You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

168 or 153 flywheels

- Thread starter ZZ71s

- Start date

if they both weigh the same the difference will be minimal at best, Id bet you could not effectively measure it on a standard dyno, Id go with the 168 even if it did require a minute bit of extra torque , because it will tend to dissipate heat faster, have more clutch options . be less prone to starter wear issues and easier for any shop to balance without effecting strength

viewtopic.php?f=53&t=1042

viewtopic.php?f=53&t=1042

ZZ71s said:It seems like I saw the l88 vettes used a 153 flywheel.

You see some guys out there on the net using AL. flywheels to rev the engine faster my question could a 153 steel flywheel gain the same advantages as using a 168 AL flywheel

think about this.....the ONLY time you get power transferred to the rear differential, the clutch is locked to the flywheel, that means the weight/mass of the total engine assembly , transmission and drive train needs to be accelerated, to move the car, stock cars typically use a direct drive,or manual transmission, and a much smaller clutch, and rarely weigh more than 1000 lbs LESS than your average street car, so a light weight flywheel has some advantages, on a street car its rarely an advantage

ZZ71s said:It seems like I saw the l88 vettes used a 153 flywheel.

You see some guys out there on the net using AL. flywheels to rev the engine faster my question could a 153 steel flywheel gain the same advantages as using a 168 AL flywheel

on the plus side , when your working with the Chevy v8 engines SBC and BBC, if you select the correct two piece or one piece rear seal components, many aftermarket manufacturers of flex plates and flywheels to reduce manufacturing costs , build a neutral balance flywheel or flexplate and simply bolt on or weld on a weight to allow the same basic part to work with both potential combos

Counter Weight Kit General Motors Flywheel (1A/2C/3C/4C)

Fits Externally Balanced Applications

1986-1999 SBC

1970-1990 BBC

1991-1997 BBC

1970-1980 SBC 383/400

LOOK THRU THE LINKED INFO

http://www.bulkpart.com/Merchant2/merch ... YcatalogGM

http://www.gmpartsdirect.com/performanc ... D=913.html

viewtopic.php?f=71&t=447

http://www.mre-books.com/chevy/engines/parts_interchange/crankshaft.html

http://www.crossmembers.com/shop/fly-wheels-c-18.html

viewtopic.php?f=53&t=5155

Small Block Chevy Flywheel Part Numbers

Part # DIA. Teeth Comments

3991469 14" 168 two-piece seal, internally balanced

3986394 14" 168 400 External balance, two-piece seal

10105832 14" 168 86-later, one-piece rear seal, ext. balance

14085720 12.75" 153 Lightweight (15 lbs.), nodular iron, two-piece seal, int bal

14088646 12.75" 153 86-up, Lightweight (15 lbs.), nodular iron, one-piece rear seal, ext bal

14088648 14" 168 86-up, one-piece rear seal, ext. balance

14088650 12.75" 153 86-up, one-piece rear seal, ext balance

10174482 89-up with six-speed m/t, requires starter (10455709)

Common clutch sizes are: 10.4", 11.0", and 11.85". Some flywheels are drilled for two different clutch patterns.

Small Block Chevy Flexplate Part Numbers

Part # DIA. Teeth Comments

471529 12.75" 153 Two-piece seal blocks, int balance

471578 14" 168 400 ext. bal, two-piece rear seal

471598 14" 168 Two-piece seal blocks, internal balance

10128412 12.75" 153 86-up, one-piece rear seal ext. balance

10128413 14" 168 86-up, one-piece seal, extra thick, HD, ext bal

10128414 14" 168 86-96, one-piece rear seal, ext. balance

14088761 14" 168 89-up 350 HO, one-piece rear seal, ext. bal.

14088765 12.75" 153 86-up, one-piece rear seal, ext. bal.

14088767 14" 168 89-up 350 HO, one-piece rear seal, HD, ext. bal

a typical street car uses a 30 lb 11 " flywheel and a 20 lb pressure plate and clutch

a typical stock car uses a 10-15lb aluminum flywheel and a 18 lb multi disc clutch that 7.25"-5.5" in diam.

but in a 1800lb-2400lb car that will see almost daily maintenance that makes some sense

http://www.summitracing.com/expertadvic ... chArticles

http://www.performancebodies.com/Produc ... s&pid=1193

think about this.....the ONLY time you get power transferred to the rear differential, the clutch is locked to the flywheel, that means the weight/mass of the total engine assembly , transmission and drive train needs to be accelerated, to move the car, stock cars typically use a direct drive,or manual transmission, and a much smaller clutch, and rarely weigh more than 1000 lbs LESS than your average street car, so a light weight flywheel has some advantages, on a street car its rarely an advantage

Finding a flywheel to fit your Chevrolet in the mid-Fifties used to be simple: There were only two possible units from 1942-'53. One flywheel (#3705385) covered all 1937-'53 cars and trucks with a 9 1/8-inch clutch disc and a six-bolt mounting pattern; the other (#3705387) covered all 1942-'53 cars and trucks with a 10-inch clutch disc and nine-bolt pattern. Both used 139-tooth ring gears for the starter. After 1953, Chevrolet changed to 12-volt starters, and the number of teeth on the ring gear was changed, but there are still just a few different flywheels used (excluding Hydra-Matic and Powerglide automatics). Some of these flywheels were used on models from the mid-Fifties up into the Eighties. We have included some of the original casting numbers for easy reference.

Flywheel #3704831

• 1954-'55 cars and trucks with 10-inch clutch Flywheel #373919

• 1958-'65 trucks with 13-inch clutch Flywheel #3739423 • 1956-'65 cars and trucks with 10 or 10 1/2-inch clutch and 11 5/8-inch bolt pattern Flywheel #3705409

• 1955-'62 cars and trucks with 10 1/2-inch clutch and 168-tooth ring gear Flywheels #3789730 and #3705410

• 1955-'62 cars and trucks with 11-inch clutch and 168-tooth ring gear Flywheels #3758595, 3714463 and 3789733

• 1955-'71 cars and 1955-'85 Chevy and GMC trucks with 11-inch clutch and 12 5/8-inch bolt pattern and a two-piece rear main seal. (1986 and newer flywheels are different because they used a one-piece rear main seal)

• 1969-'85 Blazer and Sprint

• 1966-'72 Chevelle

• 1966-'81 Corvette

• 1967-'70 Chevy II and Nova

• 1967-'74 Camaro and 1977-'81 Camaro (with Warner transmission)

• 1970-'72 Monte Carlo (except 400-cu.in. two-barrel)

• 1981 Firebird with 305 Chevy engine Flywheel #3971021

• 1964-'73 full-size Chevy cars and 1965-'73 trucks with 10- or 10.4-inch clutch and 153-tooth ring gear

• 1967-'85 Camaro

• 1964-'77 Chevelle

• 1965-'79 Chevy II and Nova

• 1965-'68 Corvette with 327

• 1978-'81 Malibu

• 1978-'79 Monte Carlo Also these other GM models with straight six-cylinder, V-6 or 262/305 V-8 Chevy engine:

• 1973-'75 Apollo

• 1968-'71 Buick Special

• 1972-'76 Ventura

• 1973-'76 Omega

• 1975-'79 Cutlass

• 1970-'76 and 1980-'85 Firebird

• 1965-'72 Tempest

• 1973-'80 Le Mans

• 1966-'71 F-85 Flywheels #3703870 and #3729004

Models with 11-inch clutch and 168-tooth ring gear

• 1969-'74 Blazer/Jimmy

• 1970-'81 Camaro

• 1970-'71 Impala

• 1965-'74 Trucks

• 1970-'75 Chevelle, Monte Carlo

• 1977-'78 Corvette (180 and 185hp)

• 1978-'81 Firebird with 305 engine

• 1978 El Camino

• 1971-'79 Nova

• 1977-'79 Omega and Phoenix with 305 engine Flywheel #3993827

• 1973-'90 Chevy and GMC Truck w/454

• 1970-'74 Chevelle and Corvette w/454

• 1971-'74 El Camino and Sprint w/454 Exceptions to the above listings are these few special flywheels that do not interchange with each other or any of the above:

• 1970-'71 Impala and Monte Carlo with 400-cu.in. two-barrel flywheel does not interchange with any other two-barrel listing

• 1967-'89 truck with 292 engine (different from all other six-cylinders)

• 1969 Corvette with a dual disc clutch

Last edited by a moderator:

DZAUTO said:With the 153 teeth flywheel, you can ONLY USE a 10 1/2in clutch.

ALL V8 flywheels up through 62 were ONLY the 168 teeth version, BUT, they had a bolt pattern for the smaller 10 1/2in clutch. A later model 168 teeth flywheel will have the bolt pattern for the larger, 11in clutch, which I would STRONGLY recommend if you are going to use a 3.08 rear gear. The reason is because slightly more torque will be required to get the 3.08 turning, thus, just a little additional feathering of the clutch will be necessary from a dead stop and the larger 11in clutch will simply be a better choice because of the greater contact surface of an 11in clutch vs a 10 1/2in clutch.

Now, for me personally, I run a 168 teeth flywheel/11in clutch in EVERYTHING I own.

My philosophy regarding a clutch is the same as my philosophy regarding cubic inches. Too much is just right!I thought I made that clear. Yes, that's what I have in my cars that have the 55-62 style open bottom bell housings (BOTH iron and alum versions).

Up through 1985, ANY 168 teeth flywheel with the bolt pattern for an 11in clutch will retrofit all the way back to a 1955 V8.

Now, just as sure as God make little green apples, someone is going to jump in here with a comment regarding EXternal balanced flywheels such as those used on the SB400 and the 454BB. So, I better clarify that before someone gets all bent out of shape.

The NEUTRAL balance 168 teeth and the EXternal balance 168 teeth flywheels are 100% the same and are TOTALLY interchangeable with each other and will bolt onto the back of ANY 55-85 V8 engine and ANY 63-later inline Chevy 6cyl. The ONLY difference between neutral and EXternal balance flywheels is that added weight on the EXternal balance flywheels which is needed for a SB400 and a 454 (YES, there is a difference in the added weight between a SB400 and a 454 flywheel). See picture below.

Furthermore, the ONLY size flywheel used on the SB400 and 454 was the larger 168 teeth version (because of that needed extra weight on one side for balance purposes). They never got the smaller 153 teeth flywheel.

As an example of where this is important, is let's say you have a 55 Chevy with a 4sp and you want to drop in a SB400 or a 454. You can literally unbolt the stock 265 from the 55 (or later) bell housing, and drop in the SB400 or 454, with the large 168 teeth flywheel/11in clutch, bolt it up to the 55 bell housing and drive it away. Ya, ya, ya, ya, ya I know, you gotta do a little massaging to a 55-57 Chevy to drop in a BB if it is to fit in there with the bell housing/tranny in the stock position.

First, let me hit on a couple of basics.

ALLLLLLLLLLLL 55-85 Chevy V8 flywheels are a 100% bolt-on fit on ANY 55-85 V8 crankshaft.

ALL 168teeth flywheels are also totally interchangeable. BUUUUUUUUUT, the EARLY 168 teeth flywheels only had a bolt pattern for the 10in clutch. SOME early 168 teeth flywheels (HD, police, taxi, truck, etc) did have a bolt pattern for the 11in clutch.

Soooooooooo, here's where I'm going with this. ANY 55-85 168teeth flywheel WITH a bolt pattern for an 11in clutch will work. For your purposes, that's all you need.

Over the years, I've picked up good used 168teeth flywheels with an 11in bolt pattern at swap meets for $25-50. Some needed to be surfaced, but many did not. SOME had burn marks on the surface, but DID NOT have gouges. For those kinds of flywheels, I just bead blasted the heck out of the surface, bolted them on with a new clutch and went on down the road. That is the type of flywheel that is on my 51 Chevy, 56 Vette and 70 Chevelle. Now, I'm talking about regular driver/mild performance engines ---------------------- I'm NOT talking about hardcore, full on race engines!!!!!!!!!

Everybody and their dog tells you to get a scatter shield for a performance car with a 4sp. Well, just think about it, REALLY, how many Chevys have you read, heard, seen that have had a stock flywheel explode under regular driving conditions and kill everyone in the car???

This is an EARLY 168 teeth flywheel with the bolt pattern for ONLY a 10in clutch (the other holes are just for balance). As can be seen, even if holes were drilled and tapped for the larger 11in clutch, there is a groove machined into the flywheel surface (I have NO CLUE why the heck GM did that!!!!!!) which would prevent any benefit from installing an 11in clutch!

Here is a later 168 teeth flywheel with the bolt pattern for the 11in clutch.

Here is part of my stash of various flywheels and flex plates.

f.i.57chevynut said:Probably as important is the pressure plate, make sure the plate you use is forged, not cast. This happened to a guy I know. I told him to get a scatter shield, but he shined me on. Then this happened:

Last edited:

Just some information gained due to watching the results of use of what my experience tells me is the wrong flywheel choice,

As some of the older members will know I help out lots of the local guys and enjoy mentoring some of them, and watching them learn, and gain skills.

as most of you know if you observe carefully you'll see trends and learn from your own and other peoples successes and mistakes.

we all learn through experience and this choice, in components one guy made might be helpful, if we discuss it a bit, it won,t make or break the car,

but it will in my opinion make it less enjoyable to drive on the street for daily transportation. (I've driven dozens of similar cars and after awhile you notice significant differences, in results due to the choices, made during the cars build.),

one of the neighborhood kids (hes really 22 years old ) built a 1969 nova with a 496 stroker engine in the car,its his first manual transmission and he installed a fairly heavy long style clutch he bought at a swap meet at a darn good price, but its a serious heavy duty version with fairly stiff springs, for street/strip use so it takes some effort to depress.

when it came time to purchase a flywheel he selected a 15 lb aluminum flywheel based almost 100% on the fact that he got it at a swap/meet for $50 .

light weight flywheels work great if your seldom running the engine below about 4000 rpm, thats one reason circle track guys love them, theres no use for a heavy flywheel or rotating assembly that slows down your acceleration out of the corner of a curve if you come in at 4500 rpm and reach 7000 rpm on the long strait, when your driving a 2000 lb sock car, and you use engine compression to slow the car going into the next curve, but thats not the case in a high performance street driven muscle car. that might weight 3300 lbs-3700 lbs

now after he already bought it he came over and asked me if it was a good idea....... I explained that his crankshaft, clutch assembly with pressure plate, (22 lbs) and connecting rods, ,pistons, damper etc all together , probably weigh about (75 lbs) so the difference between a 15-17 lb vs a 32-36 lb steel flywheel,

(like so many of the internet genius claim (most of them obviously have never driven a serious muscle car)

would not make the engine reve noticeably faster and pull the car too a faster ET, noticeable better, once the cars clutch is engaged, and from past experience I would have never used a 15 lb aluminum flywheel , in a street driven muscle car application, I would personally have used a 36-40 lb steel billet SFI rated flywheel.

keep in mind the car weights about 3400 plus lbs with him in the drivers seat, and the engine probably makes 550 hp and 570 tq and its got a 3.36:1 rear gear 12 bolt rear differential.

and remember the engine can only move the car once the clutch in allowing power transmission through the transmission to the differential to the tires and then the full 3400 lb plus car weight is being accelerated , not just the engines rotating assembly alone!

yes if the clutch is depressed a lighter weight flywheel allows the engine too free wheel marginally faster, but if you install slicks and launch the car from a 3000 3500 rpm launch, to maximize acceleration over that first critical 60 foot distance the heavier flywheels inertia has very obvious advantages, in a heavier car.

well he gets it all assembled and takes the car out for the first test drive and complains that he needs to reve the engine just a bit, and slip the clutch or at least let it en-gauge slowly to get a smooth take-off ,its just not smooth, and if he doesn,t get it just right he applies a bit too much power to street tires and spins the tires briefly which is not always ideal when street driving, especially in stop and go traffic that's barely moving or if hes trying not to attract attention from the local L.E.O.'s

much of this can be over come through gained experience and gaining the skills to familiarize yourself with a cars individual characteristics, and not having decades of experience with shifting a manual transmission certainly does not help here!

But you can,t ignore basic physics, inertia and mass makes a difference and learning to handle the potential power of a well built muscle car takes some time and experience takes time to prefect the required skills of applying power to a car with very limited traction, compared to what he was used too driving.

A 32 lb-40 lb flywheel would not be a instant cure, but it would make letting the clutch out a smoother deal especially if your not familiar with driving a powerful engine on street tires with limited traction.

RELATED

BTW I assume you gentlemen do know theres

even a correct and very inexpensive tool for spinning it from the flex-plate or flywheel,

once the cylinder heads are installed,

so your not stressing the damper retention bolt spinning the engine over manually,

https://www.summitracing.com/parts/wmr-w80510/overview/

https://www.summitracing.com/parts/sum-900178/overview/

read ALL the links

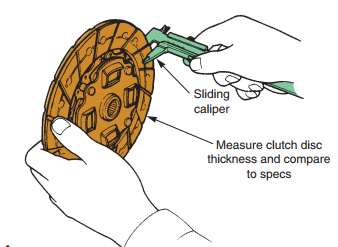

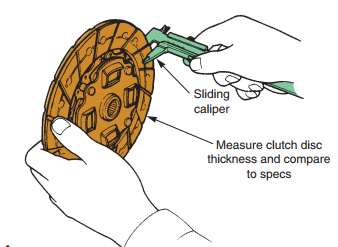

since youve already replaced the clutch disc and pressure plate, I'd point out that,

many times clutch chatter is the result of an un-even flywheel surface, any decent machine shop can surface grind the existing friction surface a few thousands to correct that issue.

clutch chatter is the result of un-evenly applied clamping surfaces, usually a high spot(S) on the clutch pressure plate its housing or the flywheel surface, but grease and or oil on the clutch disk, or loose disc pads could also be too blame , but heat warping or a broken spring or mis-aligned spring will also cause this symptom.

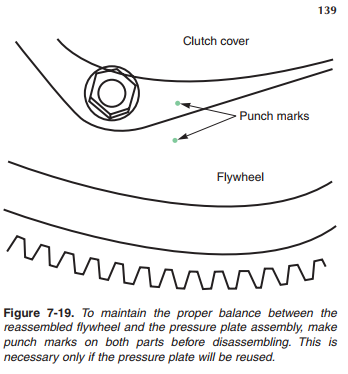

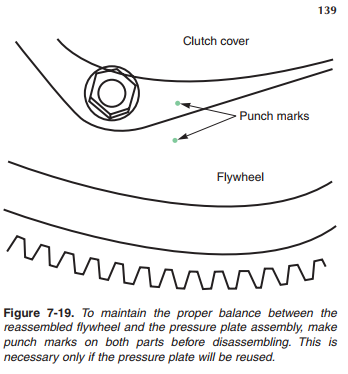

the flywheel should be torqued to the crank flange, an impact gun should never be used as its possible to warp the mount surfaces is tightened un-evenly

if the clutch vibration does not go away once the clutch locks up,

you've more than likely, got a drive line component alignment or rotation assembly or drive line balance issue.

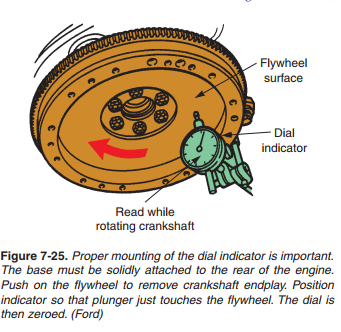

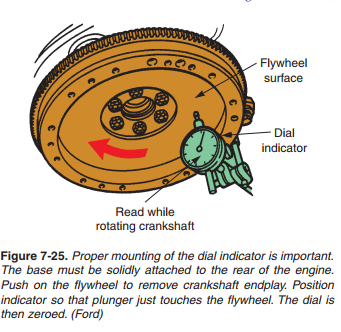

you'll want to verify the flywheels mounted so its not wobbling, it may be warped,

or the crank flange its mounted too has been bent or theres debris between the flywheel and crank flange,

you,ll want too use a dial indicator mounted on the block and rotate the flywheel to find out,

if the flywheel friction surface or outer diameter

,changes its distance from the block as it rotates

read ALL the links

Turbo 400 uses the Big Bolt pattern torque converter.

11.5" inches bolt circle pattern.

4L80E uses same.

4L60E, 700R4, 200R4, & Turbo 350 uses the small bolt pattern torque converter.

10.75" inch bolt circle pattern.

http://www.freeasestudyguides.com/manual-transmission-clutch-chatter.html

http://www.brakeandfrontend.com/causes-clutch-failure-diagnosing-chatter/

http://www.onallcylinders.com/2012/10/02/clutch-tips-troubleshooting-faqs-from-the-experts/

https://www.schaeffler.com/remoteme...ler_2/symposia_1/downloads_11/2_chatter_1.pdf

https://www.g-w.com/pdf/sampchap/9781605252131_ch07.pdf

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/#post-59459

http://garage.grumpysperformance.com/index.php?threads/huge-vibration-issue.12548/#post-63812

http://garage.grumpysperformance.co...rrectly-installing-bellhousings.584/#post-785

http://garage.grumpysperformance.co...rnal-balance-crank-question.13560/#post-70119

http://garage.grumpysperformance.co...tion-about-throw-out-bearing.6258/#post-19701

http://garage.grumpysperformance.co...ools-diagnosing-clutch-issues.3553/#post-9431

http://garage.grumpysperformance.co...ng-to-drive-a-really-fast-car.906/#post-27083

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/

http://garage.grumpysperformance.co...s-daughter-to-drive-a-stick.10702/#post-46542

parts

https://www.summitracing.com/parts/sca-1-42460bi

https://www.summitracing.com/parts/ctf-700162/overview/

http://www.jegs.com/i/RAM-Clutches/798/437/10002/-1

As some of the older members will know I help out lots of the local guys and enjoy mentoring some of them, and watching them learn, and gain skills.

as most of you know if you observe carefully you'll see trends and learn from your own and other peoples successes and mistakes.

we all learn through experience and this choice, in components one guy made might be helpful, if we discuss it a bit, it won,t make or break the car,

but it will in my opinion make it less enjoyable to drive on the street for daily transportation. (I've driven dozens of similar cars and after awhile you notice significant differences, in results due to the choices, made during the cars build.),

one of the neighborhood kids (hes really 22 years old ) built a 1969 nova with a 496 stroker engine in the car,its his first manual transmission and he installed a fairly heavy long style clutch he bought at a swap meet at a darn good price, but its a serious heavy duty version with fairly stiff springs, for street/strip use so it takes some effort to depress.

when it came time to purchase a flywheel he selected a 15 lb aluminum flywheel based almost 100% on the fact that he got it at a swap/meet for $50 .

light weight flywheels work great if your seldom running the engine below about 4000 rpm, thats one reason circle track guys love them, theres no use for a heavy flywheel or rotating assembly that slows down your acceleration out of the corner of a curve if you come in at 4500 rpm and reach 7000 rpm on the long strait, when your driving a 2000 lb sock car, and you use engine compression to slow the car going into the next curve, but thats not the case in a high performance street driven muscle car. that might weight 3300 lbs-3700 lbs

now after he already bought it he came over and asked me if it was a good idea....... I explained that his crankshaft, clutch assembly with pressure plate, (22 lbs) and connecting rods, ,pistons, damper etc all together , probably weigh about (75 lbs) so the difference between a 15-17 lb vs a 32-36 lb steel flywheel,

(like so many of the internet genius claim (most of them obviously have never driven a serious muscle car)

would not make the engine reve noticeably faster and pull the car too a faster ET, noticeable better, once the cars clutch is engaged, and from past experience I would have never used a 15 lb aluminum flywheel , in a street driven muscle car application, I would personally have used a 36-40 lb steel billet SFI rated flywheel.

keep in mind the car weights about 3400 plus lbs with him in the drivers seat, and the engine probably makes 550 hp and 570 tq and its got a 3.36:1 rear gear 12 bolt rear differential.

and remember the engine can only move the car once the clutch in allowing power transmission through the transmission to the differential to the tires and then the full 3400 lb plus car weight is being accelerated , not just the engines rotating assembly alone!

yes if the clutch is depressed a lighter weight flywheel allows the engine too free wheel marginally faster, but if you install slicks and launch the car from a 3000 3500 rpm launch, to maximize acceleration over that first critical 60 foot distance the heavier flywheels inertia has very obvious advantages, in a heavier car.

well he gets it all assembled and takes the car out for the first test drive and complains that he needs to reve the engine just a bit, and slip the clutch or at least let it en-gauge slowly to get a smooth take-off ,its just not smooth, and if he doesn,t get it just right he applies a bit too much power to street tires and spins the tires briefly which is not always ideal when street driving, especially in stop and go traffic that's barely moving or if hes trying not to attract attention from the local L.E.O.'s

much of this can be over come through gained experience and gaining the skills to familiarize yourself with a cars individual characteristics, and not having decades of experience with shifting a manual transmission certainly does not help here!

But you can,t ignore basic physics, inertia and mass makes a difference and learning to handle the potential power of a well built muscle car takes some time and experience takes time to prefect the required skills of applying power to a car with very limited traction, compared to what he was used too driving.

A 32 lb-40 lb flywheel would not be a instant cure, but it would make letting the clutch out a smoother deal especially if your not familiar with driving a powerful engine on street tires with limited traction.

RELATED

BTW I assume you gentlemen do know theres

even a correct and very inexpensive tool for spinning it from the flex-plate or flywheel,

once the cylinder heads are installed,

so your not stressing the damper retention bolt spinning the engine over manually,

https://www.summitracing.com/parts/wmr-w80510/overview/

https://www.summitracing.com/parts/sum-900178/overview/

read ALL the links

since youve already replaced the clutch disc and pressure plate, I'd point out that,

many times clutch chatter is the result of an un-even flywheel surface, any decent machine shop can surface grind the existing friction surface a few thousands to correct that issue.

clutch chatter is the result of un-evenly applied clamping surfaces, usually a high spot(S) on the clutch pressure plate its housing or the flywheel surface, but grease and or oil on the clutch disk, or loose disc pads could also be too blame , but heat warping or a broken spring or mis-aligned spring will also cause this symptom.

the flywheel should be torqued to the crank flange, an impact gun should never be used as its possible to warp the mount surfaces is tightened un-evenly

if the clutch vibration does not go away once the clutch locks up,

you've more than likely, got a drive line component alignment or rotation assembly or drive line balance issue.

you'll want to verify the flywheels mounted so its not wobbling, it may be warped,

or the crank flange its mounted too has been bent or theres debris between the flywheel and crank flange,

you,ll want too use a dial indicator mounted on the block and rotate the flywheel to find out,

if the flywheel friction surface or outer diameter

,changes its distance from the block as it rotates

read ALL the links

Turbo 400 uses the Big Bolt pattern torque converter.

11.5" inches bolt circle pattern.

4L80E uses same.

4L60E, 700R4, 200R4, & Turbo 350 uses the small bolt pattern torque converter.

10.75" inch bolt circle pattern.

http://www.freeasestudyguides.com/manual-transmission-clutch-chatter.html

http://www.brakeandfrontend.com/causes-clutch-failure-diagnosing-chatter/

http://www.onallcylinders.com/2012/10/02/clutch-tips-troubleshooting-faqs-from-the-experts/

https://www.schaeffler.com/remoteme...ler_2/symposia_1/downloads_11/2_chatter_1.pdf

https://www.g-w.com/pdf/sampchap/9781605252131_ch07.pdf

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/#post-59459

http://garage.grumpysperformance.com/index.php?threads/huge-vibration-issue.12548/#post-63812

http://garage.grumpysperformance.co...rrectly-installing-bellhousings.584/#post-785

http://garage.grumpysperformance.co...rnal-balance-crank-question.13560/#post-70119

http://garage.grumpysperformance.co...tion-about-throw-out-bearing.6258/#post-19701

http://garage.grumpysperformance.co...ools-diagnosing-clutch-issues.3553/#post-9431

http://garage.grumpysperformance.co...ng-to-drive-a-really-fast-car.906/#post-27083

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/

http://garage.grumpysperformance.co...s-daughter-to-drive-a-stick.10702/#post-46542

parts

https://www.summitracing.com/parts/sca-1-42460bi

https://www.summitracing.com/parts/ctf-700162/overview/

http://www.jegs.com/i/RAM-Clutches/798/437/10002/-1

Last edited: