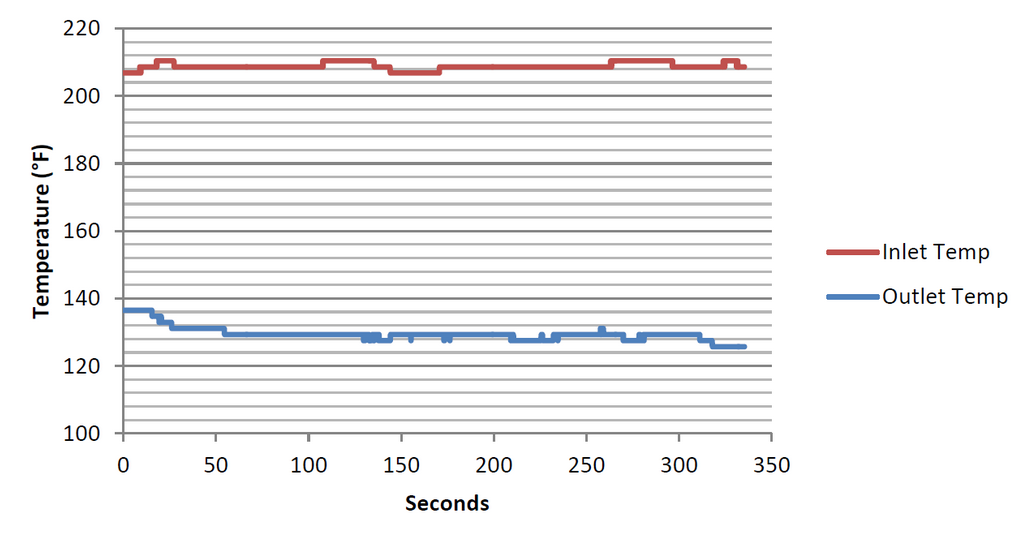

If your thinking of adding an oil cooler for either engine oil or trans fluid cooling, ,the first question ID have is WHY are you adding an oil cooler and WHAT are your current oil temps, and transmission fluid temps that require one?

IF you can,t tell what your current fluid and oil temps ARE, and if you don,t have temp gauges to monitor the fluid temps, how do you even know you need one, or could reasonably function without adding one.

AND IF you do add one, be sure to think thru the location, and routing the hydraulic lines and what fittings you select.

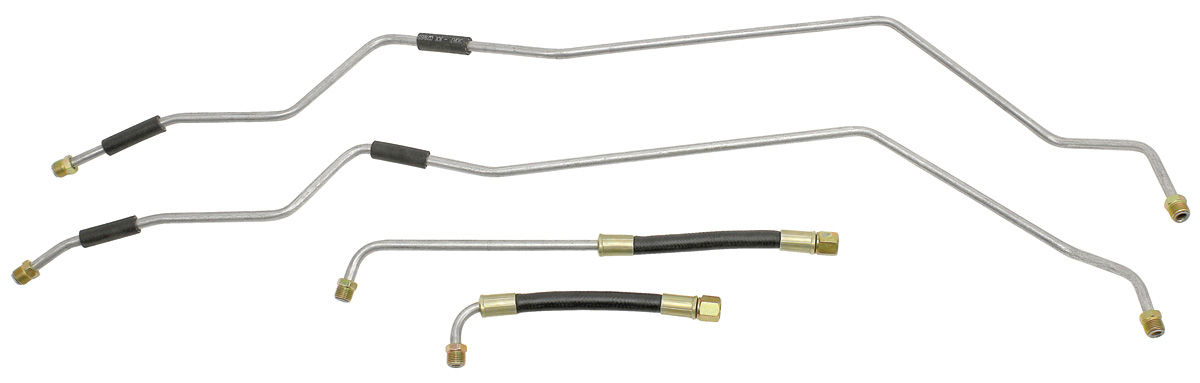

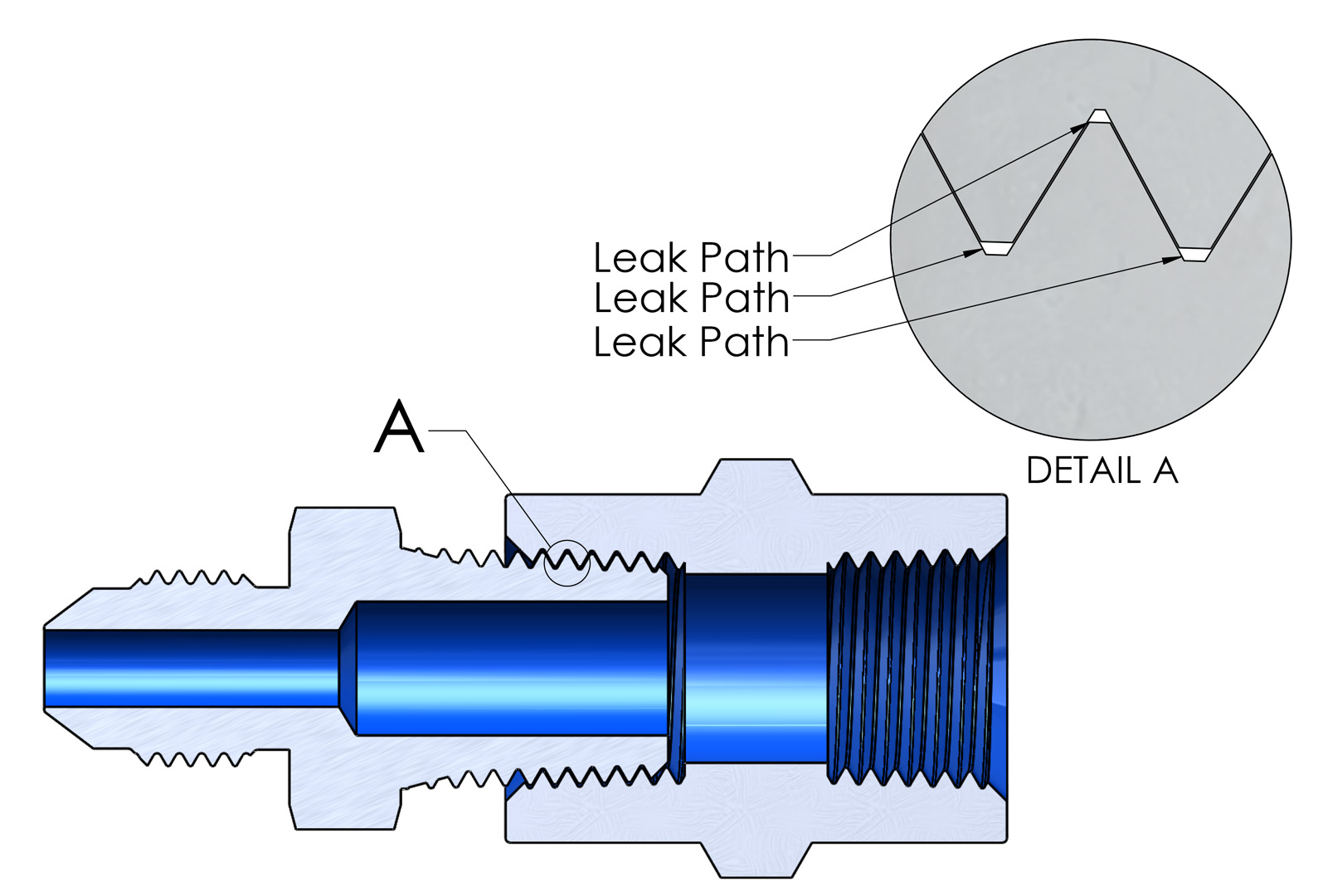

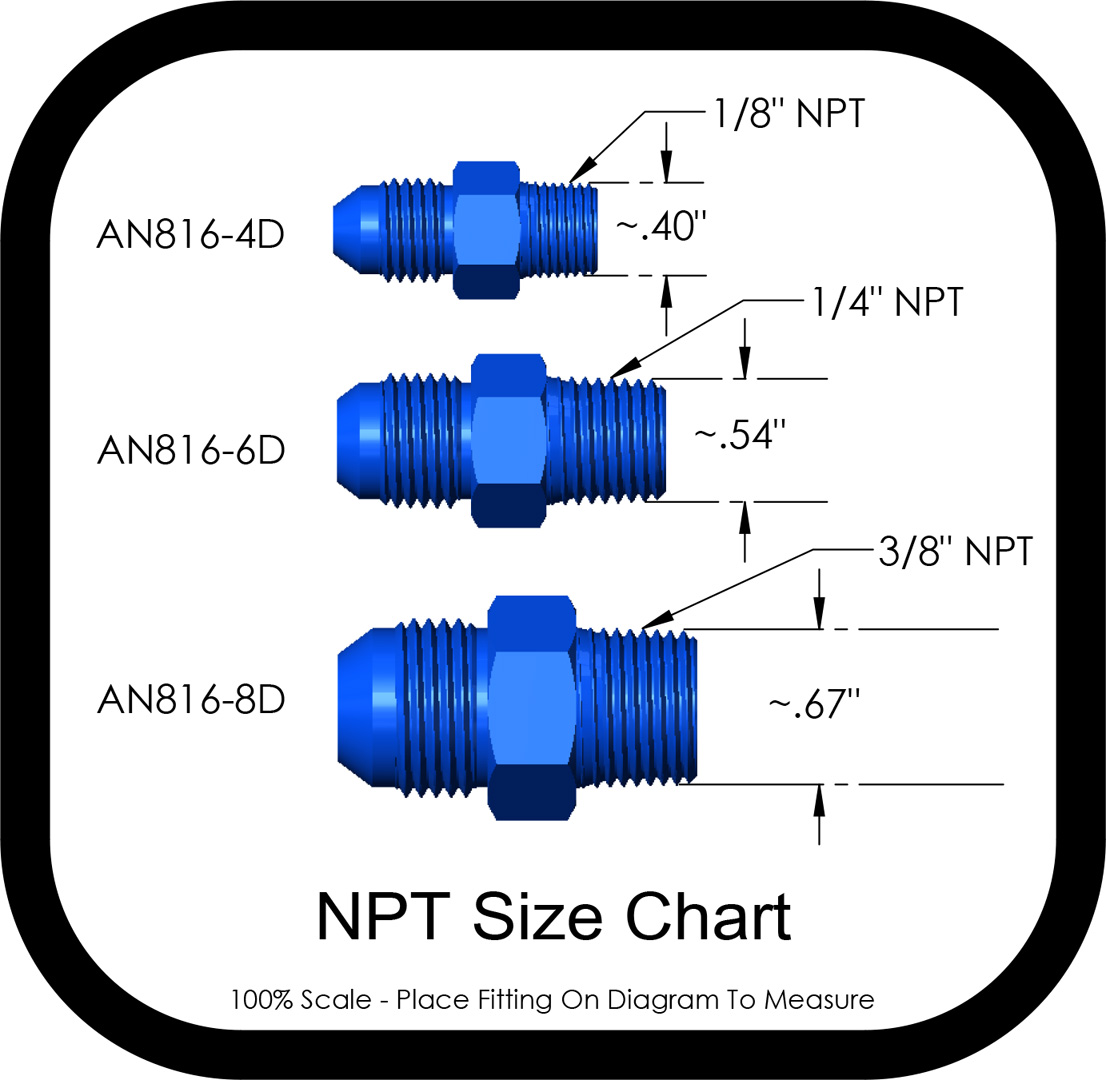

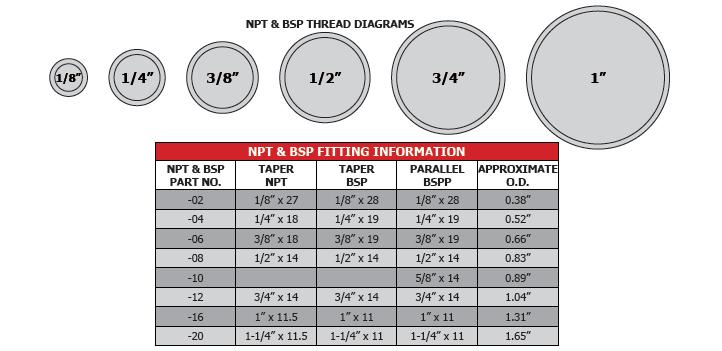

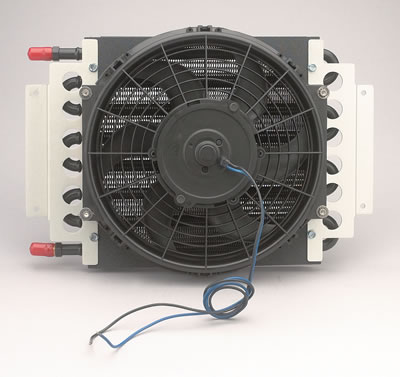

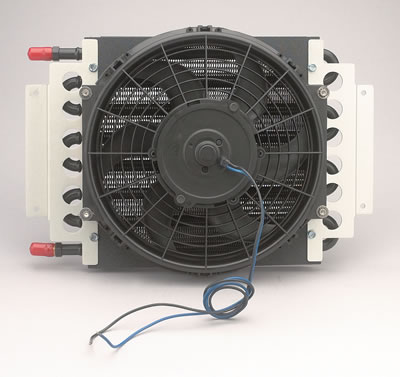

most hydraulic supply shops can very easily fabricate flex hydraulic lines with matching ends at any length required, pressure drops with remote coolers or filter mounts are almost always the result of using hydraulic lines AND hydraulic line connections with too small an INTERNAL cross sectional area, anything less than AN#8 is bound to be restrictive and AN#10 is far better, and much less likely to cause issues with pressure drops, obviously the adapters and fittings used for fluid transmission must also have at least AN# 8 OR PREFERABLY AN#10 CONNECTIONS , if you run 3/8" OR AN#6 LINES YOUR BOUND TO FIND IT DROPS RETURN LINE PRESSURE, and just as obviously this would mean the passage or tube size of the oil cooler must be at least AN#8 as the coolers with AN#6 internal passages tend to restrict flow so read carefully before you buy an oil or trans coolerand from experience I can assure you that if you need a trans cooler , or OIL COOLER the type with the built in fan and at least 1/2"inside diameter hydraulic lines or AN#10 fittings is by far the best choice, and obviously youll need to carefully measure where your going to mount the cooler and run the lines before ordering a cooler but the larger the surface area the better in most applications

I had similar issues, that many guys experience with oil pressure and flow at higher rpms until I installed less restrictive oil lines to the accessories, when I installed my oil cooler with the AN#6 lines that came in the mounting kit from SUMMIT RACING, swapping to AN #8 lines at first which helped a great deal but once I swapped to AN#10 lines those cured the issue, and yes I mounted my oil cooler where the spare tire normally mounts , so its a good distance from the engine.

