I'm building up a ZZ4 block....Rotating assembly is installed and hove purchased the ZZ4 cam....Will be adding AFR 180cc heads...The heads come with these springs: http://www.jegs.com/i/AFR-Airflow-Research/033/8017/10002/-1 Which seem rather stiff to me, considering the stock spring for the ZZ4/LT4 is this: http://www.jegs.com/i/GM+Performanc...PRjh249p9QEvrRS_SWUpCS45QE7aW_TDBqBoCtILw_wcB

its generally a very good idea to keep all the cam, lifter,valve train and cylinder head components in matched sets, keep components in labeled matched sets, if you intend to reuse used parts in a rebuild. as each wears in, or laps in to its matched components a bit differently thus random assembly increases the chances of future parts

failures

https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=POW735002

I believe the ZZ4/LT4 hot cam springs are a little weak, however, the difference them and the AFR's seems too much to me....Looking for suggestions from those who have "been there and done that" before.

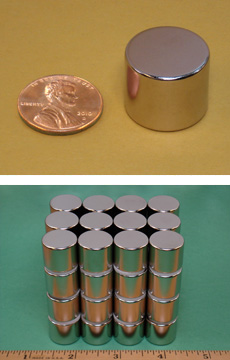

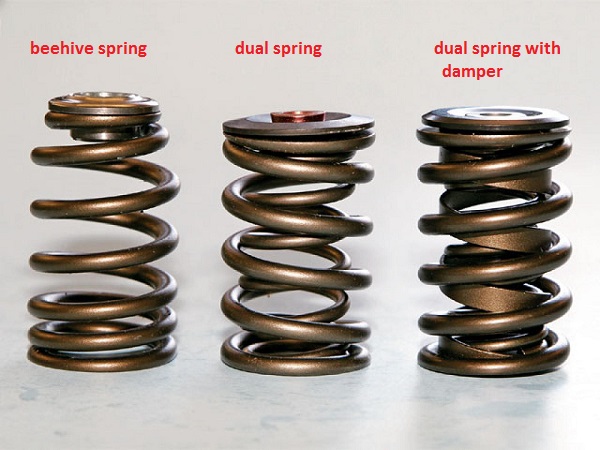

the reduced diameter of beehive valve springs usually eliminates the rocker too retainer clearance issue

BEEHIVE SPRINGS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

http://www.kmotion.biz/instht.htm

the first springs are correct for most hydraulic roller cams

http://www.jegs.com/i/AFR-Airflow-Research/033/8017/10002/-1

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/

http://garage.grumpysperformance.co...lve-springs-loads-and-installed-height.10709/

OBVIOUSLY YOULL WANT THE CORRECT VALVE SPRINGS

http://www.competitionproducts.com/1500-1585-OD-Valve-Springs/products/2631/1/0

https://www.summitracing.com/search/part-type/valve-springs

https://www.iskycams.com/cart/valve-springs-c-99.html

http://www.cranecams.com/userfiles/file/334-343.pdf

https://www.racingsprings.com/Valve-Spring/Store/13

http://www.lunatipower.com/Category.aspx?id=23

http://www.pspring.com/products/engine-valve-springs/

http://www.competitionproducts.com/Valve-Springs/departments/49/

http://psisprings.com/products/

http://www.compcams.com/Products/CC-'Valve Springs By Usage'-0.aspx

http://www.racingsprings.com/Beehive-Valve-Springs

https://www.supertechperformance.com/valve-springs-p109

http://www.cvproducts.com/index.php/psi-springs/

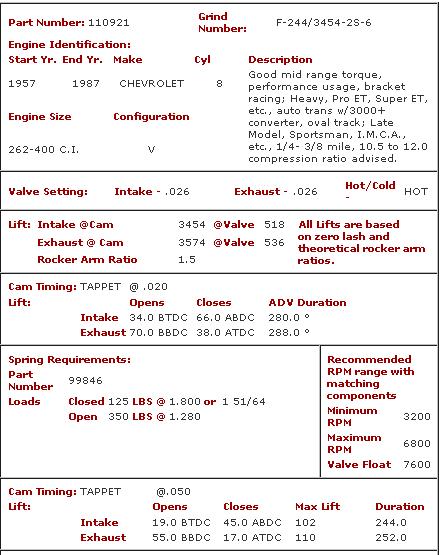

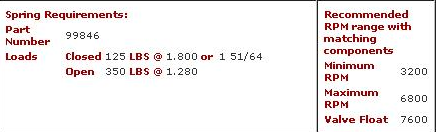

The following recommendations are from Erson Cams. If you have questions, you can reach their tech department at 800-641-7920.

Hydraulic Flat Tappet Camshaft: 110 lbs Seat pressure/250-280 lbs open pressure

Solid Flat Tappet Camshaft: 130 lbs Seat Pressure/300-325 lbs open pressure

Hydraulic Roller Camshaft: 130-140 lbs Seat Pressure/300- 355 lbs open pressure

Solid Roller Camshaft: (Minimum Safe Pressures DEPEND ON SEVERAL FACTORS)

Up to .600Ë valve lift: 200-235 lbs Seat Pressure/600 lbs open pressure

Over .600Ë valve lift: 250-280 lbs Seat pressure /100 lbs pressure for every .100Ë of valve lift

CAST CAM CORES ARE NOT DESIGNED TO HANDLE OVER ABOUT 130lbs SEAT and 400lbs OPEN SPRING LOADS YOU NEED A BILLET CAM CORE FOR DURABILITY IF THOSE LIMITS ARE EXCEEDED

Id also point out that youll want to lubricate any valve you install in a valve guide and verify the valve train clearances very carefully, and use the correct valve springs and add the correct valve seals installed

yeah! as I stated the valve spring diameter and heights varies with engine, type.

the cam used and application,yes BBC valve springs tend to be larger as the valves weigh more, but generally there's not a huge amount of compression during the install from the in the box vs the installed height, and obviously the cam generally comes with the installed height, valve spring part numbers and intended load rates that should be used, and yes you still need to use shims, valve spring cups and watch out that at max lift you still maintain the required clearances

yes I'm aware a few guys would prefer being skinned alive and dipped in alcohol to reading links!

but for those guys who care to learn more these links might be useful

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/#post-50534

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46662

http://garage.grumpysperformance.co...u-buy-bare-or-assembled-heads.534/#post-41292

http://garage.grumpysperformance.com/index.php?threads/busted-valve-spring.7716/#post-38047

http://garage.grumpysperformance.co...pring-cooling-via-engine-oil.6491/#post-20681

http://garage.grumpysperformance.com/index.php?threads/vortec-spring-upgrade.6175/#post-19304

http://garage.grumpysperformance.co...per-valve-spring-seats-shims.1005/#post-15534

Valve Spring Tech

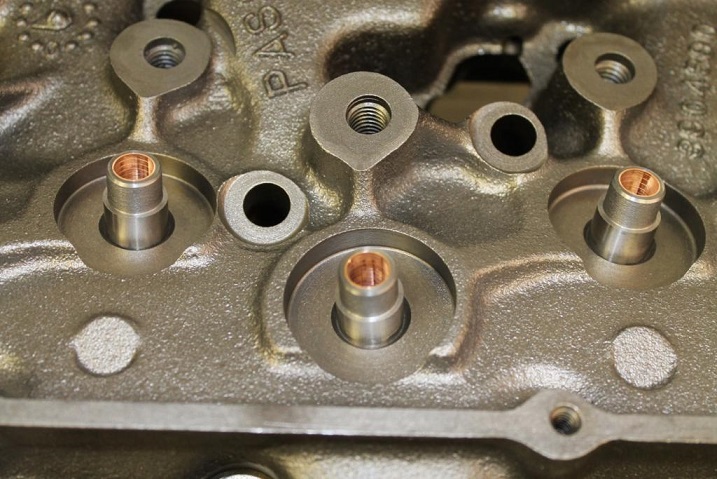

Valve Spring Pocket Clearance

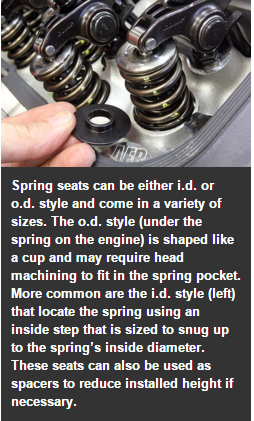

Valve spring pocket clearance is the gap between the inside diameter of the valve spring pocket (or cup, if used) and the outside diameter of the valve spring.

- Too much clearance will result in the spring "dancing" around in the head, which "beats up" the spring mounting surface and the spring itself. If this is the case, a spring cup may be used. Additional machining of the spring pocket may be required to accept the spring cup.

- Not enough clearance will bind the spring in the pocket, overstressing the bottom coil by limiting its movement and not allowing the spring to "grow". This will cause the bottom coil to wear against the head and/or prematurely fail. Machine the valve pocket using a Spring Seat Cutter if not enough clearance exists.

Valve Spring Retainer Fit

The valve spring retainer should fit the valve spring being used. A slightly snug fit is acceptable, however a fit that is too tight can overstress the top coil, and cause it to fail. A fit that is too loose can lead to spring "dancing."

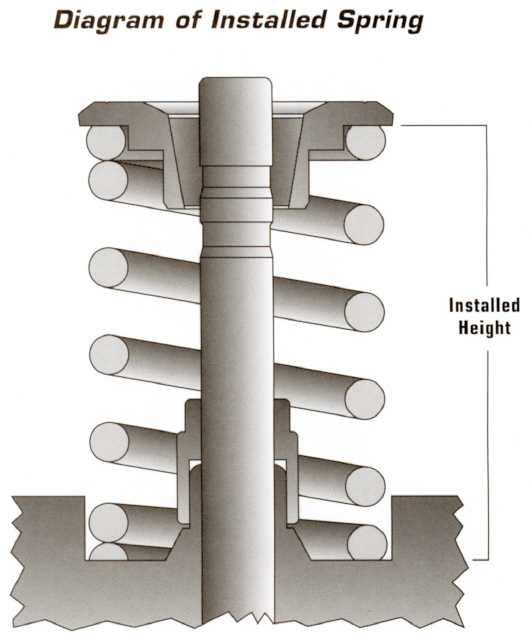

Valve Spring Installed Height

The installed height of the valve spring is the distance between the valve pocket (or cup, or shims) and the outer edge of the spring retainer (which is the height of the valve spring) when the valve is closed. To check installed height, follow the following procedure:

- Install the valve in the guide.

- Install the retainer and valve locks.

- Install all spring cups and/or valve spring shims (basically, everything except the valve spring).

- Hold the valve closed by pulling the retainer up tightly against the valve locks.

- Measure the distance between the outside edge of the valve spring retainer and the spring seat. A snap gage or a height micrometer should be used.

- Check the distance against what is recommended on the camshaft specification card. An installed height of +/- 0.020" is acceptable.

- If the installed height is not within 0.020", either machining of the valve pocket, or removal/installation of valve spring shims is necessary.

- Repeat this procedure for the rest of the valves.

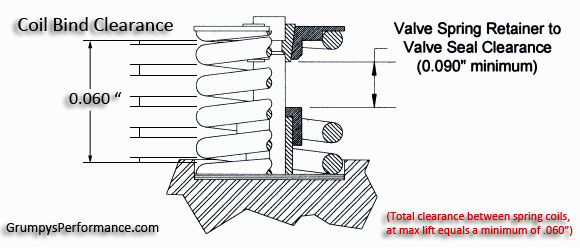

Valve Spring Retainer to Valve Seal Clearance

The distance between the innermost step on the valve spring retainer and the valve guide must be 0.090" larger than the maximum valve lift of the camshaft. Measure the distance between the top of the valve seal to the bottom of the valve spring retainer. After adding 0.090" to your measurement, it should still be larger than the maximum valve lift of the camshaft. If not, machining of the valve guide in necessary for adequate clearance.

Valve Spring Coil Clearance

Coil clearance is the distance between the valve spring coils when the valve is it maximum lift (fully open). A minimum of 0.060" must exist between the coils at maximum lift. Coil bind is when the valve spring is compressed fully-to the point that all of the coils are "stacked up" on top of each other. For high RPM applications, .100" is recommended . Coil bind is a catastrophic condition that will result in valve train failure. Disassemble each spring (if multiple springs are employed at each valve). Check all the springs (both inner, and outer springs) If there is not 0.060" - 0.100" minimum of clearance between the coils, the solutions are: the valve retainer, the valve locks, the valve, or the spring must be changed; the spring pocket must be machined. Keep in mind that these modifications will change the valve spring installed height

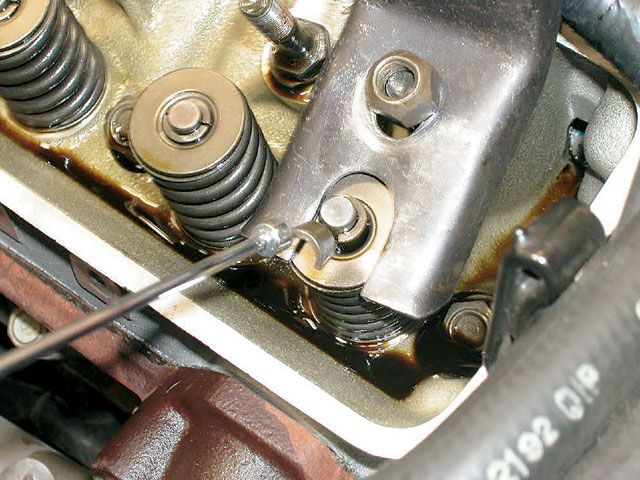

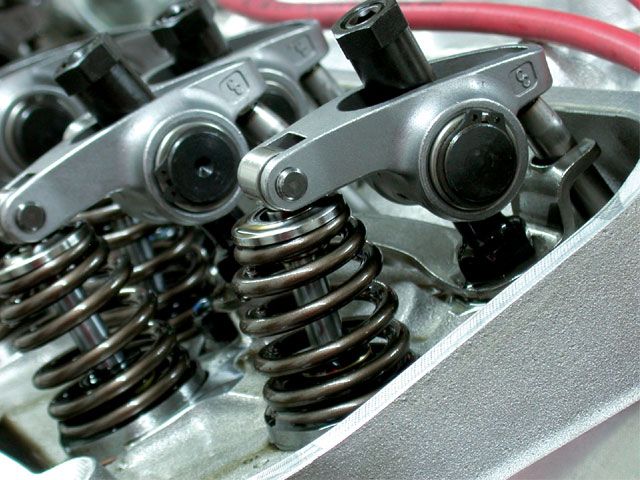

Valve Spring Retainer to Rocker Arm Clearance

When installing the rocker arms, check to see that the inside of the rocker arms clear the spring retainers. Many rocker arms have a "relief" to accommodate large valve spring retainers.

Valve Spring Run-In

Each set of Lunati valve springs are hand-selected to keep load variations below +/- 10% of the next. However, it is important to "run in" your new valve springs at low RPM using the following procedure:

- Start the engine and run the engine between 1500 and 2000 RPM until the engine reaches operating temperature.

- Shut off the engine and allow the springs to cool.

- After initial run-in, most springs will lose a slight amount of pressure. Re-check and shim up the valve springs if necessary. After the springs are "run in", spring pressure should remain constant until the point of replacement.

Last edited: