You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

source for knife blade steel

- Thread starter Grumpy

- Start date

https://morethanjustsurviving.com/knife-blade-steels/

KNIFE BLADE STEELS – A COMPREHENSIVE GUIDE

July 24, 2015 By Thomas Xavier | Updated: April 29, 2017 46 Comments

I have written a number of in-depth articles on the topic of blade steels and their relative strengths and weaknesses over the years – from detailing whether or not I think super steels for knives are worth it, to guides on how to sharpen stainless steels, all the way over to common knife myths and why they’re not true (again, many of which are about knife steels).

I think it’s fair to say that I have a lot to say on the matter. However, even with all I’ve already written on the topic, I still do get a number of related questions directed my way. This made me feel that a truly comprehensive guide on the topic of blade steels was warranted; so here’s my attempt – with a basic overview of steel as a whole, a decent (non-exhaustive) list of all the steels I consider to be relevant in the knife community by today’s standards, and an outline of each steel’s place in the market. So let’s start at the very beginning…

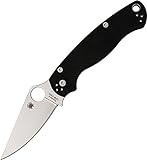

Spyderco Sage 2 Titanium Framelock Knife – Amazon

Spyderco Sage 2 Titanium Framelock Knife – Amazon

WHY DOES KNIFE STEEL MATTER?

A very good place to start.

While steel in itself is not the only determining factor you’d use when discussing the performance of a knife, it’s certainly important, and arguably has taken front and center stage when it comes to advertising.

Very rarely do manufacturers discuss grinds or heat treat, and yet every year we are flooded with a deluge of the “next greatest super steel” that will completely revolutionize knives as you know them! This is of course absolute baloney because the upgrades in steels are incremental at best, and last year’s “top end steel” truly won’t be significantly (or noticeably) inferior to the current flavor of the month.

At the end of the day, edge geometry, and not blade steel, is the most significant aspect of a knife with regards to real-world impact. A glorified pry bar of a knife will not become a super slicer just because it has a high carbide super steel that is conceived with edge retention in mind, and in the same vein, an anemic filleting knife in CPM-3V will not be optimal as a beater/rough duty blade just because it features a tough steel. Like everything in life, we should try to view things logically and not get swindled and carried away by marketing nonsense. And while yes, it’d be nice to think your recently purchased knife with some newly created super steel meant that you were holding the latest, greatest, very best thing since sliced bread in realm of knives – if you’ve led yourself to believe this and thereby bought into the product hype, you’re unfortunately deluding yourself.

With that said, some steels are better than others, and if you wish to drop big bucks to have the optimal performing blade in terms of matching the blade profile, edge geometry, and blade steel, then certainly there are steels that would be better suited compared to others.

It all depends on what you’re planning on using that steel for. Right tool for the right job? Always true. And in this case, you’re going to be learning which blade steels make for the right tool for your particular right job.

WHAT MAKES A STEEL? STEEL COMPOSITION & PROPERTIES

First, let’s take a look at the more common elements used to manufacture steel.

It’s important to note that I didn’t list all of the elements of steel composition to the chart below. Nitrogen (used in H1 steel and supposedly in Busse’s INFI steel), for instance, I have not listed. I did not go into length over the elements’ reactions with other elements either, but rather, just focused on an overview so as to help you clearly understand what goes into the making of a steel. Bare this in mind as you take a look!

BLADE STEEL COMPOSITIONS

Element Properties

Carbon (C) -Increases resistance to wear & hardness

-Improves edge retention & tensile strength

-Single most important hardening element

Chromium (Cr) -Imporoves hardness, toughness & tensile strength.

-Significantly improves corrosion resistance.

Cobalt (Co) -Enables higher temps when quenching during heat treat.

-Works well with other elements to boost properties in complex steels.

-Increases strength and hardness

Copper (Cu) -Increases wear resistance as well as corrosion resistance

Manganese (Mn) -Allows higher levels of hardening.

-Improves wear resistance & tensile strength

Molybdenum (Mo) -Improves ease of machining.

-Increases harden-ability, toughness & strength.

-Prevents brittleness

Nickel (Ni) -Adds corrosion resistance, hardness & strength.

Phosphorous (P) -Increases machinability, hardness and strength.

-In high enough concentration, causes brittleness.

Silicon (Si) -Increases tensile & yield strength.

Sulphur (S) -Improves machinability but lowers toughness.

Tungsten (W) -Increases strength, hardness & toughness.

Vanadium (V) -Increases strength, hardness and shock (impact) resistance.

-Retards growth.

While the above table is a good primer on steel composition, steel foundries have over the years developed new ways to make steel – from powder metallurgy to exotic friction forging. The elemental composition will only tell you so much, and at the end of the day, you will have to go with your own experiences on top of the information floating around the internet when ascertaining the viability of a specific steel for your given purpose, especially considering the ridiculous amount of hype on various forums whenever something new is introduced to the market. Being a cynic is strongly recommended these days.

Kershaw Thermite Everyday Carry Knife – Amazon

Kershaw Thermite Everyday Carry Knife – Amazon

HOW TO CHOOSE A BLADE STEEL

The core attributes you will want to use when categorizing steels are the following;

ATTRIBUTE #1: EDGE RETENTION & STABILITY

Ability to hold an acute edge. This is probably the most important metric if you consider a knife’s core purpose to cut. When discussing steels and super steels, the measuring rod is usually based on edge retention. Check out the excellent testing by Jim Ankerson concerning edge retention of the current crop of modern steels at their respective hardness.

ATTRIBUTE #2: DUCTILITY

The ability to flex under load without fracturing. Not necessarily tied with toughness, as a filleting knife needs to have high ductility without needing to be tough.

ATTRIBUTE #3: TOUGHNESS

The ability for a steel to absorb impact before fracturing under stress. A good example of a tough steel is S7 tool steel. Note: toughness is not at all the same thing as hardness. In fact, many times the hardest steels are not the toughest, as the hardest steels will fracture under stress much easier than slightly softer steels.

If you work near salt water or live in a high humidity area (looking at you Florida!) then corrosion resistance will probably matter a great deal to you. Stainless steel is generally considered to be a steel with 13% or more of chromium. As per the name, stainless only means it is resistant to staining (i.e. “stain less” not “stain free”). Stainless steel can still rust under the right conditions. If you are having issues with stainless steel, and want something that’s basically rust proof (not merely stainless), then check out blades made out of H1 steel (example: the Spyderco Salt series knives, like the Pacific Salt) and X15TN (example: this version of the Benchmade Pardue). Blades made out of these steels will be an optimal choice for high humidity areas.

ATTRIBUTE #5: ROCKWELL HARDNESS

Some manufacturers chose not to harden steel to optimal levels for edge retention. Some do this due to lack of manufacturing tolerances, others because they prefer to heat treat a knife to the lower end of the hardness scale so that it can handle higher levels rough use and thus do not have to budget for more returns under warranty. Whatever the reason, it’s important to note that CPM S30V from Spyderco (used for the Paramilitary 2) will have marked difference compared to CPM S30V from Kershaw (used for this version of the Kershaw Blur); so don’t go looking at the steel type exclusively without doing your due diligence.

Kershaw Shuffle EDC Folding Knife – Amazon

Kershaw Shuffle EDC Folding Knife – Amazon

MY COMPENDIUM OF STEELS

Before we get to the nitty gritty, I want to explain my choice to not use numerical values in my tables. I do not wish to use loosely defined metrics such as “7.5 out of 10 edge holding” or any other derivative metric due to the shifts in the steel landscape over time. To use a metric today would mean that in 10 years time, that metric would no longer be accurate, as the ceiling gets pushed higher and higher over time. Consider that 30 years ago, 440C was considered a premium steel!

As a result, here I’ve used metrics (ambiguously) that I think will stand the test of time: the name, general purpose of the steel, and ease of sharpening.

My list is not exhaustive. If you want a digital spread sheet of all steels and their compositions, check out the zknives steel chart!

Concerning edge retention and toughness, for further research you may want to consult charts from credible third party sources, as well as rankings from respected aficionados like Frank R.and Jim Ankerson. You’ll also find the world of performance cutlery interesting if you’re looking for a more exhaustive analysis; if this strikes your fancy, check out the detailed work of Cliff Stamp here and the CATRA testing results here.

And finally, if you want me to add a steel that’s not listed below, please just leave a comment and I will get to it (even if it’s not suggested I will update these tables with more steels as time allows).

COMMON STAINLESS BLADE STEELS

Steel Name Type Ease of Sharpening

CPM S90V High Edge Retention Very Hard

M390 High Edge Retention Very Hard

ZDP-189 High Edge Retention Very Hard

Elmax General use (Premium) Hard

CTS-XHP General use (Premium) Hard

CPM S35VN General use (Mainstream) Moderate

CPM S30V General use (Mainstream) Moderate

CPM 154 General use (Mainstream) Moderate

154CM General use (Mainstream) Moderate

ATS-34 General use (Mainstream) Moderate

D2 *Semi-Stainless General use (Mainstream) Moderate

VG-10 General use (Budget) Easy

H1 Marine use (Rust Proof) Easy

X15TN Marine use (Rust Proof) Easy

N690 General use (Mainstream) Easy

440C General use (Budget) Easy

AUS-8 General use (Budget) Easy

CTS-BD1 General use (Budget) Easy

8Cr13MoV General use (Budget) Easy

14C28N General use (Budget) Easy

13C26 General use (Budget) Easy

12C27 General use (Budget) Easy

420HC General use (Budget) Extremely Easy

440A General use (Budget) Extremely Easy

AUS-6 General use (Budget) Extremely Easy

COMMON CARBON BLADE STEELS

Steel Name Type Ease of sharpening

CPM M4 General use (Premium) Moderate

D2 *Semi-Stainless General use (Mainstream) Moderate

INFI *Semi-Stainless Toughness (Premium) Moderate

M2 General Use (Mainstream) Moderate

Carbon V General use (Mainstream) Moderate

5150 Toughness Easy

1050 Toughness Easy

1075 General use (Budget) Easy

1095 General use (mainstream/budget) Easy

S7 Extreme toughness Easy

W1 General use (Mainstream) Easy

52100 General use (Mainstream) Easy

CPM 3V Toughness Moderate

O1 Toughness Easy

Super Blue General use (Premium) Easy

https://morethanjustsurviving.com/super-steels-for-knives/

ARE KNIFE SUPER STEELS WORTH IT?

October 2, 2014 By Thomas Xavier | Updated: June 18, 2017 53 Comments

After over a decade of being heavily involved in the knife world, not only as a knife user, but as a collector as well, I have found myself completely jaded by the knife industry’s enduring tactic of releasing new steels and declaring them clear upgrades. I am not arguing that there isn’t an actual improvement from steel to steel, but rather that this has been overplayed for the sake of marketing and generating more sales.

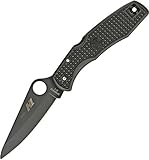

Spyderco Military EDC Knife – Amazon

Spyderco Military EDC Knife – Amazon

When S30V first became mainstream as a high-end cutlery steel, the propaganda machine went full blast and touted it as the end all be all of steels. This prompted its ubiquitous adoption. Is S30V a good steel? Yes. Is it significantly better than S60V, which was its predecessor in the Spyderco Military, for example? No.

I own an ungodly amount of knives, the vast majority of them from high performance companies like Spyderco. The steels used in my knives run the gamut from the “lowly” 8Cr13MoV all the way down to CPM S110V. I’m not saying I’m an expert on metallurgy, but I think I have enough experience with knives to be able to make a somewhat educated post on the value (perceived or otherwise) of super steels.

Spyderco Dragonfly 2 EDC Knife – Amazon

Spyderco Dragonfly 2 EDC Knife – Amazon

For the sake of not writing a novel, I will define a super steel by its edge retention as the measuring rod. Plenty of other metrics can be introduced to rank steels, such as tensile strength or corrosion resistance, for instance. Yet for the sake of having a linear upgrade path, I think edge retention is the best method. The reality is that to achieve other characteristics you will always have to sacrifice something. If a steel had amazing toughness, edge retention, and corrosion resistance: manufacturers would be using it for pretty much every knife on the market. A knife is defined by its primary function as a cutting tool. This is important because a steel with high tensile strength does not necessarily make a good knife. A good example would be the 300 series of stainless steel – good luck breaking them, but edge retention will be almost non-existent, hence, not good knives. Tough steels like 5160 are middle-of-the-road in many tests as a consequence of being utilized for a cutting tool whilst emphasizing toughness (you can’t have your cake and eat it), and as such, do not qualify as super steels.

RARE SUPER STEELS

A friend of mine works in drywall and his EDC of choice is a Kershaw Volt SS with 8Cr13MoV. It’s been beaten to pieces, but functionally it works. For a supposedly “mediocre” steel, I gotta say, it holds up damn well. Objectively speaking, I will always pick a super steel over a “regular” steel if I have the choice, and that’s, again, purely because I am a giant nerd: it’s not because having a super steel is a functional necessity. The problem is that people mistake this fascination most of us seem to have with super steels as meaning super steels are objectively better than other steels when it comes down to improvement of knife function, and that isn’t actually true. Remember when people freaked out about CPM S35VN? Based on just a few negative opinion user reports, the entire community seemed to rip the steel to pieces, proclaiming to have “noticed” sub par performance.

Kershaw Volt Stainless Steel Folding Knife – Amazon

Kershaw Volt Stainless Steel Folding Knife – Amazon

Listen, if you want to know for sure whether super steels are worth it: get off the internet forums and start using your damn knives! In regular use, I can’t actually tell the difference between S30V and S35VN, and I doubt you can either! Unless I am doing a regulated cut test, using consistently uniform abrasive materials and a lot of whisky to get me through such a boring test, I’m just not going to notice a difference.

The reality is that the “super” part is pretty much all in our heads. It’s like when people have a serious problem with the Kershaw Emerson CQC-6K purely because it’s made in China with an average blade steel. I can’t get over how biased this is, especially considering it’s pretty much the best knife you can buy for under $200, and it costs like $30. Can you actually tell the difference between a super steel and 8cr13MoV in everyday use? No (and be honest here – I know you can’t). So my question for you is, then why do you care?

Kershaw Emerson CQC-6K Folding Knife – Amazon

Kershaw Emerson CQC-6K Folding Knife – Amazon

There is nothing wrong with always seeking the best, but when the knife industry takes note of our obsession with super steel and begins capitalizing on the nonsense by releasing folders with Cruwear blades (why?!) and small EDC fixed blades with CPM 3V steel, you’ve got to admit we all have a problem. These kinds of knives are absurd, and quite frankly go against all sense of logic and reason. But they’re on the market! And it’s all because the lot of us are super steel addicts.

At the end of the day, advertising exists because it works. Try to resist the endless deluge of the latest generation steels that can cut atoms and pry open tanks, and instead focus on knives with consistent heat treating, good edge geometry, and a steel that suits its intended application. That means going for a tough steel like CPM 3V for a chopper, an edge retention focused steel like CPM S30V for your folders, and a super stainless steel like H1 or X15TN for your marine-use blades.

Spyderco Delica 4 EDC Folding Knife – Amazon

Spyderco Delica 4 EDC Folding Knife – Amazon

To reiterate, I am not saying that supersteels don’t have their place. What I’m saying is, no matter the steel, if the knife is badly made, it will still be bad. The crux of the matter is that, while I’d always choose a super steel over an average blade steel, I’m not turning down a knife just because it’s not offered with a super steel blade steel. And if you would turn down a great knife simply because it’s blade isn’t a super steel – well I really think you need to reassess your priorities when it comes to knives.

If you insist on having the toughest EDC knife possible, I can make you a 5/8 inch thick, 302 stainless steel, full convex 5 inch fixed blade for a mere $700. Edge retention is good enough to open at least 1 parcel guaranteed. Email to order.

KNIFE BLADE STEELS – A COMPREHENSIVE GUIDE

July 24, 2015 By Thomas Xavier | Updated: April 29, 2017 46 Comments

I have written a number of in-depth articles on the topic of blade steels and their relative strengths and weaknesses over the years – from detailing whether or not I think super steels for knives are worth it, to guides on how to sharpen stainless steels, all the way over to common knife myths and why they’re not true (again, many of which are about knife steels).

I think it’s fair to say that I have a lot to say on the matter. However, even with all I’ve already written on the topic, I still do get a number of related questions directed my way. This made me feel that a truly comprehensive guide on the topic of blade steels was warranted; so here’s my attempt – with a basic overview of steel as a whole, a decent (non-exhaustive) list of all the steels I consider to be relevant in the knife community by today’s standards, and an outline of each steel’s place in the market. So let’s start at the very beginning…

WHY DOES KNIFE STEEL MATTER?

A very good place to start.

While steel in itself is not the only determining factor you’d use when discussing the performance of a knife, it’s certainly important, and arguably has taken front and center stage when it comes to advertising.

Very rarely do manufacturers discuss grinds or heat treat, and yet every year we are flooded with a deluge of the “next greatest super steel” that will completely revolutionize knives as you know them! This is of course absolute baloney because the upgrades in steels are incremental at best, and last year’s “top end steel” truly won’t be significantly (or noticeably) inferior to the current flavor of the month.

At the end of the day, edge geometry, and not blade steel, is the most significant aspect of a knife with regards to real-world impact. A glorified pry bar of a knife will not become a super slicer just because it has a high carbide super steel that is conceived with edge retention in mind, and in the same vein, an anemic filleting knife in CPM-3V will not be optimal as a beater/rough duty blade just because it features a tough steel. Like everything in life, we should try to view things logically and not get swindled and carried away by marketing nonsense. And while yes, it’d be nice to think your recently purchased knife with some newly created super steel meant that you were holding the latest, greatest, very best thing since sliced bread in realm of knives – if you’ve led yourself to believe this and thereby bought into the product hype, you’re unfortunately deluding yourself.

With that said, some steels are better than others, and if you wish to drop big bucks to have the optimal performing blade in terms of matching the blade profile, edge geometry, and blade steel, then certainly there are steels that would be better suited compared to others.

It all depends on what you’re planning on using that steel for. Right tool for the right job? Always true. And in this case, you’re going to be learning which blade steels make for the right tool for your particular right job.

WHAT MAKES A STEEL? STEEL COMPOSITION & PROPERTIES

First, let’s take a look at the more common elements used to manufacture steel.

It’s important to note that I didn’t list all of the elements of steel composition to the chart below. Nitrogen (used in H1 steel and supposedly in Busse’s INFI steel), for instance, I have not listed. I did not go into length over the elements’ reactions with other elements either, but rather, just focused on an overview so as to help you clearly understand what goes into the making of a steel. Bare this in mind as you take a look!

BLADE STEEL COMPOSITIONS

Element Properties

Carbon (C) -Increases resistance to wear & hardness

-Improves edge retention & tensile strength

-Single most important hardening element

Chromium (Cr) -Imporoves hardness, toughness & tensile strength.

-Significantly improves corrosion resistance.

Cobalt (Co) -Enables higher temps when quenching during heat treat.

-Works well with other elements to boost properties in complex steels.

-Increases strength and hardness

Copper (Cu) -Increases wear resistance as well as corrosion resistance

Manganese (Mn) -Allows higher levels of hardening.

-Improves wear resistance & tensile strength

Molybdenum (Mo) -Improves ease of machining.

-Increases harden-ability, toughness & strength.

-Prevents brittleness

Nickel (Ni) -Adds corrosion resistance, hardness & strength.

Phosphorous (P) -Increases machinability, hardness and strength.

-In high enough concentration, causes brittleness.

Silicon (Si) -Increases tensile & yield strength.

Sulphur (S) -Improves machinability but lowers toughness.

Tungsten (W) -Increases strength, hardness & toughness.

Vanadium (V) -Increases strength, hardness and shock (impact) resistance.

-Retards growth.

While the above table is a good primer on steel composition, steel foundries have over the years developed new ways to make steel – from powder metallurgy to exotic friction forging. The elemental composition will only tell you so much, and at the end of the day, you will have to go with your own experiences on top of the information floating around the internet when ascertaining the viability of a specific steel for your given purpose, especially considering the ridiculous amount of hype on various forums whenever something new is introduced to the market. Being a cynic is strongly recommended these days.

HOW TO CHOOSE A BLADE STEEL

The core attributes you will want to use when categorizing steels are the following;

ATTRIBUTE #1: EDGE RETENTION & STABILITY

Ability to hold an acute edge. This is probably the most important metric if you consider a knife’s core purpose to cut. When discussing steels and super steels, the measuring rod is usually based on edge retention. Check out the excellent testing by Jim Ankerson concerning edge retention of the current crop of modern steels at their respective hardness.

ATTRIBUTE #2: DUCTILITY

The ability to flex under load without fracturing. Not necessarily tied with toughness, as a filleting knife needs to have high ductility without needing to be tough.

ATTRIBUTE #3: TOUGHNESS

The ability for a steel to absorb impact before fracturing under stress. A good example of a tough steel is S7 tool steel. Note: toughness is not at all the same thing as hardness. In fact, many times the hardest steels are not the toughest, as the hardest steels will fracture under stress much easier than slightly softer steels.

-39%

-39%

Spyderco Pacific Salt black FRN H-1 black Blade PlainEdge

Price: $85.49

Was: $139.95

If you work near salt water or live in a high humidity area (looking at you Florida!) then corrosion resistance will probably matter a great deal to you. Stainless steel is generally considered to be a steel with 13% or more of chromium. As per the name, stainless only means it is resistant to staining (i.e. “stain less” not “stain free”). Stainless steel can still rust under the right conditions. If you are having issues with stainless steel, and want something that’s basically rust proof (not merely stainless), then check out blades made out of H1 steel (example: the Spyderco Salt series knives, like the Pacific Salt) and X15TN (example: this version of the Benchmade Pardue). Blades made out of these steels will be an optimal choice for high humidity areas.

ATTRIBUTE #5: ROCKWELL HARDNESS

Some manufacturers chose not to harden steel to optimal levels for edge retention. Some do this due to lack of manufacturing tolerances, others because they prefer to heat treat a knife to the lower end of the hardness scale so that it can handle higher levels rough use and thus do not have to budget for more returns under warranty. Whatever the reason, it’s important to note that CPM S30V from Spyderco (used for the Paramilitary 2) will have marked difference compared to CPM S30V from Kershaw (used for this version of the Kershaw Blur); so don’t go looking at the steel type exclusively without doing your due diligence.

MY COMPENDIUM OF STEELS

Before we get to the nitty gritty, I want to explain my choice to not use numerical values in my tables. I do not wish to use loosely defined metrics such as “7.5 out of 10 edge holding” or any other derivative metric due to the shifts in the steel landscape over time. To use a metric today would mean that in 10 years time, that metric would no longer be accurate, as the ceiling gets pushed higher and higher over time. Consider that 30 years ago, 440C was considered a premium steel!

As a result, here I’ve used metrics (ambiguously) that I think will stand the test of time: the name, general purpose of the steel, and ease of sharpening.

My list is not exhaustive. If you want a digital spread sheet of all steels and their compositions, check out the zknives steel chart!

Concerning edge retention and toughness, for further research you may want to consult charts from credible third party sources, as well as rankings from respected aficionados like Frank R.and Jim Ankerson. You’ll also find the world of performance cutlery interesting if you’re looking for a more exhaustive analysis; if this strikes your fancy, check out the detailed work of Cliff Stamp here and the CATRA testing results here.

And finally, if you want me to add a steel that’s not listed below, please just leave a comment and I will get to it (even if it’s not suggested I will update these tables with more steels as time allows).

COMMON STAINLESS BLADE STEELS

Steel Name Type Ease of Sharpening

CPM S90V High Edge Retention Very Hard

M390 High Edge Retention Very Hard

ZDP-189 High Edge Retention Very Hard

Elmax General use (Premium) Hard

CTS-XHP General use (Premium) Hard

CPM S35VN General use (Mainstream) Moderate

CPM S30V General use (Mainstream) Moderate

CPM 154 General use (Mainstream) Moderate

154CM General use (Mainstream) Moderate

ATS-34 General use (Mainstream) Moderate

D2 *Semi-Stainless General use (Mainstream) Moderate

VG-10 General use (Budget) Easy

H1 Marine use (Rust Proof) Easy

X15TN Marine use (Rust Proof) Easy

N690 General use (Mainstream) Easy

440C General use (Budget) Easy

AUS-8 General use (Budget) Easy

CTS-BD1 General use (Budget) Easy

8Cr13MoV General use (Budget) Easy

14C28N General use (Budget) Easy

13C26 General use (Budget) Easy

12C27 General use (Budget) Easy

420HC General use (Budget) Extremely Easy

440A General use (Budget) Extremely Easy

AUS-6 General use (Budget) Extremely Easy

COMMON CARBON BLADE STEELS

Steel Name Type Ease of sharpening

CPM M4 General use (Premium) Moderate

D2 *Semi-Stainless General use (Mainstream) Moderate

INFI *Semi-Stainless Toughness (Premium) Moderate

M2 General Use (Mainstream) Moderate

Carbon V General use (Mainstream) Moderate

5150 Toughness Easy

1050 Toughness Easy

1075 General use (Budget) Easy

1095 General use (mainstream/budget) Easy

S7 Extreme toughness Easy

W1 General use (Mainstream) Easy

52100 General use (Mainstream) Easy

CPM 3V Toughness Moderate

O1 Toughness Easy

Super Blue General use (Premium) Easy

https://morethanjustsurviving.com/super-steels-for-knives/

ARE KNIFE SUPER STEELS WORTH IT?

October 2, 2014 By Thomas Xavier | Updated: June 18, 2017 53 Comments

After over a decade of being heavily involved in the knife world, not only as a knife user, but as a collector as well, I have found myself completely jaded by the knife industry’s enduring tactic of releasing new steels and declaring them clear upgrades. I am not arguing that there isn’t an actual improvement from steel to steel, but rather that this has been overplayed for the sake of marketing and generating more sales.

When S30V first became mainstream as a high-end cutlery steel, the propaganda machine went full blast and touted it as the end all be all of steels. This prompted its ubiquitous adoption. Is S30V a good steel? Yes. Is it significantly better than S60V, which was its predecessor in the Spyderco Military, for example? No.

I own an ungodly amount of knives, the vast majority of them from high performance companies like Spyderco. The steels used in my knives run the gamut from the “lowly” 8Cr13MoV all the way down to CPM S110V. I’m not saying I’m an expert on metallurgy, but I think I have enough experience with knives to be able to make a somewhat educated post on the value (perceived or otherwise) of super steels.

For the sake of not writing a novel, I will define a super steel by its edge retention as the measuring rod. Plenty of other metrics can be introduced to rank steels, such as tensile strength or corrosion resistance, for instance. Yet for the sake of having a linear upgrade path, I think edge retention is the best method. The reality is that to achieve other characteristics you will always have to sacrifice something. If a steel had amazing toughness, edge retention, and corrosion resistance: manufacturers would be using it for pretty much every knife on the market. A knife is defined by its primary function as a cutting tool. This is important because a steel with high tensile strength does not necessarily make a good knife. A good example would be the 300 series of stainless steel – good luck breaking them, but edge retention will be almost non-existent, hence, not good knives. Tough steels like 5160 are middle-of-the-road in many tests as a consequence of being utilized for a cutting tool whilst emphasizing toughness (you can’t have your cake and eat it), and as such, do not qualify as super steels.

RARE SUPER STEELS

- Vanax 75

- REX 121

- CPM – S110V

- CPM – S90V

- CPM – M4

- CTS – 20CP

- CTS – 204P

- M390

- ZDP 189

- CTS – XHP

- Hitachi Super Blue

- CPM – S30V

- VG-1

- D2

- Elmax

- N690

- 154CM

- ATS – 34

- 420HC

- 8Cr13MoV

- 13C26N

- 440C

- 14C28N

A friend of mine works in drywall and his EDC of choice is a Kershaw Volt SS with 8Cr13MoV. It’s been beaten to pieces, but functionally it works. For a supposedly “mediocre” steel, I gotta say, it holds up damn well. Objectively speaking, I will always pick a super steel over a “regular” steel if I have the choice, and that’s, again, purely because I am a giant nerd: it’s not because having a super steel is a functional necessity. The problem is that people mistake this fascination most of us seem to have with super steels as meaning super steels are objectively better than other steels when it comes down to improvement of knife function, and that isn’t actually true. Remember when people freaked out about CPM S35VN? Based on just a few negative opinion user reports, the entire community seemed to rip the steel to pieces, proclaiming to have “noticed” sub par performance.

Listen, if you want to know for sure whether super steels are worth it: get off the internet forums and start using your damn knives! In regular use, I can’t actually tell the difference between S30V and S35VN, and I doubt you can either! Unless I am doing a regulated cut test, using consistently uniform abrasive materials and a lot of whisky to get me through such a boring test, I’m just not going to notice a difference.

The reality is that the “super” part is pretty much all in our heads. It’s like when people have a serious problem with the Kershaw Emerson CQC-6K purely because it’s made in China with an average blade steel. I can’t get over how biased this is, especially considering it’s pretty much the best knife you can buy for under $200, and it costs like $30. Can you actually tell the difference between a super steel and 8cr13MoV in everyday use? No (and be honest here – I know you can’t). So my question for you is, then why do you care?

There is nothing wrong with always seeking the best, but when the knife industry takes note of our obsession with super steel and begins capitalizing on the nonsense by releasing folders with Cruwear blades (why?!) and small EDC fixed blades with CPM 3V steel, you’ve got to admit we all have a problem. These kinds of knives are absurd, and quite frankly go against all sense of logic and reason. But they’re on the market! And it’s all because the lot of us are super steel addicts.

At the end of the day, advertising exists because it works. Try to resist the endless deluge of the latest generation steels that can cut atoms and pry open tanks, and instead focus on knives with consistent heat treating, good edge geometry, and a steel that suits its intended application. That means going for a tough steel like CPM 3V for a chopper, an edge retention focused steel like CPM S30V for your folders, and a super stainless steel like H1 or X15TN for your marine-use blades.

To reiterate, I am not saying that supersteels don’t have their place. What I’m saying is, no matter the steel, if the knife is badly made, it will still be bad. The crux of the matter is that, while I’d always choose a super steel over an average blade steel, I’m not turning down a knife just because it’s not offered with a super steel blade steel. And if you would turn down a great knife simply because it’s blade isn’t a super steel – well I really think you need to reassess your priorities when it comes to knives.

If you insist on having the toughest EDC knife possible, I can make you a 5/8 inch thick, 302 stainless steel, full convex 5 inch fixed blade for a mere $700. Edge retention is good enough to open at least 1 parcel guaranteed. Email to order.