shop carefully swapping in an oil cooler or trans cooler with fluid line diameter too small for the application will have a huge effect on the coolers efficiency, and can restrict flow rates

https://www.summitracing.com/parts/prm-13182/overview/

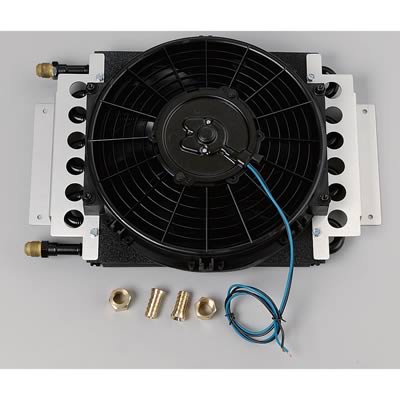

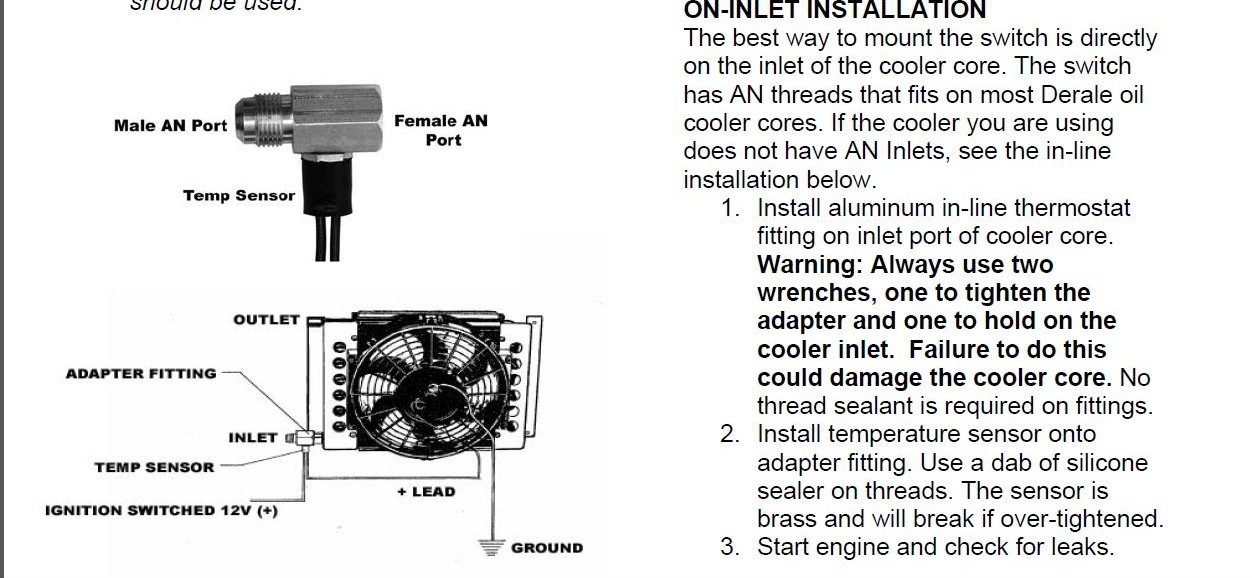

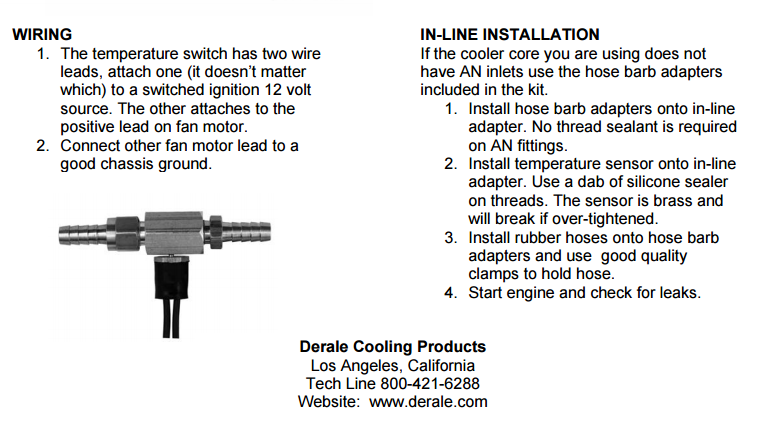

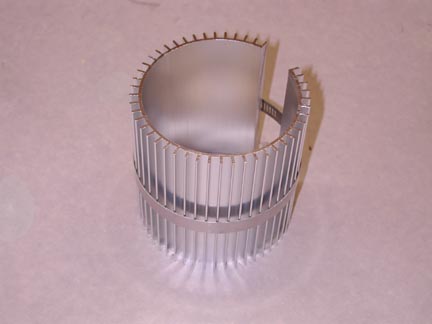

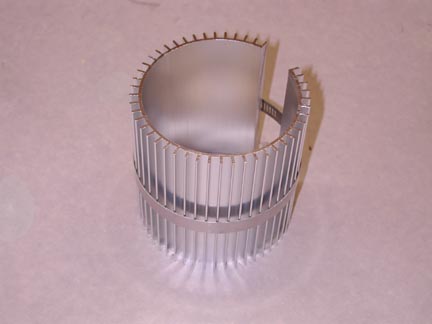

adding an oil cooler with a fan generally helps improve engine durability, I've found those similar to this one( linked below,)make a significant reduction in either trans fluid or oil temps (obviously that depends on what your using it for, and yeah, before ordering one look at the cooler mounting diagram and figure out where you can mount it with enough room for it and the fluid coolant lines feeding it to fit easily and figure out how you connect the electric fan wiring, I've generally suggested use of a temperature switch sensor that turns on the fan on a transmission cooler at about 160F and if used as an oil cooler at 195F-200F

www.summitracing.com

www.summitracing.com

the rotating assembly bearings ,wrist pins and complete valve train,valve springs, lifters, valves and valve guides and the pistons and rings are where a great deal of the engine heat is generated, and those components are initially cooled with oil flow that absorbs and transfers the heat collected , and transported from those components to the block and coolant, so having a constant flow of pressurized oil flow over those parts are mandatory for maximum durability.thus adding a larger capacity baffled oil pan and an oil cooler will generally enhance and extend an engines life span.

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

one question that always comes up, is the ideal, size and length of the fluid transmission lines required,

too feed and return hot oil from remote mounted oil coolers and transmission fluid coolers, the simple answer, visit a local professional hydraulic supply shop after taking careful measurements and verifying the type of fittings, thread types used etc.

I would strongly suggest you select, and ask too have fabricated,

(after taking careful measurements and verifying the connection fitting type and threads etc.) high temp ,high pressure ,lines, AN#8-1/2" lines designed to handle 250F temps and 350 PSI. MINIMUM

keep in mind most performance cars with an auto transmission and a higher rpm stall converter, will need an auxiliary trans fluid cooler, Id strongly suggest you find one with an electric fan and 1/2" or AN#8 line size as you'll want to allow a minimum of 2 -3 gallons a minute trans fluid flow rate.

engine oil coolers , TRANSMISSION FLUID COOLERS and remote mounted engine oil coolers with remote filters, also benefit from use of a MINIMUM of a AN#8/1/2" inside diameter fluid transmission line .

Up to 250 GPH =4.2 GPM= 1/2" or -08 AN

nearly ideal for transmission and oil coolers

*

Up to 450 GPH =7.5 GPM= 5/8" or -10 AN

*

Up to 900 GPH = 15GPM 3/4"or -12 AN

keep in mind oil does almost all the initial engine cooling so adding a larger efficient oil cooler with a fan

, and as large an oil pan as clearances allow goes a long way toward reducing engine temps,

you certainly will see a difference if a properly sized and installed oil cooler is used.

you don,t need something this large in most cases

https://www.summitracing.com/parts/flx-700040

something like this makes a noticeable improvement

https://www.summitracing.com/parts/der-15800

remember to accurately measure the area you intend to install any oil cooler,

and leave lots of room for the connecting high pressure oil feed & return lines and access to connect them.

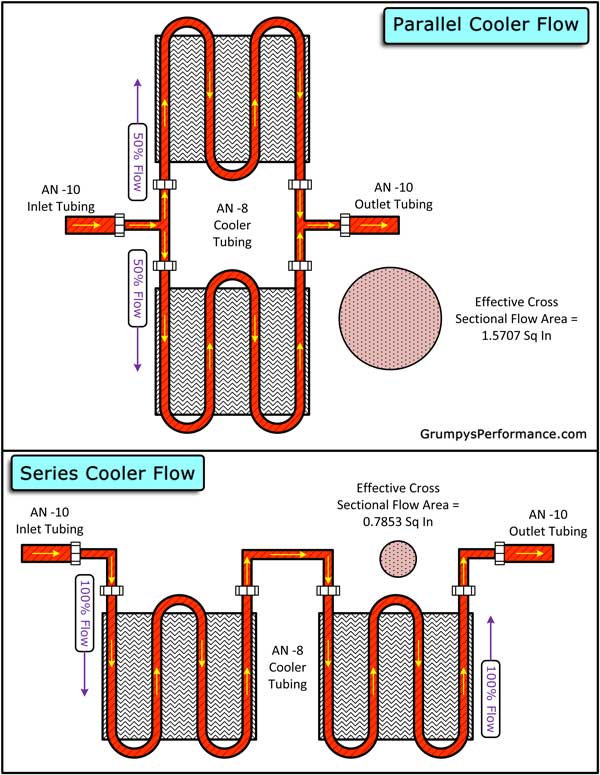

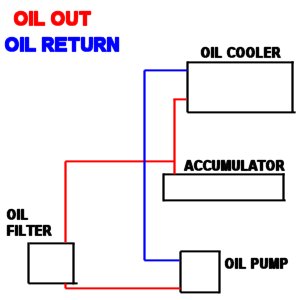

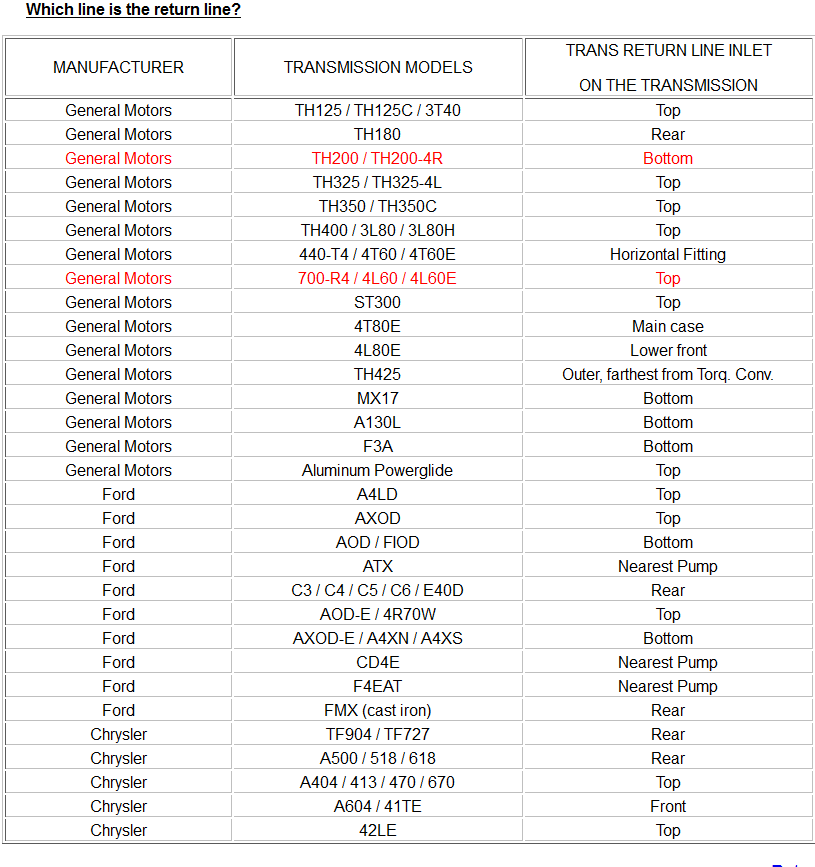

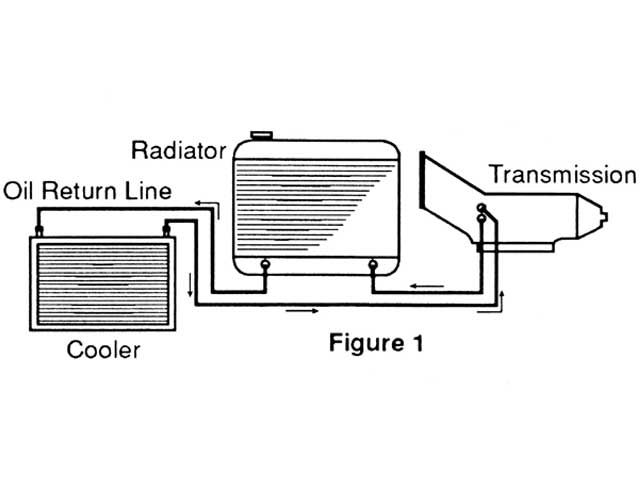

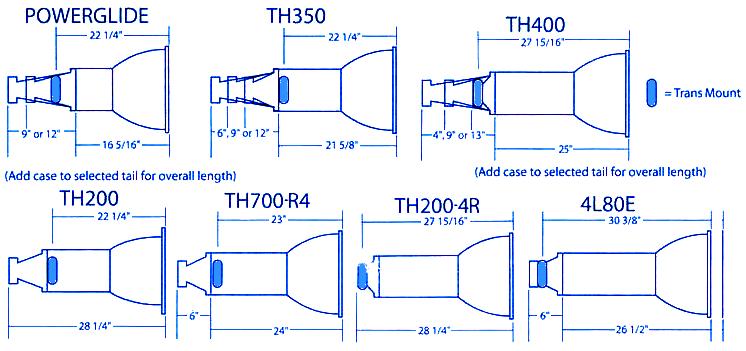

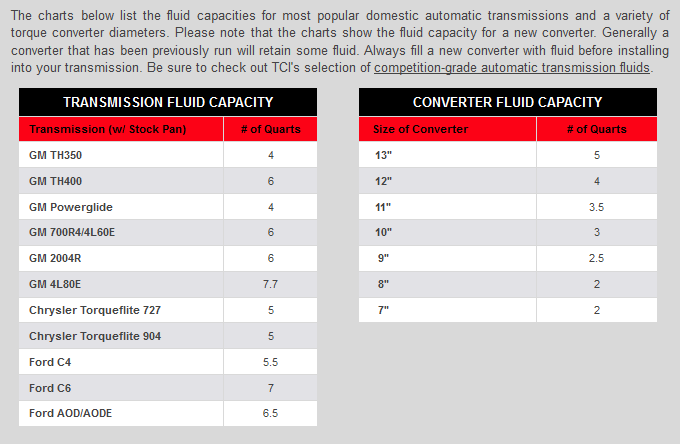

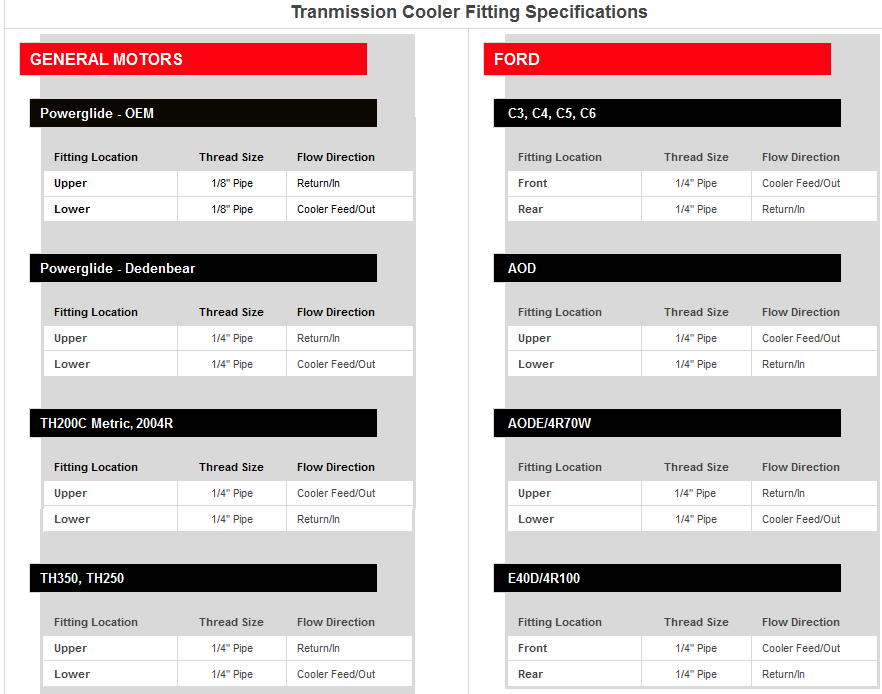

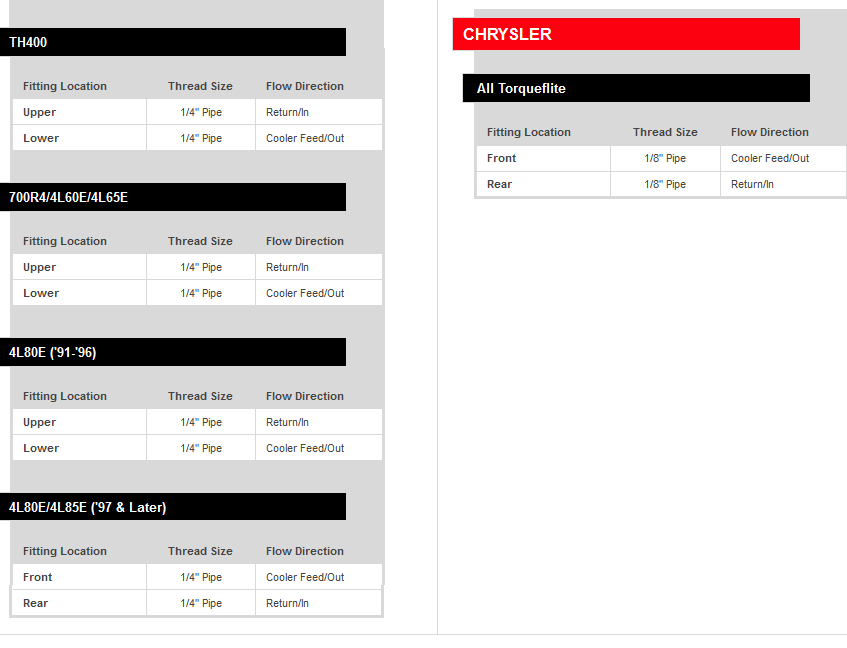

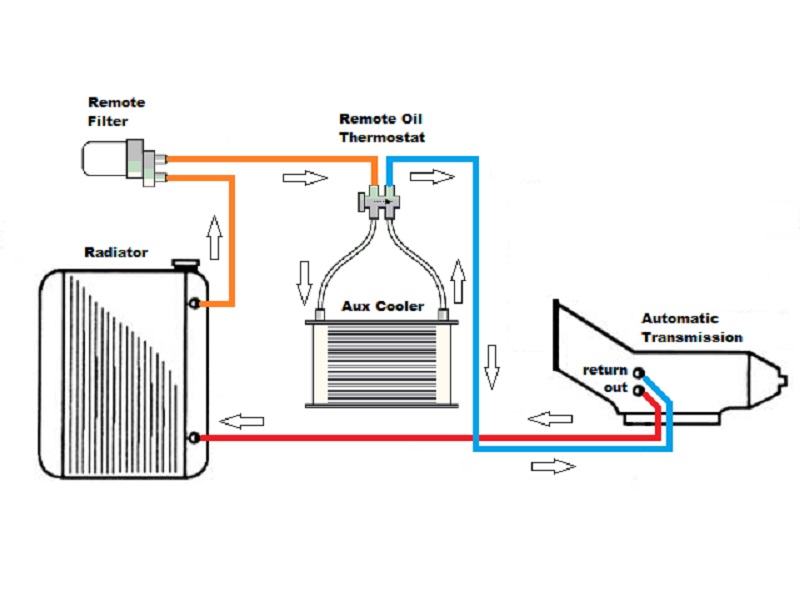

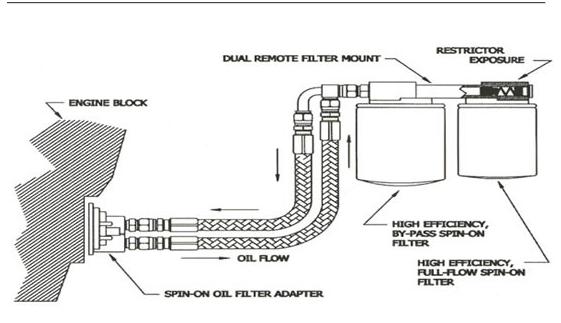

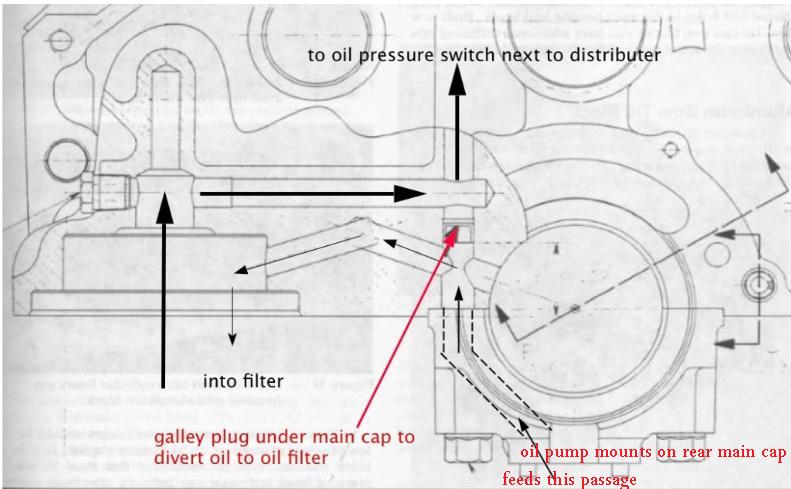

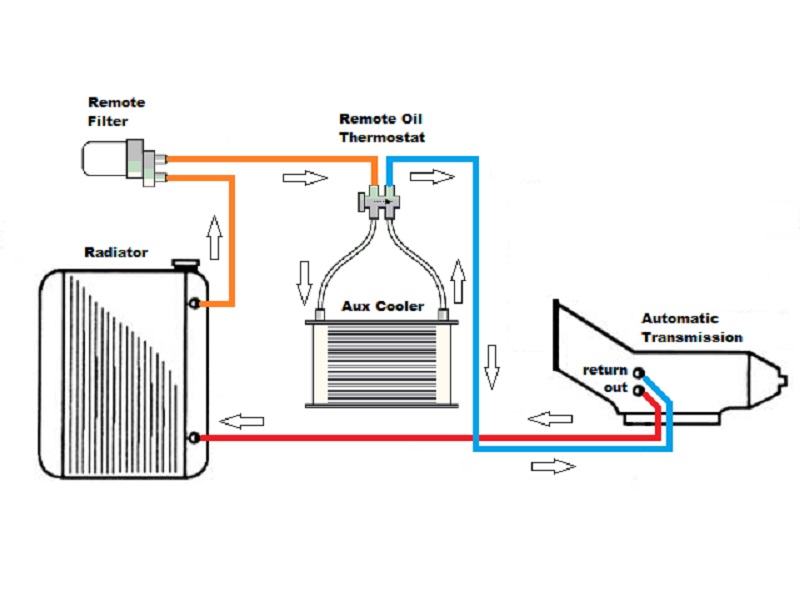

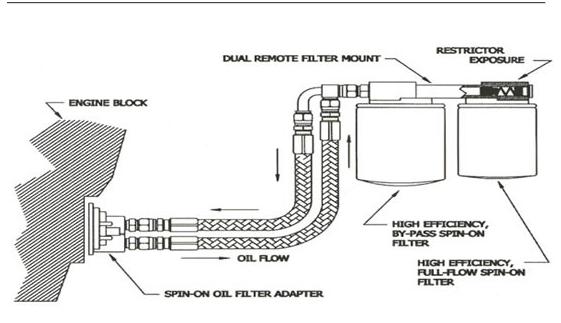

Loves302Chevy posted these diagrams that will be helpful

www.summitracing.com

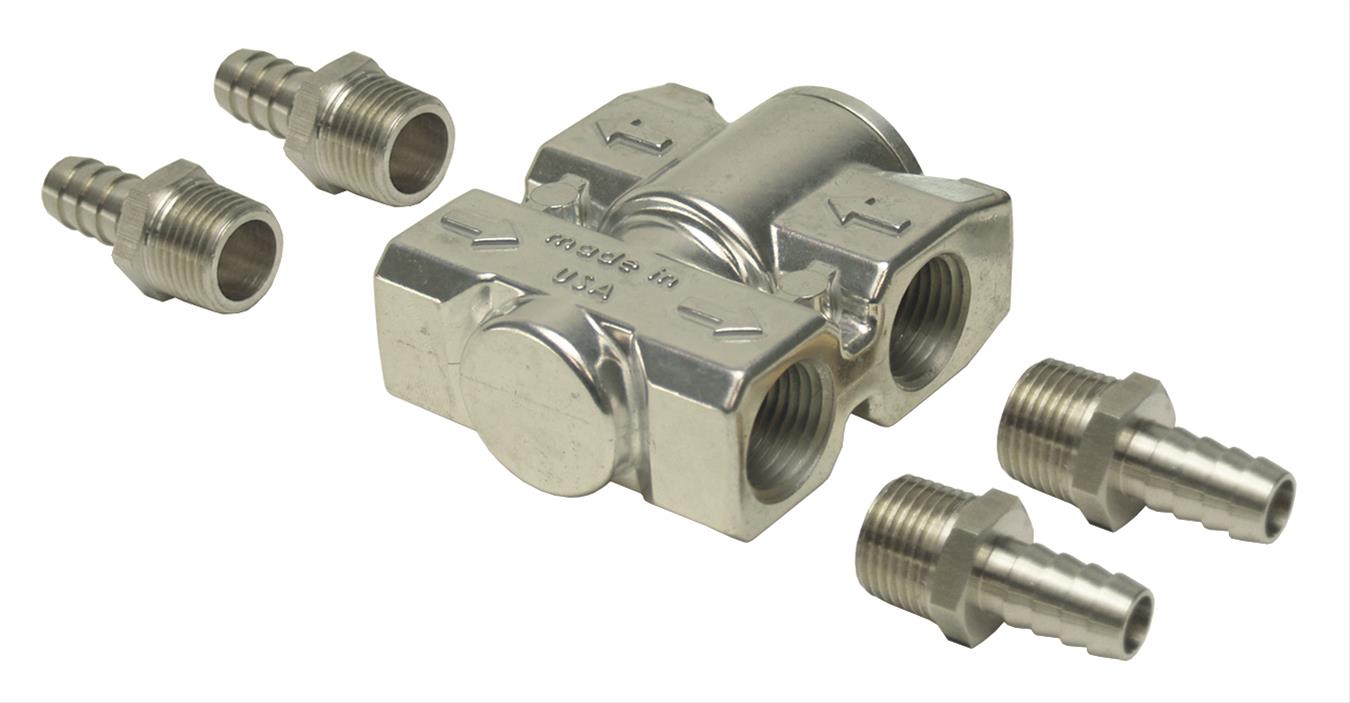

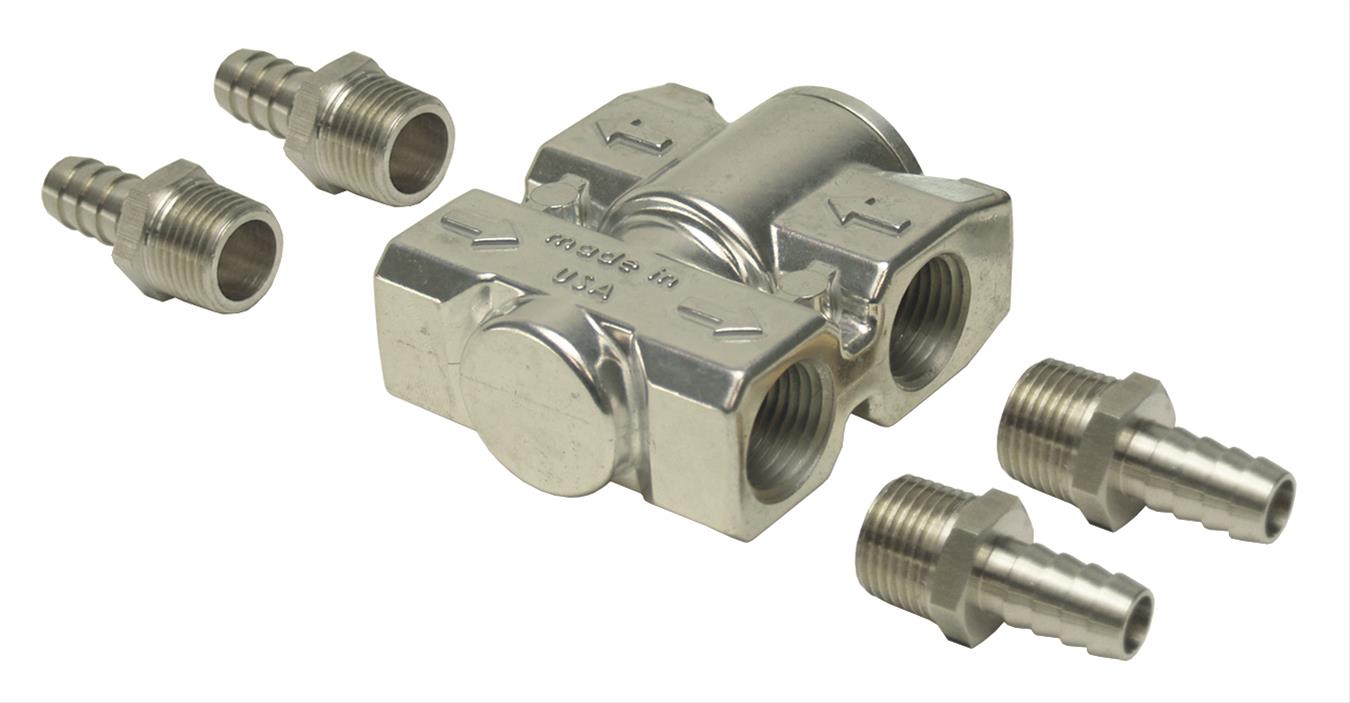

short cut makes sense, if that valve is not functioning correctly a certain percentage (20%-80% ) might be bypassing the coolers, if thats the case ,no mater how effective the aux coolers are the trans fluid returning to the trans would almost never be cooler than the engine coolant temps. and might be marginally higher as the vast majority of the fluid volume never circulated through the coolers at all.

now Im not using that type of thermostat to control fluid temps,

my thermostat control on the trans cooler, simply turns on the FANS on the aux cooler once the temps reach 160F,

www.summitracing.com

www.summitracing.com

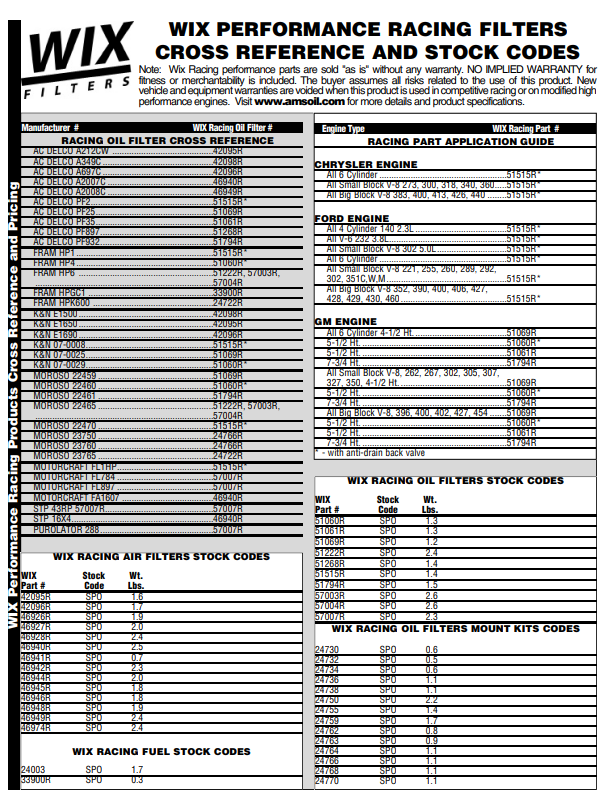

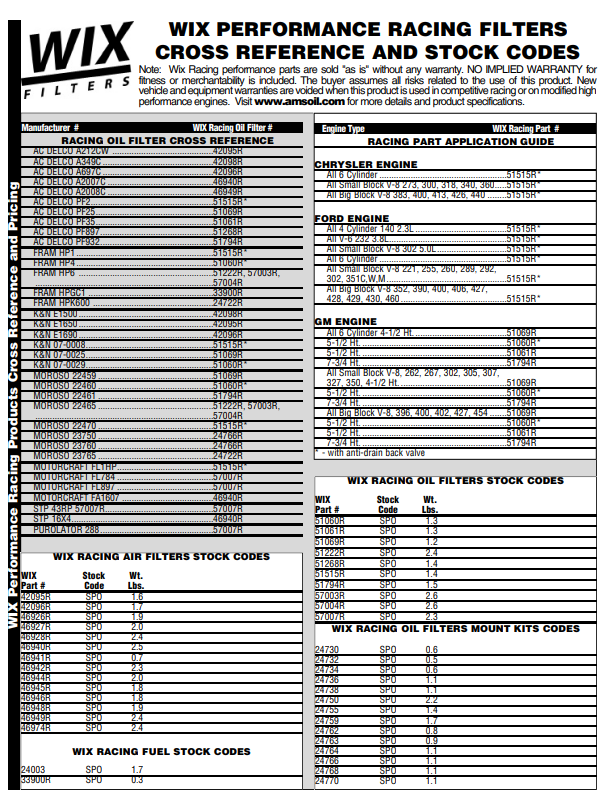

extended length oil filter or even dual extended length oil filters ,

that way you have, a greatly increased filter surface area surface that significantly reduces the resistance to oil flow rates and a significantly larger surface area on the filter medium, that will in theory allow longer use before the filter medium starts to clog with debris .

remember the goal here is two fold, effective cooling of the oil and low flow rate restriction, which a remotely mounted oil filter(s) can supply, plus the option of selecting an easily accessed remote mount filter location

Last edited: Jun 11, 2017

http://www.tciauto.com/tc/cooler-fittings

READ THESE LINK's

http://garage.grumpysperformance.co...-stabilization-temp-vs-time.11043/#post-48999

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/cooling-off-that-c4-corvette.3954/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

http://garage.grumpysperformance.com/index.php?threads/1995-corvette-fan-motor-quit-working.10559/

www.dewitts.com

speedcooling.com

speedcooling.com

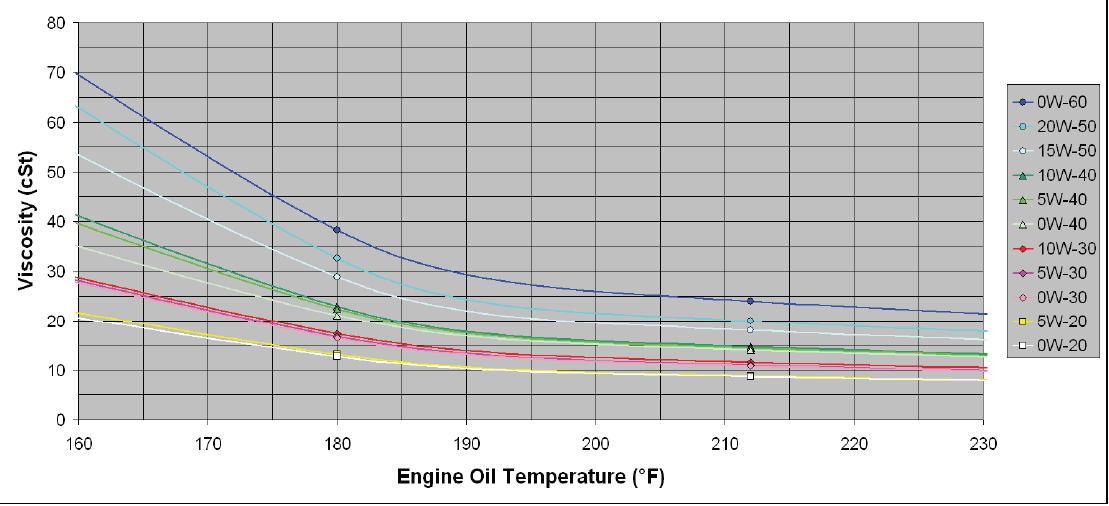

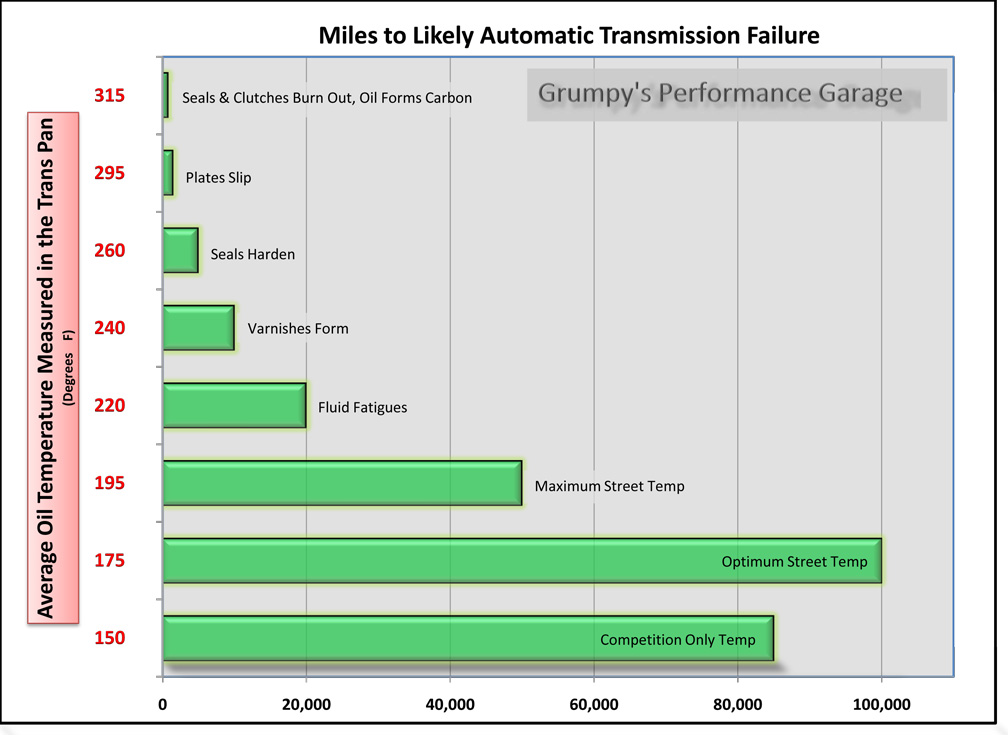

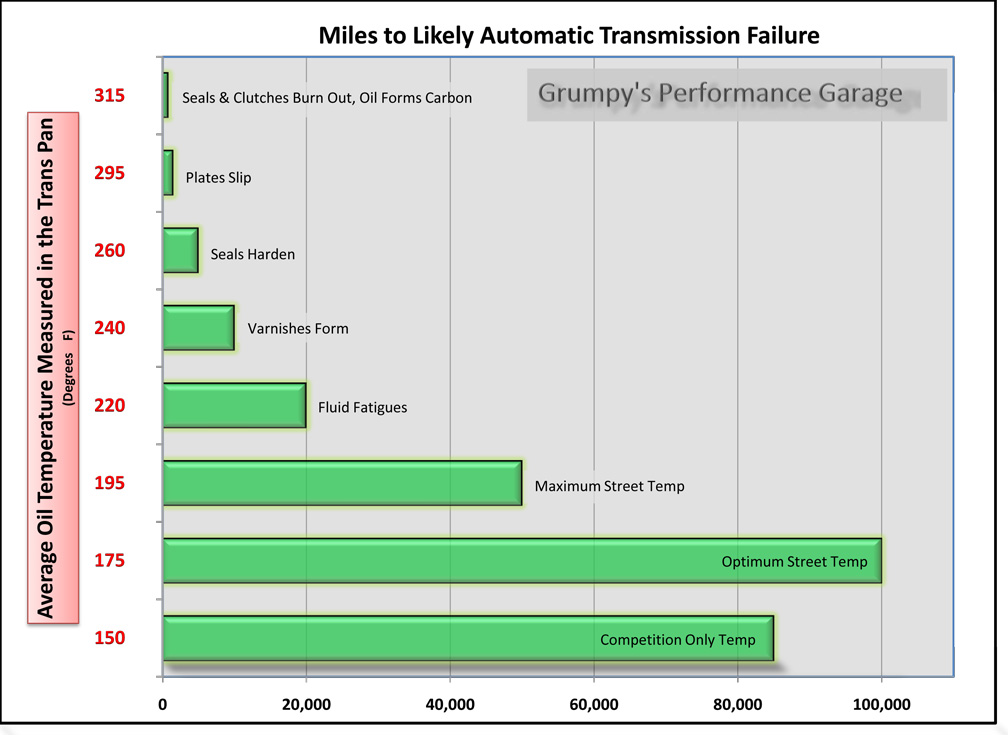

your much more likely to need a trans fluid cooler, than an engine oil cooler ,engine oil needs to reach 215F to burn off moisture,(measured in the oil pan) (bearing surface temps tend to run 50-60f higher than sump temps.) and as long as it stays under about 230F most of the time its going to function, trans fluid over about 180F tends to reduce trans durability,

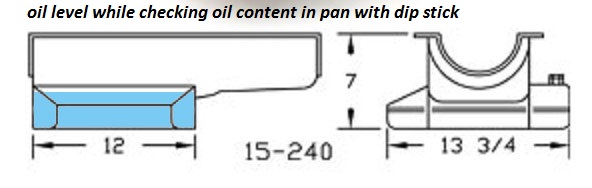

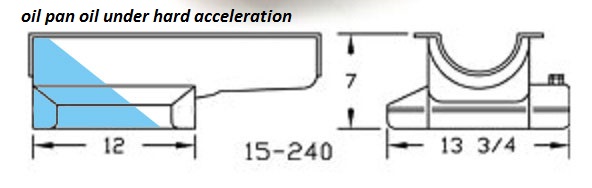

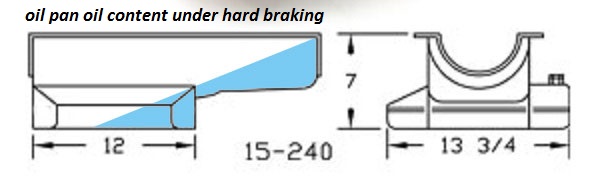

a high capacity 7-8 qt baffled oil pan with a windage screen will frequently reduce oil temps to the range where an oil coolers not required, your first step is installing a engine oil temp gauge and transmission fluid temp. gauge..engine coolant temps tend to run about 20f lower than oil in the sump.

BTW HERES AN IMPORTANT TIP, IT is really common for guys to use lines that are far to small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER

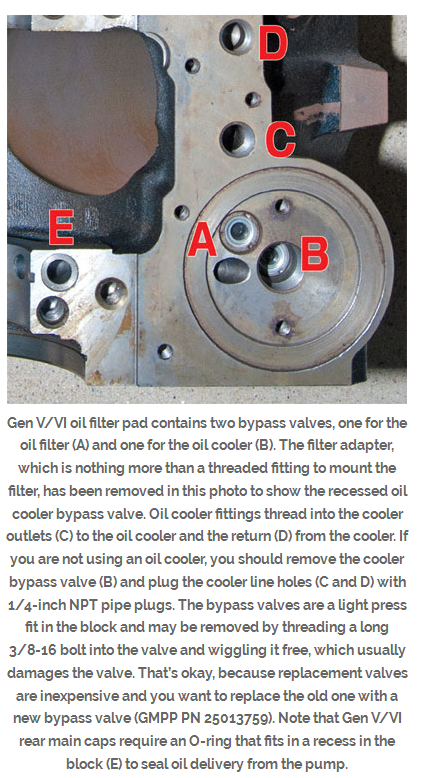

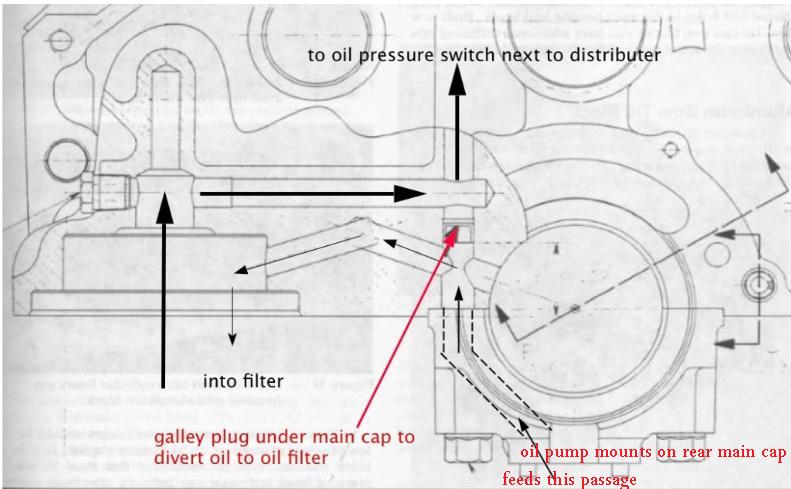

think about it, your measuring the oil pressure in most cases AFTER its been thru the cooler and returned to the oil passages in the block, oil leaves the oil pump and its routed to the oil filter where the oil filter adapter routes it thru the oil cooler and back to the adapter then into the block, your measuring the restricted oil flow after its returned to the block, if the lines or cooler passages restrict oil flow its potentially a problem for lubrication of the moving parts if pressure or oil volumes reduced

adding a transmission cooler like this one dropped my trans fluid temps significantly, vastly increasing the potential life expectancy of my 4l80e transmission, I originally had an identical oil cooler installed also, but found that with a trans cooler installed it dropped the heat loads on my radiator to the point getting my engine oil temps above 215F was much more difficult even without the oil cooler.

http://www.summitracing.com/parts/FLX-45901/?rtype=10

http://static.summitracing.com/global/i ... -45901.pdf

http://www.summitracing.com/parts/der-15719

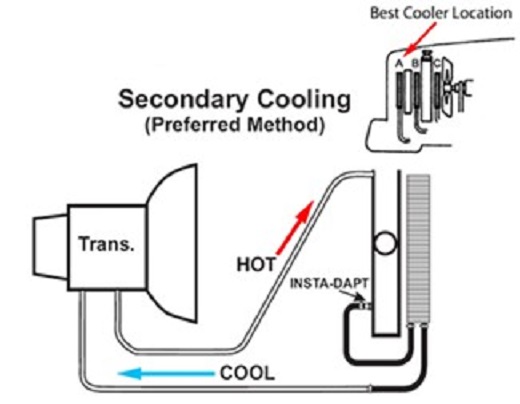

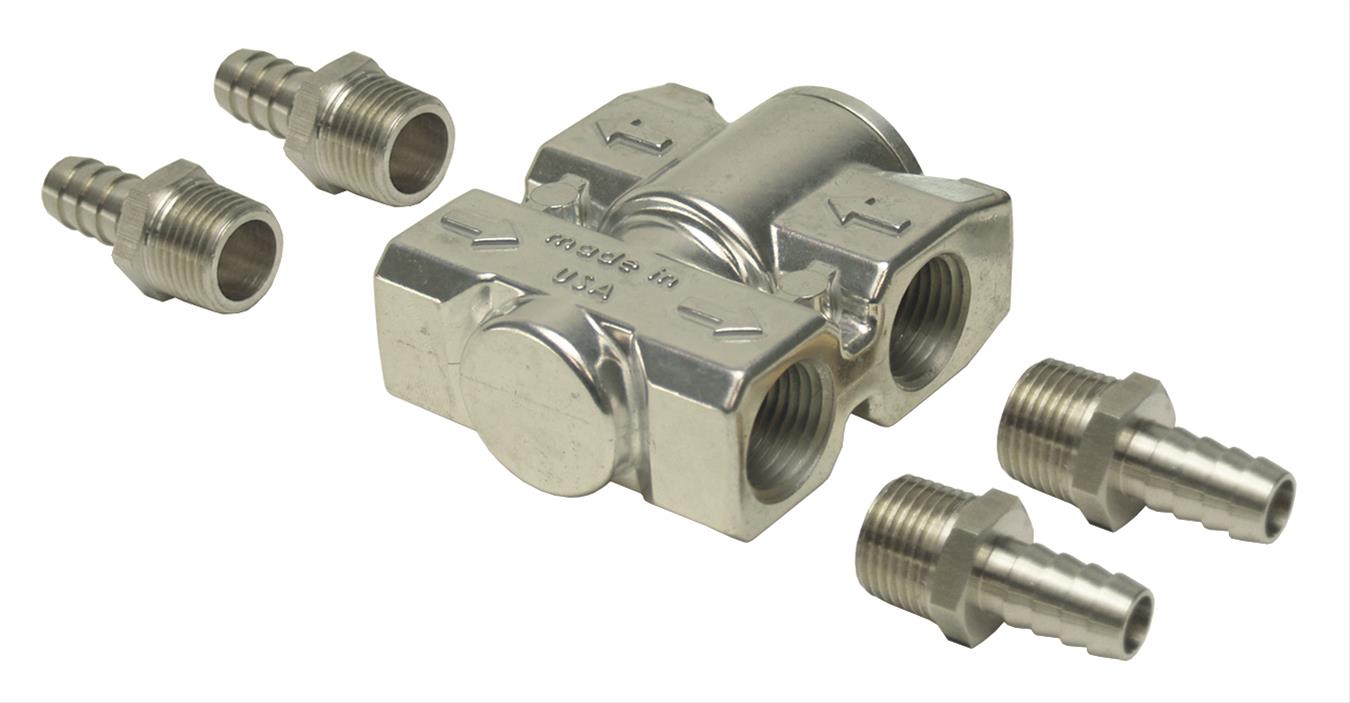

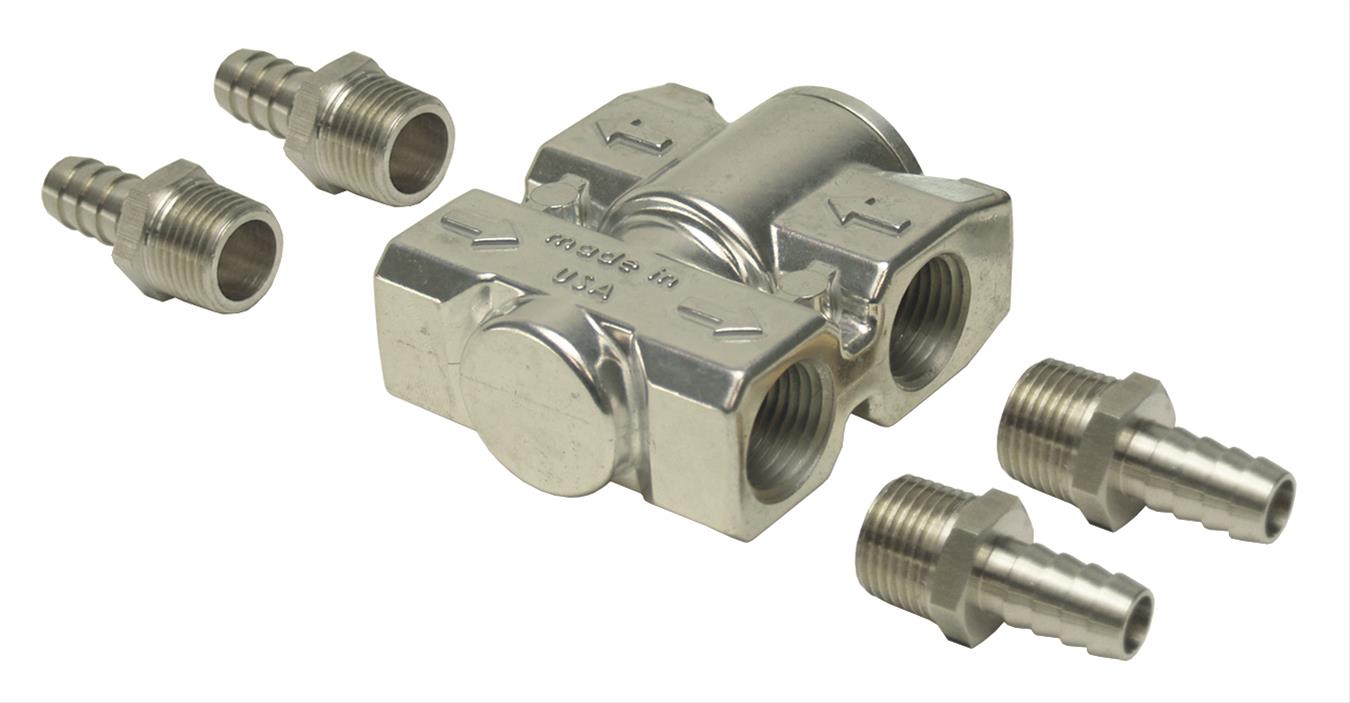

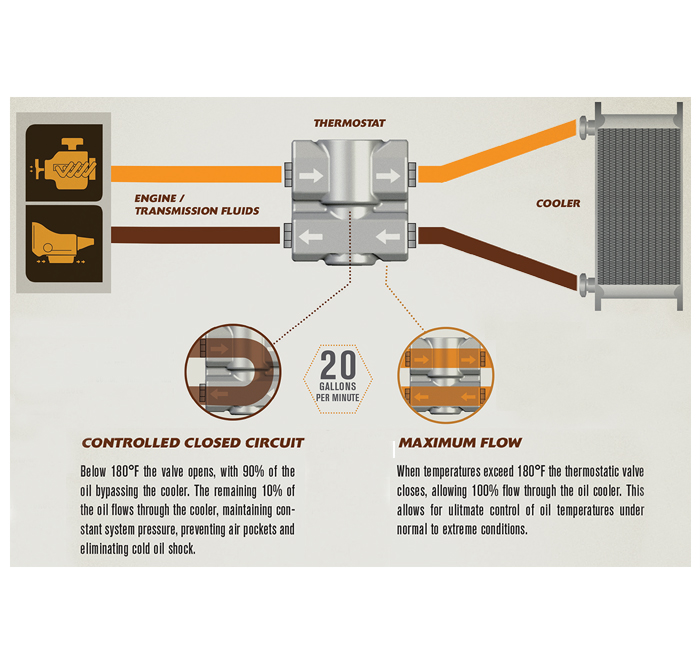

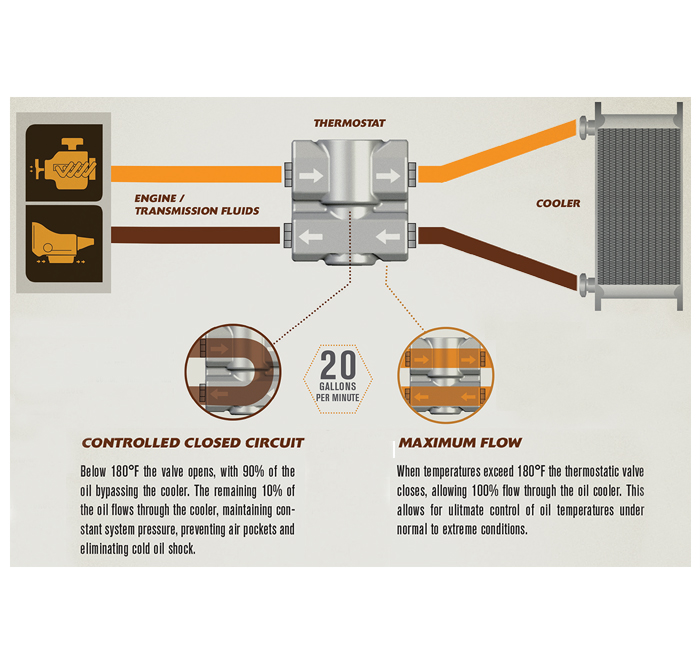

keep in mind a trans fluid t-stat valve like this routes the fluid through the valves bypass directly back to the transmission , bypassing the aux cooler until the trans fluid temp heat reaches a point where a bi-metal valve closes the bypass and then all the hot trans fluid passes through the aux cooler beyond the t-stat valve, no mater how effective the aux fluid cooler is, or how well the fans are at removing heat, the aux cooler never gets a chance to cool fluid until the valve allows fluid to flow through the aux cooler.

On my corvette, I routed the trans fluid through the lower radiator so it rapidly heats by close contact to engine coolant, in the lower radiator just like most cars use,

and then the trans fluid routes through the aux cooler, where its cooled before it route's back to the transmission,

but to prevent over cooling the aux cooler FANS are on a temp controlled switch that only turns the fans on once the fluid reaches 155F, thus the trans rapidly reaches operational temps, but once trans fluid hits about 155F-165F it rarely goes much higher

one of the first things I noticed when I installed a 8 quart baffled oil pan (further modified with extended sump) and a separate transmission and oil cooler on my car was the very noticeable drop in engine temps, in fact the engine had a hard time getting the oil temps up to 215F which is required to burn off moisture in the oil that gets into the engine if it sits for days in Florida, the cure was installing a 190f t-stat and a bye-pass/return on the oil cooler, that bye-passed the cooler with about 90% of the oil flow routed to the cooler until the oil got hot.

if you want to keep the temp from making wide swings as the car runs..

there are 190F-195F t-stats

http://www.ecklers.com/corvette-thermos ... -1991.html

http://www.ecklers.com/corvette-dual-ra ... ct_Related

http://www.tciauto.com/Products/TechInf ... pacity.asp

http://www.ecklers.com/corvette-low-tem ... -1995.html

remote mounted oil filters can be used along with an oil cooler to to increase transmission cooler efficiency

and optional sensors you can use to turn on the fans at lower temps like 155f-200f

If you don,t have both an oil and transmission fluid temp gauge, in addition to the engine coolant temp gauge your probably guessing at the source of your engine heat to some extent

the reason I ask is that I added a 8 quart baffled, oil pan, and a dual transmission and oil cooler to my corvette about 8 years ago plus an oil and transmission fluid temp gauge at the same time

similar to this

READ THRU THIS LINK ALSO

viewtopic.php?f=71&t=662

http://www.summitracing.com/parts/prm-12318

I rapidly became aware that it was the transmission fluid that was the main thing needing to be cooled and that the baffled 8 qt oil pan, was maintaining the oil temps at much lower than the stock oil pan, in fact it was rare for the oil temps to exceed 230F once I installed the 8 quart oil pan,

viewtopic.php?f=54&t=65&p=7977&hilit=canton+baffled#p7977

in fact getting the oil temps up to 215F that is required to burn off oils moisture content and prevent acids forming took a good long time under normal driving conditions, I eventually swapped to a larger transmission cooler and had a bye-pass valve installed so it maintained about 180F , and did away with the oil cooler as the baffled 8 qt oil pan that I modified to a 10 quart capacity by extending the sump was all that was required to maintain a consistent oil temp range.

http://www.tciauto.com/Products/TechInf ... ctancy.asp

theres good info in this thread BELOW also

viewtopic.php?f=71&t=662

your best off installing a transmission fluid cooler of significant size to cool the trans under high stress/high heat load conditions,that has a separate electric fan and a thermostatically controlled switch that routes coolant thru the aux cooler once it reaches 180F, so it can,t get any hotter

http://www.transmissioncoolers.us/Merch ... Code=guide

http://www.transmissioncoolers.us/Merch ... an-coolers

# Small compact cars, No towing Coolers with GVW ratings of 10,000 to 16,000 lbs.

Mid-size cars, Light towing

# Coolers with GVW ratings of 14,000 to 18,000 lbs.

Mid-size trucks & full size cars

Towing up to 5,000 lbs.

# Coolers with GVW ratings of 18,000 to 24,000 lbs.

Pickup Trucks, SUV's

# Towing up to 7,500 lbs. Coolers with GVW ratings of 22,000 to 26,000 lbs.

HD Trucks, Motor homes

Towing up to 10,000 lbs.

# Coolers with GVW ratings of 22,000 to 30,000 lbs.

Super Duty trucks

Large Motor homes

# Coolers with GVW ratings of 28,000 lbs. and UP

keep in mind high hp levels build heat in the transmission fast! once the trans fluid temp exceeds 180 degrees F the trans life expectancy drops, the higher the heat the shorter the expected trans life, trans fluid heat over 220f is sure to hurt the trans after awhile

http://www.transmissioncenter.net/TransTemp.htm

http://www.txchange.com/heatchrt.htm

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRM-12318&N=700+115&autoview=sku

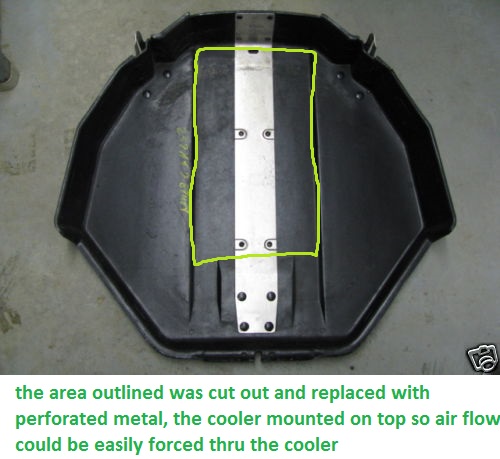

EXAMPLE on my corvette with its limited room .you can (I DID IN the PAST)replace the spare tire/carrier with this

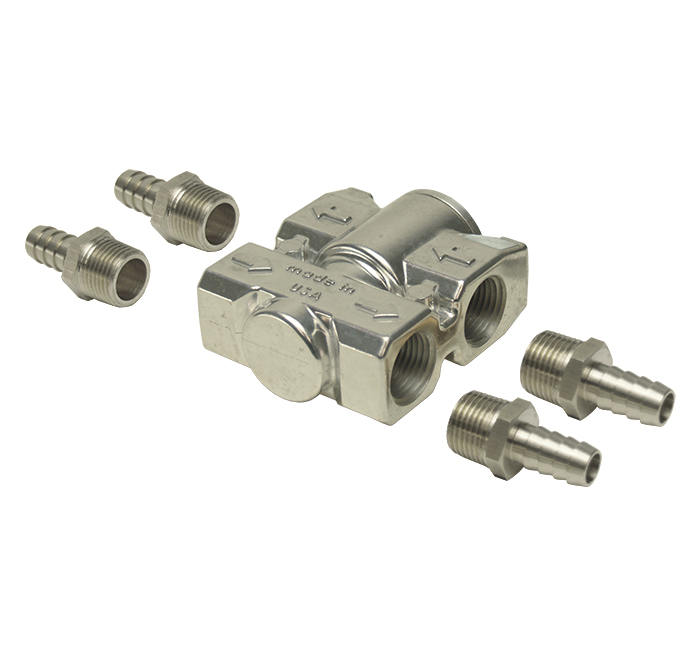

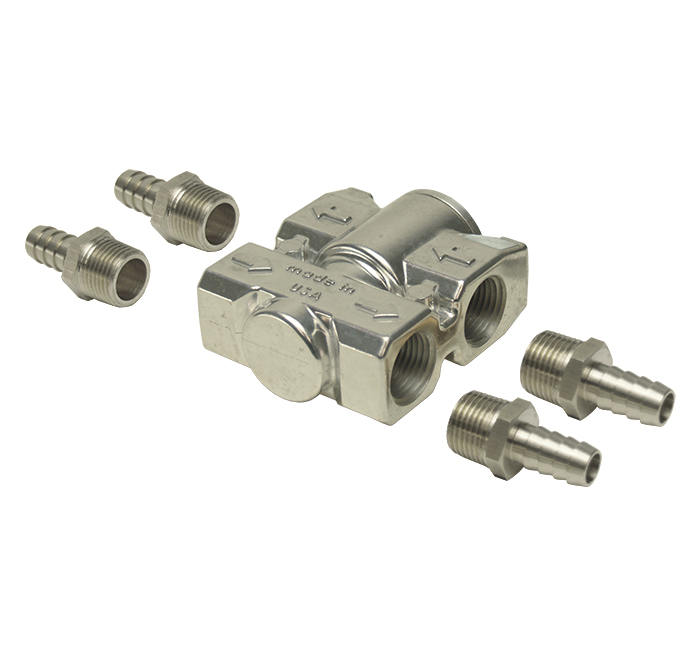

these guys sell adapters

http://www.cantonracing.com/

http://www.summitracing.com/parts/prm-12318

IM currently using this on my 1985 corvertte but have used others in the past

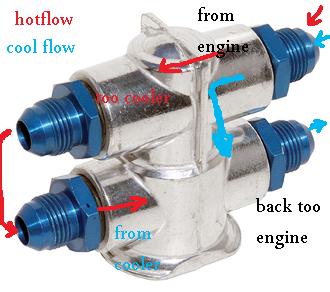

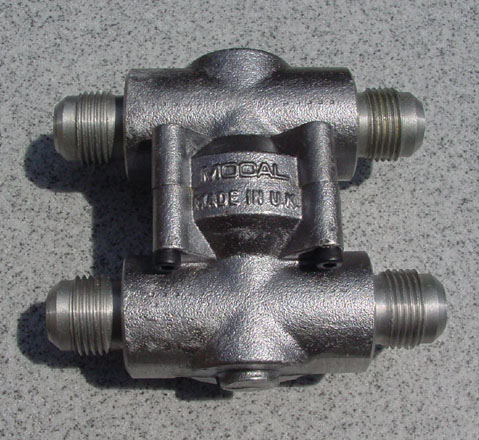

the upper 4 pass connectors went to the trans, the lower two connections to the oil cooler, BUT Ive since swapped to a 6 pass for the trans only as the oil cooler worked TOO effectively and I never got up to full temp..

your correct! LINE SIZE IS IMPORTANT !! a 3/8" inside line size is marginal too useless depending on what percentage of the engine oil that is routed thru the coolers or remote filters, a 1/2" inside dia, line would be in my opinion the minimum that should be considered.

my trans cooler uses a 3/8" line , my oil cooler used to run a 1/2" but I found that the oil cooler was not necessary once I installed the trans cooler and 10 qt baffled oil pan on the car

http://store.summitracing.com/partdetail.asp?part=PRM-185&view=32&N=700+400006+314601

BTW your local hydrolic hose supply house can make good high pressure (MINIMUM 200 PSI hot oil (300 degrees F rated) braided hoses with screw ends if you measure carefully.

route it inside the frame rails and away from the exhaust and drive train, up away from the potential for speed bumps and crap hitting the lines

engine oil needs to reach and stay at about 215F-240f

trans fluid I try to keep under 160F,surely below 180F ,Ideally I try to keep coolant in the engine in the 190F-200F range but don,t get overly worried below 230F.I run a 190F t-stat

you can install AUTO temp control switchs and GAUGES (ideal) or manual switchs and GAUGES (FAR FROM IDEAL), your correct that the engine fluids take slightly longer to reach ideal temps, but then they rarely change after getting into the ideal ranges after you set up the system correctly

http://www.racerpartswholesale.com/mocal.htm

http://store.summitracing.com/partdetail.asp?part=SUM-890015

http://store.summitracing.com/partdetail.asp?part=PRF-30103

http://store.summitracing.com/partdetail.asp?part=PRF-30110

these allow the fluids to circulate but the fan won,t run untill the temp reachs a set limit

keep in mind the hot engine oil running over the blocks surfaces and trans fluid running thru the lower radiator add a good deal of heat to the coolant in the radiator and removing heat elseware from both reduces the radiators heat load, generally stabilizing the engine temp swings

Could an oil cooler be easily disconnected for the winter months? I'd want one in the summer, but not in the winter when it's -25 out."

they are easily disconnected or a re-route valve too bye-pass can be installed, but like I said, the fan never comes on unless the temp band gets exceeded, keep in mind I don,t have that problem living in FLORIDA where its seldom cooler than 60F and usually in the 75F-95F range

"Also, if I were to buy a bigger-than-stock oil pan, would I be able to run it with a quart or two missing during the winter, to help it warm up faster, or no? "

I run a 10 qt oil pan with 10 qts of oil in it with a windage screen on the engine and a two qt deeper than stock trans pan,but about 2 qts are always in the lines and cooler, so IM running slightly lower effective oil levels in the oil pan,as far as windage and the crank spinning thru oil in the sump. it takes about 3-4 miles normal driving or 7-9 minutes at idle too get up to temp if that helps

theres INSTRUCTIONS with the kit, but basically you install the sensor and wire in any fan you choose to , following those instructions and using the new sensor. you can use the original fan, but in most cases a larger aftermarket fan or an additional transmission cooler is used. the sensor screws into the cylinder head

you can also install just an aftermarket fan

http://store.summitracing.com/partdetail.asp?autofilter=1&part=FLX-365&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=HFM-ZFB16S&N=700+320174+4294775279+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=DER-13720&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=DER-15800&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRM-12318&N=700+115&autoview=sku

IM currently using this on my 1985 corvertte but have used others in the past

IF YOUR ON A REALLY LIMITED BUDGET, TAURUS FANS FROM A SALVAGE YARD CAN NORMALLY BE FOUND DIRT CHEAP........HERES INFO LARRY POSTED

"The two diagrams above show how to build and wire an auto relay switched 2-speed FORD TAURUS fan.

Parts needed......10 guage wire for the power circuit. 18 guage wire for the control cicuit.

Three relays..... 1) High speed relay, Tyco VF7-12V,70amps

2)Low speed relay and Aux relay, standard BOSCH relays

Two switches,,,,.1)Low speed temp. switch- Adj. Flexilite, FLX-31147 from SUMMIT.

2)High speed temp. switch from Standard Motor Products, TS-158 or TS-392.

I put the adj. low speed switch and the three relays in seperate relay boxes and mounted them in the engine comp. The high speed temp switch I mounted where one of the heater hoses went. Est. cost of parts, less the fan, is $50.00 . 10 guage wire is used in the power circuit and 18 guage in the control circuit. The 12V switched control circuit can be connected to any live connection with ignition on.

The control circuit shown is as follows..... When the temp. reaches your set low speed figure, let's say 190 deg.the low speed relay is energized thru pin 86, 85 connects to 87A of the AUX relay and pulls 30 of that relay, 87 of the low speed relay and 30 are closed sending power to the fan to run at low speed.

When the temp. reaches your high speed switch figure, let's say 210 deg. pin 86 of the AUX. relay energizes thru 85 and 30 releases from 87A of the low speed relay and connects with 85 of the high speed relay which thru 87 of that relay powers the fan to run at high speed.

ARE we confused yet?????

When the temp falls below the high speed swich figure the AUX relay will switch back to the low speed relay.

Therfore low and high speeds will never be on at the same time and you will have the following conditions...

1) No fan on.

2) Low speed on.

3) High speed on."

BTW

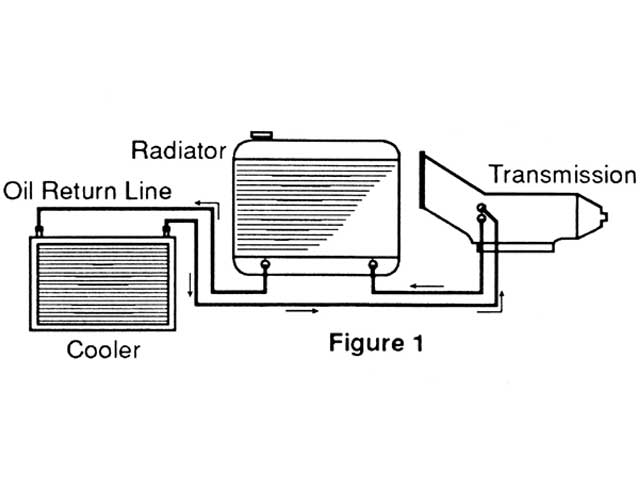

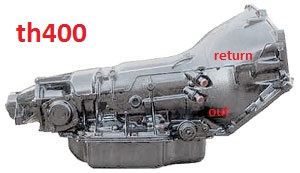

the out flow connection for the trans flluid from the trans which should go to the radiator LOWER connection.

Just remove or re-route the upper radiator connection and run it thru your choice of external cooler and back to the trannie return line (upper radiator connection).

DON,T OVER COOL YOUR ENGINE!

normal, depends on several factors, its state of tune, how you drive, type of oil, etc. but you want it to reach at least 215f on occasions to burn off moisture and anything under 240f is fine, even expected and normal, for short runs while you drive hard, most stock vettes have the oil temp of around 200F-210F while cruising at low rpms

it takes approximately 214F-215F to burn all the moisture out of oil, that moisture comes from outside air when the engine cools and from combustion when the engines not up too temp. and can form acids and rust if it sits, if your cars driven frequently IE it seldom sits for several days at a time your unlikely to have significant moisture forming, especially if the cars garaged most of the time its not in use.

short trips seldom allow the engine to fully reach a stable temp, the state of tune,the outside temps, the amount and type of oil and the temp switch on the fans , the T-STAT, allow or prevent the oil reaching full temp,the RPMS and LOADS the enge sees effects the temps

If you drive the car frequently and seldom let it sit for days at a time AND change oil fairly regularly (3000-4500 miles between changes) you may be fine with the slightly lower temps ,especially if the cars garaged but you can easily check the condition of your engine, pull a valve cover and inspect its inside surface carefully, it should be clean, possiably stained but not have minor acid etching and there should be no sludge , build up,or chocolate milk or waxey film, if there is your engines not running hot enought or your not changing the oil,filter ETC. frequently

BTW I DON,T KNOW WHO SELLS THESE BUT IVE GOT TWO ON MY CORVETTES OIL FILTERS AND THEY EASILY REDUCE OIL TEMPS 7-15 DEGREES

to raise temp install a 190F-200F T-stat, oil temp generally runs 15F-25F higher than COOLANT temps

"MY TRANS FLUID TEMP RUNS 223F is this NORMAL"

no! its NOT normal its a bit higher than normal , normal is about 200F OR LOWER, (check you trans fluid level )and find out the reason WHY its running hotter because its sure to hurt the life span of the transmission, ID add an aux trans cooler, if you can,t find out why its running hotter than it should, check the radiator for crap in the airflow path,check the radiator fluid and make sure the fans are operating, check the sensors, trouble codes, engine timing, etc.

http://www.tciauto.com/Products/Cooling/

http://www.compperformancegroupstor...Screen=PROD&Store_Code=TC&Product_Code=378000

have you installed a higher stall converter or differant rear gear ratio?

adding a aluminum deep sump oil pan helps as it extends down into the airflow under the car, I installed the 2 qt pan, as the 3 qt hurt the under car road clearance too much, but I still needed to install an aux trans cooler once my engine combo started making about twice the stock torque

http://www.digitalcorvettes.com/forums/showthread.php?t=81691

"3/8 inlet on an oil cooler is too restrictive racing or not.

redvetracr"

Id totally agree with that statement if all the oil needed too be run thru the cooler,to keep the temps low but I don,t run all the oil flow, in fact the ENGINE OIL cooler rarely gets much oil flow unless Im racing as theres a temp control switch that opens only when necessary,because just the 10 qt baffled oil pan ON MY ENGINE, does a very effective job of keeping the oil temps reasonable most of the time, just some of the oil bye-passes to the cooler at times, most bye-passes the cooler and it all bye-passes the cooler except on the rare occasions when the oil temp exceeds about 230F. in fact my main problem was getting the oil to REACH and stay above 215F in normal driving where it tended to stay at about 200F-210f untill I starting racing the car, or driving with the over drive gear locked out, then it jumps slowly to 245f-250F which thou higher than ID prefer is still ok for short durrations, I installed the oil cooler mostly to keep the oil temp steady not that it was mandatory, it was the trans fluid cooler that was and is mandatory in my particular application

BTW you can do the same thing if you want to, the oil temp sensor port just above the oil filter in the block, can be used with a TEE, as a feed too the oil cooler , or the more traditional sandwitch adapter over the oil filter, or a modified dual remote oil filter adapter can be used,and theres several options for return paths to the block or oil pan

Ive had about 6 differant configs on my engine and trans cooler set-ups over the last two years alone, trying to get everything to function IDEALLY

remember my hobby is PLAYING WITH, and EXPERIMENTING ON these three corvettes, I own (especially the 1985)and changing combos, cams, heads, exhaust systems , etc, is part of the deal

http://store.summitracing.com/partdetail.asp?autofilter=1&part=FLX-45951&N=700+115&autoview=sku

BTW THERE'S A BIG DIFFERENCE BETWEEN AN OIL COOLER AND A TRANS COOLER, if your looking to run all your ENGINE oil thru a cooler... that's fine, but Id bet you'll find like I did that that's not necessary with a decent baffled high capacity oil pan, and that running SOME of the oil flow is all that's necessary

if its correctly plumbed into the system, but Id point out that there are thermostatically controlled valves that limit the flow thru the cooler too maintain a minimum oil or trans fluid temperature

BUT YOU WILL WANT ALL THE TRANS FLUID TOO RUN THRU A COOLER

IF you can,t tell what your current fluid and oil temps ARE, and if you don,t have temp gauges to monitor the fluid temps, how do you even know you need one, or could reasonably function without adding one.

AND IF you do add one, be sure to think thru the location, and routing the hydraulic lines and what fittings you select.

most hydraulic supply shops can very easily fabricate flex hydraulic lines with matching ends at any length required, pressure drops with remote coolers or filter mounts are almost always the result of using hydraulic lines AND hydraulic line connections with too small an INTERNAL cross sectional area, anything less than AN#8 is bound to be restrictive and AN#10 is far better, and much less likely to cause issues with pressure drops, obviously the adapters and fittings used for fluid transmission must also have at least AN# 8 OR PREFERABLY AN#10 CONNECTIONS , if you run 3/8" OR AN#6 LINES YOUR BOUND TO FIND IT DROPS RETURN LINE PRESSURE, and just as obviously this would mean the passage or tube size of the oil cooler must be at least AN#8 as the coolers with AN#6 internal passages tend to restrict flow so read carefully before you buy an oil or trans coolerand from experience I can assure you that if you need a trans cooler , or OIL COOLER the type with the built in fan and at least 1/2"inside diameter hydraulic lines or AN#10 fittings is by far the best choice, and obviously youll need to carefully measure where your going to mount the cooler and run the lines before ordering a cooler but the larger the surface area the better in most applications

I had similar issues, that many guys experience with oil pressure and flow at higher rpms until I installed less restrictive oil lines to the accessories, when I installed my oil cooler with the AN#6 lines that came in the mounting kit from SUMMIT RACING, swapping to AN #8 lines at first which helped a great deal but once I swapped to AN#10 lines those cured the issue, and yes I mounted my oil cooler where the spare tire normally mounts , so its a good distance from the engine.

shop carefully swapping in an oil cooler or trans cooler with fluid line diameter too small for the application will have a huge effect on the coolers efficiency, and can restrict flow rates

https://www.summitracing.com/parts/prm-13182/overview/

adding an oil cooler with a fan generally helps improve engine durability, I've found those similar to this one( linked below,)make a significant reduction in either trans fluid or oil temps (obviously that depends on what your using it for, and yeah, before ordering one look at the cooler mounting diagram and figure out where you can mount it with enough room for it and the fluid coolant lines feeding it to fit easily and figure out how you connect the electric fan wiring, I've generally suggested use of a temperature switch sensor that turns on the fan on a transmission cooler at about 160F and if used as an oil cooler at 195F-200F

Derale Cooling Products 15870 Derale Hyper-Cool Extreme Remote Fluid Coolers with Fan | Summit Racing

Free Shipping - Derale Hyper-Cool Extreme Remote Fluid Coolers with Fan with qualifying orders of $109. Shop Fluid Coolers at Summit Racing.

the rotating assembly bearings ,wrist pins and complete valve train,valve springs, lifters, valves and valve guides and the pistons and rings are where a great deal of the engine heat is generated, and those components are initially cooled with oil flow that absorbs and transfers the heat collected , and transported from those components to the block and coolant, so having a constant flow of pressurized oil flow over those parts are mandatory for maximum durability.thus adding a larger capacity baffled oil pan and an oil cooler will generally enhance and extend an engines life span.

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

one question that always comes up, is the ideal, size and length of the fluid transmission lines required,

too feed and return hot oil from remote mounted oil coolers and transmission fluid coolers, the simple answer, visit a local professional hydraulic supply shop after taking careful measurements and verifying the type of fittings, thread types used etc.

I would strongly suggest you select, and ask too have fabricated,

(after taking careful measurements and verifying the connection fitting type and threads etc.) high temp ,high pressure ,lines, AN#8-1/2" lines designed to handle 250F temps and 350 PSI. MINIMUM

keep in mind most performance cars with an auto transmission and a higher rpm stall converter, will need an auxiliary trans fluid cooler, Id strongly suggest you find one with an electric fan and 1/2" or AN#8 line size as you'll want to allow a minimum of 2 -3 gallons a minute trans fluid flow rate.

engine oil coolers , TRANSMISSION FLUID COOLERS and remote mounted engine oil coolers with remote filters, also benefit from use of a MINIMUM of a AN#8/1/2" inside diameter fluid transmission line .

Up to 250 GPH =4.2 GPM= 1/2" or -08 AN

nearly ideal for transmission and oil coolers

*

Up to 450 GPH =7.5 GPM= 5/8" or -10 AN

*

Up to 900 GPH = 15GPM 3/4"or -12 AN

keep in mind oil does almost all the initial engine cooling so adding a larger efficient oil cooler with a fan

, and as large an oil pan as clearances allow goes a long way toward reducing engine temps,

you certainly will see a difference if a properly sized and installed oil cooler is used.

you don,t need something this large in most cases

https://www.summitracing.com/parts/flx-700040

something like this makes a noticeable improvement

https://www.summitracing.com/parts/der-15800

remember to accurately measure the area you intend to install any oil cooler,

and leave lots of room for the connecting high pressure oil feed & return lines and access to connect them.

Loves302Chevy posted these diagrams that will be helpful

Derale Cooling Products 15719 Derale Fluid Control Thermostats | Summit Racing

Free Shipping - Derale Fluid Control Thermostats with qualifying orders of $99. Shop Remote Oil Thermostats at Summit Racing.www.summitracing.com

short cut makes sense, if that valve is not functioning correctly a certain percentage (20%-80% ) might be bypassing the coolers, if thats the case ,no mater how effective the aux coolers are the trans fluid returning to the trans would almost never be cooler than the engine coolant temps. and might be marginally higher as the vast majority of the fluid volume never circulated through the coolers at all.

now Im not using that type of thermostat to control fluid temps,

my thermostat control on the trans cooler, simply turns on the FANS on the aux cooler once the temps reach 160F,

Mishimoto MMFAN-CNTL-U18NPT Mishimoto Electric Fan Controller Kits | Summit Racing

Free Shipping - Mishimoto Electric Fan Controller Kits with qualifying orders of $99. Shop Fan Switches at Summit Racing.www.summitracing.com

Mishimoto MMFAN-CNTL-UPROBE Mishimoto Electric Fan Controller Kits | Summit Racing

Free Shipping - Mishimoto Electric Fan Controller Kits with qualifying orders of $99. Shop Fan Switches at Summit Racing.www.summitracing.com

extended length oil filter or even dual extended length oil filters ,

that way you have, a greatly increased filter surface area surface that significantly reduces the resistance to oil flow rates and a significantly larger surface area on the filter medium, that will in theory allow longer use before the filter medium starts to clog with debris .

remember the goal here is two fold, effective cooling of the oil and low flow rate restriction, which a remotely mounted oil filter(s) can supply, plus the option of selecting an easily accessed remote mount filter location

Last edited: Jun 11, 2017

http://www.tciauto.com/tc/cooler-fittings

READ THESE LINK's

http://garage.grumpysperformance.co...-stabilization-temp-vs-time.11043/#post-48999

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/cooling-off-that-c4-corvette.3954/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

http://garage.grumpysperformance.com/index.php?threads/1995-corvette-fan-motor-quit-working.10559/

1984-1989 Corvette Direct Fit®

All Aluminum Radiator for 1984-89 Corvettewww.dewitts.com

1984 – 1989 Corvette C4 Aluminum Radiator | ECP

your much more likely to need a trans fluid cooler, than an engine oil cooler ,engine oil needs to reach 215F to burn off moisture,(measured in the oil pan) (bearing surface temps tend to run 50-60f higher than sump temps.) and as long as it stays under about 230F most of the time its going to function, trans fluid over about 180F tends to reduce trans durability,

a high capacity 7-8 qt baffled oil pan with a windage screen will frequently reduce oil temps to the range where an oil coolers not required, your first step is installing a engine oil temp gauge and transmission fluid temp. gauge..engine coolant temps tend to run about 20f lower than oil in the sump.

BTW HERES AN IMPORTANT TIP, IT is really common for guys to use lines that are far to small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER

think about it, your measuring the oil pressure in most cases AFTER its been thru the cooler and returned to the oil passages in the block, oil leaves the oil pump and its routed to the oil filter where the oil filter adapter routes it thru the oil cooler and back to the adapter then into the block, your measuring the restricted oil flow after its returned to the block, if the lines or cooler passages restrict oil flow its potentially a problem for lubrication of the moving parts if pressure or oil volumes reduced

adding a transmission cooler like this one dropped my trans fluid temps significantly, vastly increasing the potential life expectancy of my 4l80e transmission, I originally had an identical oil cooler installed also, but found that with a trans cooler installed it dropped the heat loads on my radiator to the point getting my engine oil temps above 215F was much more difficult even without the oil cooler.

http://www.summitracing.com/parts/FLX-45901/?rtype=10

http://static.summitracing.com/global/i ... -45901.pdf

http://www.summitracing.com/parts/der-15719

keep in mind a trans fluid t-stat valve like this routes the fluid through the valves bypass directly back to the transmission , bypassing the aux cooler until the trans fluid temp heat reaches a point where a bi-metal valve closes the bypass and then all the hot trans fluid passes through the aux cooler beyond the t-stat valve, no mater how effective the aux fluid cooler is, or how well the fans are at removing heat, the aux cooler never gets a chance to cool fluid until the valve allows fluid to flow through the aux cooler.

On my corvette, I routed the trans fluid through the lower radiator so it rapidly heats by close contact to engine coolant, in the lower radiator just like most cars use,

and then the trans fluid routes through the aux cooler, where its cooled before it route's back to the transmission,

but to prevent over cooling the aux cooler FANS are on a temp controlled switch that only turns the fans on once the fluid reaches 155F, thus the trans rapidly reaches operational temps, but once trans fluid hits about 155F-165F it rarely goes much higher

one of the first things I noticed when I installed a 8 quart baffled oil pan (further modified with extended sump) and a separate transmission and oil cooler on my car was the very noticeable drop in engine temps, in fact the engine had a hard time getting the oil temps up to 215F which is required to burn off moisture in the oil that gets into the engine if it sits for days in Florida, the cure was installing a 190f t-stat and a bye-pass/return on the oil cooler, that bye-passed the cooler with about 90% of the oil flow routed to the cooler until the oil got hot.

if you want to keep the temp from making wide swings as the car runs..

there are 190F-195F t-stats

http://www.ecklers.com/corvette-thermos ... -1991.html

http://www.ecklers.com/corvette-dual-ra ... ct_Related

http://www.tciauto.com/Products/TechInf ... pacity.asp

http://www.ecklers.com/corvette-low-tem ... -1995.html

remote mounted oil filters can be used along with an oil cooler to to increase transmission cooler efficiency

and optional sensors you can use to turn on the fans at lower temps like 155f-200f

If you don,t have both an oil and transmission fluid temp gauge, in addition to the engine coolant temp gauge your probably guessing at the source of your engine heat to some extent

the reason I ask is that I added a 8 quart baffled, oil pan, and a dual transmission and oil cooler to my corvette about 8 years ago plus an oil and transmission fluid temp gauge at the same time

similar to this

READ THRU THIS LINK ALSO

viewtopic.php?f=71&t=662

http://www.summitracing.com/parts/prm-12318

I rapidly became aware that it was the transmission fluid that was the main thing needing to be cooled and that the baffled 8 qt oil pan, was maintaining the oil temps at much lower than the stock oil pan, in fact it was rare for the oil temps to exceed 230F once I installed the 8 quart oil pan,

viewtopic.php?f=54&t=65&p=7977&hilit=canton+baffled#p7977

in fact getting the oil temps up to 215F that is required to burn off oils moisture content and prevent acids forming took a good long time under normal driving conditions, I eventually swapped to a larger transmission cooler and had a bye-pass valve installed so it maintained about 180F , and did away with the oil cooler as the baffled 8 qt oil pan that I modified to a 10 quart capacity by extending the sump was all that was required to maintain a consistent oil temp range.

http://www.tciauto.com/Products/TechInf ... ctancy.asp

theres good info in this thread BELOW also

viewtopic.php?f=71&t=662

your best off installing a transmission fluid cooler of significant size to cool the trans under high stress/high heat load conditions,that has a separate electric fan and a thermostatically controlled switch that routes coolant thru the aux cooler once it reaches 180F, so it can,t get any hotter

http://www.transmissioncoolers.us/Merch ... Code=guide

http://www.transmissioncoolers.us/Merch ... an-coolers

# Small compact cars, No towing Coolers with GVW ratings of 10,000 to 16,000 lbs.

Mid-size cars, Light towing

# Coolers with GVW ratings of 14,000 to 18,000 lbs.

Mid-size trucks & full size cars

Towing up to 5,000 lbs.

# Coolers with GVW ratings of 18,000 to 24,000 lbs.

Pickup Trucks, SUV's

# Towing up to 7,500 lbs. Coolers with GVW ratings of 22,000 to 26,000 lbs.

HD Trucks, Motor homes

Towing up to 10,000 lbs.

# Coolers with GVW ratings of 22,000 to 30,000 lbs.

Super Duty trucks

Large Motor homes

# Coolers with GVW ratings of 28,000 lbs. and UP

keep in mind high hp levels build heat in the transmission fast! once the trans fluid temp exceeds 180 degrees F the trans life expectancy drops, the higher the heat the shorter the expected trans life, trans fluid heat over 220f is sure to hurt the trans after awhile

http://www.transmissioncenter.net/TransTemp.htm

http://www.txchange.com/heatchrt.htm

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRM-12318&N=700+115&autoview=sku

EXAMPLE on my corvette with its limited room .you can (I DID IN the PAST)replace the spare tire/carrier with this

these guys sell adapters

http://www.cantonracing.com/

http://www.summitracing.com/parts/prm-12318

IM currently using this on my 1985 corvertte but have used others in the past

the upper 4 pass connectors went to the trans, the lower two connections to the oil cooler, BUT Ive since swapped to a 6 pass for the trans only as the oil cooler worked TOO effectively and I never got up to full temp..

your correct! LINE SIZE IS IMPORTANT !! a 3/8" inside line size is marginal too useless depending on what percentage of the engine oil that is routed thru the coolers or remote filters, a 1/2" inside dia, line would be in my opinion the minimum that should be considered.

my trans cooler uses a 3/8" line , my oil cooler used to run a 1/2" but I found that the oil cooler was not necessary once I installed the trans cooler and 10 qt baffled oil pan on the car

http://store.summitracing.com/partdetail.asp?part=PRM-185&view=32&N=700+400006+314601

BTW your local hydrolic hose supply house can make good high pressure (MINIMUM 200 PSI hot oil (300 degrees F rated) braided hoses with screw ends if you measure carefully.

route it inside the frame rails and away from the exhaust and drive train, up away from the potential for speed bumps and crap hitting the lines

engine oil needs to reach and stay at about 215F-240f

trans fluid I try to keep under 160F,surely below 180F ,Ideally I try to keep coolant in the engine in the 190F-200F range but don,t get overly worried below 230F.I run a 190F t-stat

you can install AUTO temp control switchs and GAUGES (ideal) or manual switchs and GAUGES (FAR FROM IDEAL), your correct that the engine fluids take slightly longer to reach ideal temps, but then they rarely change after getting into the ideal ranges after you set up the system correctly

http://www.racerpartswholesale.com/mocal.htm

http://store.summitracing.com/partdetail.asp?part=SUM-890015

http://store.summitracing.com/partdetail.asp?part=PRF-30103

http://store.summitracing.com/partdetail.asp?part=PRF-30110

these allow the fluids to circulate but the fan won,t run untill the temp reachs a set limit

keep in mind the hot engine oil running over the blocks surfaces and trans fluid running thru the lower radiator add a good deal of heat to the coolant in the radiator and removing heat elseware from both reduces the radiators heat load, generally stabilizing the engine temp swings

Could an oil cooler be easily disconnected for the winter months? I'd want one in the summer, but not in the winter when it's -25 out."

they are easily disconnected or a re-route valve too bye-pass can be installed, but like I said, the fan never comes on unless the temp band gets exceeded, keep in mind I don,t have that problem living in FLORIDA where its seldom cooler than 60F and usually in the 75F-95F range

"Also, if I were to buy a bigger-than-stock oil pan, would I be able to run it with a quart or two missing during the winter, to help it warm up faster, or no? "

I run a 10 qt oil pan with 10 qts of oil in it with a windage screen on the engine and a two qt deeper than stock trans pan,but about 2 qts are always in the lines and cooler, so IM running slightly lower effective oil levels in the oil pan,as far as windage and the crank spinning thru oil in the sump. it takes about 3-4 miles normal driving or 7-9 minutes at idle too get up to temp if that helps

theres INSTRUCTIONS with the kit, but basically you install the sensor and wire in any fan you choose to , following those instructions and using the new sensor. you can use the original fan, but in most cases a larger aftermarket fan or an additional transmission cooler is used. the sensor screws into the cylinder head

you can also install just an aftermarket fan

http://store.summitracing.com/partdetail.asp?autofilter=1&part=FLX-365&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=HFM-ZFB16S&N=700+320174+4294775279+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=DER-13720&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=DER-15800&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRM-12318&N=700+115&autoview=sku

IM currently using this on my 1985 corvertte but have used others in the past

IF YOUR ON A REALLY LIMITED BUDGET, TAURUS FANS FROM A SALVAGE YARD CAN NORMALLY BE FOUND DIRT CHEAP........HERES INFO LARRY POSTED

"The two diagrams above show how to build and wire an auto relay switched 2-speed FORD TAURUS fan.

Parts needed......10 guage wire for the power circuit. 18 guage wire for the control cicuit.

Three relays..... 1) High speed relay, Tyco VF7-12V,70amps

2)Low speed relay and Aux relay, standard BOSCH relays

Two switches,,,,.1)Low speed temp. switch- Adj. Flexilite, FLX-31147 from SUMMIT.

2)High speed temp. switch from Standard Motor Products, TS-158 or TS-392.

I put the adj. low speed switch and the three relays in seperate relay boxes and mounted them in the engine comp. The high speed temp switch I mounted where one of the heater hoses went. Est. cost of parts, less the fan, is $50.00 . 10 guage wire is used in the power circuit and 18 guage in the control circuit. The 12V switched control circuit can be connected to any live connection with ignition on.

The control circuit shown is as follows..... When the temp. reaches your set low speed figure, let's say 190 deg.the low speed relay is energized thru pin 86, 85 connects to 87A of the AUX relay and pulls 30 of that relay, 87 of the low speed relay and 30 are closed sending power to the fan to run at low speed.

When the temp. reaches your high speed switch figure, let's say 210 deg. pin 86 of the AUX. relay energizes thru 85 and 30 releases from 87A of the low speed relay and connects with 85 of the high speed relay which thru 87 of that relay powers the fan to run at high speed.

ARE we confused yet?????

When the temp falls below the high speed swich figure the AUX relay will switch back to the low speed relay.

Therfore low and high speeds will never be on at the same time and you will have the following conditions...

1) No fan on.

2) Low speed on.

3) High speed on."

BTW

the out flow connection for the trans flluid from the trans which should go to the radiator LOWER connection.

Just remove or re-route the upper radiator connection and run it thru your choice of external cooler and back to the trannie return line (upper radiator connection).

DON,T OVER COOL YOUR ENGINE!

normal, depends on several factors, its state of tune, how you drive, type of oil, etc. but you want it to reach at least 215f on occasions to burn off moisture and anything under 240f is fine, even expected and normal, for short runs while you drive hard, most stock vettes have the oil temp of around 200F-210F while cruising at low rpms

it takes approximately 214F-215F to burn all the moisture out of oil, that moisture comes from outside air when the engine cools and from combustion when the engines not up too temp. and can form acids and rust if it sits, if your cars driven frequently IE it seldom sits for several days at a time your unlikely to have significant moisture forming, especially if the cars garaged most of the time its not in use.

short trips seldom allow the engine to fully reach a stable temp, the state of tune,the outside temps, the amount and type of oil and the temp switch on the fans , the T-STAT, allow or prevent the oil reaching full temp,the RPMS and LOADS the enge sees effects the temps

If you drive the car frequently and seldom let it sit for days at a time AND change oil fairly regularly (3000-4500 miles between changes) you may be fine with the slightly lower temps ,especially if the cars garaged but you can easily check the condition of your engine, pull a valve cover and inspect its inside surface carefully, it should be clean, possiably stained but not have minor acid etching and there should be no sludge , build up,or chocolate milk or waxey film, if there is your engines not running hot enought or your not changing the oil,filter ETC. frequently

BTW I DON,T KNOW WHO SELLS THESE BUT IVE GOT TWO ON MY CORVETTES OIL FILTERS AND THEY EASILY REDUCE OIL TEMPS 7-15 DEGREES

to raise temp install a 190F-200F T-stat, oil temp generally runs 15F-25F higher than COOLANT temps

"MY TRANS FLUID TEMP RUNS 223F is this NORMAL"

no! its NOT normal its a bit higher than normal , normal is about 200F OR LOWER, (check you trans fluid level )and find out the reason WHY its running hotter because its sure to hurt the life span of the transmission, ID add an aux trans cooler, if you can,t find out why its running hotter than it should, check the radiator for crap in the airflow path,check the radiator fluid and make sure the fans are operating, check the sensors, trouble codes, engine timing, etc.

http://www.tciauto.com/Products/Cooling/

http://www.compperformancegroupstor...Screen=PROD&Store_Code=TC&Product_Code=378000

have you installed a higher stall converter or differant rear gear ratio?

adding a aluminum deep sump oil pan helps as it extends down into the airflow under the car, I installed the 2 qt pan, as the 3 qt hurt the under car road clearance too much, but I still needed to install an aux trans cooler once my engine combo started making about twice the stock torque

http://www.digitalcorvettes.com/forums/showthread.php?t=81691

"3/8 inlet on an oil cooler is too restrictive racing or not.

redvetracr"

Id totally agree with that statement if all the oil needed too be run thru the cooler,to keep the temps low but I don,t run all the oil flow, in fact the ENGINE OIL cooler rarely gets much oil flow unless Im racing as theres a temp control switch that opens only when necessary,because just the 10 qt baffled oil pan ON MY ENGINE, does a very effective job of keeping the oil temps reasonable most of the time, just some of the oil bye-passes to the cooler at times, most bye-passes the cooler and it all bye-passes the cooler except on the rare occasions when the oil temp exceeds about 230F. in fact my main problem was getting the oil to REACH and stay above 215F in normal driving where it tended to stay at about 200F-210f untill I starting racing the car, or driving with the over drive gear locked out, then it jumps slowly to 245f-250F which thou higher than ID prefer is still ok for short durrations, I installed the oil cooler mostly to keep the oil temp steady not that it was mandatory, it was the trans fluid cooler that was and is mandatory in my particular application

BTW you can do the same thing if you want to, the oil temp sensor port just above the oil filter in the block, can be used with a TEE, as a feed too the oil cooler , or the more traditional sandwitch adapter over the oil filter, or a modified dual remote oil filter adapter can be used,and theres several options for return paths to the block or oil pan

Ive had about 6 differant configs on my engine and trans cooler set-ups over the last two years alone, trying to get everything to function IDEALLY

remember my hobby is PLAYING WITH, and EXPERIMENTING ON these three corvettes, I own (especially the 1985)and changing combos, cams, heads, exhaust systems , etc, is part of the deal

http://store.summitracing.com/partdetail.asp?autofilter=1&part=FLX-45951&N=700+115&autoview=sku

BTW THERE'S A BIG DIFFERENCE BETWEEN AN OIL COOLER AND A TRANS COOLER, if your looking to run all your ENGINE oil thru a cooler... that's fine, but Id bet you'll find like I did that that's not necessary with a decent baffled high capacity oil pan, and that running SOME of the oil flow is all that's necessary

if its correctly plumbed into the system, but Id point out that there are thermostatically controlled valves that limit the flow thru the cooler too maintain a minimum oil or trans fluid temperature

BUT YOU WILL WANT ALL THE TRANS FLUID TOO RUN THRU A COOLER

Last edited by a moderator: