You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vortec Bowtie For Marine 383?

- Thread starter JohnCanoe

- Start date

the answer to the question on the choice between the standard port vortec heads ,

and the larger would be heavily influenced by what the engines intended to do, and over what expected rpm range,

on a milder 383 that will seldom exceed about 5500 rpm the smaller port size would be my selection.

this linked info might help, be aware that the cam may need to be changed if the exhaust is in the water ,

as some cams are not compatible with marine exhaust use ,

as they tend to suck water into the engine at some rpm ranges.

be sure you discuss that in depth with the engines cam supply manufacturer

http://www.superchevy.com/how-to/76178-chevrolet-ht-383-engine

http://www.compcams.com/xr282hr

and the larger would be heavily influenced by what the engines intended to do, and over what expected rpm range,

on a milder 383 that will seldom exceed about 5500 rpm the smaller port size would be my selection.

this linked info might help, be aware that the cam may need to be changed if the exhaust is in the water ,

as some cams are not compatible with marine exhaust use ,

as they tend to suck water into the engine at some rpm ranges.

be sure you discuss that in depth with the engines cam supply manufacturer

http://www.superchevy.com/how-to/76178-chevrolet-ht-383-engine

http://www.compcams.com/xr282hr

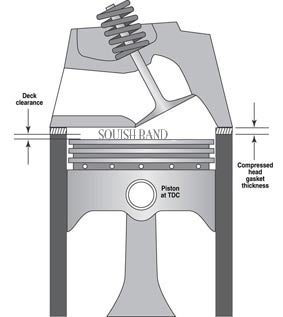

Awesome. I was leaning toward that one. On a different subject. Someone was telling me to go with an LCQ style piston to maximize Q/E with Vortec heads. What exactly qualifies as an LCQ style piston? I think it’s a subset of dished pistons but what exactly defines it?the milder cam looks good too me in the application you describe

you should try for a 8:1 dynamic compression,

a vortec cylinder head and dual plane intake on a 383 SBC, and that cam ,

matched to a dynamic 8:1 compression should produce a very useable,

and quickly accessible power band well over 440 ft lbs of tq.

a vortec cylinder head and dual plane intake on a 383 SBC, and that cam ,

matched to a dynamic 8:1 compression should produce a very useable,

and quickly accessible power band well over 440 ft lbs of tq.

Last edited:

So I made my first component purchase for my build and I’m pretty stoked about it. I got a set of Wiseco Pro Tru Reverse Dome Pistons with 20 cc dish volumes. With these pistons my SCR should be as high as 9.54:1 and my DCR 7.83:1. https://kmjperformance.com/wiseco-p...MIuZaPt5__5AIVBm6GCh0OSAczEAQYAiABEgJLSvD_BwE

One of the things I’ve been wondering is what size of carb would be optimal for the build? There’s a Holley marine carb with annular boosters originally designed for ski boats that I like but it only comes in a 600 cfm rating. When I ran the carb calculator on Summit’s website the recommendation is actually in that ballpark but it seems many think 600 cfm is too small for my application. Thoughts?

One of the things I’ve been wondering is what size of carb would be optimal for the build? There’s a Holley marine carb with annular boosters originally designed for ski boats that I like but it only comes in a 600 cfm rating. When I ran the carb calculator on Summit’s website the recommendation is actually in that ballpark but it seems many think 600 cfm is too small for my application. Thoughts?

600 cfm for a 383 used in a marine application should be fine/

http://4secondsflat.com/Carb_CFM_Calculator.html

http://www.wallaceracing.com/carb-cfm-vacuum.php

http://www.wallaceracing.com/calcdchg.php

keep in mind youll rarely exceed 85% efficiency with a wet exhaust or exceed about 6000 rpm the cam you sellected will be well past max power by 6000 rpm

Id also point out flow is measured at a vacuum of 1.5" of mercury, if the vacuum is higher flow increases, or put a different way..

Id have selected a 600-650 cfm carb.

http://4secondsflat.com/Carb_CFM_Calculator.html

http://www.wallaceracing.com/carb-cfm-vacuum.php

http://www.wallaceracing.com/calcdchg.php

keep in mind youll rarely exceed 85% efficiency with a wet exhaust or exceed about 6000 rpm the cam you sellected will be well past max power by 6000 rpm

Id also point out flow is measured at a vacuum of 1.5" of mercury, if the vacuum is higher flow increases, or put a different way..

Id have selected a 600-650 cfm carb.

your choice of use of a properly balanced, one piece rear seal crank, in that 383 has almost zero effect on anything you might be concerned with at any power or rpm range you'll see,

internally balanced cranks have less inertial stress, but that stress is almost only an important factor if your intention is to spin the engine over 6000 rpm for extended periods.

And one piece rear seals tend to last longer and leak less frequently.

http://garage.grumpysperformance.com/index.php?threads/ballancing-the-assembly.259/

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

internally balanced cranks have less inertial stress, but that stress is almost only an important factor if your intention is to spin the engine over 6000 rpm for extended periods.

And one piece rear seals tend to last longer and leak less frequently.

http://garage.grumpysperformance.com/index.php?threads/ballancing-the-assembly.259/

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

Last edited:

Thanks! It’s settled, late model roller block it is. Based on this, I’ve purchased a crank. I also just bought the connecting rods. I’m pretty excited! The components I’ve bought for the build so far are linked below. I know its probably a random order to purchase components in but the pistons were the only reverse/inverted dome model I could find in 4032 alloy in the dish volume range I wanted and they were discontinued a few years ago so supply is essentially nonexistent. This also applies to the marine Holley as it is not made anymore in that exact configuration with the annular boosters. Based on that I figured I’d go ahead and get them. Grumpy asked earlier about my budget for the build. I haven’t really set a hard budget, I’m just picking up the components as I go. I’m not really in a hurry as I’m going to be away from home at work on tugboats until April and the SeaCraft for which I’m building the engine is going to be in storage until May.

https://kmjperformance.com/wiseco-p...MIuZaPt5__5AIVBm6GCh0OSAczEAQYAiABEgJLSvD_BwE

https://allcarbs.com/product/holley-marine-carburetor-600-cfm-75021/

https://www.cnc-motorsports.com/4-3...d-weight-crankshaft-sb-chevy-383-stroker.html

https://www.cnc-motorsports.com/sca...-premium-pro-comp-i-beam-connecting-rods.html

https://kmjperformance.com/wiseco-p...MIuZaPt5__5AIVBm6GCh0OSAczEAQYAiABEgJLSvD_BwE

https://allcarbs.com/product/holley-marine-carburetor-600-cfm-75021/

https://www.cnc-motorsports.com/4-3...d-weight-crankshaft-sb-chevy-383-stroker.html

https://www.cnc-motorsports.com/sca...-premium-pro-comp-i-beam-connecting-rods.html

Last edited: