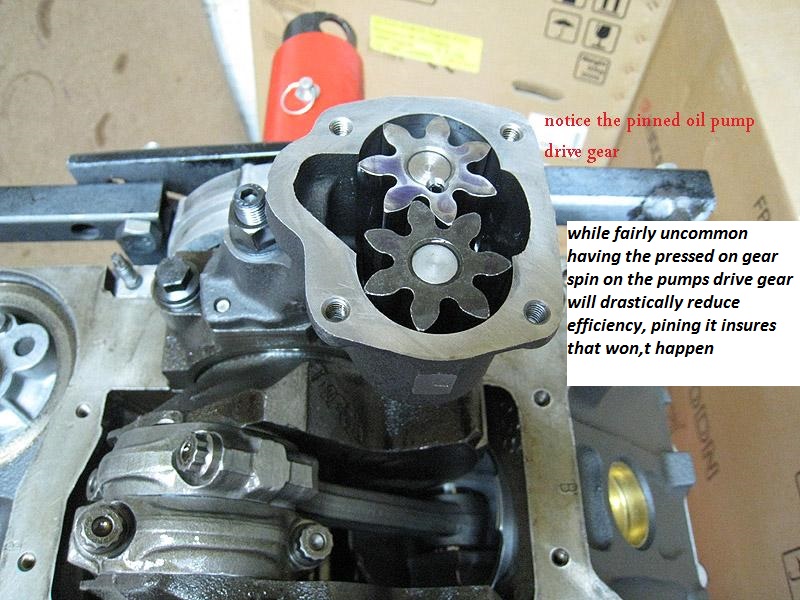

and Id check the oil pump drive shaft too block clearance is correct with the distributor installed ,as if it touches or partly binds thats a potential problem,

as potential clearance issues, Id check the distributor and shim it and use a NEW distributor gear,

"noise"= vibration, if your hearing something, its the result of some component rubbing or vibrating, Id suggest swapping the oil pump and seeing if anything changes,logic would indicate, if it does its obviously the oil pump, if it does not obviously its related to some other component

if it was a big block oil pump I would suggest looking at the oil pump pick-up being installed too deeply and touching the gears.

Id also look to see if you might have installed the oil pump mount bolt so deeply that its partly binding on the rear main cap bearing.

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

https://www.summitracing.com/parts/mel-10774

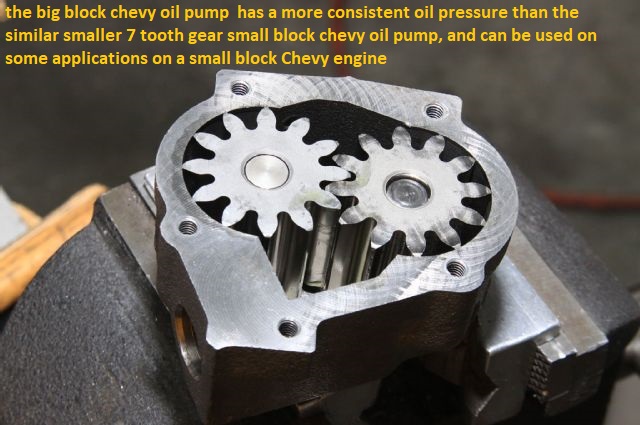

your typical big block oil pump has a 5 bolt cover, a 3/4" pick-up tube diameter and the pick-up presses into the pump body , it has the larger more efficient 12 tooth gears and in many cases can be mounted on a small block, but its usually not required

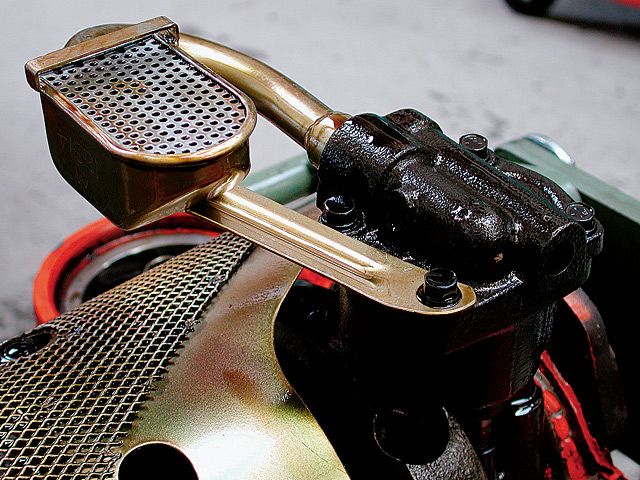

BIG BLOCK CHEVY 5 BOLT cover pump

the standard SMALL block chevy oil pump has a 5/8" oil pump pick-up that is inserted in the lower oil pump 4 bolt lower gear cover

SBC 4 BOLT COVER OIL PUMP

adding "ST" to the end of the existing melling SBC OIL PUMP part number denotes the helical gear set option

first choice

http://www.summitracing.com/parts/mel-10552/overview/SBC

or

http://www.jegs.com/i/Melling/689/10778C/10002/-1BBC

second choice

http://www.summitracing.com/parts/mil-18750/overview/SBC

Does it make a difference in what oil viscosity you use vs the pump that is in the engine?

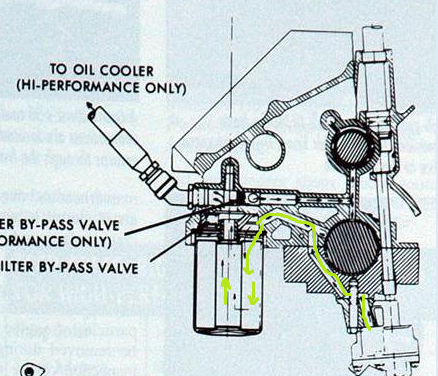

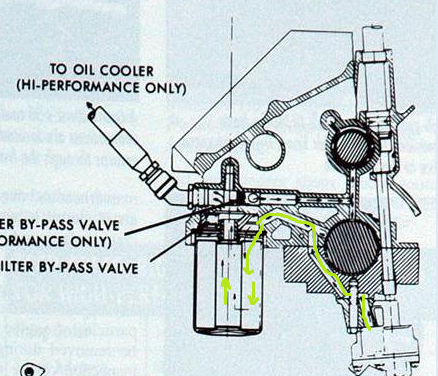

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

http://www.summitracing.com/search?keyword=5556F&dds=1

(chevy small block oil pump bye-pass springs)

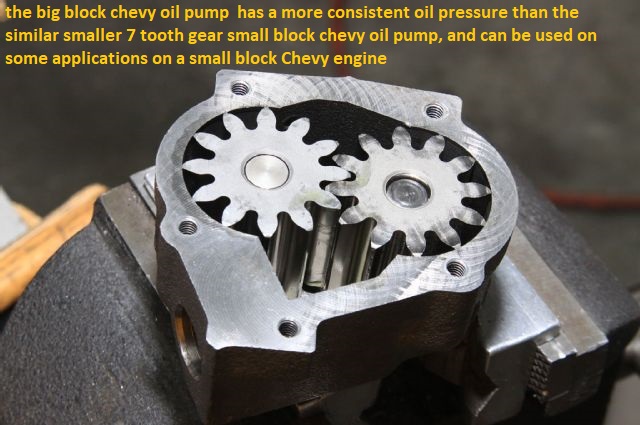

SBC pumps have 7 tooth gears and BBC pumps generally have 12 tooth gears making the flow more consistent

a well supported oil pump pick-up tends to cause far fewer issues than one that cab flex and vibrate as metal fatigue can eventually cause them to break

the lower spool shape part of the oil pump primer tool forms part of the oil passage walls in the area of the lifter gallery, if its inserted to the correct depth,

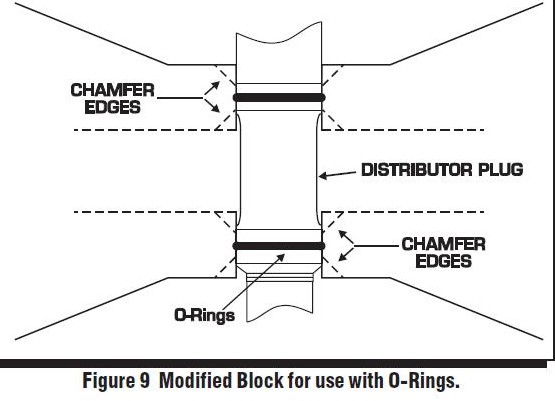

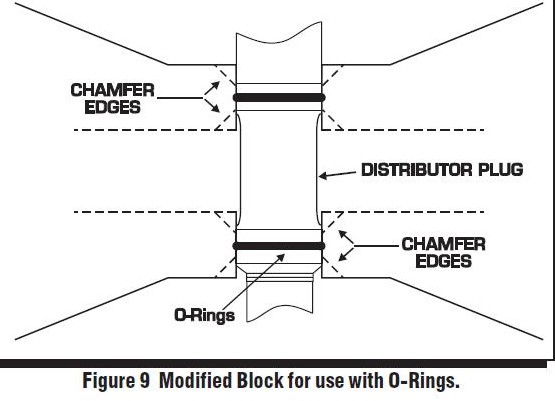

its designed to be a very close tolerance fit , if it does not fit snugly its generally designed to use o-rings (aftermarket) but it should be a fairly close fit (O.E.M.) to the block walls,

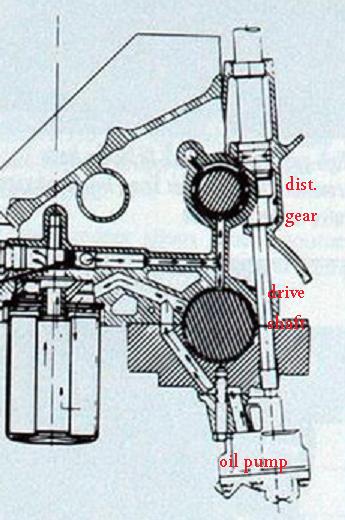

if its properly located

it is designed to leak a bit of pressurized oil to keep the distributor & cam gear bathed in oil,the clearance is designed to leak pressurized oil on the cam/distributor gear, O.E.M. distributors are a close tolerance fit that limits oil leakage, aftermarket distributors can be designed too use O-rings and have a hole drilled to direct pressurized oil to the cam/distributor gear contact area.

http://garage.grumpysperformance.com/index.php?threads/oil-pump-primer.6150/#post-19099

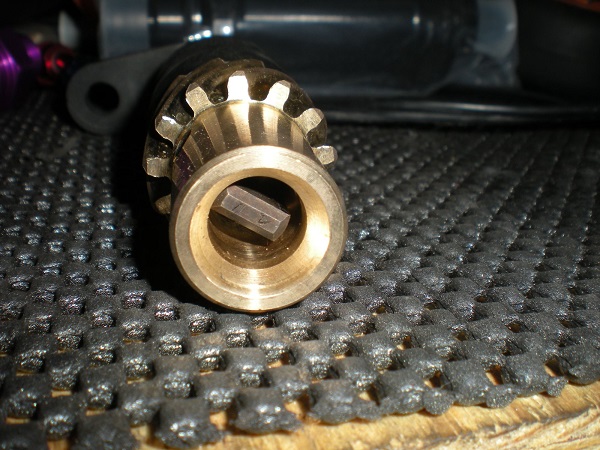

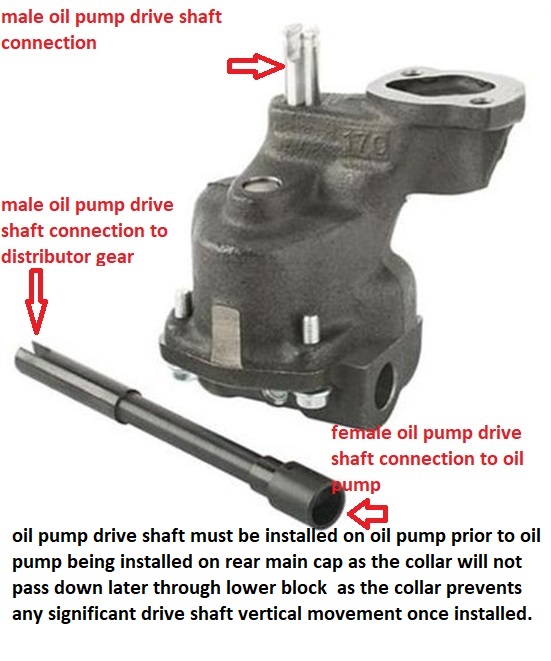

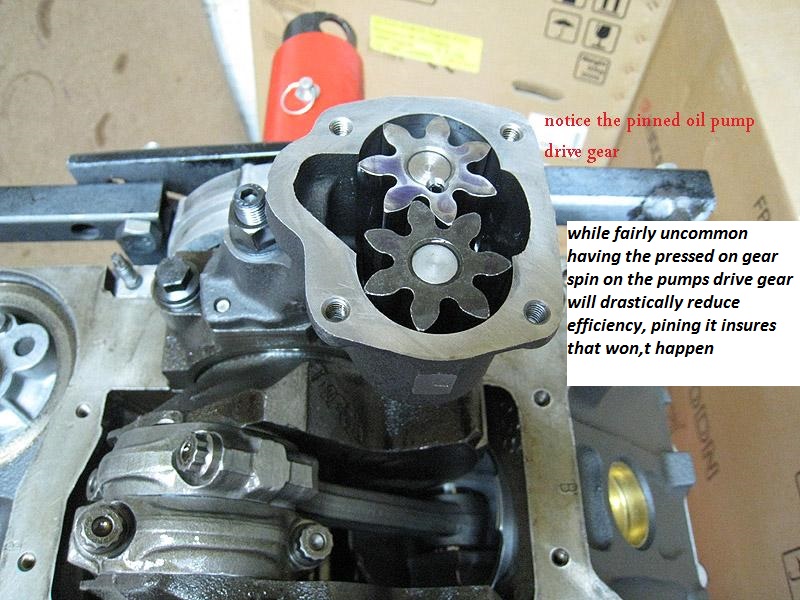

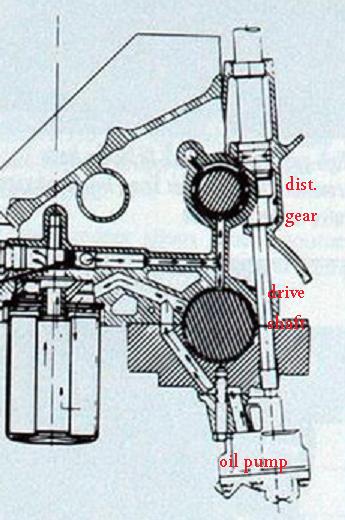

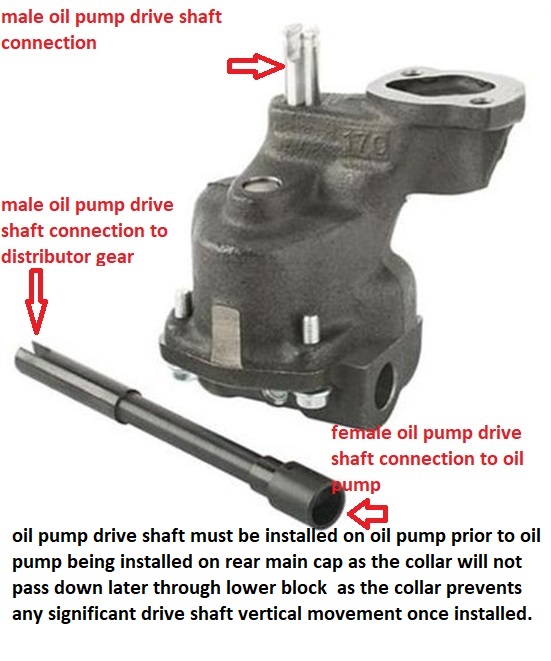

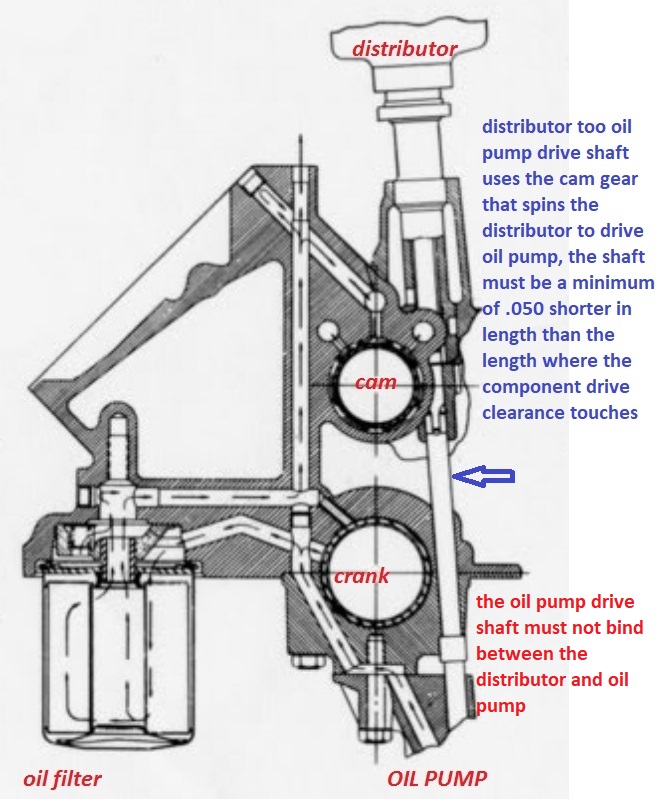

the oil pump drive shaft length MUST BE about .050 SHORTER than the distance it would take to firmly seat it inside the distributor drive gear, the cam has a gear that spins the distributor and the oil pump drive shaft is driven by that distributor gear in the lower distributor that extends down to the oil pump drive.

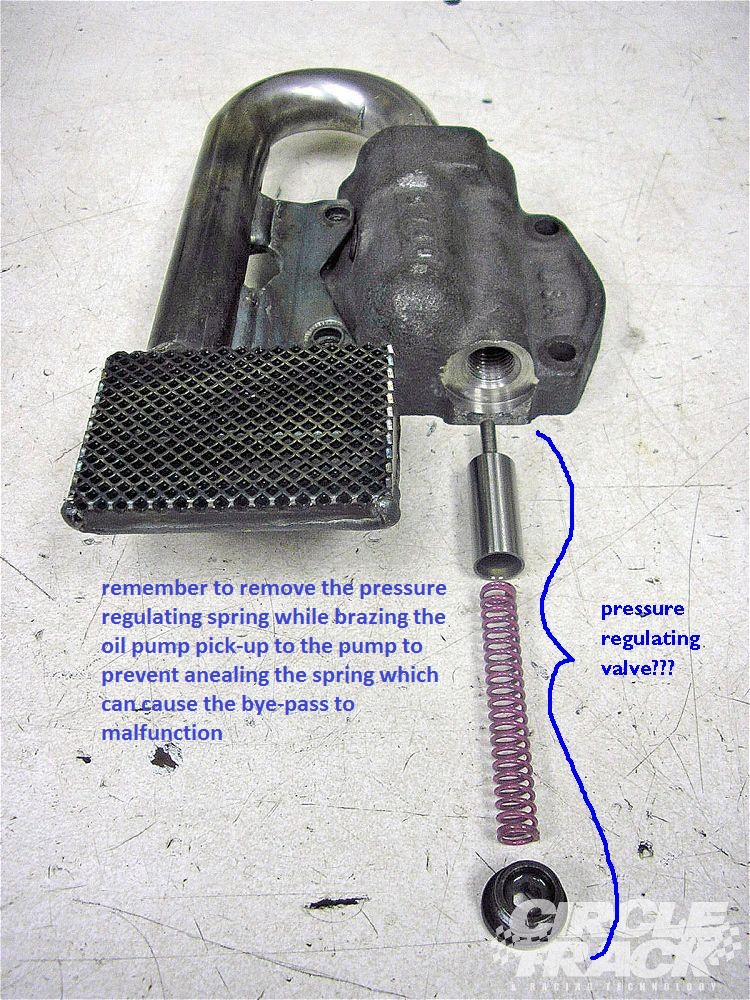

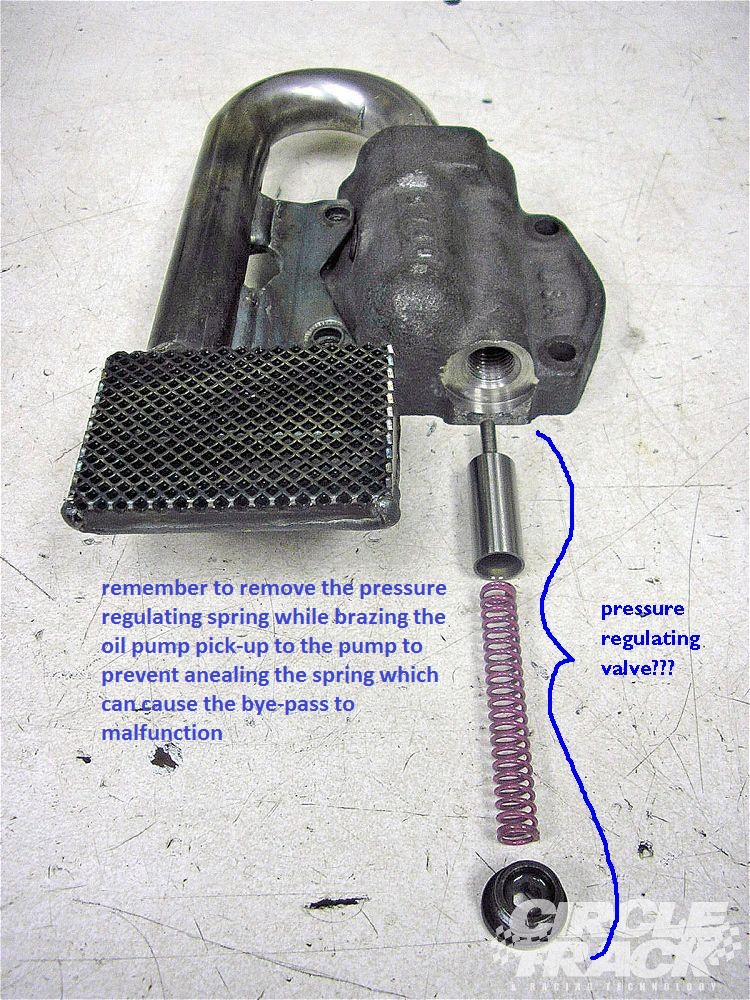

ITS always a good idea to verify the oil pan floor to oil pump pick-up clearance and to braze the pick-up to the oil pump, to reduce the potential for it to come loose.

yes you can MIG ,TIG or TORCH WELD the pick-up but I found BRAZING works the best and is less likely to warp or crack the pump or pick-up

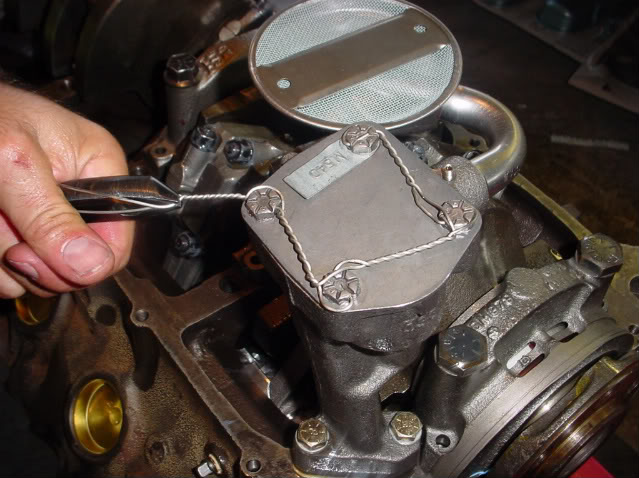

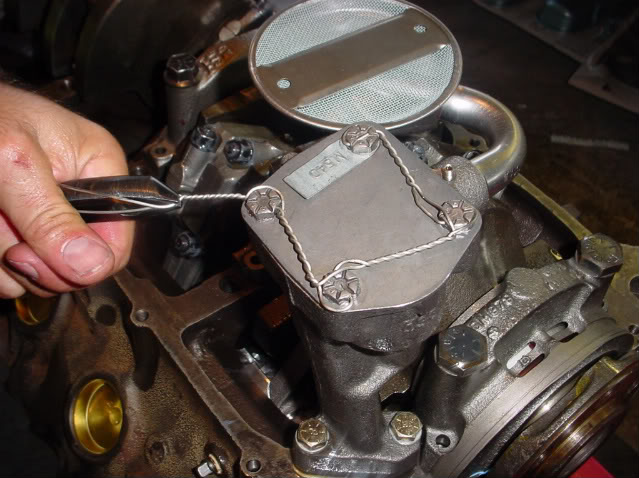

"how in hell do those twisty, safety wire pliers work?"

this gear must not bind on the distributor too oil pump drive shaft when the distributor is seated firmly on the intake manifold and clamped into place there must be about .050 clearance minimum

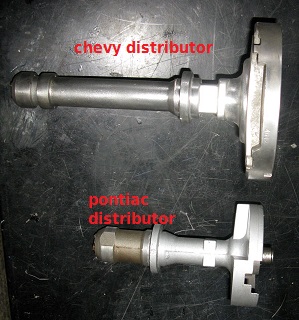

I never tried the chevy oil pump primer tool in dual use situation,

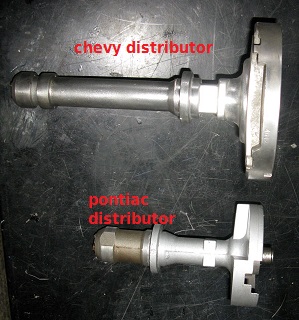

(I never thought to try it) (priming a pontiac V8)(or a buick or caddy)

I simply fabricated one to use in the PONTIAC, BUICK, CADDY) engines, I built , the same way I did for CHEVYS,

in that I fabricated one using a used pontiac distributor,

I got dirt cheap from a local salvage yard as the basis for the priming tool

http://garage.grumpysperformance.com/index.php?threads/oil-pump-primer.6150/#post-19099

SHOP CAREFULLY , WHEN YOU GO TO BUY AN OIL PAN<AND ASK LOTS OF QUESTIONS ABOUT WHAT WILL FIT YOUR CAR CORRECTLY AND ASK FOR SUGGESTIONS ON MATCHING COMPONENTS OR PARTS THAT WON,T FIT

MILODON,

http://www.milodon.com/

CHAMP

http://www.champpans.com/products/c/oil-pans/

CANTON,

https://www.cantonracingproducts.com/category/1501/Chevy-SS--Road-Race-Oil-Pans/1.html

MOROSO

http://www.moroso.com/

AVIAID

http://aviaid.com/shopsite_sc/store/html/ws_oilpns_sbc.html

STEFS

http://www.stefs.com/products/oilpans/circletrackwetsump.htm

HAMBURGERPERFORMANCE

http://www.hamburgersperformance.com/

KEVKO

https://kevko.myshopify.com/

http://en.wikipedia.org/wiki/Brazing

http://www.weldguru.com/braze-cast-iron.html

reading these threads,

AND THE RELATED SUB LINKED INFO, THATS CONTAINED,

THERE IN!

should help.

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/#post-19025

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/distrib-gear-issues.11291/#post-51208

http://garage.grumpysperformance.co...sic-info-on-your-v8-lube-system.52/#post-8265

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-29042

http://garage.grumpysperformance.co...ing-an-oil-pump-pick-up-tube.1800/#post-43117

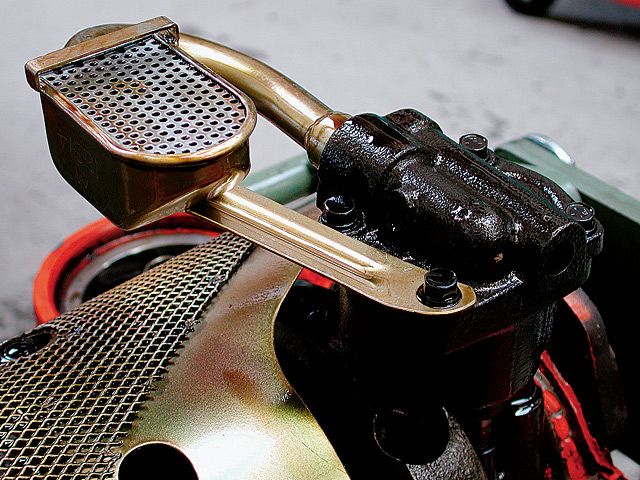

looks like the wrong (too short of a bolt was used) and torqued into the block threads to secure the oil pump,

stripping & cracking the block threads

failure to use the correct oil pump, mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems, use of too short a bolt can strip the main cap threads, if its too long it may damage the rear main bearing, use of studs avoid both potential issues.

at least one bright point is its only the rear main cap thats damaged and while its a P.I.T.A. to find and replace, the blocks not trash

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP,(like the picture shows below) IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

So here I am with my fully rebuilt '69 LM1 which by the way is running fantastic. Smooth as silk, engine is steady as a rock at idle, and you can feel the power even though I haven't jumped on it (because I'm still breaking it in). I got to this point because of a lot of solid advise from folks on here...thank you. Especially Grumpyvette who gave a lot of good and well thought out advice.

So after all that, there's one thing bugging me. The oil pump seems to be "noisy". Now Grumpy if you're reading this know I've already been to your forum and read the links on pump noise and that it shouldn't really have any, causes etc. So let me first qualify "noise".

As the engine runs, you can here a whirling almost like a belt driven accessory or gear whine but its quiet enough that you'd never notice if you weren't looking for things (new engine, after all). Using a stethoscope I confirmed it is loudest at the sump end of the pan. The stethoscope defined it better to be a little more of a sound you would expect from two gears meshing. Once the engine is at operating temp it becomes undetectable to the ear.

The pump is a new Melling M155 with the stock (58#) relief spring. I used Mellings steel-coupling drive shaft and confirmed it to be the correct one for the block. I opened the pump and measured everything inside for clearence and all was good, and I put assy lube on the gears and then primed the pump with oil before install. There is lots of distributor to drive shaft clearance, with the disty fully installed I can pull the rotor up almost 3/16", if anything it may be too much clearance. Finally the pan was clearanced to the pump, the pickup was set 1/2" pff the bottom of the pan including accounting for the felpro 1-pc gasket. When I drill-primed the engine, I thought the pump was on the loud side but other than volume, no unusual sounds, and it spun without any kind of binding. Oil pressure is great and consistant. I'm running Brad Penn Grade 1 10W30

I feel like I've done everything right, but it feels wrong that I should be able to hear it at all with the engine running. Before the rebuild I never heard the oil pump. But then again that pump was 48 years old with 130K miles on it and God knows how clean the oil may or may not have been before I got it, or how much wear it may have had. But the M155 is a higher flow pump (but not HV - those things are taller and need a different pan, and would be too much for my stock rebuild with stock bearing clearances) so maybe being new + higher flow, it makes more noise.

Finally, I called Melling and they said "oh yeah, don't worry about it". But its the oil pump, and a new engine. Of course I'm going to worry. Its what I do best in the absence of sound facts.

So tell me, am I being paranoid?

update...since this is bugging the heck out of me, and since I know its oil-pump related, the easiest and least effort check is to pull the disty (On a '69 Impala, you can't drop the pan without more or less pulling the motor. Some books will tell say you can jack it up and put wood blocks under the mount, but in reality the tranny will hit the floor before you can get that far..._

So disty out and on the bench. First observation, the shaft has a full 1/8 inch slack back/forth between the washer and the gear. So that's probably what you mean by shims, not the intake shims but gear shims to take up the slack. Book says it should be .005 - .007. Wear pattern on the disty gear is just south of centre so I'll bet it "floats" with engine RPM and will no doubt impact timing etc. Wondering if that's the noise, when oil is cold it will take more effort to turn the pump and shove the disty shaft upward and when it warms up it will lay back down. Even if its not the cause, I need to fix it.

GM Small Block Performance Pumps

10550

High volume performance upgrade for M-55HV.

25% increase in volume over stock oil pump.

The 10550 housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide. Uses 5/8” press in screen.

10551

High volume performance upgrade for M155HV.

25% increase in volume over stock oil pump.

The 10551 housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide. Uses 3/4” press in screen.

10552

High volume performance oil pump.

10% increase in volume over stock oil pump.

The 10552 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and phosphate coated.

Includes intermediate shaft with steel guide. Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571.

10552C (Anti-Cavitation)

10552CHigh volume performance oil pump.

10% increase in volume over stock oil pump.

Same as the 10552 with the addition of grooves machined in the body and cover. The grooves reduce cavitation effects in high RPM applications.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

Using this oil pump will reduce pressure at idle.

The 10552C uses the high pressure spring only.

Racing Applications Only.

Patent No. 5,810,571.

10553

10553High pressure performance upgrade for M-55 & M-55A.

Standard volume oil pump.

The 10553 housing and cover are CNC machined and phosphate coated.

Manufactured with pink spring installed for higher pressure (M-55A).

To change pump to lower pressure (M-55) install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10553 uses a 5/8” press in screen.

10554

Performance upgrade for M155. Standard volume oil pump.

The 10554 housing and cover are CNC machined and manganese phosphate coated.

Manufactured with pink spring installed for higher pressure.

To change pump to lower pressure install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10554 uses a 3/4” press in screen.

10555

High Volume performance upgrade for the 10550 oil pump.

25% increase in volume over stock oil pump.

The 10555 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and manganese phosphate coated.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571

10555C (Anti-Cavitation)

High volume performance upgrade for the 10550 oil pump.

25% increase in volume over stock oil pump.

Same as the 10555 with the addition of grooves machined in the body and cover. The grooves reduce cavitation effects in high RPM applications.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

Using this oil pump will reduce pressure at idle.

The 10555C uses the high pressure spring only.

Racing Applications Only.

Patent No. 5,810,571

10990

High volume performance upgrade for the M-99HV-S.

Increase in volume of 25% over stock oil pump.

The 10990 is a Big Block style oil pump made to fit the Small Block applications.

The drive and idler shafts have been extended to allow for additional support in the cover. Additional support eliminates dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

The relief valve has a screw-in plug instead of a pin.

The housing and cover are CNC machined and phosphate coated.

An additional spring, the original stock replacement is supplied which will reduce bypass pressure if needed.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Patent No. 5,810,571.

10990C (Anti-Cavitation)

High volume performance upgrade for the M-99HV-S.

Increase in volume of 25% over stock oil pump.

The same as the 10990 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571.

GM B.B. Performance Pumps

10770

High volume performance upgrade for M-77HV.

25% increase in volume over stock pump.

The housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

10774

10774Standard volume performance upgrade for M-77.

The housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

10778

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The drive shaft has been manufactured from chrome-moly steel.

The drive and idler shafts have been extended to allow for additional support in the cover. Additional support eliminates dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

The relief valve has a screw-in plug instead of a pin.

The housing and cover are CNC machined and phosphate coated.

An additional spring, the original stock replacement is supplied which will reduce bypass pressure if needed.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Patent No. 5,810,571.

10778C (Anti-Cavitation)

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The same as the 10778 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571

RELATED INFO

viewtopic.php?f=54&t=6479&p=20555&hilit=testing+pump#p20555

viewtopic.php?f=54&t=2598

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/page-2#post-75256

viewtopic.php?f=54&t=8735&p=30834&hilit=test+pump#p30834

I've built hundreds of engines over the last 50 years and I can,t remember a single issue with oil pumps making excessive noise,

posting a video with a sound track would help,

as obviously I can,t hear the noise on a web site.

as always it will require an isolate and test procedure,

too locate and verify the exact source of the noise.

I would have temporarily swapped oil pumps as a test ,

too see if the issue was with the oil pump or else ware

since you stated you checked the oil pump end to plate clearance,

Id be looking into the distributor to cam gear wear,

Id check to verify the oil pump pick-up is not loose,

touching thee oil pan,or windage tray,etc.

and Id check the oil pump drive shaft too block clearance is correct with the distributor installed ,as if it touches or partly binds thats a potential problem,

as potential clearance issues, Id check the distributor and shim it and use a NEW distributor gear,

"noise"= vibration, if your hearing something, its the result of some component rubbing or vibrating, Id suggest swapping the oil pump and seeing if anything changes,logic would indicate, if it does its obviously the oil pump, if it does not obviously its related to some other component

if it was a big block oil pump I would suggest looking at the oil pump pick-up being installed too deeply and touching the gears.

Id also look to see if you might have installed the oil pump mount bolt so deeply that its partly binding on the rear main cap bearing.

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

https://www.summitracing.com/parts/mel-10774

your typical big block oil pump has a 5 bolt cover, a 3/4" pick-up tube diameter and the pick-up presses into the pump body , it has the larger more efficient 12 tooth gears and in many cases can be mounted on a small block, but its usually not required

BIG BLOCK CHEVY 5 BOLT cover pump

the standard SMALL block chevy oil pump has a 5/8" oil pump pick-up that is inserted in the lower oil pump 4 bolt lower gear cover

SBC 4 BOLT COVER OIL PUMP

adding "ST" to the end of the existing melling SBC OIL PUMP part number denotes the helical gear set option

first choice

http://www.summitracing.com/parts/mel-10552/overview/SBC

or

http://www.jegs.com/i/Melling/689/10778C/10002/-1BBC

second choice

http://www.summitracing.com/parts/mil-18750/overview/SBC

Does it make a difference in what oil viscosity you use vs the pump that is in the engine?

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

http://www.summitracing.com/search?keyword=5556F&dds=1

(chevy small block oil pump bye-pass springs)

SBC pumps have 7 tooth gears and BBC pumps generally have 12 tooth gears making the flow more consistent

a well supported oil pump pick-up tends to cause far fewer issues than one that cab flex and vibrate as metal fatigue can eventually cause them to break

the lower spool shape part of the oil pump primer tool forms part of the oil passage walls in the area of the lifter gallery, if its inserted to the correct depth,

its designed to be a very close tolerance fit , if it does not fit snugly its generally designed to use o-rings (aftermarket) but it should be a fairly close fit (O.E.M.) to the block walls,

if its properly located

it is designed to leak a bit of pressurized oil to keep the distributor & cam gear bathed in oil,the clearance is designed to leak pressurized oil on the cam/distributor gear, O.E.M. distributors are a close tolerance fit that limits oil leakage, aftermarket distributors can be designed too use O-rings and have a hole drilled to direct pressurized oil to the cam/distributor gear contact area.

http://garage.grumpysperformance.com/index.php?threads/oil-pump-primer.6150/#post-19099

the oil pump drive shaft length MUST BE about .050 SHORTER than the distance it would take to firmly seat it inside the distributor drive gear, the cam has a gear that spins the distributor and the oil pump drive shaft is driven by that distributor gear in the lower distributor that extends down to the oil pump drive.

ITS always a good idea to verify the oil pan floor to oil pump pick-up clearance and to braze the pick-up to the oil pump, to reduce the potential for it to come loose.

yes you can MIG ,TIG or TORCH WELD the pick-up but I found BRAZING works the best and is less likely to warp or crack the pump or pick-up

"how in hell do those twisty, safety wire pliers work?"

this gear must not bind on the distributor too oil pump drive shaft when the distributor is seated firmly on the intake manifold and clamped into place there must be about .050 clearance minimum

I never tried the chevy oil pump primer tool in dual use situation,

(I never thought to try it) (priming a pontiac V8)(or a buick or caddy)

I simply fabricated one to use in the PONTIAC, BUICK, CADDY) engines, I built , the same way I did for CHEVYS,

in that I fabricated one using a used pontiac distributor,

I got dirt cheap from a local salvage yard as the basis for the priming tool

http://garage.grumpysperformance.com/index.php?threads/oil-pump-primer.6150/#post-19099

SHOP CAREFULLY , WHEN YOU GO TO BUY AN OIL PAN<AND ASK LOTS OF QUESTIONS ABOUT WHAT WILL FIT YOUR CAR CORRECTLY AND ASK FOR SUGGESTIONS ON MATCHING COMPONENTS OR PARTS THAT WON,T FIT

MILODON,

http://www.milodon.com/

CHAMP

http://www.champpans.com/products/c/oil-pans/

CANTON,

https://www.cantonracingproducts.com/category/1501/Chevy-SS--Road-Race-Oil-Pans/1.html

MOROSO

http://www.moroso.com/

AVIAID

http://aviaid.com/shopsite_sc/store/html/ws_oilpns_sbc.html

STEFS

http://www.stefs.com/products/oilpans/circletrackwetsump.htm

HAMBURGERPERFORMANCE

http://www.hamburgersperformance.com/

KEVKO

https://kevko.myshopify.com/

http://en.wikipedia.org/wiki/Brazing

http://www.weldguru.com/braze-cast-iron.html

reading these threads,

AND THE RELATED SUB LINKED INFO, THATS CONTAINED,

THERE IN!

should help.

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/#post-19025

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/distrib-gear-issues.11291/#post-51208

http://garage.grumpysperformance.co...sic-info-on-your-v8-lube-system.52/#post-8265

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-29042

http://garage.grumpysperformance.co...ing-an-oil-pump-pick-up-tube.1800/#post-43117

looks like the wrong (too short of a bolt was used) and torqued into the block threads to secure the oil pump,

stripping & cracking the block threads

failure to use the correct oil pump, mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems, use of too short a bolt can strip the main cap threads, if its too long it may damage the rear main bearing, use of studs avoid both potential issues.

at least one bright point is its only the rear main cap thats damaged and while its a P.I.T.A. to find and replace, the blocks not trash

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP,(like the picture shows below) IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

Last edited: