hey grumpyvette?

I need to be able to roll over my crank several times, Especially while I work on my engine ,

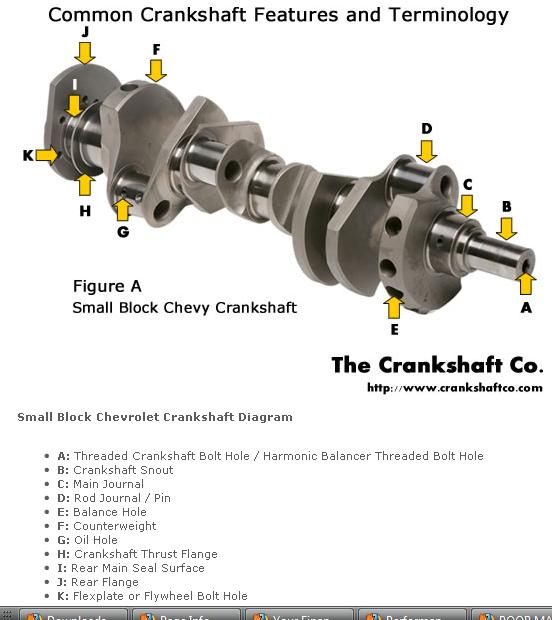

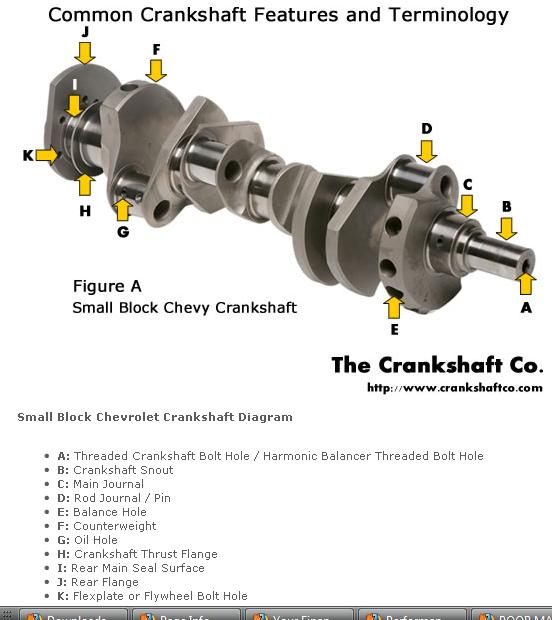

and I would prefer not to risk messing up the crank snout threads for the balancer bolt.

I need to check crank to cam TDC and turn the crank during cam installation and piston installation!

keep in mind...

The motor is in the car, and I would like to avoid removing it.

Is there a socket that goes over the crank shaft snout in the front that locks onto the for most woodruff key?

I'm imagining something that would slide over the snout, engage that woodruff key,

and have a 3/4" hex head on the end of it mate with a socket or wrench. Does any such animal exist?"

yes both a crank nose socket that fits the existing wood drift key and a tool that bolts to a damper if its installed also exists, and there's a flywheel turning tool that allows you to use the flywheel or flex plate to turn the engine in either direction

sure they do,read these threads posted below

BTW I assume you gentlemen do know theres

even a correct and very inexpensive tool for spinning it from the flex-plate or flywheel,

once the cylinder heads are installed,

so your not stressing the damper retention bolt spinning the engine over manually,

https://www.summitracing.com/parts/wmr-w80510/overview/

https://www.summitracing.com/parts/sum-900178/overview/

RELATED INFO

http://www.circletrack.com/enginetech/c ... ce_basics/

http://www.dougherbert.com/engine-rotat ... 3f028e3b64

http://www.summitracing.com/parts/PRO-67491/

viewtopic.php?f=50&t=455&p=559&hilit=crank+turning#p559

MORE USEFUL INFO

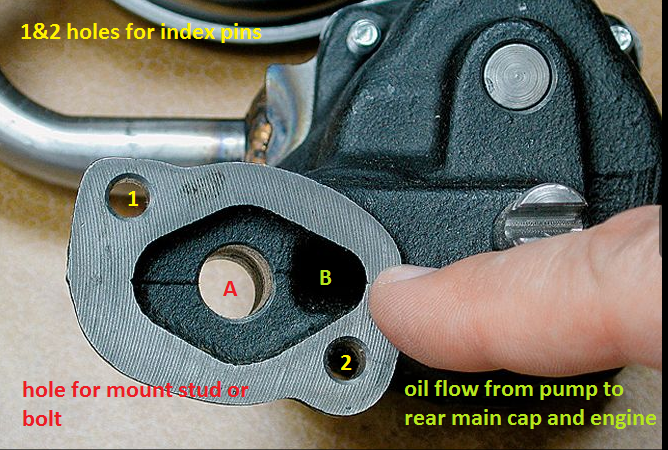

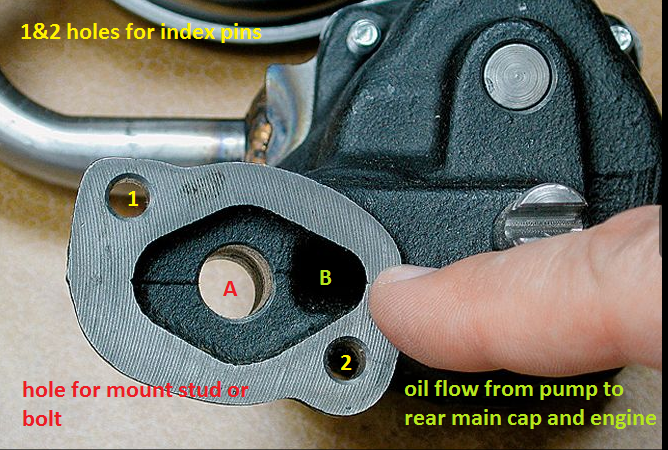

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing

failure to use the correct stud, bolt or nut or check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

THE PROFORM SOCKETS ARE ALUMINUM

http://www.summitracing.com/parts/PRO-67492/

http://www.summitracing.com/parts/PRO-67491/

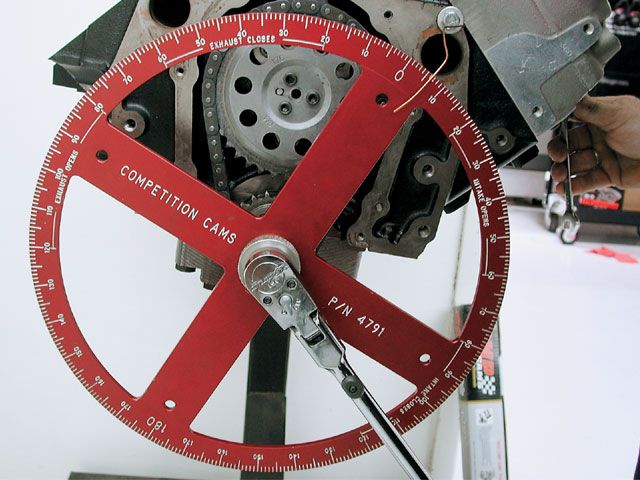

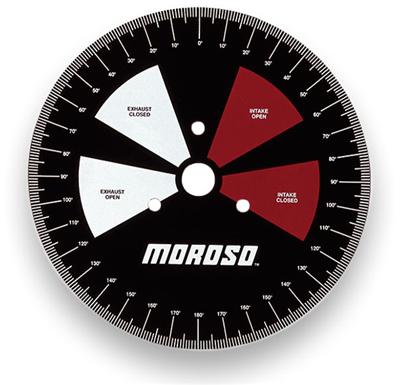

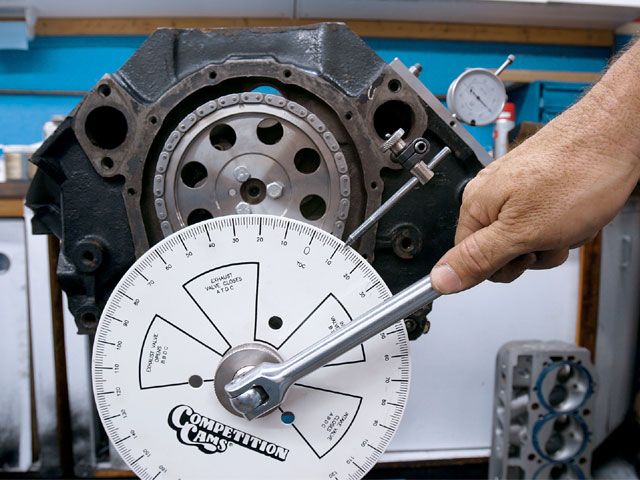

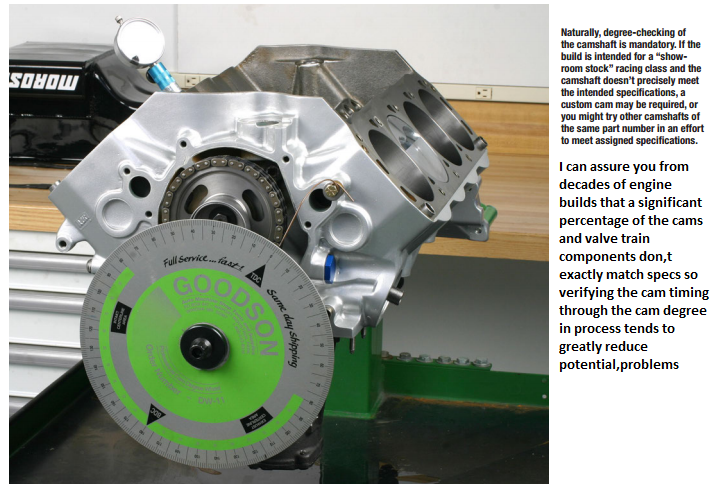

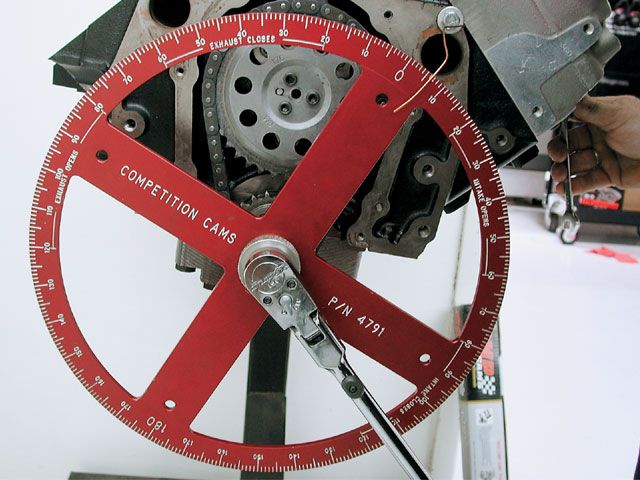

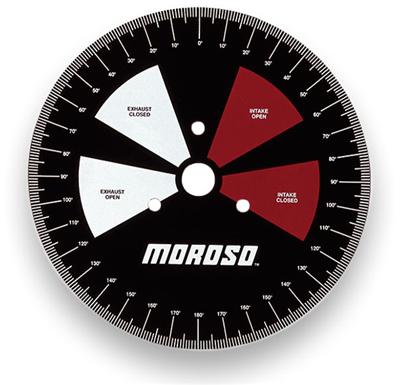

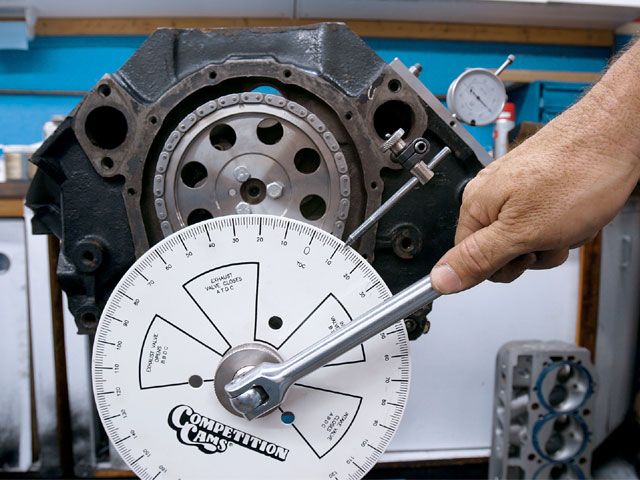

when purchasing a crank socket try to find one designed to easily accept and lock down a degree wheel

THE COMP SOCKETS ARE FAR MORE DURABLE STEEL

http://www.jegs.com/i/COMP+Cams/249/4914/10002/-1 LS ENGINES

http://www.jegs.com/i/COMP-Cams/249/479 ... ProductId= BBC ENGINES

http://www.jegs.com/i/COMP-Cams/249/479 ... ProductId= SBC ENGINES

as to the rotational smoothness, be aware that, all assembly lubes and oil on blocks bore the rings ride over and all bearing surfaces, coated with oil and assembly lube provide a surface shear tension that must be broken before the crank turns,

so its not un-usually for the rotating assembly after the pistons and rings are installed, too require lets say 35 ft lbs to get the assembly too start too spin ,but only 15-26 ft lbs to keep in rotating , (low tension rings provide less drag) you can generally call the piston ring manufacturers and they should know approximately what torque reading on the crank snout,a socket and a torque wrench will require to have the engine assembly rotate with their rings installed.

a crank snout, turning socket,but if that short block assembly,takes over 35-40 lbs to start it rotating once its assembled without cylinder heads attached, you've got serious issues, like cam lobe to connecting roods hitting or a connecting rod facing the wrong way on the crank journal, or the wrong size bearings, or the crank journals not the right size, badly polished or not round

that's why you'll need a torque beam deflection torque wrench to check that

(btw when using a piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow entrance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

you then buy a 6" threaded bolt, screw it into the plug body

be aware that on BBC engines with flat top pistons that probe bolt must be extended rather deeply ,

to contact the piston, simply because the plug thread angle is so shallow, this also means you'll want to remove all the spark plugs and make damn sure the engines in neutral when you manually turn the engine over so you easily feel the probe bolt contact the piston,

you don't want to bend the piston stop probe bolt or damage a piston crown,

bending a valve, or be fighting valve spring resistance

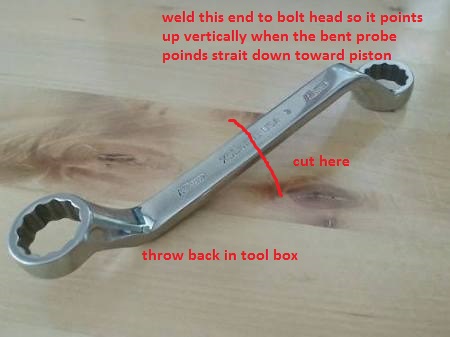

with similar thread pitch and thread that fully threaded bolt about 3" of that bolt extending past the spark plug base,

and heat and bend it with your propane or acetolene torch in a shallow curve,

now BRAZE or weld a cheap socket head wrench to the bolt head so it can,t move off the bolt and indexed so ,

its pointing strait up when the bent internal part of the piston stop points strait down ward

now you can stick the bent bolt into the cylinder, thread the bolt body into the head and once its seated in the head,

you can easily index the bent part to point down into the cylinder where it will contact the piston as it rotates

which a strait bolt would not do due to the shallow entrance angle

be aware that you need to be able to feel the engine stop when it contacts the probe tip, if you don't manually turn the engine after first removing the other spark plugs ,

and backing off the rockers the resistance to rotation the valve train and compression have will make felling the piston contacting the piston stop difficult,

and you damn sure don't want to bend or break the piston stop.

I need to be able to roll over my crank several times, Especially while I work on my engine ,

and I would prefer not to risk messing up the crank snout threads for the balancer bolt.

I need to check crank to cam TDC and turn the crank during cam installation and piston installation!

keep in mind...

The motor is in the car, and I would like to avoid removing it.

Is there a socket that goes over the crank shaft snout in the front that locks onto the for most woodruff key?

I'm imagining something that would slide over the snout, engage that woodruff key,

and have a 3/4" hex head on the end of it mate with a socket or wrench. Does any such animal exist?"

yes both a crank nose socket that fits the existing wood drift key and a tool that bolts to a damper if its installed also exists, and there's a flywheel turning tool that allows you to use the flywheel or flex plate to turn the engine in either direction

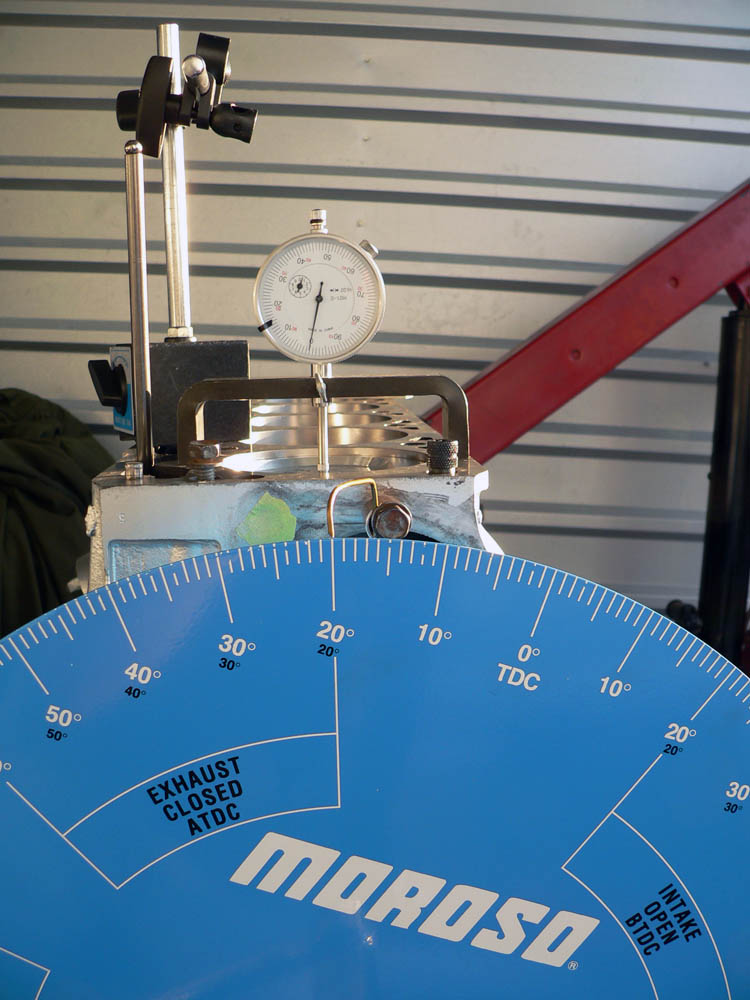

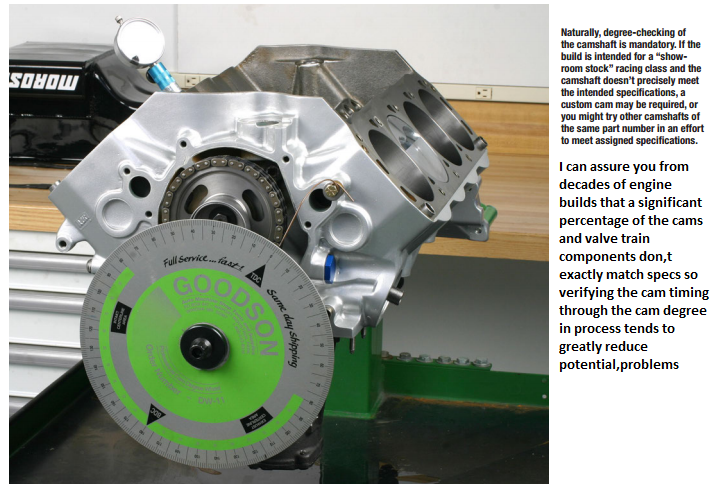

Cam Degree equipment / tools

GrumpyVette I've bin reading alot about cam degreeing since i'll be attempting this in the next week or so, I'm pretty sure I can handle the process but wanted to know about the tools used I've read and also watch a video about degreeing a cam but have not found out is it better to use the...

garage.grumpysperformance.com

resistance to rotation, of crank durring short blk assembly

Ok youve just installed your crankshaft in the engine block, with new main bearings and everything's well coated with assembly lube,and oil, and youve torqued down the main caps to spec. in at least three stages, and then gone back and rechecked the studs or bolts per the manufacturers...

garage.grumpysperformance.com

degreeing cam and shifting the lca

I finally got to degree my cam tonight. First cam I've ever done on a build. How far off the cam card timing numbers before most builders would correct with adv/ret? My cam timing numbers were withing 1 to 1.5 degrees and my intake and exhaust C.L. were withing 1/2 a degree...

garage.grumpysperformance.com

sure they do,read these threads posted below

flywheel turning tool?

GRUMPY??? Im trying to install a flex plate and torque converter, and degree in a cam, install a damper etc. with the mostly fully assembled engine in the car , and access to the damper retention bolt is not an option, with a socket and breaker bar and you certainly can't do it under most...

garage.grumpysperformance.com

even a correct and very inexpensive tool for spinning it from the flex-plate or flywheel,

once the cylinder heads are installed,

so your not stressing the damper retention bolt spinning the engine over manually,

https://www.summitracing.com/parts/wmr-w80510/overview/

https://www.summitracing.com/parts/sum-900178/overview/

RELATED INFO

http://www.circletrack.com/enginetech/c ... ce_basics/

http://www.dougherbert.com/engine-rotat ... 3f028e3b64

http://www.summitracing.com/parts/PRO-67491/

viewtopic.php?f=50&t=455&p=559&hilit=crank+turning#p559

MORE USEFUL INFO

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing

failure to use the correct stud, bolt or nut or check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

THE PROFORM SOCKETS ARE ALUMINUM

http://www.summitracing.com/parts/PRO-67492/

http://www.summitracing.com/parts/PRO-67491/

when purchasing a crank socket try to find one designed to easily accept and lock down a degree wheel

THE COMP SOCKETS ARE FAR MORE DURABLE STEEL

http://www.jegs.com/i/COMP+Cams/249/4914/10002/-1 LS ENGINES

http://www.jegs.com/i/COMP-Cams/249/479 ... ProductId= BBC ENGINES

http://www.jegs.com/i/COMP-Cams/249/479 ... ProductId= SBC ENGINES

as to the rotational smoothness, be aware that, all assembly lubes and oil on blocks bore the rings ride over and all bearing surfaces, coated with oil and assembly lube provide a surface shear tension that must be broken before the crank turns,

so its not un-usually for the rotating assembly after the pistons and rings are installed, too require lets say 35 ft lbs to get the assembly too start too spin ,but only 15-26 ft lbs to keep in rotating , (low tension rings provide less drag) you can generally call the piston ring manufacturers and they should know approximately what torque reading on the crank snout,a socket and a torque wrench will require to have the engine assembly rotate with their rings installed.

a crank snout, turning socket,but if that short block assembly,takes over 35-40 lbs to start it rotating once its assembled without cylinder heads attached, you've got serious issues, like cam lobe to connecting roods hitting or a connecting rod facing the wrong way on the crank journal, or the wrong size bearings, or the crank journals not the right size, badly polished or not round

that's why you'll need a torque beam deflection torque wrench to check that

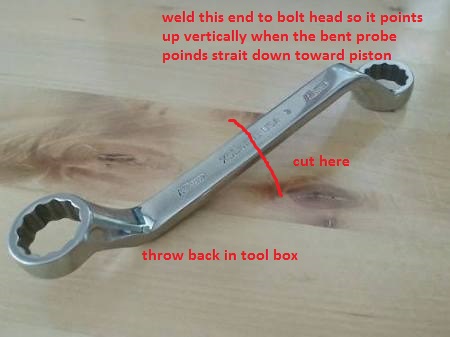

(btw when using a piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow entrance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

you then buy a 6" threaded bolt, screw it into the plug body

be aware that on BBC engines with flat top pistons that probe bolt must be extended rather deeply ,

to contact the piston, simply because the plug thread angle is so shallow, this also means you'll want to remove all the spark plugs and make damn sure the engines in neutral when you manually turn the engine over so you easily feel the probe bolt contact the piston,

you don't want to bend the piston stop probe bolt or damage a piston crown,

bending a valve, or be fighting valve spring resistance

finding top dead center #1 for timing ignition & cam

INSTRUCTIONS, on the procedure Find Top Dead Center before you can set the ignition timing or install a cam correctly youll need to know how to locate TOP DEAD CENTER on cylinder #1 yeah, it takes a bit of work and a few accurate tools, but you don,t need to do much compared to tearing the...

garage.grumpysperformance.com

and heat and bend it with your propane or acetolene torch in a shallow curve,

now BRAZE or weld a cheap socket head wrench to the bolt head so it can,t move off the bolt and indexed so ,

its pointing strait up when the bent internal part of the piston stop points strait down ward

now you can stick the bent bolt into the cylinder, thread the bolt body into the head and once its seated in the head,

you can easily index the bent part to point down into the cylinder where it will contact the piston as it rotates

which a strait bolt would not do due to the shallow entrance angle

be aware that you need to be able to feel the engine stop when it contacts the probe tip, if you don't manually turn the engine after first removing the other spark plugs ,

and backing off the rockers the resistance to rotation the valve train and compression have will make felling the piston contacting the piston stop difficult,

and you damn sure don't want to bend or break the piston stop.

Last edited by a moderator: