Stuart Wall

Member

Let it be known, first and foremost, that this thread is about a E7TE roller short block purchased at a self-service junkyard during a 40% off sale. The fact that it was on sale should help you understand the priorities of the build. It is also the first engine I have ever put a dial indicator on, and the first Ford I have ever built. So, with the experimental nature of this project and full disclosure of my lack of experience, take whatever learning you wish from it at your own risk. If this motor proves to be a dud, or dies in the first 100 miles, I promise to be honest about it.

What: E7TE non HO block, GT40 iron heads, factory HO cam, performer RPM (American casting because I bought an old crusty used one), Holley 600 vacuum secondary, electric ignition and fan. Headers, single 3" exhaust.

Goal: to use 87 or 89 octane, horsepower will be whatever it will be, stock converter, 3.25 gear, C4 trans, 2850 pound car.

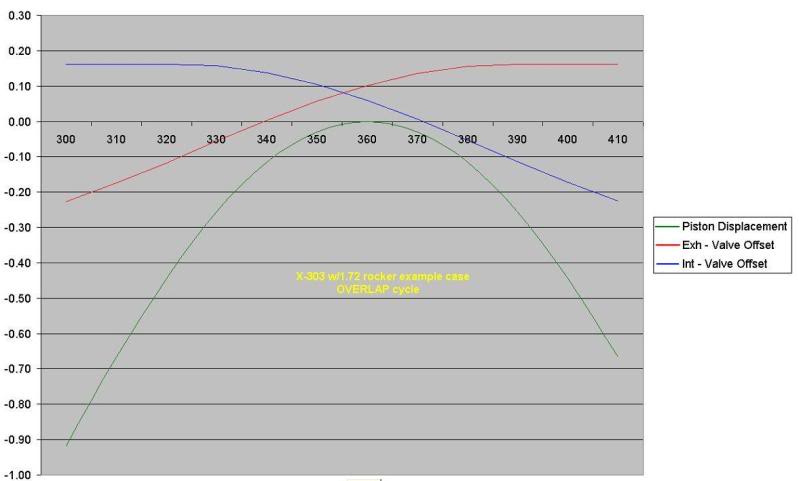

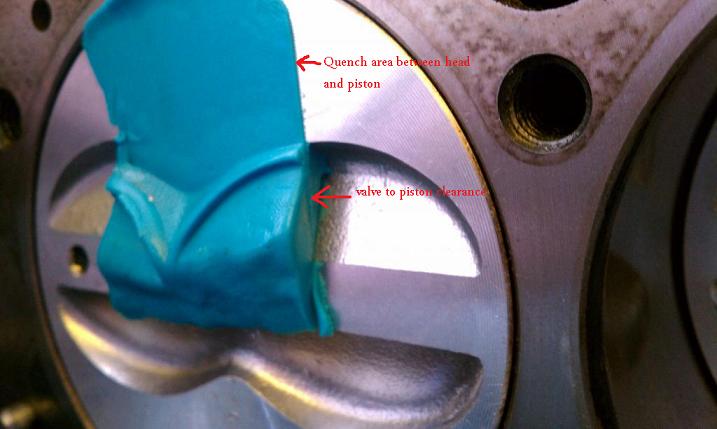

The block is on my engine stand. I am estimating it to have about 150K miles on it. It had a replacement timing chain that was tight, re-built 1978 heads that I left in the junkyard, and cross hatching still visible. The piston tops had no valve reliefs and are .020 out of the hole on one bank, and .015 out on the other. I took it upon myself to create valve reliefs, as there were small dents in 2 pistons. I have also scrounged up a Ford HO cam from a 1995 mustang GT. The cam is installed dot to dot with a new chain + a mechanical fuel pump eccentric. I have also replaced the rod bearings. This is how it sits currently. pictures are not in chronological order.

The heads, GT40 iron, were purchased out of the junkyard 2+ years ago, and were meant for a different engine, but will use them on this. I read a bit about "porting," and many warnings about how easily these can be messed up, but finally decided to do light bowl blending as outlined at http://diyporting.com/ . The valves got lapped in, new seals, and a spring kit. I had .040 milled off the bottom to go from a 65 cc chamber to a 58 cc chamber. I will admit for this application, .040 was probably too much.....but I was under the impression that any block I could find in a junkyard would have pistons below the deck.

My next chore is placing the heads on the block with .055 sheet metal shims and put clay in all 8 cylinders to check clearances and make sure ALL of the valves are in the home made cut outs.

What: E7TE non HO block, GT40 iron heads, factory HO cam, performer RPM (American casting because I bought an old crusty used one), Holley 600 vacuum secondary, electric ignition and fan. Headers, single 3" exhaust.

Goal: to use 87 or 89 octane, horsepower will be whatever it will be, stock converter, 3.25 gear, C4 trans, 2850 pound car.

The block is on my engine stand. I am estimating it to have about 150K miles on it. It had a replacement timing chain that was tight, re-built 1978 heads that I left in the junkyard, and cross hatching still visible. The piston tops had no valve reliefs and are .020 out of the hole on one bank, and .015 out on the other. I took it upon myself to create valve reliefs, as there were small dents in 2 pistons. I have also scrounged up a Ford HO cam from a 1995 mustang GT. The cam is installed dot to dot with a new chain + a mechanical fuel pump eccentric. I have also replaced the rod bearings. This is how it sits currently. pictures are not in chronological order.

The heads, GT40 iron, were purchased out of the junkyard 2+ years ago, and were meant for a different engine, but will use them on this. I read a bit about "porting," and many warnings about how easily these can be messed up, but finally decided to do light bowl blending as outlined at http://diyporting.com/ . The valves got lapped in, new seals, and a spring kit. I had .040 milled off the bottom to go from a 65 cc chamber to a 58 cc chamber. I will admit for this application, .040 was probably too much.....but I was under the impression that any block I could find in a junkyard would have pistons below the deck.

My next chore is placing the heads on the block with .055 sheet metal shims and put clay in all 8 cylinders to check clearances and make sure ALL of the valves are in the home made cut outs.