HEY GRUMPY?

I am thinking of freshening up my 400 in my '73 chevelle and was wondering what you guys think of changing to a set of cast vortec heads from gm? Like the ones from the last 90's trucks and such? This should increase my compression, right, just by switching these heads. I think my original heads are like 78cc or something? This seems like a cheap few extra horses and I don't mind changing the manifold to a vortec style.

Ive had good results in several cars building 406 sbc engines that were designed for brisk street performance (NOT RACING) with a combo like this,the correct answer depends on the cam used and the rpm levels you want to efficiently make power in.

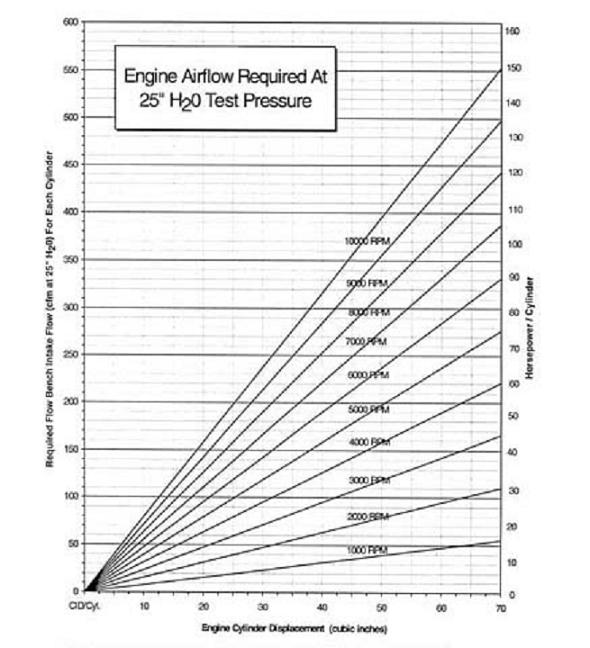

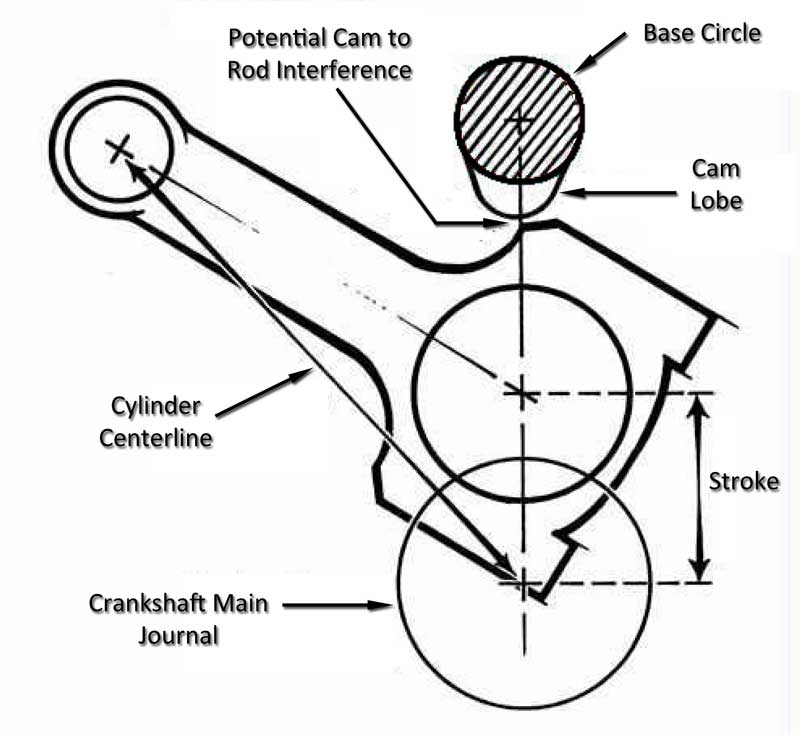

it makes zero sense to put large ports on an engine with a cam that won,t allow the engine to breath at the higher rpm levels the larger ports potentially can provided much greater hp at , just as its silly to throw a huge cam in an engine that can never hope to spin up into the cams power range due to small restrictive ports, you need to think things thru and match components.

with most cars currently equipped with 2.73:1 -3>07:1 rear gears, and power brakes, you really don,t want or need a cam with a good deal of duration to make it lope noticeably at idle, remember ever change you make effects your results

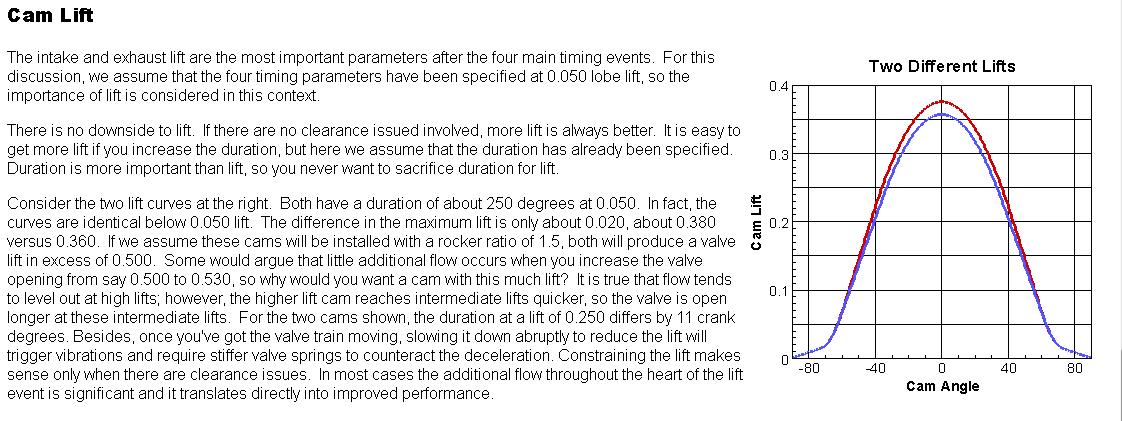

max lift is about .470 with stock vortec heads and having a higher stall speed converter would be almost mandatory if you select a cam with enough duration to make it lope noticeably with that 2.73:1 -3>07:1 rear gear ratio, and power brakes.

now you need to understand what your trying to do, vortec heads are built to maximize torque in the 1500rpm-5000rpm power band so you can,t really use a great big long duration cam or you run into port flow restrictions well before the cams extra duration becomes effective.

first you want to decide on if the cam should be a flat tappet or roller lifter design and if your willing to upgrade the valve train, and converter stall speed and possibly the rear gear ratio.

Yes you can increase hp significantly but it won,t be just a cam alone required

GRUMPY? WHAT WOULD BE A CAM TO USE IN A 350 STOCK WITH VORTEC HEADS ,400 TURBO , LOOKING FOR LOPEY SOUND

AND WHAT IS THE MAX LIFT

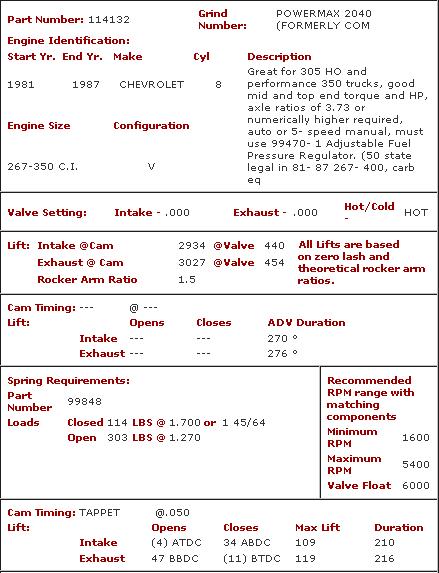

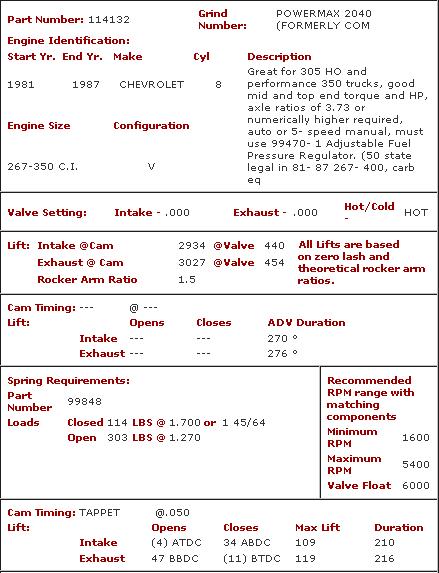

Ive used this in similar combos with decent results, yes I know its not that wild and you think you might just go with a bit more duration and lift...THAT would be a big mistake unless you do other mods, yes IM well aware it says you need a 3.73:1 rear gear ratio , it will work with a stock converter its just not ideal, and works better with a 3.73:1 rear gear ,but it will function and add about 30 peak hp in most engines over the stock cam, but cost you a bit of low rpm torque

NEWER vortec heads require different valve covers that the traditional first gen SBC but there are adapters available to sallow their use, but they cost almost as much or more than many valve covers themselves

http://www.jegs.com/i/JEGS+Performance+ ... 0/10002/-1

ID STRONGLY SUGGEST HAVING A LONG TALK WITH SEVERAL CAM MANUFACTURERS BEFORE YOU PURCHASE A CAM

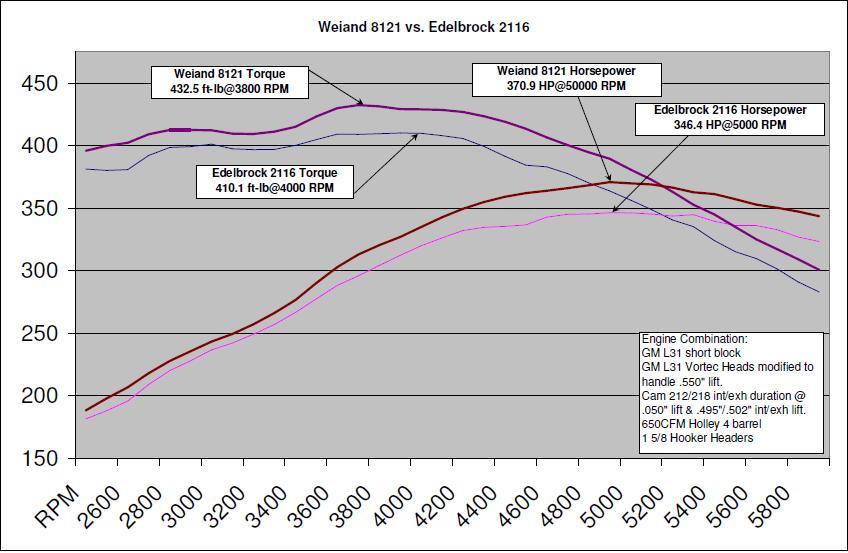

now your results will depend on how well you match components with the power & RPM band you intend to operate in and the compression ratio. vortecs on a 400 make a great combo if your mostly concerned with mid rpm torque and cruising , obviously an over drive trans and a properly matched rear gear ratio that keep the engine below 4500rpm most of the time will help a great deal on a 400 with those vortec heads

(remember to drill steam holes in the heads)

obviously the drive train gearing ,cpr, and cam must match the heads

vortec heads have a port size and cross sectional area that is best matched on a 406 displacement with stock components in the lower engine to make the best power in about the 2400rpm-5500rpm range with about a 9:1 cpr and a cam like this

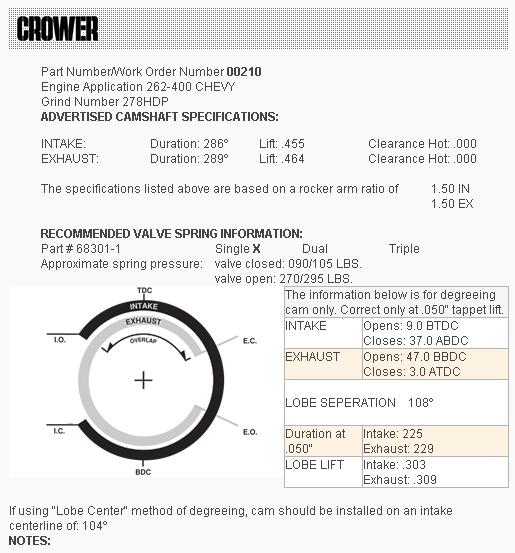

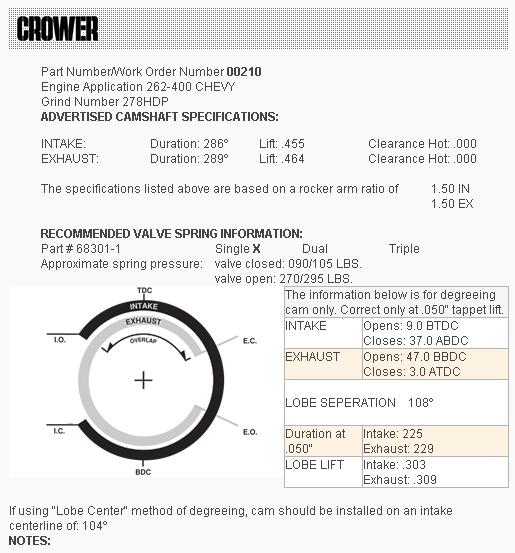

CROWER 00210

a good dual plane intake, like an EDELBROCK RPM AIR GAP, a good HOLLEY 750 VACUUM secondary carb, full length 1 5/8" headers and a manual trans or an auto with about a 2600 stall converter, and in most muscle cars a 3.73:1-4.11:1 rear gear ratio.a good baffled 7 quart oil pan matching your cars frame, will give you that brisk performance on the street but still maintain drive-ability and dependability

obviously if your compression ratio, gearing, converter stall etc does not fall close to this the cam may need to be different

you might want to read thru these links

http://www.kb-silvolite.com/calc.php?action=comp

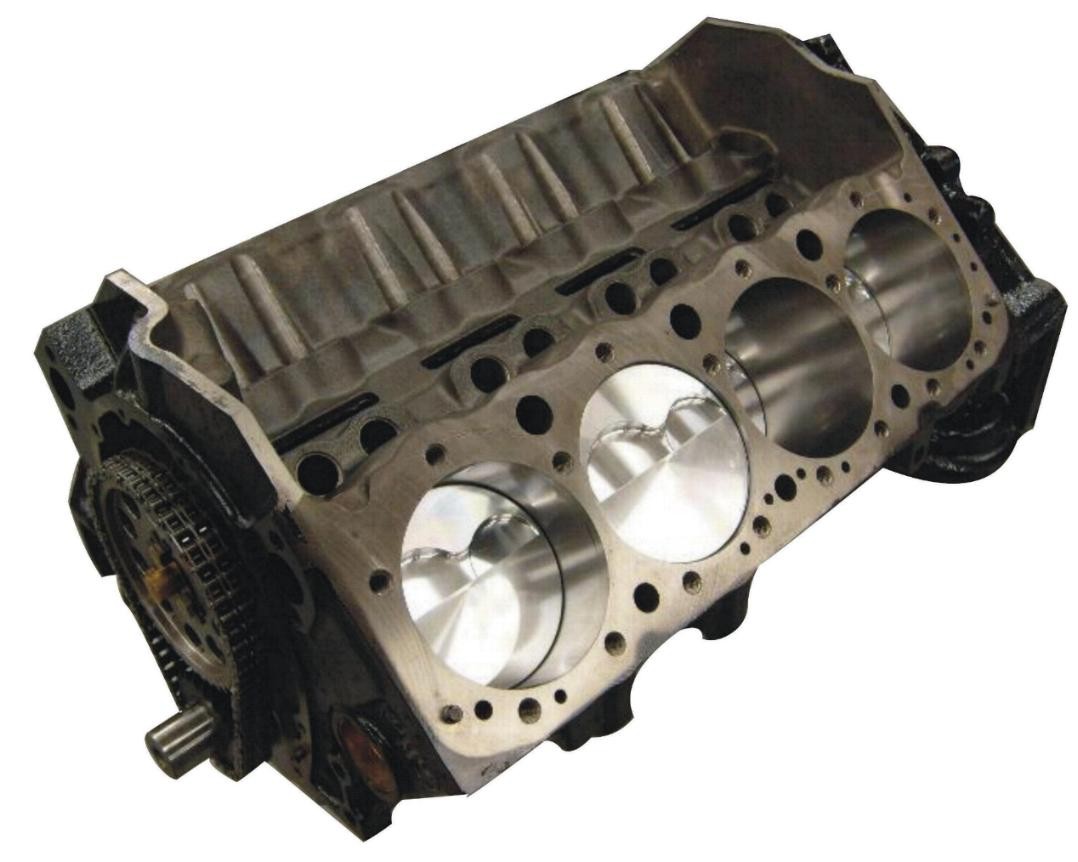

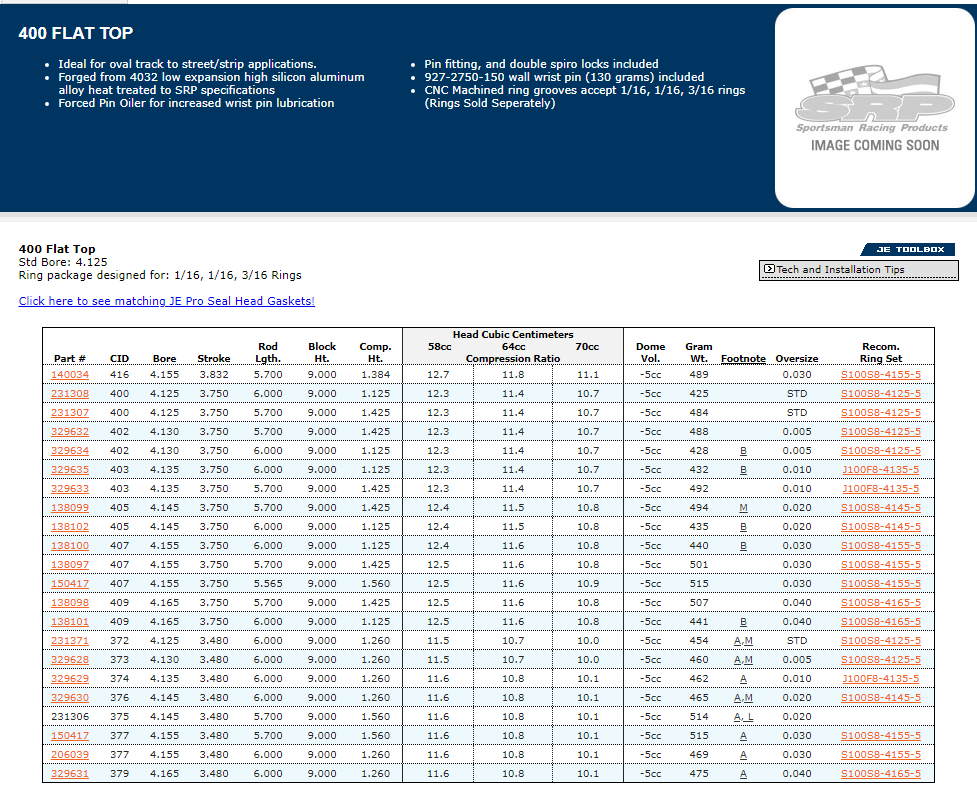

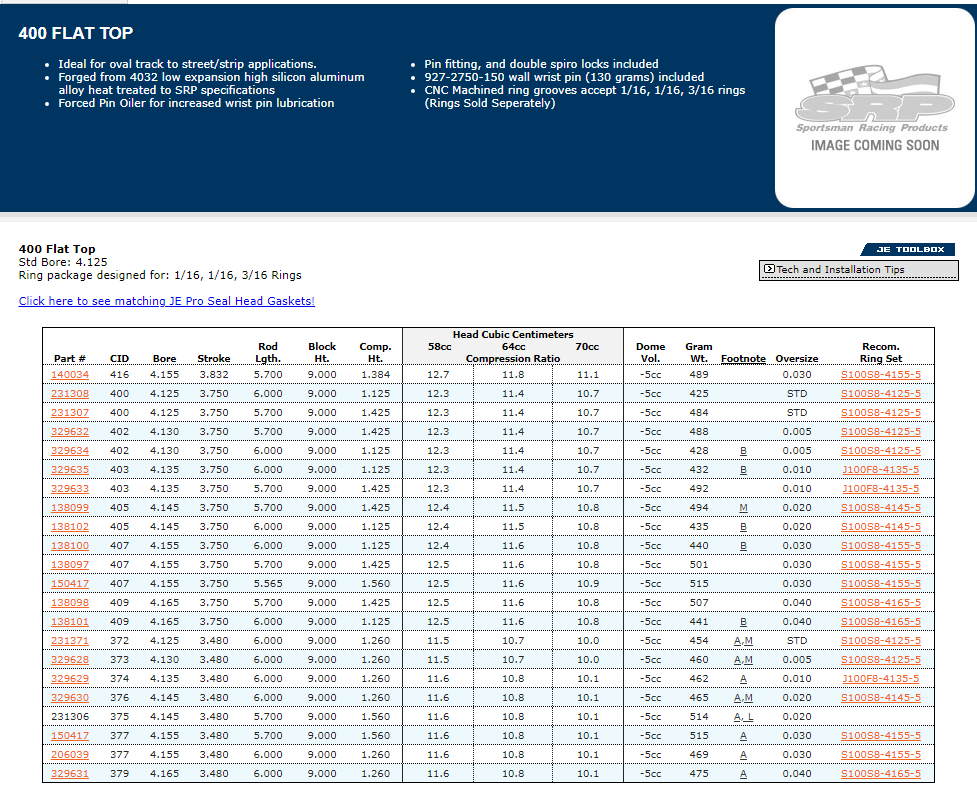

in many cases using vortec heads on a 400 plus displacement sbc short block is basically a bad idea if your goal is impressive hp levels, rather than low and mid rpm torque.unless other mods like a different cam and forged pistons and better rods etc. are used, simply because swapping from a 78cc to about a 61cc -64cc vortec head will more than likely make the compression ratio jump up to where detonation is a potential issue with pump gas. now making 400-450hp on a vortec head 400-434 sbc combo is not un-heard of but durability tends to suffer, if your retaining all the stock lower engine components.

http://www.sallee-chevrolet.com/Cylinde ... Vortec.cfm

http://www.kb-silvolite.com/calc.php?action=comp

http://www.wallaceracing.com/ca-calc.php

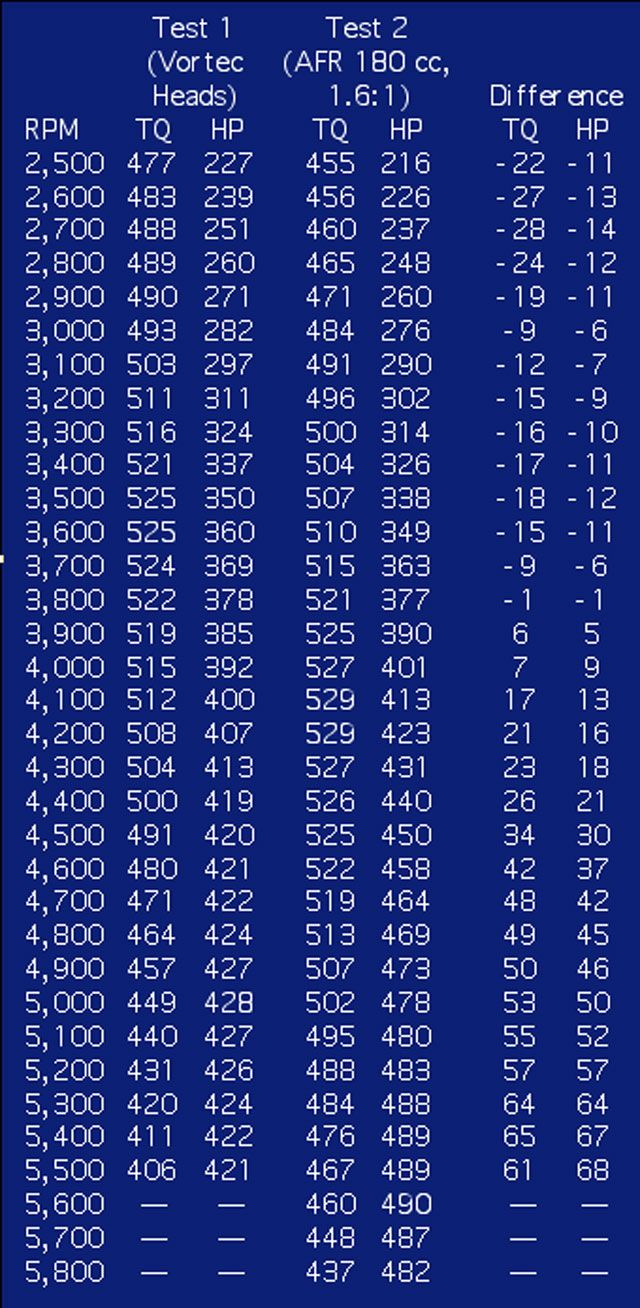

now IM certainly NOT about to give you the impression a vortec head top end on a 406 SBC won,t produce gobs of low and mid rpm torque, because it does have a great deal of potential to do so below about 5000rpm. but what I am suggesting is that on a larger displacement engine theres a great deal of untapped potential that larger and better flowing heads can allow you to access, vortec heads produce very good mid rpm torque but lack the cross sectional area to allow true high rpm maximum power levels that better heads will allow your to access.

http://www.chevyhiperformance.com/techa ... index.html

now theres a good deal of torque to be gained in the 1500rpm-4000rpm range with that swap if you do the required up grades along with the head swap, but a simple head swap on a well worn short block is probably asking for trouble, because your boosting stress significantly and the stock cast 400 crank, not overly strong block main caps and flimsy connecting rods are not known for strength.and vortec heads on a 400 will limit your upper rpm power curve to under 5000rpm-5500rpm, where the intake ports cross sectional area,become a restriction.

now theres a good deal of torque to be gained in the 1500rpm-4000rpm range with that swap if you do the required up grades along with the head swap, but a simple head swap on a well worn short block is probably asking for trouble, because your boosting stress significantly and the stock cast 400 crank, not overly strong block main caps and flimsy connecting rods are not known for strength.and vortec heads on a 400 will limit your upper rpm power curve to under 5000rpm-5500rpm, where the intake ports cross sectional area,become a restriction.

vortec......................1.66.sq inch cross section

http://www.wallaceracing.com/ca-calc.php

I am thinking of freshening up my 400 in my '73 chevelle and was wondering what you guys think of changing to a set of cast vortec heads from gm? Like the ones from the last 90's trucks and such? This should increase my compression, right, just by switching these heads. I think my original heads are like 78cc or something? This seems like a cheap few extra horses and I don't mind changing the manifold to a vortec style.

Ive had good results in several cars building 406 sbc engines that were designed for brisk street performance (NOT RACING) with a combo like this,the correct answer depends on the cam used and the rpm levels you want to efficiently make power in.

it makes zero sense to put large ports on an engine with a cam that won,t allow the engine to breath at the higher rpm levels the larger ports potentially can provided much greater hp at , just as its silly to throw a huge cam in an engine that can never hope to spin up into the cams power range due to small restrictive ports, you need to think things thru and match components.

with most cars currently equipped with 2.73:1 -3>07:1 rear gears, and power brakes, you really don,t want or need a cam with a good deal of duration to make it lope noticeably at idle, remember ever change you make effects your results

max lift is about .470 with stock vortec heads and having a higher stall speed converter would be almost mandatory if you select a cam with enough duration to make it lope noticeably with that 2.73:1 -3>07:1 rear gear ratio, and power brakes.

now you need to understand what your trying to do, vortec heads are built to maximize torque in the 1500rpm-5000rpm power band so you can,t really use a great big long duration cam or you run into port flow restrictions well before the cams extra duration becomes effective.

first you want to decide on if the cam should be a flat tappet or roller lifter design and if your willing to upgrade the valve train, and converter stall speed and possibly the rear gear ratio.

Yes you can increase hp significantly but it won,t be just a cam alone required

GRUMPY? WHAT WOULD BE A CAM TO USE IN A 350 STOCK WITH VORTEC HEADS ,400 TURBO , LOOKING FOR LOPEY SOUND

AND WHAT IS THE MAX LIFT

Ive used this in similar combos with decent results, yes I know its not that wild and you think you might just go with a bit more duration and lift...THAT would be a big mistake unless you do other mods, yes IM well aware it says you need a 3.73:1 rear gear ratio , it will work with a stock converter its just not ideal, and works better with a 3.73:1 rear gear ,but it will function and add about 30 peak hp in most engines over the stock cam, but cost you a bit of low rpm torque

NEWER vortec heads require different valve covers that the traditional first gen SBC but there are adapters available to sallow their use, but they cost almost as much or more than many valve covers themselves

http://www.jegs.com/i/JEGS+Performance+ ... 0/10002/-1

ID STRONGLY SUGGEST HAVING A LONG TALK WITH SEVERAL CAM MANUFACTURERS BEFORE YOU PURCHASE A CAM

now your results will depend on how well you match components with the power & RPM band you intend to operate in and the compression ratio. vortecs on a 400 make a great combo if your mostly concerned with mid rpm torque and cruising , obviously an over drive trans and a properly matched rear gear ratio that keep the engine below 4500rpm most of the time will help a great deal on a 400 with those vortec heads

(remember to drill steam holes in the heads)

obviously the drive train gearing ,cpr, and cam must match the heads

vortec heads have a port size and cross sectional area that is best matched on a 406 displacement with stock components in the lower engine to make the best power in about the 2400rpm-5500rpm range with about a 9:1 cpr and a cam like this

CROWER 00210

a good dual plane intake, like an EDELBROCK RPM AIR GAP, a good HOLLEY 750 VACUUM secondary carb, full length 1 5/8" headers and a manual trans or an auto with about a 2600 stall converter, and in most muscle cars a 3.73:1-4.11:1 rear gear ratio.a good baffled 7 quart oil pan matching your cars frame, will give you that brisk performance on the street but still maintain drive-ability and dependability

obviously if your compression ratio, gearing, converter stall etc does not fall close to this the cam may need to be different

you might want to read thru these links

http://www.kb-silvolite.com/calc.php?action=comp

in many cases using vortec heads on a 400 plus displacement sbc short block is basically a bad idea if your goal is impressive hp levels, rather than low and mid rpm torque.unless other mods like a different cam and forged pistons and better rods etc. are used, simply because swapping from a 78cc to about a 61cc -64cc vortec head will more than likely make the compression ratio jump up to where detonation is a potential issue with pump gas. now making 400-450hp on a vortec head 400-434 sbc combo is not un-heard of but durability tends to suffer, if your retaining all the stock lower engine components.

http://www.sallee-chevrolet.com/Cylinde ... Vortec.cfm

http://www.kb-silvolite.com/calc.php?action=comp

http://www.wallaceracing.com/ca-calc.php

now IM certainly NOT about to give you the impression a vortec head top end on a 406 SBC won,t produce gobs of low and mid rpm torque, because it does have a great deal of potential to do so below about 5000rpm. but what I am suggesting is that on a larger displacement engine theres a great deal of untapped potential that larger and better flowing heads can allow you to access, vortec heads produce very good mid rpm torque but lack the cross sectional area to allow true high rpm maximum power levels that better heads will allow your to access.

http://www.chevyhiperformance.com/techa ... index.html

400 sbc steam holes posted by DennyW

DO YOU NEED STEAM HOLES DRILLED ? HERE'S HOW http://www.gregsengine.com/converting-3 ... o-400.html http://www.chevyhiperformance.com/techa ... index.html YOU MAY WANT TO READ THRU THIS LINK ALSO http://www.chevyhiperformance.com/techa ... ng_tricks/...

garage.grumpysperformance.com

vortec......................1.66.sq inch cross section

http://www.wallaceracing.com/ca-calc.php

Last edited by a moderator: