forcing the pump to fight dead head pressure is only going to complicate whatever problem you are already having. The C4 was GM's time to figure out electronic fuel injection. You should be happy you do not have their first attempt, the cross-fire fuel system that was used for just 2 years. the last of the c3 and the first of your c4. Then in 1985 the first year of your tuned port was a whole mess too. This was because there was a separate module just to interpret the mass air flow sensor and send the signal to the pcm. This maf module is out of production and even if it could be found they had an extremely high failure rate utterly killing the 1985 corvette unless you convert to a carb or aftermarket fuel injection

The maf module was so problematic that gm dumped the mass air flow sensor completely and went to Speed Density fueling with a map sensor only for a handful of years and then in the early 90's came back with both mass air flow sensor and manifold absolute pressure sensor and the ecu is constantly comparing the 2 for accuracy and diagnostics. This is the point where electronic fuel injection became stable for GM. and it happened right around the time of the LT motor being put in the C4.

There were some other strange things that were done by GM in these years as they struggled to figure things out. One problem was GM was caring too much about oil temp. And they drove the cooling fans based off of their firm belief in letting the oil achieve a temp that would allow the moisture to steam up and leave the crankcase. And so most C4's from the 80's and even into the early 90's in proper stock form will not even turn the coolant fan on until 238f is achieved in the coolant.

Also GM thought that linking fuel pump power to the engine's oil pressure was a great safety feature. Their thinking was if the oil pressure went away, the fuel would shut off saving the engine from imminent failure. What this looks like is a fuel pump relay driven by the PCM that lights the fuel pump when you turn on the key for a 2 second prime, and then an oil pressure switch that when closed sends power directly to the fuel pump. This has been the culprit of countless gremlins on these cars. This creates extremely long cranking times intermittent issues and even stalling on worn motors that drop oil pressure too low at idle.

And then we come to wiring. GM had to put so much copper in each of these Corvettes. At their peak in 1993 the Chevrolet Corvette had right around 200lbs of copper in each car and if you took all the wire out and stretched it end to end you would have over 2 miles of wire. That is a lot of 30+ year old connections to break down from fretting / micro motion. This problem drove GM to create and invent GMLAN. A novel way to drastically reduce the amount of wires and connections in each vehicle by letting modules communicate on 2 networks. A 1 wire low speed network for unimportant stuff and accessories and a 2 wire high speed network for all the important stuff like communications between the engine controller, abs unit, airbags, stuff that needs big information and fast. And for diagnostics here the stuff that talks on high speed usually also communicates on low speed.

There is a very good reason the aftermarket fuel injection companies have put together specific retrofit kits for these early GM fuel systems. They help. And from the time it goes in you don't fight with it anymore.

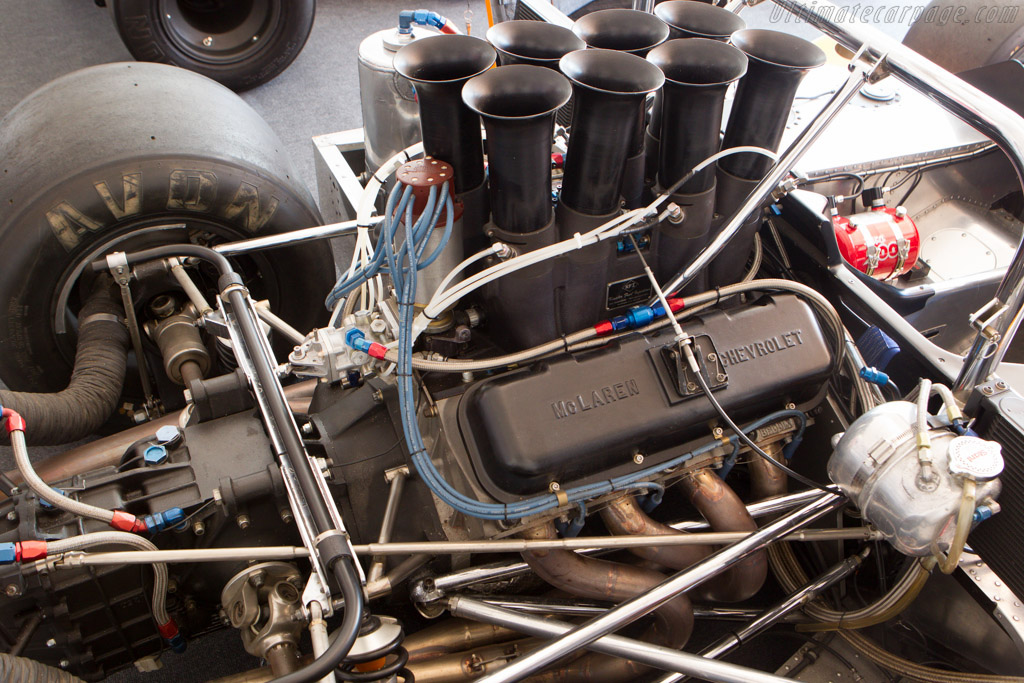

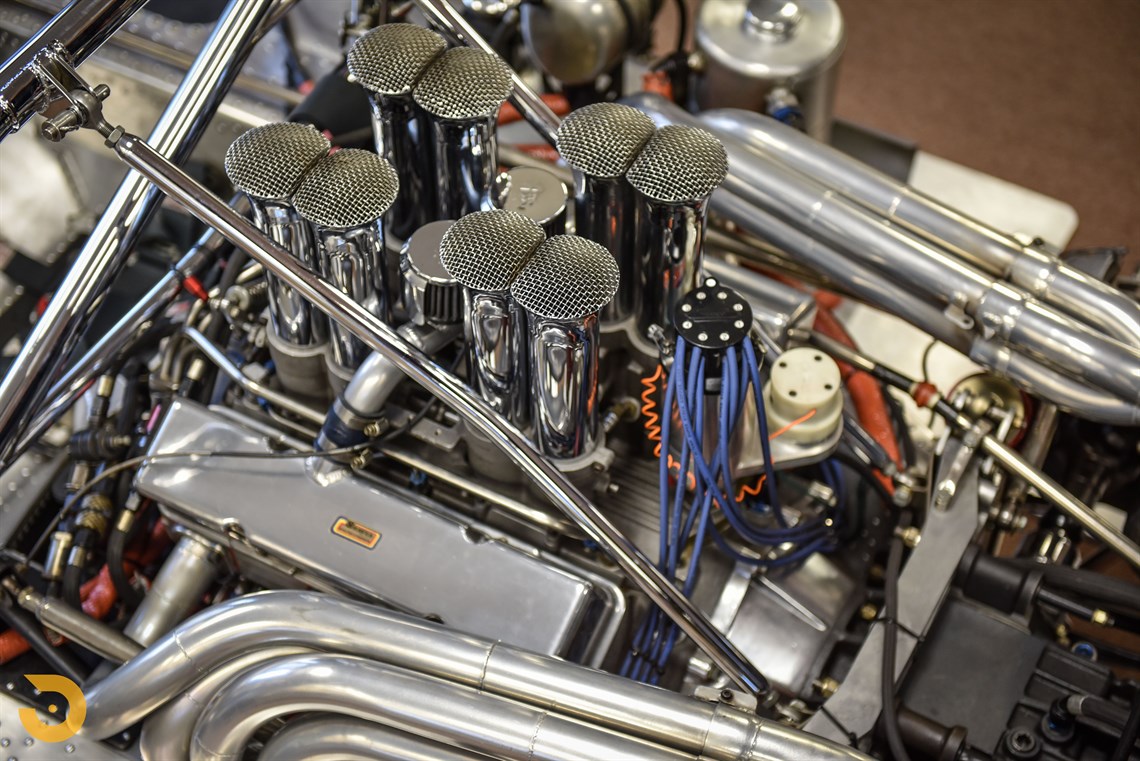

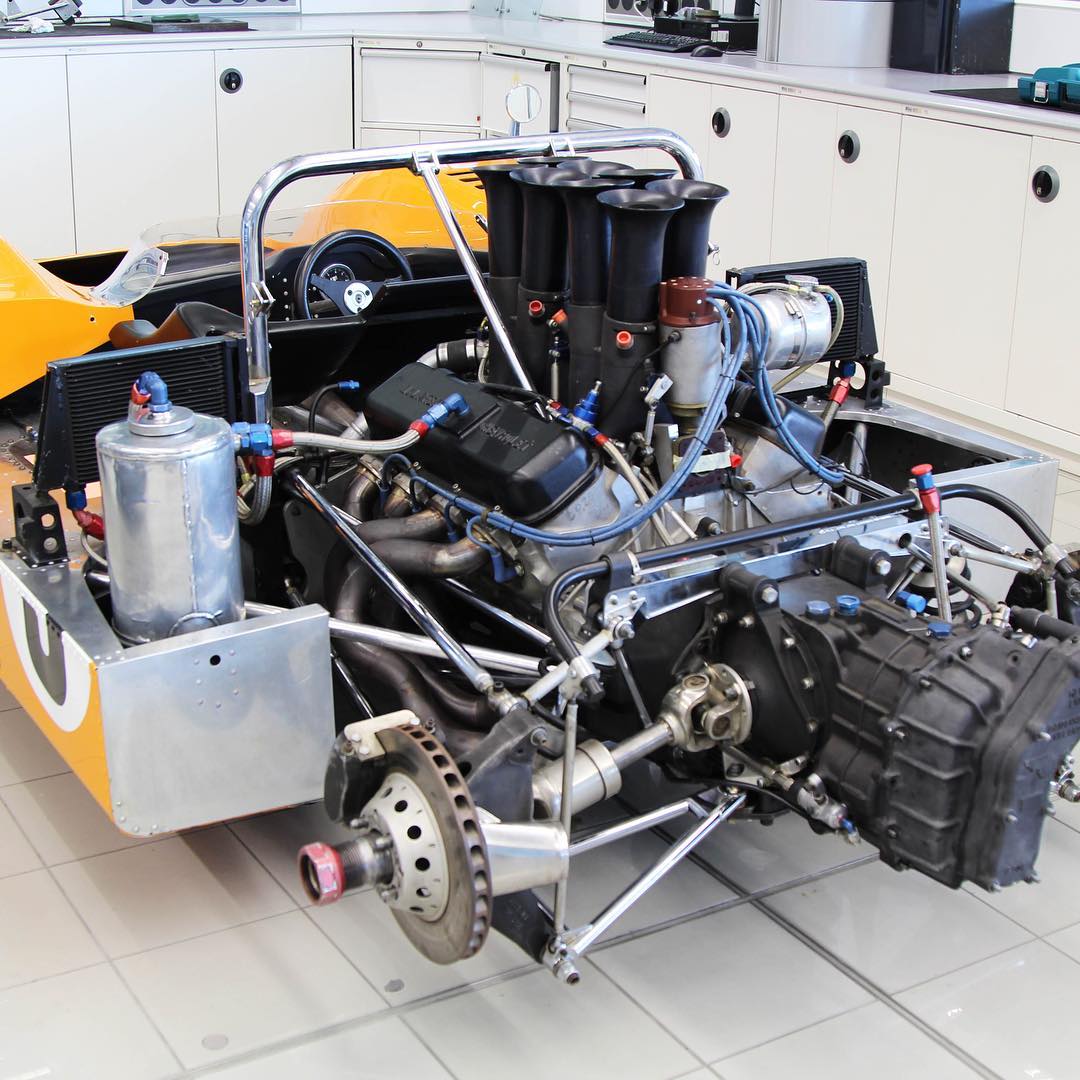

There is also another thing here I would like to point out about these early control systems. The cross fire in '82 & '84 had 2 fuel injectors. So it's controller had 2 injector drivers. One fuel injector fired each bank. These were low impedence(peak and hold) fuel injectors we do not use today. Their drivers in the pcm had to be robust for their operation. When your tuned port came out GM added 8 fuel injectors as you see but made no changes to the controller. They used these 2 robust drivers to drive 4 injectors each simultaneously. Thus achieving bank fueling. This allows fuel/air mix to collect at the head of the closed intake valve and begin to separate from the atomized mix.

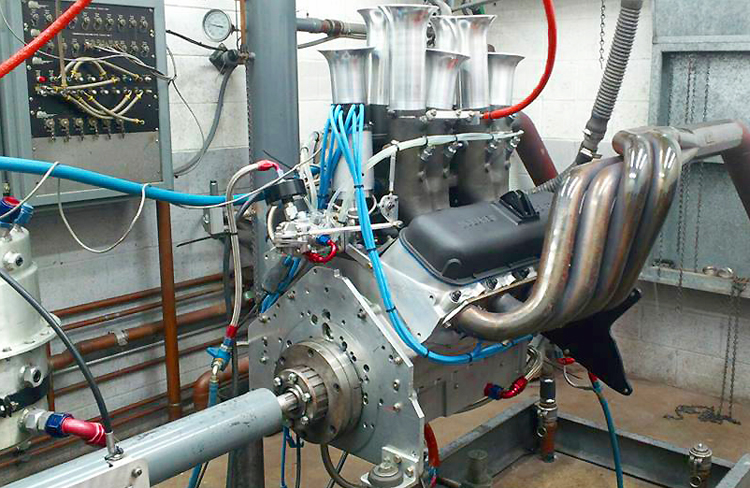

Sequential fuel injection is where we have a crankshaft position sensor and a camshaft position sensor and we have 8 fuel injector drivers and we time the opening of each fuel injector to the opening of that cylinder's intake valve. There are nothing but upsides to sequential fueling. From power production to efficiency to emissions to cleanliness of the intake and valves. So great and profound was sequential fueling when it came on the scene that it what everything made today is.

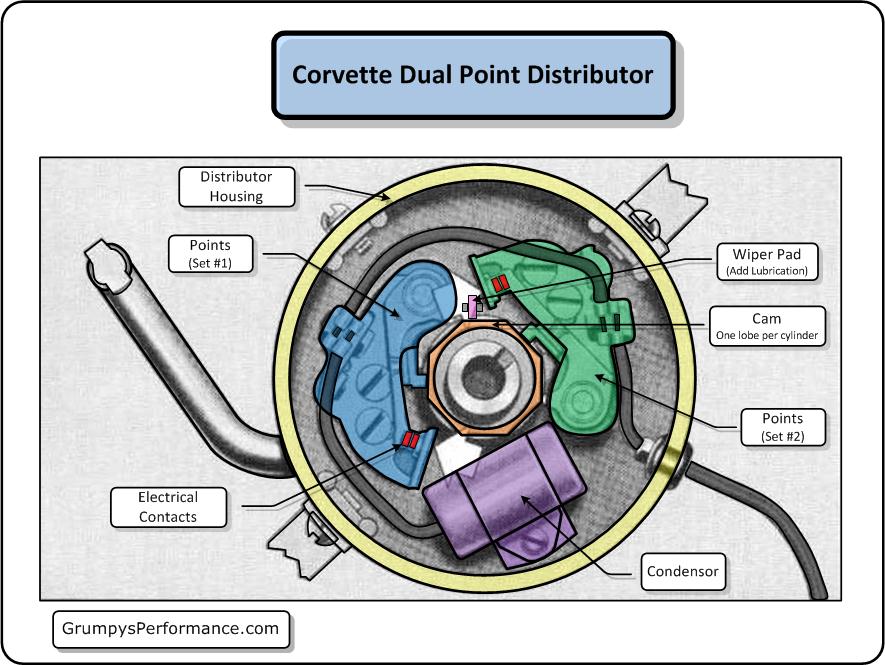

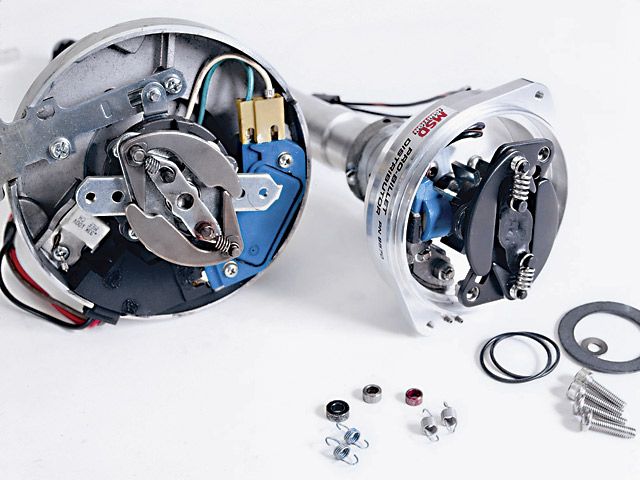

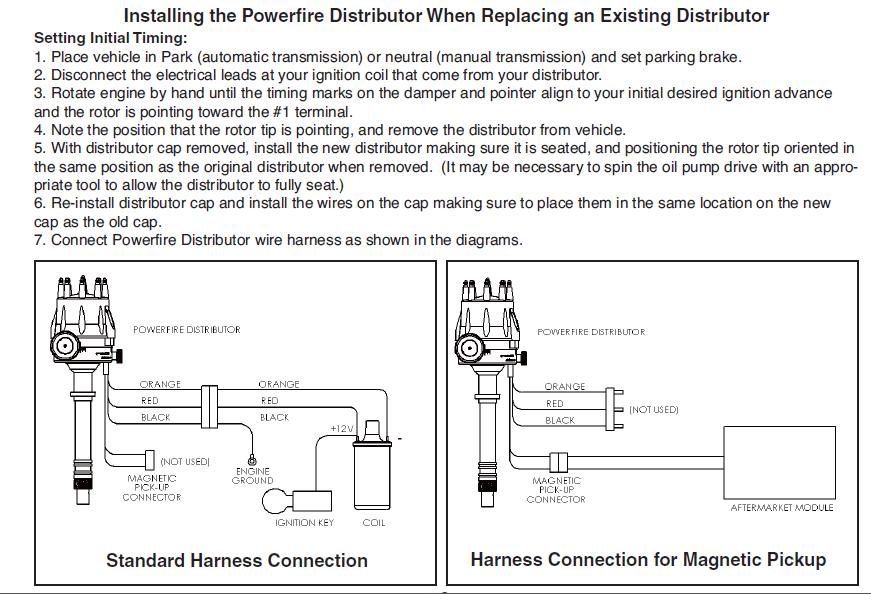

FAST makes a 'dual sync' distributor that provides both a cam and a crank signal back to the fast controller. This dual sync distributor with the multiport retrofit would allow you to achieve modern day fueling with your older Tuned Port fuel system. Here is that distributor:

https://www.fuelairspark.com/chevy-s...stributor.html

IF you were not interested in the more cost effective route of the multi port retrofit and wanted the fuel system that were gonna make the most power that you would feel driving then you should consider dumping the tuned port all together. Just unbolt everything toss it all even the lower intake. And rebuild with an edlebrock intake for a carb. Whichever you like. If you got a cam and are good past 6k rpm then get the victor jr. single plane, or get the performer RPM if you have the stock cam and valvetrain. And then get the FAST easy efi 2.0 kit with their carb replacing throttle body. This throttle body flows an industry leading 1150cfm. It has 8 fuel injectors built into it and claims 1200hp support all on it's own. The runners and throttle body on your tuned port will never flow these numbers no matter what you do. So if you were not looking to just solve your problems but wanted to make yourself some of that Lemonade we all love so much you might consider an Edlebrock intake and a FAST 30400-kit:

https://www.fuelairspark.com/ez-efi-...-base-kit.html

I have set this up on a few C3's here:

https://www.digitalcorvettes.com/for...d.php?t=242889

Here:

https://www.digitalcorvettes.com/for...d.php?t=255809

And here:

https://www.digitalcorvettes.com/for...d.php?t=292602

The setup with their throttle body always impresses. Every single time. And all of their stuff is labeled and engraved made in the USA.

Quote:

Originally Posted by

1963SS

I used to think that also but the oil pressure switch is wired parallel with the fuel pump. I believe it's a backup if the fuel pump relay were to fail. The fuel pump signal from the ECM energizes the relay and that supplies power to the pump. This is true on the LT1 Vettes, not real sure about an '89.

It is wired in parallel because the ecu only supplies power to the relay for the 2 second prime. When the car is running the relay is not energized and power for the pump comes from the oil pressure switch. There is even a bad part that came with the cars and a TSB on replacing them if they are a certain color plastic. I will look for this bulliten and post here.

Later years and your LT switched away from this and the relay stays energized while the car runs. This is because GM learned that powering the fuel pump from the oil pressure switch was a bad idea. Very bad. But there is nothing that can be done with an ECU that will only energize a relay for prime. The LT ecu's can not be used here because they require low and high res pulses from the optispark. These early fuel systems sere just problematic. And the entire generation of a car has suffered a certain rep for unreliability as a direct result.

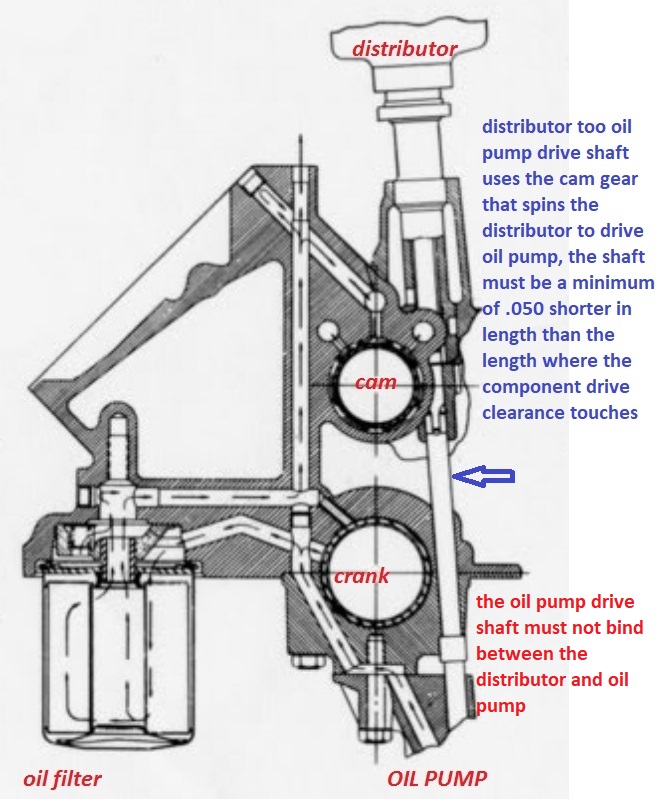

Even the opti was in and of itself a disaster. And All optispark was not sequential. The LT1 was the same bank firing as the tuned port. Only the LT4 with the red intake at the very end of the sbc's life had just touched sequential fueling. So many seals and a water pump within inches of an optical sensor. How can reliability ever be had out of that? And that was when GM finally got the right answer. CKP position sensor and a CMP position sensor. No distributor. Sequential fueling precise ignition timing without concerns about max timing adjustments allowed before jumping to adjacent towers.

Quote:

Originally Posted by

1963SS

I'm probably just getting old but I thought the FP relay was energized for 2 seconds and then again when it sees reference pulses from the distributor either cranking or running. What if the 2 second prime is used up because the car had to crank for 5 seconds. That may not be enough time for the oil pressure relay to close and the car would never start. Logically, that doesn't make a lot of sense. You'd have to keep turning the key off and on after 3-4 seconds. Kinda illogical to an old Hillbilly.

I know, right? Well we didn't start off with the knowledge. And GM's Tuned Port was an early fuel system from a time before GM understood that the relay should always be energized. The pump gets its prime and then the car cranks until oil pressure closes the switch. This made for start n stall and long crank time conditions as the cars packed on the age and wear. And this made GM quickly move to having their ecu's just keep the relay energized. And there have been no problems since. But he has an early fuel system.

This has also brought about the solution to long cranking times as cycling the key twice before cranking to make the car start right up. How many early C4 owners know this trick?