You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trans Cooler Install On Lincoln Navigator

- Thread starter Indycars

- Start date

The fans never ran during the trip to Missouri. The 10 amp fuse had blown, had I know it would

be an easy fix I would have changed it during the trip. The fans are suppose to pull 7.2 amps combined,

so I have gone to a 15 amp fuse now. I suspect it was too small for the starting amps pulled by the fans,

which is different than the 7.2 amp rating at full speed. My wiring was not completed at this time, it

was just hanging from out of the dash. It might have shorted out somehow also.

Without the fans running, the temps were 180-190°F at 70 mph. I will have to check with my IR Gun

to confirm my understanding of the factory repair manuals about which lines are output/input to the

transmission.

I have the fans running now and have finished up the wiring inside the cab except for the lighting the

gauge. I have pulled the plate that everything is mounted on in the engine compartment and getting ready

to paint it now. When that's done the project will be complete.

I'm trying find a point in the wiring where I can connect with to bring on the lights for my trans temp gauge.

I normally set the headlight switch to Auto and I want my gauge light to react like the rest of my lights.

I'm back probing the connector on the headlight switch with my volt meter. I've tried pins 4, 5 & 9 to

ground (pin 7). Either I have voltage or I don't, but it never seems to change when I cover the light sensor

and the headlights come on.

Any ideas ???

.

be an easy fix I would have changed it during the trip. The fans are suppose to pull 7.2 amps combined,

so I have gone to a 15 amp fuse now. I suspect it was too small for the starting amps pulled by the fans,

which is different than the 7.2 amp rating at full speed. My wiring was not completed at this time, it

was just hanging from out of the dash. It might have shorted out somehow also.

Without the fans running, the temps were 180-190°F at 70 mph. I will have to check with my IR Gun

to confirm my understanding of the factory repair manuals about which lines are output/input to the

transmission.

I have the fans running now and have finished up the wiring inside the cab except for the lighting the

gauge. I have pulled the plate that everything is mounted on in the engine compartment and getting ready

to paint it now. When that's done the project will be complete.

I'm trying find a point in the wiring where I can connect with to bring on the lights for my trans temp gauge.

I normally set the headlight switch to Auto and I want my gauge light to react like the rest of my lights.

I'm back probing the connector on the headlight switch with my volt meter. I've tried pins 4, 5 & 9 to

ground (pin 7). Either I have voltage or I don't, but it never seems to change when I cover the light sensor

and the headlights come on.

Any ideas ???

.

JohnHancock

Well-Known Member

I don’t see anything about dash lights. If you can find the dash light feed and hook into them the dim function will work on the temp gauge.

After reading your statement I started thinking about the dimmer switch, maybe I could connect withI don’t see anything about dash lights. If you can find the dash light feed and hook into them the dim function will work on the temp gauge.

one of those wires. The electrical system is just not that simple, it has what's called a "Smart Junction Box".

It looks like a simple fuse panel located in the kick panel on the passenger side. But it's anything beside

simple. Below is a quote from the manual.

Dimmable Backlighting

When the parking lamps are on, the smart junction box (SJB) monitors the input from the instrument

panel dimmer switch. The SJB sends a pulse-width modulated (PWM) voltage to the dimmable

components and switches based on input received from the instrument panel dimmer switch.

I may just wire it with the gauge light on anytime the ignition is in the RUN position, just like the gauge.

T-Test

solid fixture here in the forum

I may just wire it with the gauge light on anytime the ignition is in the RUN position, just like the gauge.

I think I would so it would not have to go through the PCM/ECM or body control unit. I hate new fangled stuff that can't be tested with a test light or ohm meter.

I think I would so it would not have to go through the PCM/ECM or body control unit. I hate new fangled stuff that can't be tested with a test light or ohm meter.

I'm also afraid I could end up causing problems that could be very costly to fix, so just runningI think I would so it would not have to go through the PCM/ECM or body control unit. I hate new fangled stuff that can't be tested with a test light or ohm meter.

the light all the time seems like the best compromise.

The thermostat ended up being hard to get at when I needed to add wires, but it was not impossible.

Below is how I figured out the wiring underneath the hood.

Labeling all the relay wires and then putting clear shrink tubing over the label was well worth the time spent.

With both power and ground distribution buses having 10 taps, I should have room for expansion.

.

Below is how I figured out the wiring underneath the hood.

Labeling all the relay wires and then putting clear shrink tubing over the label was well worth the time spent.

With both power and ground distribution buses having 10 taps, I should have room for expansion.

.

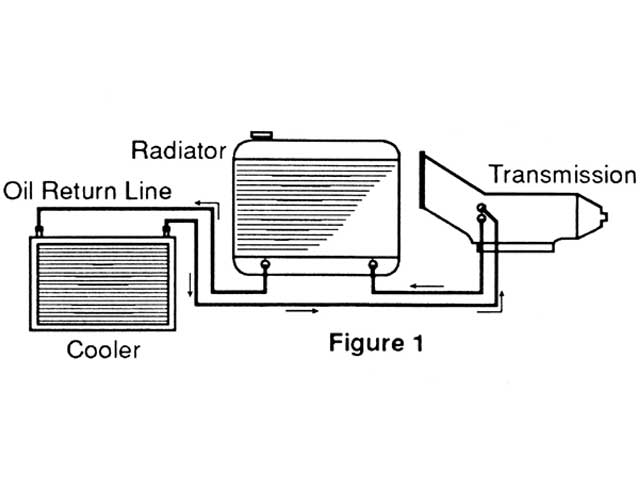

I'm not going to need a trailer again until next year, so I don't know about apples to apples test.

I want to peruse the manual to see if there is any thermostat for the OEM cooler and I also want to

confirm which line is the return line from the cooler to the trans. It's not performing like I think it

should, but a thermostat maybe skewing the numbers or I've got my cooler coming before the OEM

cooler in the fluid flow.

I want to peruse the manual to see if there is any thermostat for the OEM cooler and I also want to

confirm which line is the return line from the cooler to the trans. It's not performing like I think it

should, but a thermostat maybe skewing the numbers or I've got my cooler coming before the OEM

cooler in the fluid flow.

I wired the gauge light to the power wire I already had there for the gauge power, so it's on all

the time now. Looks good at night.

I tried to verify the trans return line with my IR gun, but that was not conclusive. I did go back and

look at the manual again and I still think I have it right. My next step is to completely bypass the

radiator circuit and go directly to the OEM cooler input.

It was very easy to remove the grill, remove the 4 screws across the top and slide off the tabs at

the bottom.

I've already got a new cooler line coming for the one that goes into the bottom of the radiator so

I will have a backup. I'm planning on cutting the line that comes in and makes a 90° turn and goes

across the bottom of the radiator. Then I will run it to the top of the OEM cooler shown below, this

will bypass the radiator completely.

Does anyone see a problem with bypassing the radiator ???

.

the time now. Looks good at night.

I tried to verify the trans return line with my IR gun, but that was not conclusive. I did go back and

look at the manual again and I still think I have it right. My next step is to completely bypass the

radiator circuit and go directly to the OEM cooler input.

It was very easy to remove the grill, remove the 4 screws across the top and slide off the tabs at

the bottom.

I've already got a new cooler line coming for the one that goes into the bottom of the radiator so

I will have a backup. I'm planning on cutting the line that comes in and makes a 90° turn and goes

across the bottom of the radiator. Then I will run it to the top of the OEM cooler shown below, this

will bypass the radiator completely.

Does anyone see a problem with bypassing the radiator ???

.

T-Test

solid fixture here in the forum

Does anyone see a problem with bypassing the radiator ???

Only in cold climates would I have the trans cooler to the radiator hooked up.

I run just a small horse shoe line on my tranny in and out and even pull a 4x8 trailer with my motorcycle on it with no problems since '09.

Only in cold climates would I have the trans cooler to the radiator hooked up.

I run just a small horse shoe line on my tranny in and out and even pull a 4x8 trailer with my motorcycle on it with no problems since '09.

JohnHancock

Well-Known Member

I don’t see much benefit. The water temp and the desired trans temps are close and it gives more chance for leaks.

I guess it would depend on what temp the trans fluid is when it gets to the radiator. There wouldI don’t see much benefit. The water temp and the desired trans temps are close and it gives more chance for leaks.

be fewer connections to leak with the radiator eliminated, if I do a good job on the new ones.

I've never noticed any problems when I've started out with a cold engine in the winter with my

other cars.