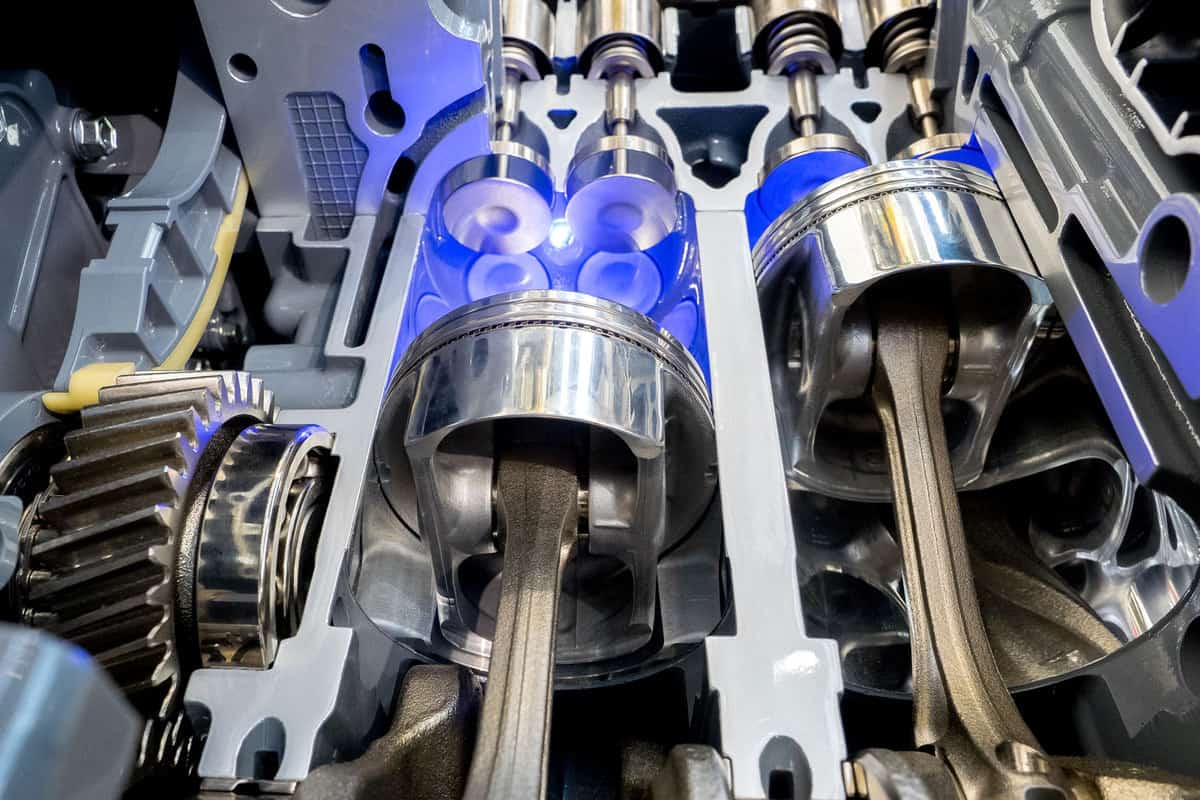

its been my experience that quench distances tighter than about .035 tend to allow the piston to almost or marginally contact the cylinder head under high heat and high load conditions.

now admittedly I mostly built BBC engines, and mostly with the longer 6.385" or with the stock 6.135" connecting rods,

keep in mind the steel used or alloy , length and cross section of the rod design has some effect,

on the connecting rods elongation under high stress and as the heat is increased.

you should keep in mind every choice made is a compromise in some areas, planning is critical, but reality can bite you in financial the ass.

incremental gains through minor mods while surely possible and yes proven, to work,but adding those mods,

are at some point ,mods to the engine,or transmission, that are becoming rapidly more, expensive and thus restrictive to completion of a durable & functional engine than the benefits are to the overall build, those mods may produce minor and documented gains, but the minor gains produced are far out weighted by the cost of the mods, especially in a daily drivers engine, things that make sense in a formula 1 or NASCAR engine build, are cost prohibitive to do on a street car, simply shedding weight on the car or improving the aerodynamics, may be far cheaper and result in greater performance.

I've built a few dozen 489-496 BBC engines in the past for guys with novas, camaros chevelles etc, that had visions of having a 10 second or faster car on the street, and the results of having a significantly more powerful engines always resulted in the need for mods like suspension mods,

like traction bars, air shocks, bigger tires, bigger brakes, better engine cooling systems, new stronger differentials, etc. that they may have never considered, that were required to make the car handle correctly, this is never a cheap hobby, but at some point there's a limit to what your wallet will tolerate and how long you want to deal with a car who's engine is (STILL UNDER CONSTRUCTION SO I CAN'T DRIVE IT YET)

Thermal expansion coefficients metals.

www.engineeringtoolbox.com

Tutorial on internal combustion engine (ICE) pistons: types, characteristics and technologies

x-engineer.org

you might want to read thru these links for info also first lets point out how you calculate 4000 Feet Per Minute, in piston speed, which in most chevy v8 engines is a reasonable durability limit in one revolution a piston moves from TDC (top dead center )TO BDC (bottom dead center)and back to...

garage.grumpysperformance.com

Do the mfg's advertise their weights with or without bolts? I have a set of 6" h-beams that weigh 715grams with 1.75 long ARP bolts. Without they weight about 645g empty They look like Scat, Callies, Carillo and others but they dont have the chamfered edge at the bolt end like all of those...

garage.grumpysperformance.com

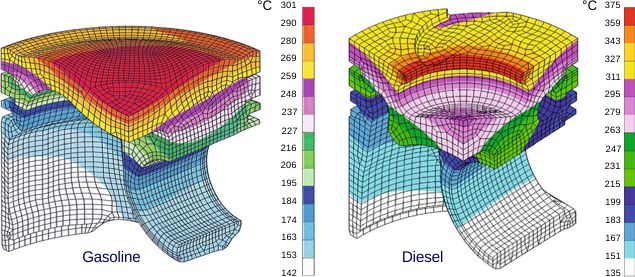

btw 301c- about 574F

now consider you measure the piston to deck clearance at lets say 80F degrees and oil temps generally run under 275F

BUT PISTON TEMPS CAN EASILY EXCEED 400f, SO LETS SAY THE CONNECTING RODS ARE EXPOSED TO A 240f INCREASE IN TEMPERATURE

now , you can generally expect a length extension, of perhaps .06% elongation per 100f rise in temp

thus .006x2.4=.00144 or maybe .00919" over a 6.135 inch long rod, due to thermal expansion alone so a .035 quench is reduced to about .026 , now remember that piston,

is under stress from inertial loads, especially on the exhaust stroke , that easily reduces quench by about a further .006, your down to maybe

.0020 quench, add slack in bearing clearances and your easily down to less than .0020 quench, that is ignoring thermal expansion of the aluminum piston, and your lucky to have .017 with effective quench clearance at 6000 plus rpm.

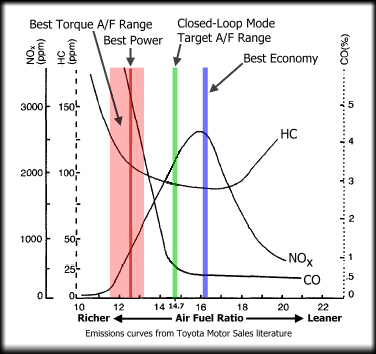

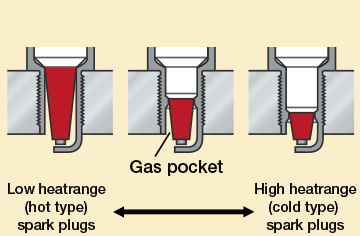

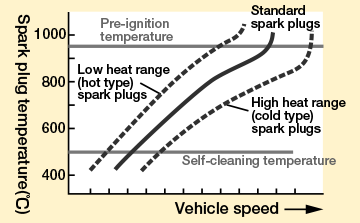

Id also point out that when the piston deck to cylinder head quench surface is less than about .040,

and if you use a fairly RICH F/A mix, you retard or prevent detonation simply because you don't allow enough HEAT to be generated to allow ignition to be maintained as the two surfaces in very close proximity will not allow combustion to continue, as they absorb a good deal of heat while the surfaces are adjacent, but remember theres only about 12-20 degrees of the 360 degrees of rotation while the two surfaces are in close proximity.

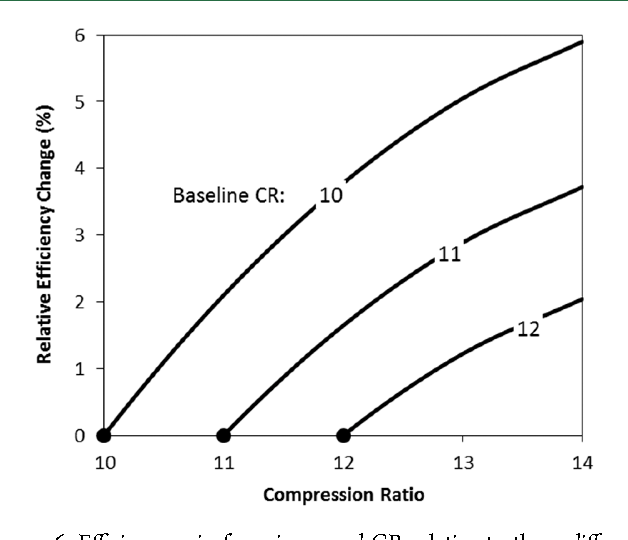

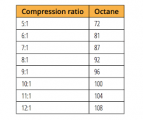

look at this chart

doing a quick check on the math,

the piston will be within 2mm off the cylinder head surface for a full 20 degrees,

of rotation from 10 degrees before to 10 degrees after tdc

www.torqsoft.net

from "both sides", no real conclusion.

from "both sides", no real conclusion.