I got a call from a guy I built a 406 SBC engine for his, 1985 corvette about 25 years ago.

he asked me to stop by and diagnose, a persistent, and annoying ,tuning issue he was having problems isolating.

he had purchased a new cam & lifter set as he was convinced the issue was related to a badly worn cam.

I brought a scanner and multi-meter.

about 15 minutes of testing showed it was a problem related to a failed TPS sensor (needed to be replaced)

a maf SENSOR THAT WAS HIGHLY SUSPECT,

and a badly corroded connector on the IAC and a bad plenum heat sensor. (mat)

the OXYGEN exhaust sensor was suspect ,

as it was not reading correctly so that was also replaced.

a trip to the local NAPA store and him having a credit card handy,

the MAF sensor needed to be ordered the sensors were in stock,

THE NAPA STORE,provided the required sensors.

he was convinced it was the cam, until we replaced and adjusted the indicated sensors ,

and the car ran far better than he remembered it doing in years.

once those issues, were corrected,

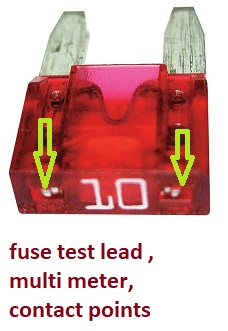

YOU NEED A MULTI METER

the cars owner was amazed at how well the engine ran,

and after I adjusted the valves it ran even better!

the point here is you never assume,

you need to carefully test every sensor,

you need to verify fuel pressure and all electrical contacts,

and use a vacuum /pressure gauge to verify exhaust back pressure.

I was surprised he had previously removed his catalytic converter,

so that was one area that was not a factor,

but he stated it had become partly clogged about 12 years earlier

simply checking fuel pressure using a multi meter and not assuming you know the answers before the facts are verified , helps a great deal.

without pulling trouble codes and testing your simply guessing at best,

break the issue down into separate issues,

check ignition strength and timing,and voltage

check fuel supply/delivery pressure and volume

check cam timing and cylinder compression.

check valve train control and valve adjustment

check firing order and spark plug gap

check the valve lift, and for work lobes

check for vacuum leaks

adjust your iac and tps

check your exhaust back

pressure

verify sensors correct function

https://www.harborfreight.com/catal...core,f,EAFeatured+Weight,f,Sale+Rank,f&q=zr13

if you purchase a ZR13 auto code scanner, from HF,

you need this info

DOWN-LOAD AND PRINT IT OUT!

https://manuals.harborfreight.com/manuals/63000-63999/Q63806.pdf

https://manuals.harborfreight.com/manuals/63000-63999/63806.pdf

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times, don,t get overwhelmed , break everything down too easy individual problems and tests, verify and test all the sensors,and test for factors like consistent fuel pressure, known temps,expected voltage or ohms resistance, and vacuum readings and don,t randomly start replacing parts as that gets expensive and its rarely the most efficient way to eliminate problems(unless you get really lucky) with modern computer diagnostic software you,ll have some advantages but think logically, most automotive problems still concern, loose electrical connectors, defective sensors, lack of compression, fuel delivery issues ,fuel pressure, vacuum, temperature or electrical issues.

http://www.helminc.com/helm

the correct matching SHOP MANUAL

TIMING LIGHT

IR TEMP GUN

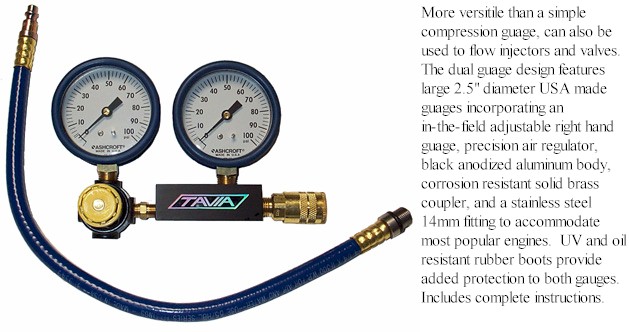

VACUUM GAUGE

MULTI METER

FUEL PRESSURE GAUGE

COMPRESSION TEST GAUGE

keep in mind the basics you need to verify the fuel pressure is at about 40 psi if your dealing with a C4 corvette,

you should NOT have significant exhaust back pressure, clogged catalytic converters,

are a common problem on older c4 corvettes,

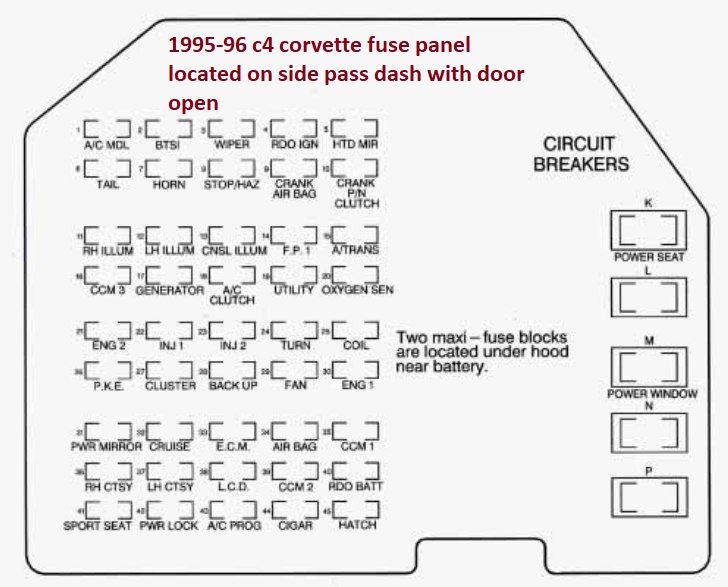

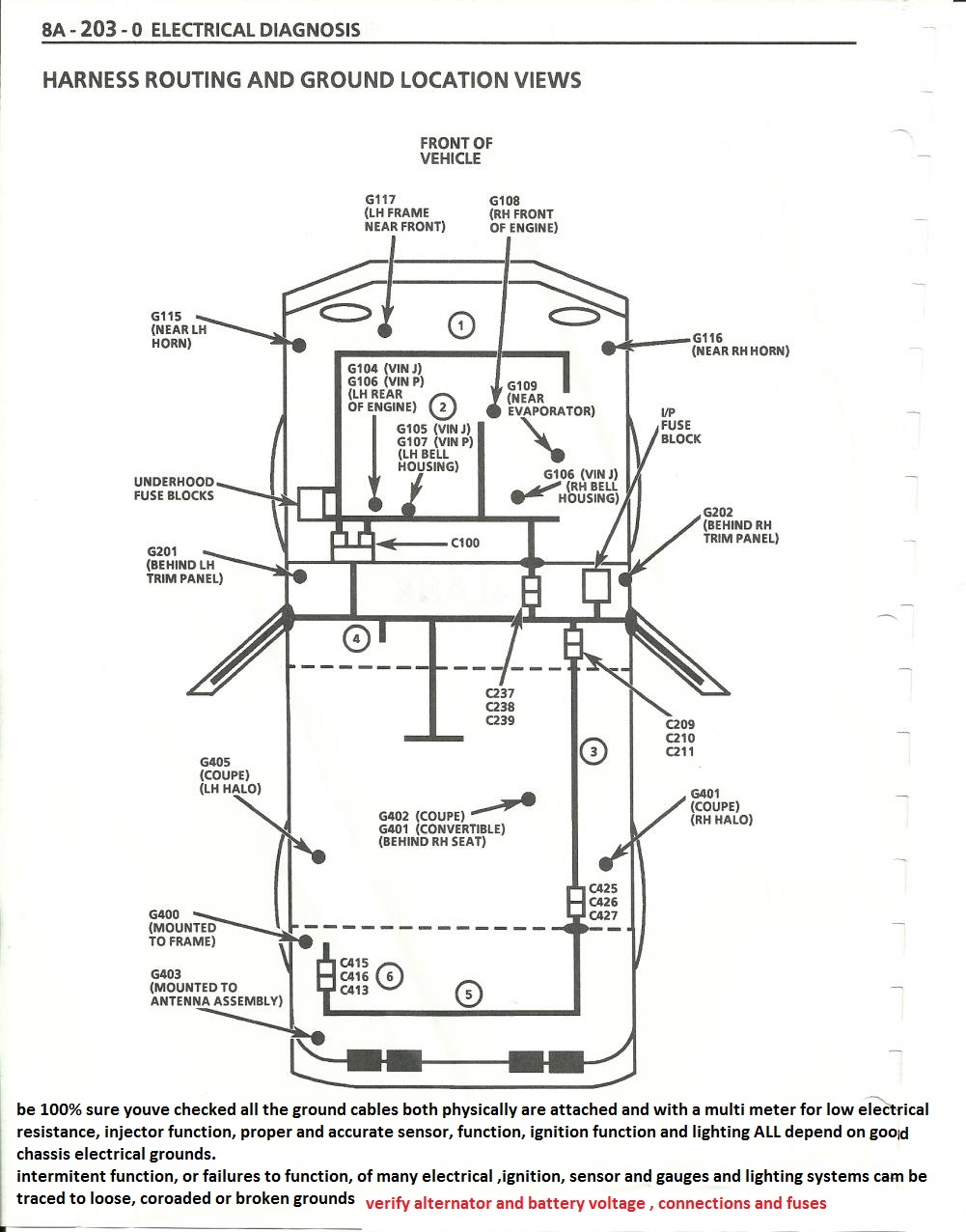

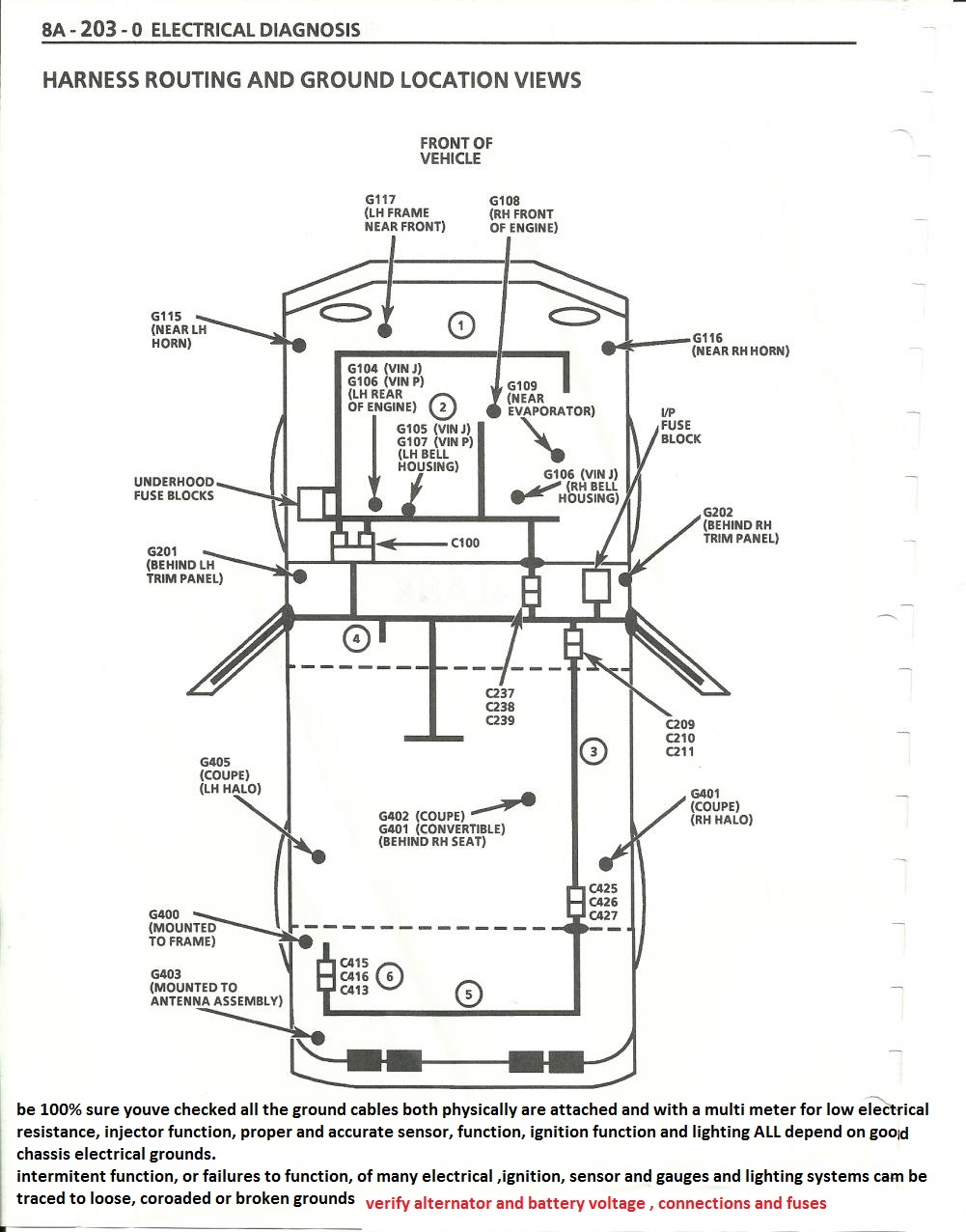

verify the fuses are not blown, the trouble codes do not show any problems,

all electrical grounds are reading good,

verify theres at least 14.5 volts at the battery while its running, so you know the alternator functions,

and all the injectors are functional with a noid light,

all cylinders should read within 10% and show about 150 psi or greater.,

on a compression test, verify the firing order,

set the spark plug gaps at .045 ,

and verify all the listed sensor values,

verify the cam lobes are not worn, verify you have at least 10 psi of oil pressure per 1000 rpm.verify theres no vacuum leaks

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

viewtopic.php?f=55&t=109

you might have clogged catalytic converters, the ignition timing may be way off, you might have a worn out cam, the fuel pump may be defective, some injector(s) may be defective,check the alternator out-put check the fuel rail pressure use a noid light on the injector wiring, check the fuses,

Ive found that the one most commonly over looked in my experience is that the stock exhaust system, is highly restrictive, especially if the catalytic converters are partly plugged and the stock fuel delivery system is not adequate,for the potential power, the heads and intake, allowable air flow potential, are all restrictive, and the stock cam timing and lift is already near max as it was designed to produce about 260 hp,and operate at under 5700 rpm, if you try too add an additional 100-200 hp, and 1000 rpm-2000 rpm to the engines power band, and too the engines output youll quickly find this to be a factor.

I've also occasionally seen guys, improperly index or install a cam without degreeing it in correctly and thus have power band limitations.

Id suggest you buy a factory shop manual, multi meter and a timing light, fuel pressure and vacuum gauge and start checking.

reading these links will be helpful

yes I know it will take some time and effort to isolate and test

but its the only 100% sure route to finding and fixing your problem,

don,t get over whelmed,

simply break the problem down to testing each basic sub system,

test each related sensor and electrical component and electrical sensor and connection.

some reading on the threads posted below, a bit of logic and deductive reasoning, and a multi meter and a shop manual will go a long way toward finding and fixing the problem.

READING RELATED THREADS THAT MIGHT BE , VERY HELPFUL

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.com/index.php?threads/help-i-cant-take-it-anymore.14805/#post-81769

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/#post-82331

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-72181

http://garage.grumpysperformance.com/index.php?threads/c3-c4-corvette-vacuum-diagrams.1773/

http://garage.grumpysperformance.co...-stock-tpi-engine-components.1509/#post-10159

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.co...s-cause-a-bad-idle-in-drive.14203/#post-72114

http://garage.grumpysperformance.co...ckpressure-hurting-your-combo.495/#post-22402

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.com/index.php?threads/basic-trouble-shooting-on-the-c4.302/

http://garage.grumpysperformance.co...t-of-logic-to-locate-a-problems-source.14297/

http://garage.grumpysperformance.com/index.php?threads/can-this-cause-a-bad-idle-in-drive.14203/

http://garage.grumpysperformance.com/index.php?threads/c-4-exhaust-system.1174/

http://garage.grumpysperformance.com/index.php?threads/1991-c4-runs-like-crap.10616/

this infos bound to be helpful at times

Sensor Locations

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

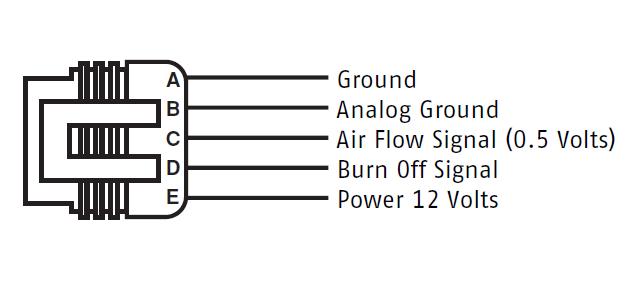

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

TPS (Throttle Position Sensor). Right side of throttle body at the front.

Sensor Outputs:

Sensor

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle.

BTW

the engine was rather basic, and in the last 25 years he put only about 70K miles on the corvette.

he had me help build him, a 406, with about 10:1 compression,

a basic crane 114142 cam, he had insisted at the time that he wanted noticeably better power but something he could use as a daily driver,

https://www.jegs.com/i/Crane-Cams/271/114142/10002/-1

dart 200cc heads, headers, 1.6:1 roller rockers and 32lb injectors

a ported stock style edelbrock, TPI intake

he has a manual transmission and 3.36:1 rear gears

and hooker headers on the car.

with the slightly improved edelbrock base and runners

he asked me to stop by and diagnose, a persistent, and annoying ,tuning issue he was having problems isolating.

he had purchased a new cam & lifter set as he was convinced the issue was related to a badly worn cam.

I brought a scanner and multi-meter.

about 15 minutes of testing showed it was a problem related to a failed TPS sensor (needed to be replaced)

a maf SENSOR THAT WAS HIGHLY SUSPECT,

and a badly corroded connector on the IAC and a bad plenum heat sensor. (mat)

the OXYGEN exhaust sensor was suspect ,

as it was not reading correctly so that was also replaced.

a trip to the local NAPA store and him having a credit card handy,

the MAF sensor needed to be ordered the sensors were in stock,

THE NAPA STORE,provided the required sensors.

he was convinced it was the cam, until we replaced and adjusted the indicated sensors ,

and the car ran far better than he remembered it doing in years.

once those issues, were corrected,

YOU NEED A MULTI METER

the cars owner was amazed at how well the engine ran,

and after I adjusted the valves it ran even better!

the point here is you never assume,

you need to carefully test every sensor,

you need to verify fuel pressure and all electrical contacts,

and use a vacuum /pressure gauge to verify exhaust back pressure.

I was surprised he had previously removed his catalytic converter,

so that was one area that was not a factor,

but he stated it had become partly clogged about 12 years earlier

simply checking fuel pressure using a multi meter and not assuming you know the answers before the facts are verified , helps a great deal.

without pulling trouble codes and testing your simply guessing at best,

break the issue down into separate issues,

check ignition strength and timing,and voltage

check fuel supply/delivery pressure and volume

check cam timing and cylinder compression.

check valve train control and valve adjustment

check firing order and spark plug gap

check the valve lift, and for work lobes

check for vacuum leaks

adjust your iac and tps

check your exhaust back

pressure

verify sensors correct function

https://www.harborfreight.com/catal...core,f,EAFeatured+Weight,f,Sale+Rank,f&q=zr13

if you purchase a ZR13 auto code scanner, from HF,

you need this info

DOWN-LOAD AND PRINT IT OUT!

https://manuals.harborfreight.com/manuals/63000-63999/Q63806.pdf

https://manuals.harborfreight.com/manuals/63000-63999/63806.pdf

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times, don,t get overwhelmed , break everything down too easy individual problems and tests, verify and test all the sensors,and test for factors like consistent fuel pressure, known temps,expected voltage or ohms resistance, and vacuum readings and don,t randomly start replacing parts as that gets expensive and its rarely the most efficient way to eliminate problems(unless you get really lucky) with modern computer diagnostic software you,ll have some advantages but think logically, most automotive problems still concern, loose electrical connectors, defective sensors, lack of compression, fuel delivery issues ,fuel pressure, vacuum, temperature or electrical issues.

http://www.helminc.com/helm

the correct matching SHOP MANUAL

TIMING LIGHT

IR TEMP GUN

VACUUM GAUGE

MULTI METER

FUEL PRESSURE GAUGE

COMPRESSION TEST GAUGE

keep in mind the basics you need to verify the fuel pressure is at about 40 psi if your dealing with a C4 corvette,

you should NOT have significant exhaust back pressure, clogged catalytic converters,

are a common problem on older c4 corvettes,

verify the fuses are not blown, the trouble codes do not show any problems,

all electrical grounds are reading good,

verify theres at least 14.5 volts at the battery while its running, so you know the alternator functions,

and all the injectors are functional with a noid light,

all cylinders should read within 10% and show about 150 psi or greater.,

on a compression test, verify the firing order,

set the spark plug gaps at .045 ,

and verify all the listed sensor values,

verify the cam lobes are not worn, verify you have at least 10 psi of oil pressure per 1000 rpm.verify theres no vacuum leaks

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

viewtopic.php?f=55&t=109

you might have clogged catalytic converters, the ignition timing may be way off, you might have a worn out cam, the fuel pump may be defective, some injector(s) may be defective,check the alternator out-put check the fuel rail pressure use a noid light on the injector wiring, check the fuses,

Ive found that the one most commonly over looked in my experience is that the stock exhaust system, is highly restrictive, especially if the catalytic converters are partly plugged and the stock fuel delivery system is not adequate,for the potential power, the heads and intake, allowable air flow potential, are all restrictive, and the stock cam timing and lift is already near max as it was designed to produce about 260 hp,and operate at under 5700 rpm, if you try too add an additional 100-200 hp, and 1000 rpm-2000 rpm to the engines power band, and too the engines output youll quickly find this to be a factor.

I've also occasionally seen guys, improperly index or install a cam without degreeing it in correctly and thus have power band limitations.

Id suggest you buy a factory shop manual, multi meter and a timing light, fuel pressure and vacuum gauge and start checking.

reading these links will be helpful

yes I know it will take some time and effort to isolate and test

but its the only 100% sure route to finding and fixing your problem,

don,t get over whelmed,

simply break the problem down to testing each basic sub system,

test each related sensor and electrical component and electrical sensor and connection.

some reading on the threads posted below, a bit of logic and deductive reasoning, and a multi meter and a shop manual will go a long way toward finding and fixing the problem.

READING RELATED THREADS THAT MIGHT BE , VERY HELPFUL

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.com/index.php?threads/help-i-cant-take-it-anymore.14805/#post-81769

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/#post-82331

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-72181

http://garage.grumpysperformance.com/index.php?threads/c3-c4-corvette-vacuum-diagrams.1773/

http://garage.grumpysperformance.co...-stock-tpi-engine-components.1509/#post-10159

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.co...s-cause-a-bad-idle-in-drive.14203/#post-72114

http://garage.grumpysperformance.co...ckpressure-hurting-your-combo.495/#post-22402

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

http://garage.grumpysperformance.com/index.php?threads/basic-trouble-shooting-on-the-c4.302/

http://garage.grumpysperformance.co...t-of-logic-to-locate-a-problems-source.14297/

http://garage.grumpysperformance.com/index.php?threads/can-this-cause-a-bad-idle-in-drive.14203/

http://garage.grumpysperformance.com/index.php?threads/c-4-exhaust-system.1174/

http://garage.grumpysperformance.com/index.php?threads/1991-c4-runs-like-crap.10616/

this infos bound to be helpful at times

Sensor Locations

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

TPS (Throttle Position Sensor). Right side of throttle body at the front.

Sensor Outputs:

Sensor

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle.

BTW

the engine was rather basic, and in the last 25 years he put only about 70K miles on the corvette.

he had me help build him, a 406, with about 10:1 compression,

a basic crane 114142 cam, he had insisted at the time that he wanted noticeably better power but something he could use as a daily driver,

https://www.jegs.com/i/Crane-Cams/271/114142/10002/-1

dart 200cc heads, headers, 1.6:1 roller rockers and 32lb injectors

a ported stock style edelbrock, TPI intake

he has a manual transmission and 3.36:1 rear gears

and hooker headers on the car.

with the slightly improved edelbrock base and runners

Last edited: