AmericanPie said:Soon I'll be doing a mostly stock rebuild of the original 327/300 from my '65 Impala, using a mild (216/228 @ .050" dur., .454"/.480" lift) hydraulic Crane cam. I've been advised that Crane springs tend to be too strong for street use and will probably wear the cam prematurely. Is this true, and if so what would be a good choice in quality springs for this engine? This will be basically a street cruiser, w/ power peak of about 5500 rpm. Thanks!

ASSUMING ALL VALVE SPRINGS FROM ANY SOURCE are too strong, too weak or anything else is absurd ! keep in mind the LAST THING any manufacture wants is customers having problems with their products , so they go to great lengths to insure durability and trouble free operation, thus they try to suggest the best possible matching components.

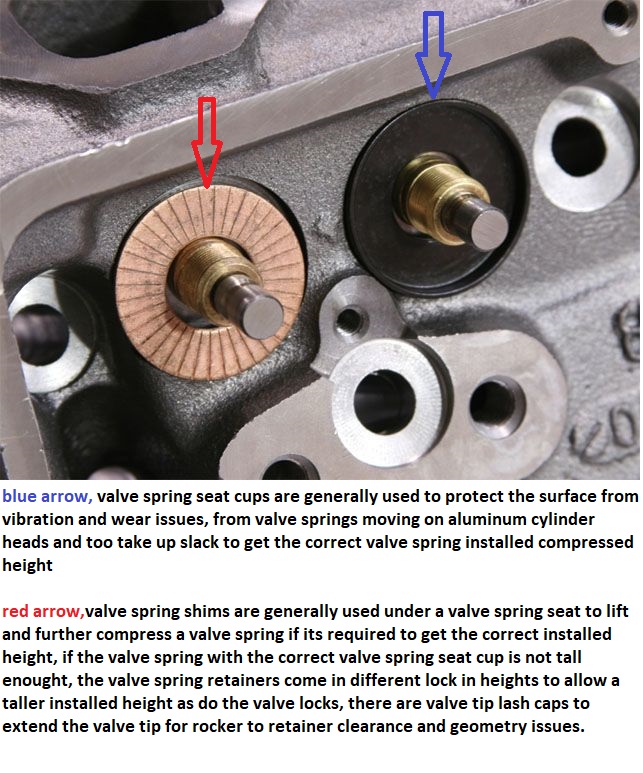

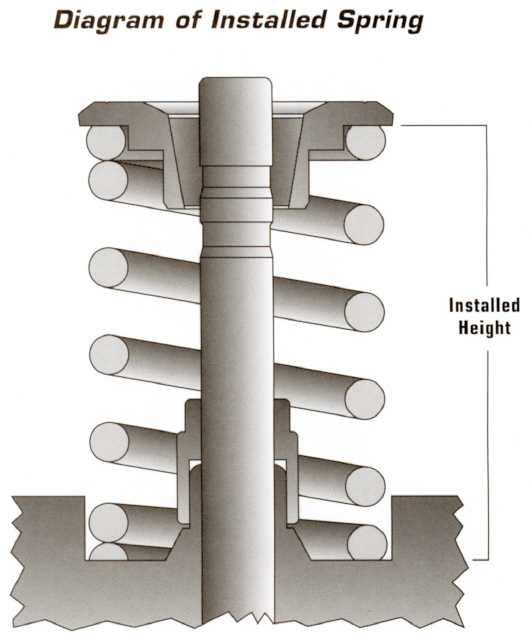

most suppliers have dozens if not hundreds of different valve springs to choose from and most valve spring load rates change to some degree depending on the installed height and cam lift used.

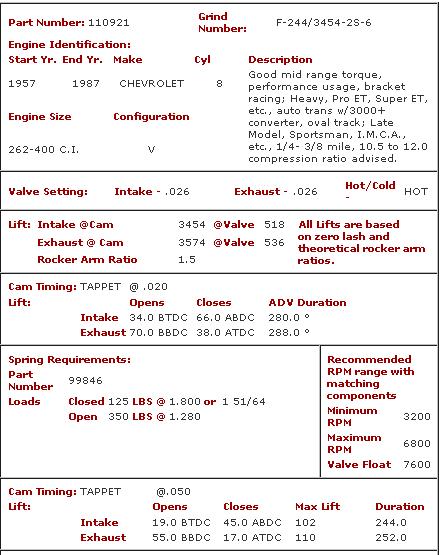

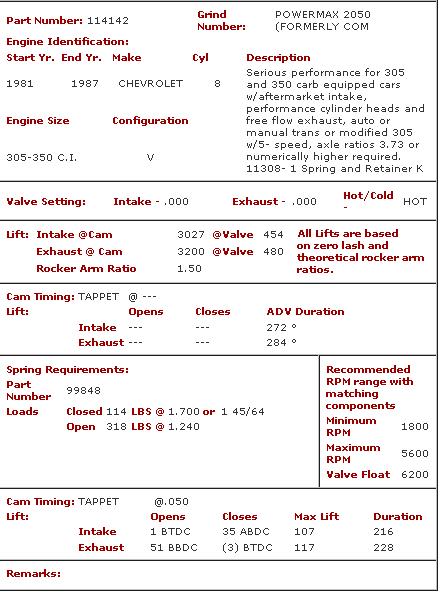

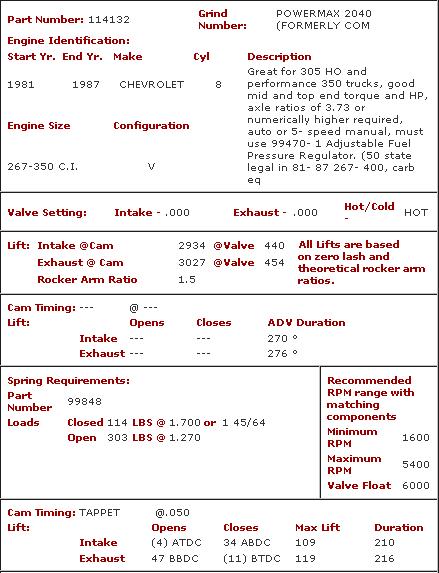

from your limited description of the cam I think your referring to this cam I'll link too, as you can see it listed the proper springs , as PART # 99848 and installed height at 1.70 inches and load rate is certainly not excessively high as listed at 114 lb seat and 318lb open btw Ive run that cam and the slightly milder crane 114132 in my corvettes 383 in the past and I think youll find the slightly milder crane cam #114132 a better match

(especially if you use 1.6:1 ratio rockers as it has better low and mid rpm torque and gives up very little peak power)

in your particular application so I'll post a link at the bottom

THE CRANE HYDRAULIC FLAT TAPPET CAM THAT I THINK YOU ARE REFERRING TOO

AND TAKE THE TIME TOO

,read this link

http://www.engineprofessional.com/articles/EPQ215_18-38.pdf

OBVIOUSLY YOULL WANT THE CORRECT VALVE SPRINGS

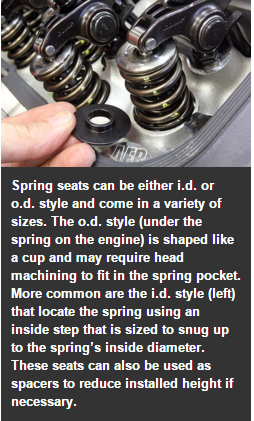

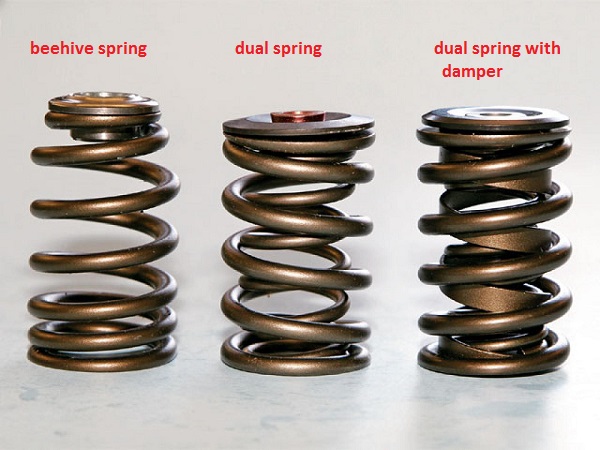

the reduced diameter of beehive valve springs usually eliminates the rocker too retainer clearance issue

BEEHIVE SPRINGS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

https://goodson.com/collections/cylinder-head-rebuilding-tools

http://www.cylinderheadsupply.com/kl8540.html

http://www.kmotion.biz/instht.htm

http://www.competitionproducts.com/1500-1585-OD-Valve-Springs/products/2631/1/0

https://www.summitracing.com/search/part-type/valve-springs

https://www.iskycams.com/cart/valve-springs-c-99.html

http://www.cranecams.com/userfiles/file/334-343.pdf

https://www.racingsprings.com/Valve-Spring/Store/13

http://www.lunatipower.com/Category.aspx?id=23

http://www.pspring.com/products/engine-valve-springs/

http://www.competitionproducts.com/Valve-Springs/departments/49/

http://psisprings.com/products/

http://www.compcams.com/Products/CC-'Valve Springs By Usage'-0.aspx

http://www.racingsprings.com/Beehive-Valve-Springs

https://www.supertechperformance.com/valve-springs-p109

http://www.cvproducts.com/index.php/psi-springs/

http://www.crower.com/media/pdf/2008b/153-155.pdf

http://www.lunatipower.com/Tech/Valvetrain/HowToVerifyValvetrainGeometry.aspx

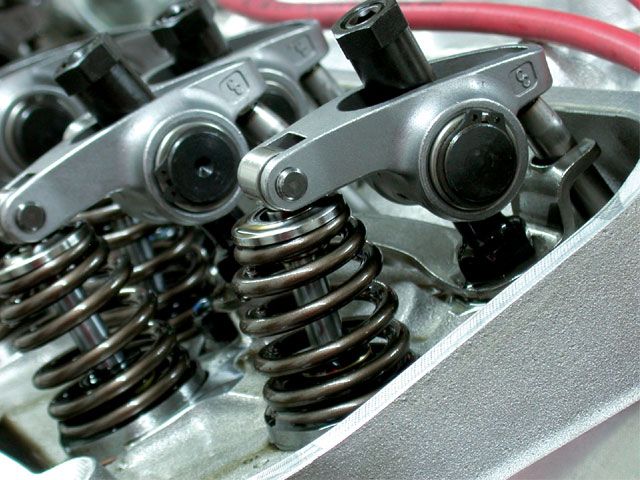

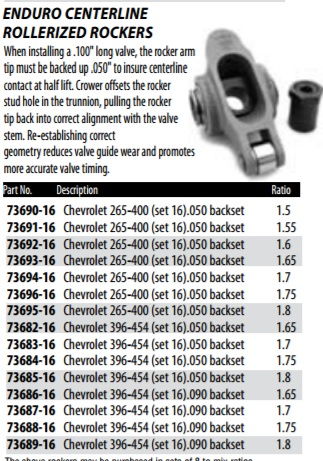

keep in mind all roller rockers do not have identical dimensions, crower offers .050 off set trunion designs ans the designs dimensions do differ slightly between manufacturers

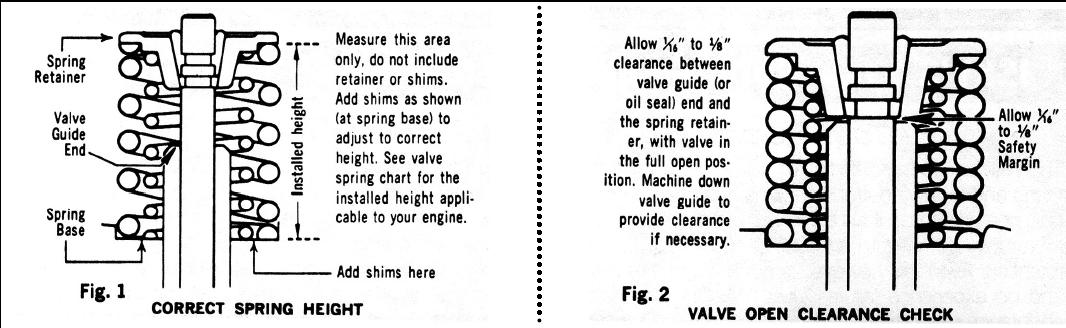

it only takes a few seconds running a new engine for an improperly installed cam , lifters and valve train, during the break-in process to generate teaspoons of metallic trash that ,once in the engine oil flow ,rapidly destroys bearings if the clearances ,spring load rates or valve train geometry is wrong

even roller cams can wipe out lobes if the valve train components, are not matched correctly, or the spring load rates are not correct, or valve train lubrication, geometry is not set up correctly

http://garage.grumpysperformance.co...d-high-spring-pressures-don-t-work-well.1489/

CRANE, ISKY,ERSON, CROWER, or most any other cam manufacturer will supply you with the correct MATCHING valve springs and the IDEAL height installed specs, if you ask and pay for them

The following recommendations are from Erson Cams. If you have questions, you can reach their tech department at 800-641-7920.

ALL MAJOR CAM MANUFACTURERS TECH DEPARTMENTS WILL SUPPLY THIS INFO IF ASKED

Hydraulic Flat Tappet Camshaft: 110 lbs Seat pressure/250-280 lbs open pressure

Solid Flat Tappet Camshaft: 130 lbs Seat Pressure/300-325 lbs open pressure

Hydraulic Roller Camshaft: 130-140 lbs Seat Pressure/300- 355 lbs open pressure

Solid Roller Camshaft: (Minimum Safe Pressures DEPEND ON SEVERAL FACTORS)

Up to .600 valve lift: 200-235 lbs Seat Pressure/600 lbs open pressure

Over .600 valve lift: 250-280 lbs Seat pressure /100 lbs pressure for every .100 of valve lift

theres also direct sources

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

heres a bit of useful related push rod length info (POSTED HERE) youll want to select the correct set or SETS for your shop

Big Block Chevy, Standard Length Big Block Intake 3/8" / .080" 8.275"

295-7941-8 Big Block Chevy, Standard Length Big Block Exhaust 3/8" / .080" 9.250"

295-7969-8 Big Block Chevy, Standard Big Block +.100" Long Intake 3/8" / .080" 8.375"

295-7979-8 Big Block Chevy, Standard Big Block +.100" Long Exhaust 3/8" / .080" 9.350"

295-7951-8 Big Block Chevy, Standard Length Big Block Tall Deck Intake 3/8" / .080" 8.675"

295-7961-8 Big Block Chevy, Standard Length Big Block Tall Deck Exhaust 3/8" / .080" 9.650"

295-7800 V8 396-454 Retro Fit Pushrod Set, Intake & Exhaust, 1965-Present

3/8" / .080"

3/8" / .080" 7.725 Int.

8.675 Exh

295-7913-16 Small Block Chevy, Standard Length Small Block Chevy 3/8" / .080" 7.800"

295-7984-16 Small Block Chevy, +.100" Long 3/8" / .080" 7.900"

295-7934-16 Big Block Ford, Standard Length Ford `72-'78 429-460 3/8" / .080" 8.550"

295-7951-16 Big Block Ford, Standard Length Ford `69-'71 429-460 3/8" / .080" 8.675"

295-7582-16 Oldsmobile, Std Length 455 5/16" 9.550"

http://www.psisprings.com/index.php?opt ... &Itemid=34

http://www.ferrea.com/Valve-Springs/c7535

http://www.racingsprings.com/

http://www.racingsprings.com/Valve-Springs/Store/13

http://www.cranecams.com/bulletins_list ... catagory=4

http://www.compcams.com/Products/CC-%27 ... %27-0.aspx

https://www.lunatipower.com/Category.aspx?id=23

RELATED INFO YOU SHOULD READ THRU

http://www.kmotion.biz/instht.htm

Id also point out that youll want to lubricate any valve you install in a valve guide and verify the valve train clearances very carefully, and use the correct valve springs and add the correct valve seals installed

Last edited by a moderator: