Virtual Cooling Solutions

The emergence—and continued development—of software-based modeling and testing is challenging some longstanding beliefs in this critical performance segment.

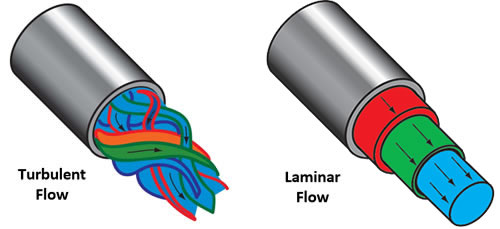

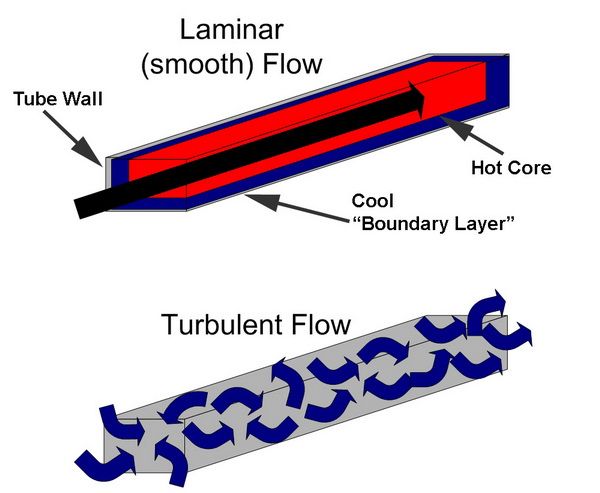

Again we can debunk the myth that slowing down the coolant flow will help cool an engine. It's all about turbulent flow that scrubs the surface of the tube ID removing the boundary layer. Turbulent flow is also why detonation is so destructive to a piston, it scrubs or wipes away the boundary layer that protects/insulates the piston from the high temperatures of combustion.

“We hit that wall every so often with customers where they have a certain belief one way,” he added, “but it’s been proven, and it’s discovered that it is the complete opposite.”

Pairaktaridis told us one persistent myth is that “you have to slow down coolant to spend more time in the radiator.”

“That’s absolutely wrong,” he continued. “You actually need to increase the velocity of the coolant so it will increase turbulent flow.”

Pairaktaridis explained, “Turbulent flow in the cooling system is ridiculously important because it is able to pull more heat and dissipate more heat into the system. You want to pull heat from the engine and dissipate it to the heat exchanger. By increasing velocity of the coolant flow, you are actually increasing turbulent flow within the cooling system, which is able to dissipate more heat.

So what is the boundary layer and why is it so important??? I couldn't find exactly what I was looking for to illustrate this. Think about flow in a pipe, the center will have the greatest velocity, but as you approach the pipe wall the velocity slows down until it reaches zero. That zero region is the boundary layer that insulates the surface. That is until the fluid exceeds a certain velocity, then the flow becomes turbulent, then it is scrubbing the surface. Turbulent flow is what you want in a radiator, but not if you are a piston.

Another myth to consider ......

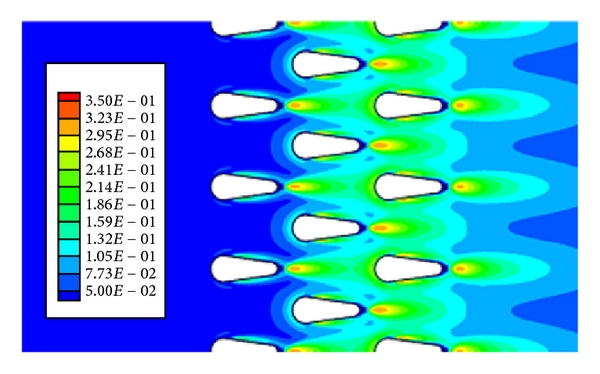

Consider radiator thickness: Whereas many still believe thicker means better, Pairaktaridis said CAD and CFD have shown evidence to the contrary.

“As air travels through the core, it picks up heat,” he explained. “At a certain point it reaches a level of saturation where no more heat is being pulled through. The thicker the core, the more restrictive it is, so air is actually slowing down; it is picking up the saturation point a lot earlier.”

Speaking to the advantage of a thinner radiator “in many cases,” Pairaktaridis pointed out that “not only are you saving in weight and space, but it also cools better. So you can have your cake and eat it, too.

Last edited:

to upgrade the quality and quantity of info in links and sub links,

to upgrade the quality and quantity of info in links and sub links,