\

2/8

While not exactly a subtle-looking '91 from the outside due to the exterior body kit and 3-inch raised hoodscoop, Cleon Stull's Corvette hides a big punch: a 509ci big-block engine.

It doesn't really take the proverbial shoehorn to install a big-block Chevy in a C4 Corvette. What it really takes is talent and an eye for details. But it doesn't hurt if you're a tool-and-die maker like Cleon Stull of Frederick, Maryland.

Stull's garage has provided shelter for many Corvettes in the past, including a '65 roadster and '86 and '96 coupes. Currently, he owns a '91 ZR2 coupe, a '72 454ci convertible, and an '01 convertible. But, even with all those interesting Corvette configurations, Cleon was looking for something a little uncharacteristic, a car that no one else had. The solution: build a big-block C4 Corvette.

For those not versed in the intricacies of such a swap, let us assure you that the challenge is very real. Our resident engineering expert, Chris Petris of The Corvette Clinic, (see sidebar), will attest to the difficult modifications that are required. But for Cleon, his apparent satisfaction with the final effort validates the old adage: Anything worth doing is worth doing well.

Cleon started with a well-worn '91 Corvette he found on the Internet. While the body was clean, the paint was tired. He installed a Side Effects body kit and applied Twilight Royal Purple paint. Inside, Cleon added saddle leather upholstery but retained the stock configuration for all other components.

3/8

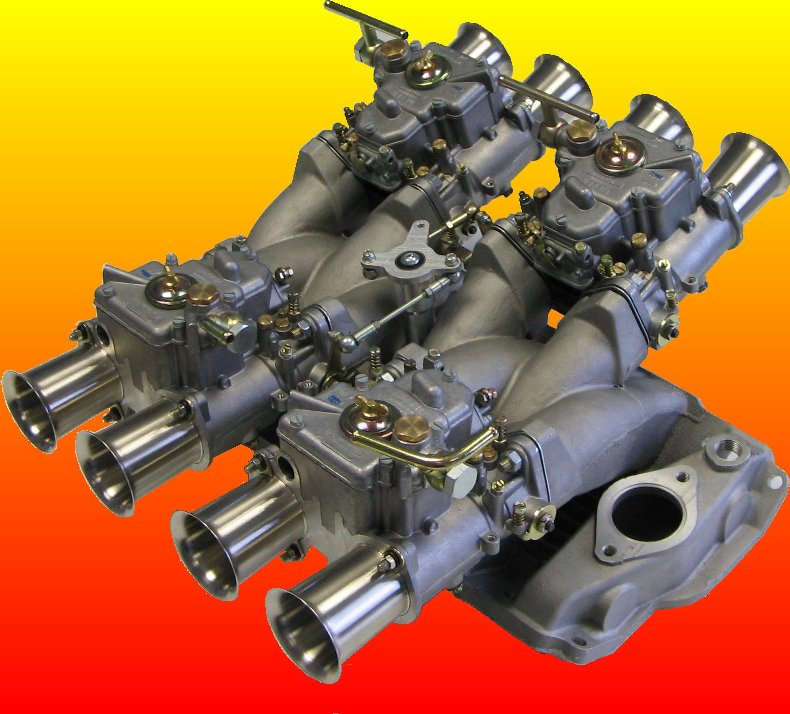

The 509ci engine has been modified with a number of high-performance parts including Edelbrock cylinder heads and intake system, Lunati rods, pistons and camshaft, and a Comp Cams rocker system.

Clearly, the biggest changes occurred underhood. The 509ci engine (built by Jeff Bane of County Engine) features a host of horsepower improvements including Lunati rods and camshaft (0.578-inch intake lift, 0.595-inch exhaust lift), and Comp Cams rocker arms. Compression is 10:1, courtesy of Lunati pistons and Edelbrock cylinder heads.

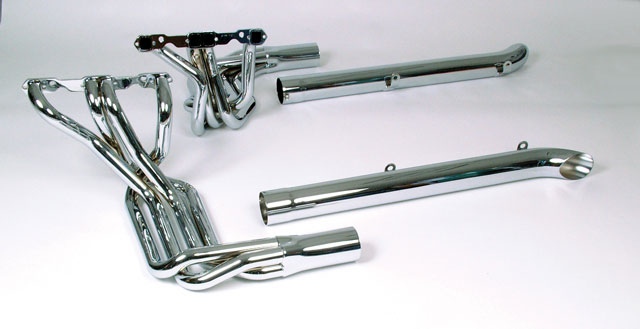

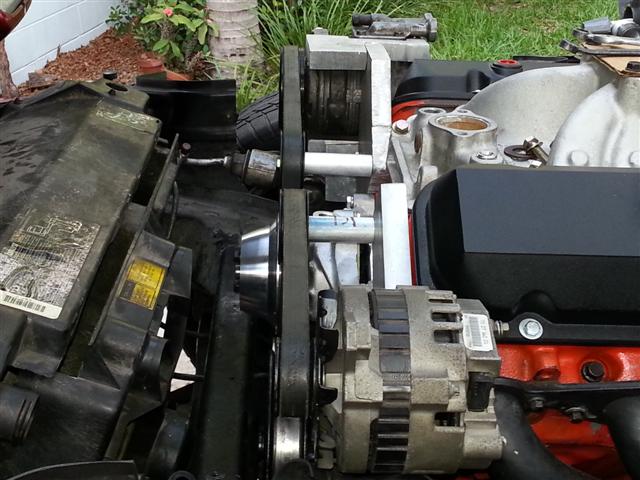

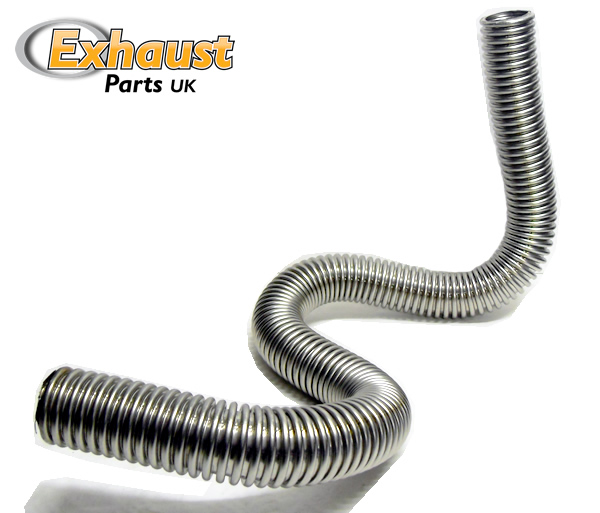

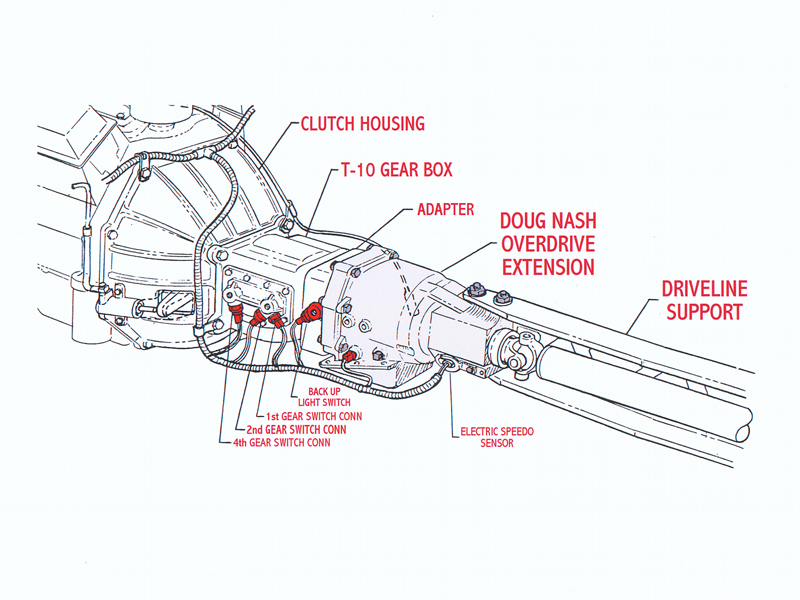

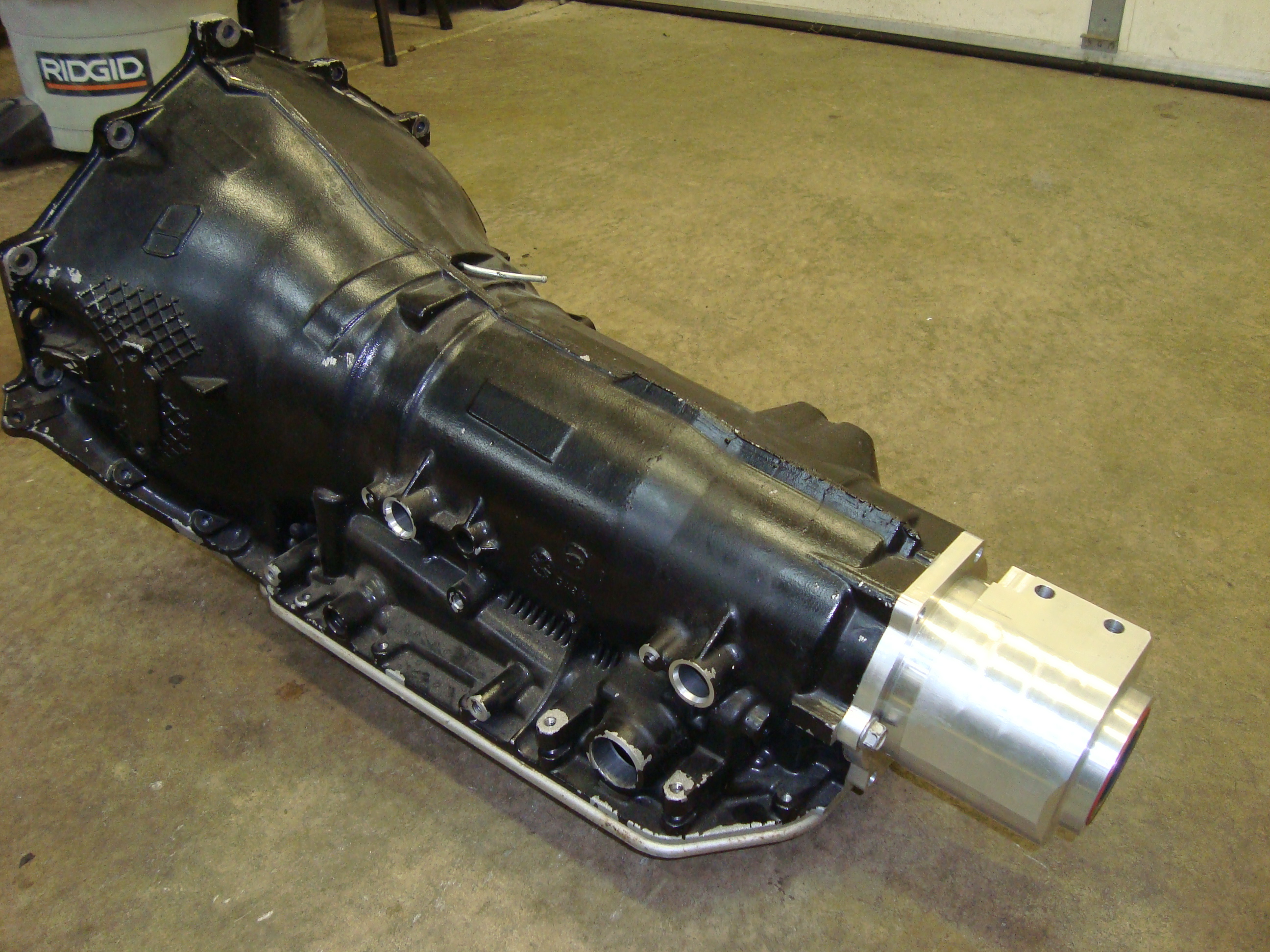

An Edelbrock Performance intake and a Pro-Flo EFI unit provide the induction, while customized Hedman headers show exhaust gases the way out, complemented by 3-inch-wide stainless steel tubing and Lawrence-Keech mufflers. Cleon machined his own distributor to clear the firewall, and added an HEI electronic distributor. The huge power is transferred to the rear tires through a manual six-speed transmission controlled by a B&M Ripper shifter.

While the car logged 140,000 miles previous to Cleon's ownership, the current configuration is still in shakedown mode with only 500 miles so far. Regardless, Cleon has great confidence in the abilities of his engineering. He, along with technical consultant Bob Loch, have engineered a seemingly bulletproof combination. So well built is the car that we suggested Cleon offer a prepackaged kit so that other Corvette owners could re-create his efforts.

No doubt, a shoehorn will not be part of the package.

4/8

The interior of the '91 is very much as the factory delivered, with the exception of saddle-leather seating and the B&M Ripper shifter to command the six-speed manual transmission.

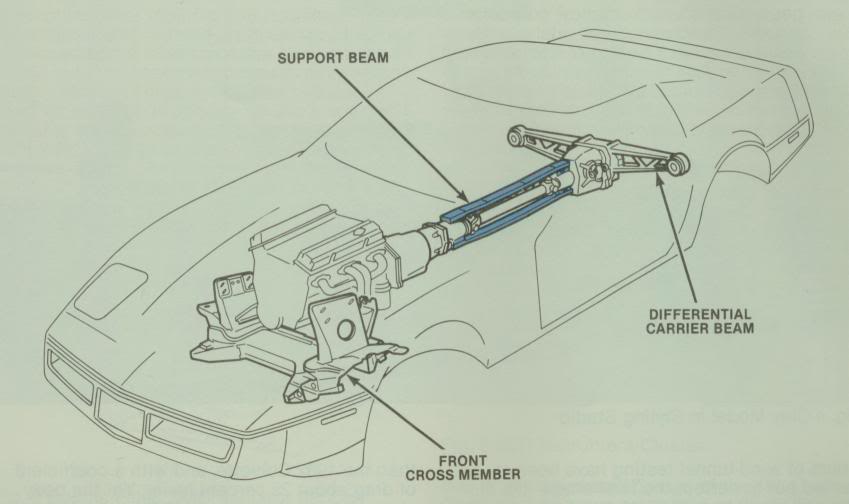

There are two major challenges when attempting to install a big-block into an '84-'96 Corvette. The first is being able to close the hood while preventing the oil pan from hanging dangerously close to the pavement. The second is to retain all the vehicle options we hold so dear.

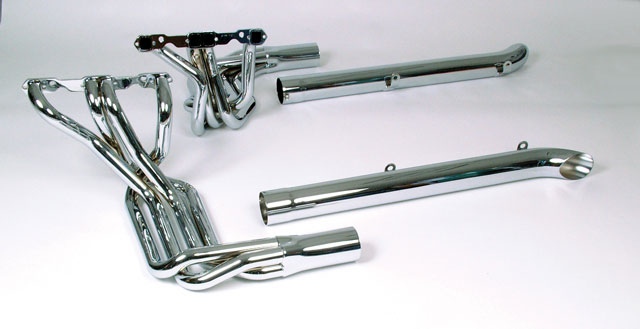

Specifically, the biggest problems are the power-steering pump and air-conditioning compressor, which come close to the lower crossmember, power-steering rack, and chassis brace. This is where Cleon Stull's 509ci effort shines. All of his custom-made accessory brackets were well planned, with adequate bracing. Cleon even designed and created a self-adjusting serpentine-belt tensioner. If you've ever installed an aftermarket accessory such as air conditioning, you know how difficult it can be simply to ensure belt alignment. Cleon did an excellent job of making all the necessary components come together and fit in tight confines.

5/8

The Twilight Royal Purple paint is a unique color for Corvettes, but not shocking since Cleon's big-block machine is full of surprises.

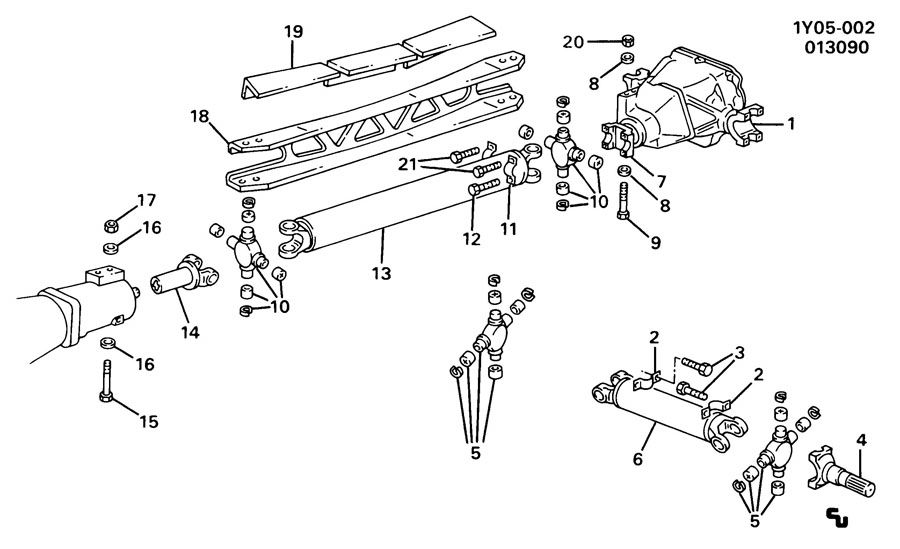

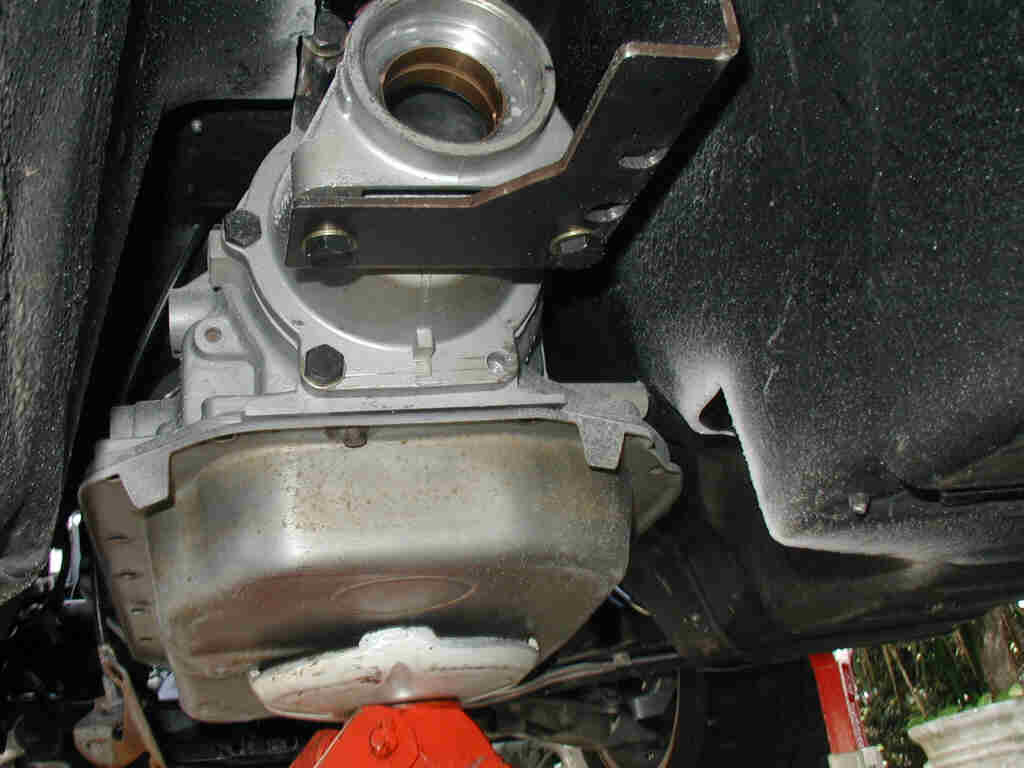

The crossmember, or K-frame, that supports the engine required modification to allow clearance for the lower crankshaft pulley and harmonic balancer. Anytime a crucial chassis component is modified, safety is critical, and it's obvious that Stull went that extra mile. The oil pan is close to the pavement, but clearance is adequate. An engine swap requires a careful balance of engine and component placement.

The air cleaner and air-intake system are also well thought out. Obviously, the clearance between the intake system and hood is minimal. The Edelbrock Pro-Flo fuel system allows adequate fuel control and air filtration with minimal hood rise. The billet ignition distributor built by Cleon shows his attention to detail. He machined a completely new housing for the application, which keeps engine rise to a minimum. It is this kind of elaborate workmanship that's required to ensure proper engine placement and chassis compatibility.

It is obvious that Cleon thought about the project before any wrenches were used, and it paid off with a nice, clean, workable installation of a big-block in his C4. My hat is off to Cleon for a job well done. Happy motoring!

-Chris Petris