CNC BLOCKS N/E http://www.cncblocksnortheast.com/

posted much of this

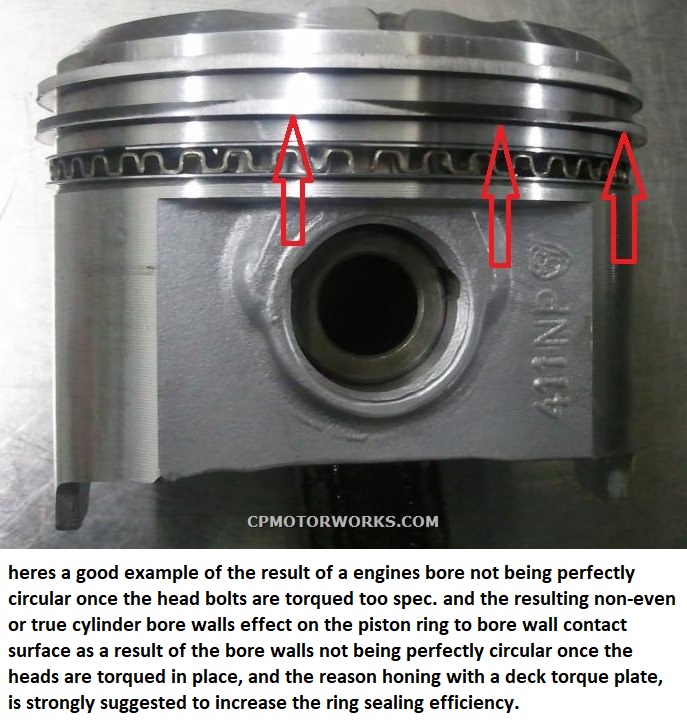

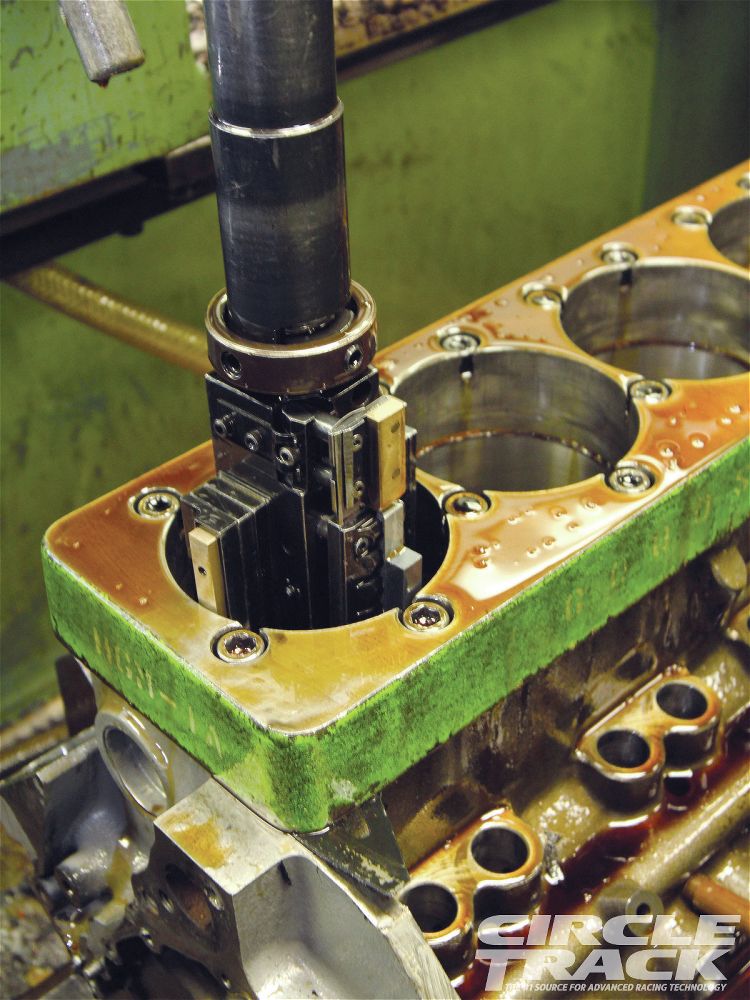

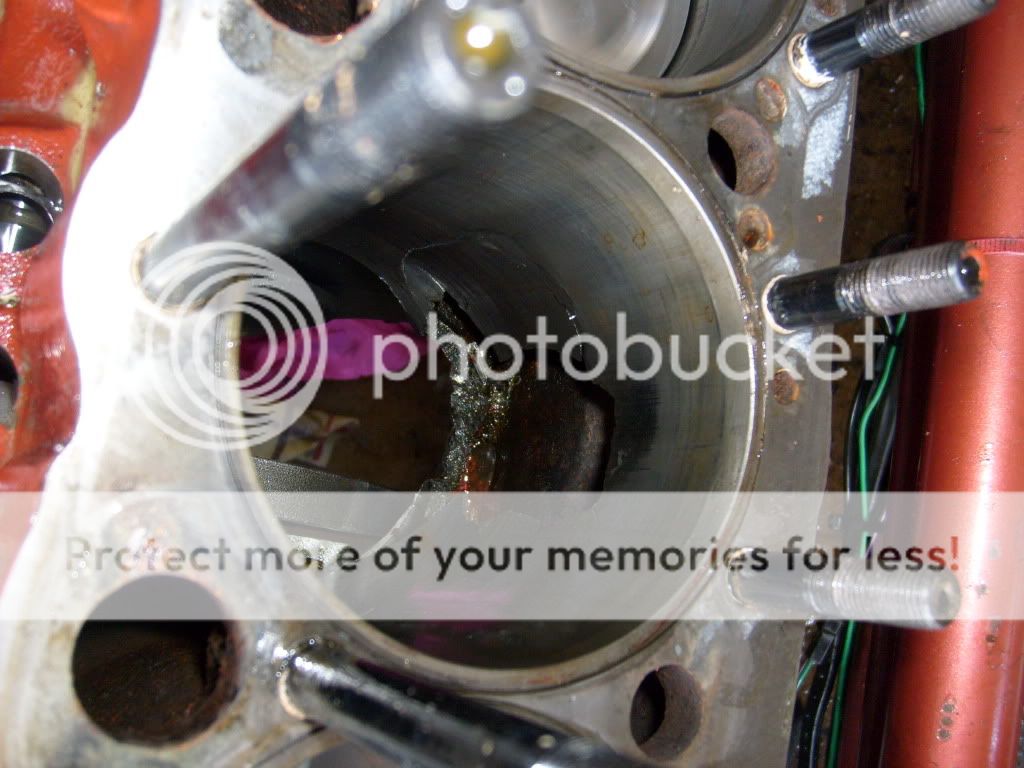

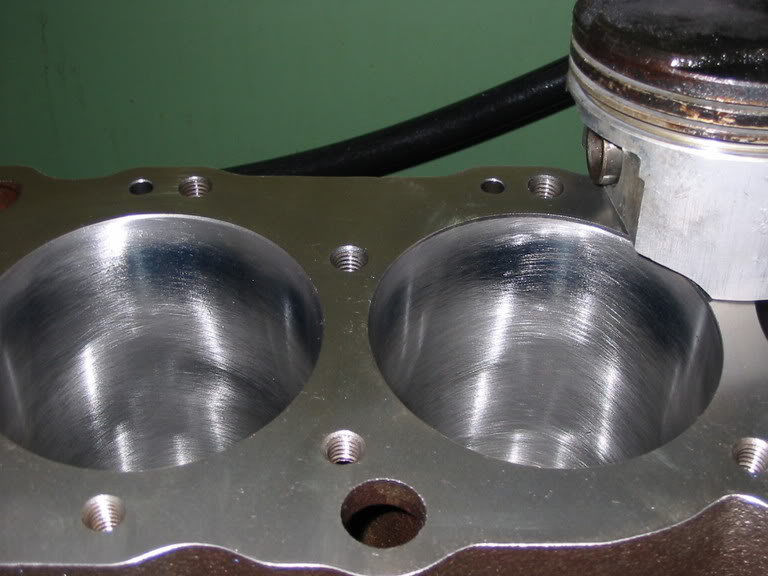

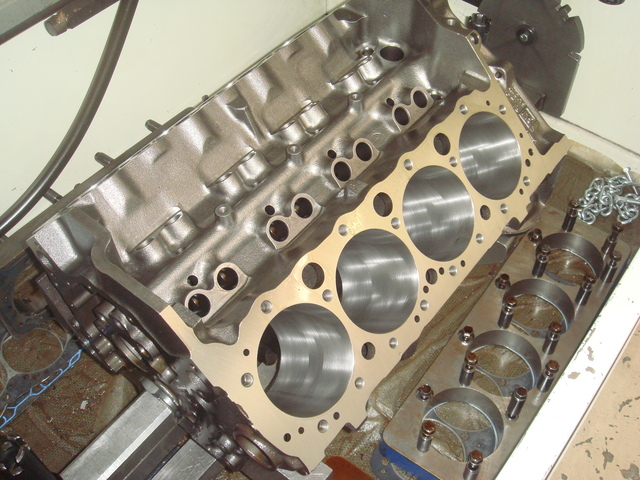

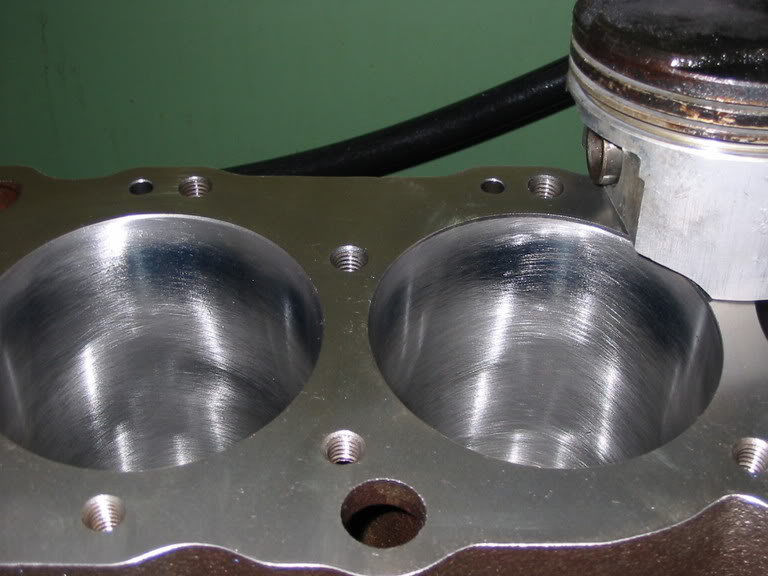

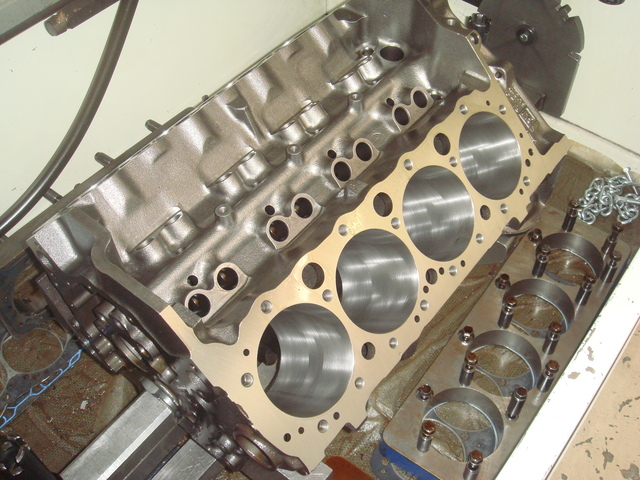

This is a pic of a 454 block that has come in for some work as it only has about 3200 miles on it since the rebuild and it was making some lower end noises. We line honed it and squared and decked it flat and bored it and we blued up the 2 center cylinders installed the gasket and torque plate and went in for 6 strokes on each cylinder as you can see the results and look at the piston as it has blow by right to the oil control rings as we could measure .003 distortion on the cylinders.

"I have seen the difference over the years, I am a believer. I have done blocks this way and gone to trade shows and guys are usually amazed at what a torque plate does to a cylinder and Id point out that on the thicker and stiffer after market blocks the distortion is minimal , but still there,compared to the OEM stuff."

"

bores must be honed with a deck torque plate to simulate the stress a installed cylinder head stress on the bore walls induces to hone the walls concentric

gaps must be correct for the application

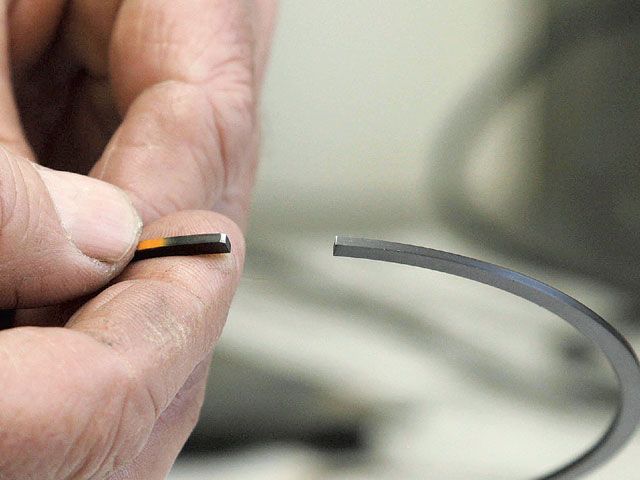

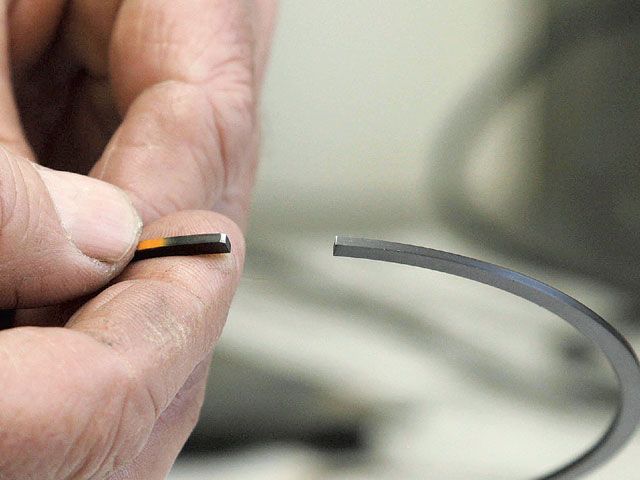

ring ends must be, correctly gaped, cut parallel and de-burred before installation

use of the proper tool helps keep the gap and ring ends square and parallel

Ive used several sets of total seal gapless rings in several engine builds over the years, they usually have a slightly better leak down test result , but I can,t really see and measurable power or durability increase

remove the burrs from the ends of the ring after gapping them,but don,t round off the ring ends like the left side, in his fingers here

http://courses.washington.edu/engr100/S ... 0Rings.htm

http://www.totalseal.com/TechPage.aspx#trRingInstall

http://www.cp-carrillo.com/LinkClick.as ... D&tabid=83

http://circletrack.automotive.com/11015 ... index.html

http://www.fme-cat.com/Docs/1204.pdf

http://www.beckracing.com/page05.htm

http://kb-silvolite.com/article.php?action=read&A_id=10

http://kb-silvolite.com/article.php?action=read&A_id=56

http://kb-silvolite.com/article.php?action=read&A_id=32

http://kb-silvolite.com/article.php?action=read&A_id=5

http://www.circletrack.com/enginetech/c ... index.html

here is where you, or your machine shop can get block deck hone plates, keep in kind you want to use the same (STUDS OR BOLTS) the machine shop used and the same torque settings they used when the cylinders were honed with deck plates or the distortion of the bore and ring seal won,t be identical (exactly round)or ideal

ask to see the hone machine and deck plates before you pay some shop to torque plate hone your block, you would not believe this but Ive been charged to have my block honed with torque plates and the machine shop did not have any torque plates that fit my engine!

http://www.yother.com

if you don,t know what your looking at, in the picture posted above, its the RESULTS of the distortion to the block the head bolts exert on the bore when torqued into place like the cylinder head being installed, on a block does to the block, theres thousands of pounds of tension applied to the cylinder walls when the bolts are torqued on the cylinder heads, stress that pulls on the back of the cylinder walls,if the torque plates are not used when the bores honed it will distort to a different shape when those stresses are applied later, greatly reducing the cylinder wall/ring contact area, in this case it should be rather obvious that the upper cylinder walls were pulled away from the ring contact area when the heads were installed, resulting in less contact and wear, and most likely compression losses.

look closely the areas near the bolt threads were distorted to a greater degree than areas further away resulting in a very shallow area approximately to the depth the bolts thread into the block deck area that was pulled away from the bore center line when the heads were torqued into place

just some info for future builds

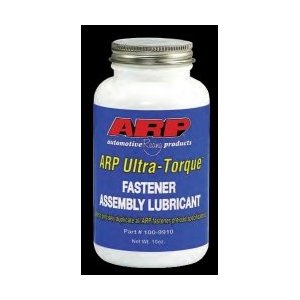

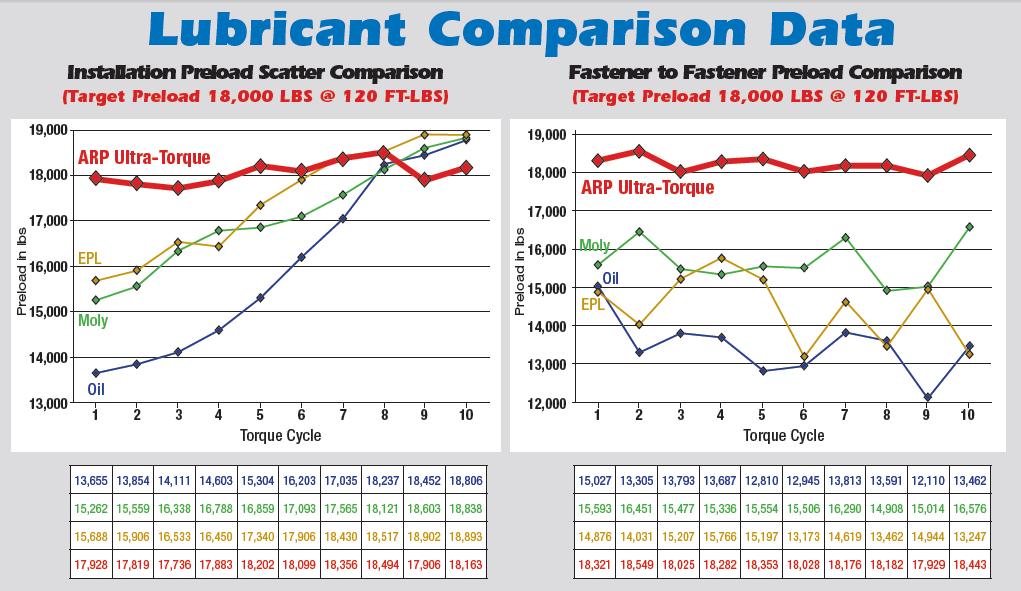

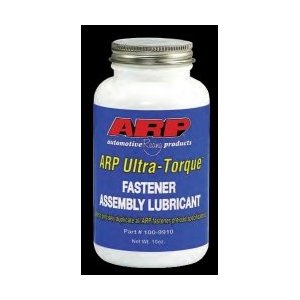

aluminum heads ALWAYS require head bolt washers with oil or ultra lube to get consistent clamp values and the flat surface faces the head the inner bevel faces the bolt head

on head STUDS the same things required on aluminum heads to get even clamp loads and no galling

unlike a OEM block DARTS blocks have blind threaded head bolt holes that don,t enter the water jacket so you need to be sure the threads are clean, theres no crud in the threaded holes and you use minimal thread sealant on the lower threads because theres little chance off coolant leaking up thru the threads like with an OEM block where head bolts enter the coolant passages

this should be used only in head bolt holes that don,t enter water jackets in the block on the lower threads

viewtopic.php?f=50&t=50&p=12558&hilit=threads+lube+torque#p12558

http://www.circletrack.com/techarticles ... index.html

http://www.cylinderheadsupply.com/block ... lates.html

http://findarticles.com/p/articles/mi_q ... n17180532/

viewtopic.php?f=51&t=5945

make sure you have the block sonic tested and mag tested theres no sense in wasting time and money if the blocks cracked or the cylinder walls are too thin

http://www.hardblok.com/

is popular, for filling blocks with thin cylinder walls, up to the lower edge of the freeze plugs which generally will not cause heat issues but does add support on thin cylinder walls, to gain ring support

Ive used a slurry of steel bird shot and liquid EPOXY for my blocks, rather than the concrete hard block

http://www.precisionreloading.com/mm5/m ... STEEL_SHOT

http://www.alvinproducts.com/Products/Products.asp?id=1

viewtopic.php?f=51&t=976&p=1706#p1706

posted much of this

This is a pic of a 454 block that has come in for some work as it only has about 3200 miles on it since the rebuild and it was making some lower end noises. We line honed it and squared and decked it flat and bored it and we blued up the 2 center cylinders installed the gasket and torque plate and went in for 6 strokes on each cylinder as you can see the results and look at the piston as it has blow by right to the oil control rings as we could measure .003 distortion on the cylinders.

"I have seen the difference over the years, I am a believer. I have done blocks this way and gone to trade shows and guys are usually amazed at what a torque plate does to a cylinder and Id point out that on the thicker and stiffer after market blocks the distortion is minimal , but still there,compared to the OEM stuff."

"

bores must be honed with a deck torque plate to simulate the stress a installed cylinder head stress on the bore walls induces to hone the walls concentric

gaps must be correct for the application

ring ends must be, correctly gaped, cut parallel and de-burred before installation

use of the proper tool helps keep the gap and ring ends square and parallel

Ive used several sets of total seal gapless rings in several engine builds over the years, they usually have a slightly better leak down test result , but I can,t really see and measurable power or durability increase

remove the burrs from the ends of the ring after gapping them,but don,t round off the ring ends like the left side, in his fingers here

http://courses.washington.edu/engr100/S ... 0Rings.htm

http://www.totalseal.com/TechPage.aspx#trRingInstall

http://www.cp-carrillo.com/LinkClick.as ... D&tabid=83

http://circletrack.automotive.com/11015 ... index.html

http://www.fme-cat.com/Docs/1204.pdf

http://www.beckracing.com/page05.htm

http://kb-silvolite.com/article.php?action=read&A_id=10

http://kb-silvolite.com/article.php?action=read&A_id=56

http://kb-silvolite.com/article.php?action=read&A_id=32

http://kb-silvolite.com/article.php?action=read&A_id=5

http://www.circletrack.com/enginetech/c ... index.html

piston to bore clearance

ok first some facts (1)cylinders will not be honed to true round as they will be in use with out the use of a deck plate to simulate and duplicate the bolt clamp stress on the cylinder walls, bores in blocks without a head or deck plate with the bolts or studs torqued to spec are not nearly the...

garage.grumpysperformance.com

ask to see the hone machine and deck plates before you pay some shop to torque plate hone your block, you would not believe this but Ive been charged to have my block honed with torque plates and the machine shop did not have any torque plates that fit my engine!

http://www.yother.com

if you don,t know what your looking at, in the picture posted above, its the RESULTS of the distortion to the block the head bolts exert on the bore when torqued into place like the cylinder head being installed, on a block does to the block, theres thousands of pounds of tension applied to the cylinder walls when the bolts are torqued on the cylinder heads, stress that pulls on the back of the cylinder walls,if the torque plates are not used when the bores honed it will distort to a different shape when those stresses are applied later, greatly reducing the cylinder wall/ring contact area, in this case it should be rather obvious that the upper cylinder walls were pulled away from the ring contact area when the heads were installed, resulting in less contact and wear, and most likely compression losses.

look closely the areas near the bolt threads were distorted to a greater degree than areas further away resulting in a very shallow area approximately to the depth the bolts thread into the block deck area that was pulled away from the bore center line when the heads were torqued into place

just some info for future builds

aluminum heads ALWAYS require head bolt washers with oil or ultra lube to get consistent clamp values and the flat surface faces the head the inner bevel faces the bolt head

on head STUDS the same things required on aluminum heads to get even clamp loads and no galling

unlike a OEM block DARTS blocks have blind threaded head bolt holes that don,t enter the water jacket so you need to be sure the threads are clean, theres no crud in the threaded holes and you use minimal thread sealant on the lower threads because theres little chance off coolant leaking up thru the threads like with an OEM block where head bolts enter the coolant passages

this should be used only in head bolt holes that don,t enter water jackets in the block on the lower threads

viewtopic.php?f=50&t=50&p=12558&hilit=threads+lube+torque#p12558

http://www.circletrack.com/techarticles ... index.html

http://www.cylinderheadsupply.com/block ... lates.html

http://findarticles.com/p/articles/mi_q ... n17180532/

viewtopic.php?f=51&t=5945

make sure you have the block sonic tested and mag tested theres no sense in wasting time and money if the blocks cracked or the cylinder walls are too thin

http://www.hardblok.com/

is popular, for filling blocks with thin cylinder walls, up to the lower edge of the freeze plugs which generally will not cause heat issues but does add support on thin cylinder walls, to gain ring support

Ive used a slurry of steel bird shot and liquid EPOXY for my blocks, rather than the concrete hard block

http://www.precisionreloading.com/mm5/m ... STEEL_SHOT

http://www.alvinproducts.com/Products/Products.asp?id=1

viewtopic.php?f=51&t=976&p=1706#p1706

Last edited by a moderator: