1965SS396 said:I have a 1966 396. Rebuild ongoing and time to select a cam. I know the '65 and '66 have the groove in the rear journal. The machine shop cut a groove on the outside of my rear bearing (like a '67 396) when they installed the new ones. When shopping, most cams start at 1967 (I assume because of the groove). So the question is, can I now buy a 1967 camshaft? Is the groove the only difference is the basic question.

thanks

the 1965 and 1966 big block 396 had unique rear cam bearings and required a grooved rear cam journal, most cams you buy currently are not grooved, the groove can be cut on a lathe in the last rear journal on the later cams , centered ,and its about .188 wide and .125 deep, if the cam is cut,for that oil groove the standard cam bearing can be used

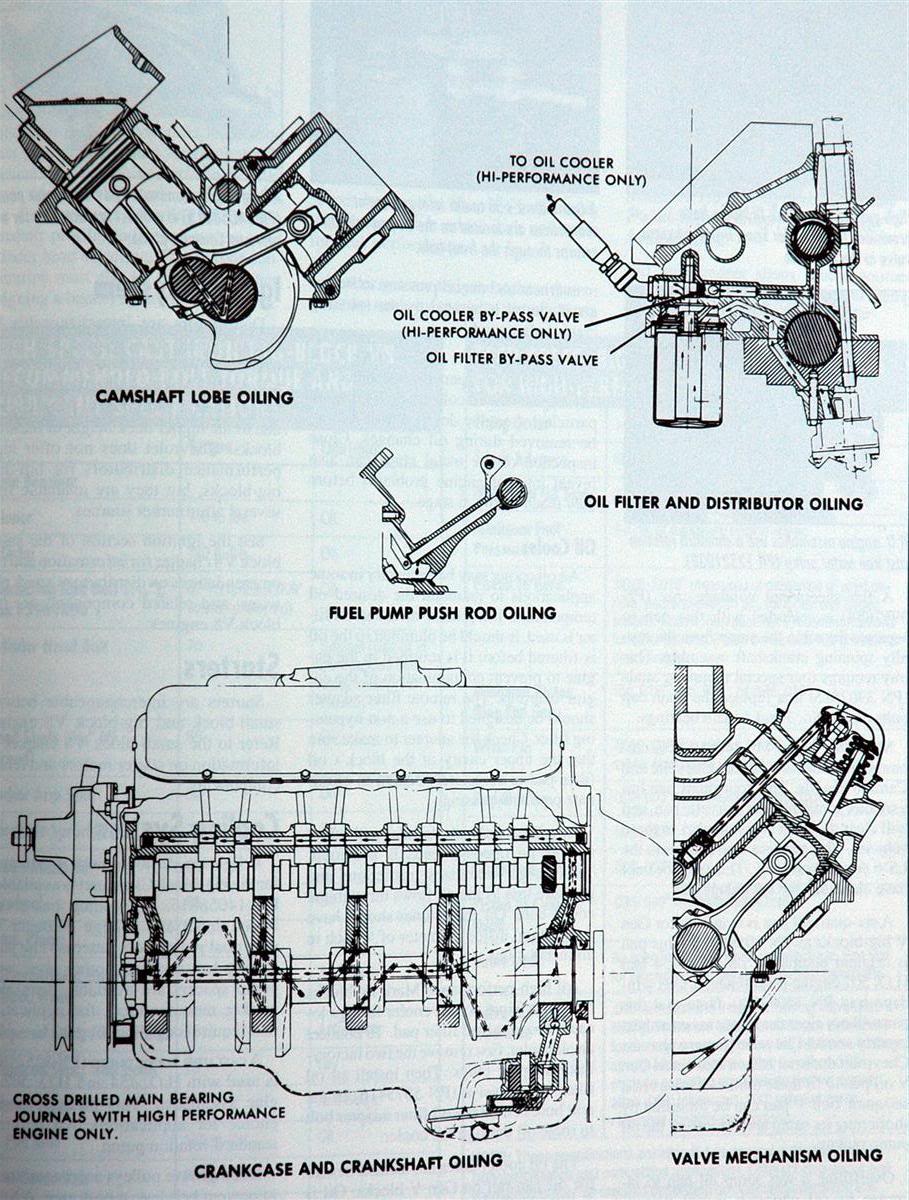

this is a diagram of the big block chevy oil passage system, its designed to feed that rear cam bearing in the center, the groove in the rear cam journal forms the walls of the oil passage cutting an additional groove, in front of the rear freeze plug behind the back cam bearing in the rear of the last cam bearing is unlikely to hurt or help as long as that groove is cut in the cam journal, I've always just cut the groove in the rear cam journal on the 65-66 engines and never had any issues, in fact I know several guys who do that mod on later engines that don,t require it, because they think it helps maintain slightly better oil flow rates to cool the valve train.

OBVIOUSLY if you want too test you manually prime the oil pump ,if you get decent oil flow volume at all the rockers,priming the engine oil pump manually, then obviously the oil flow leaving the pump reaches the intended areas and the route it takes while a bit different than originally designed may still work and not cause you any issues, keep in mind that as the engine rpms increase the oil flow rate needs to the valve train need to increase also and while it may be possible, to machine a shallow groove, in a later rear cam bearing it won,t be able to allow nearly the required oil flow rate at higher rpms as the rear bearing shell is just not thick enough,to allow a deep enough groove on the early engines, those engines, require the early rear cam bearing with the three hole aligned correctly and the grooved rear cam journal, some shops will modify the later cam bearings, installed in early blocks by cutting a large bevel in the rear edge, to allow oil to flow behind and around the rear cam journal, this is not always 100% successful, at providing full oil flow capacity on the early engines that don,t have the block grooved under the rear cam bearing ,especially at higher rpm levels.

RELATED INFO

correctly adjusting valves

this is an area that causes many newer guys problems ,a slight clicking noise at idle in any hydraulic or solid lifter valve train is usually the result of clearances in the valve train, obviously you should have, some clearance, to allow oil flow thru the lifters to provide lubrication on...

garage.grumpysperformance.com

Attachments

Screenshot_20221026-003223_eBay.jpg

160.3 KB · Views: 1

Screenshot_20221026-003403_eBay.jpg

97.9 KB · Views: 1

Screenshot_20221026-003444_eBay.jpg

72.1 KB · Views: 1

later blocks had a groove cut under and around the outside and behind the cam bearing for oil to reach the valve train, similar to this picture below

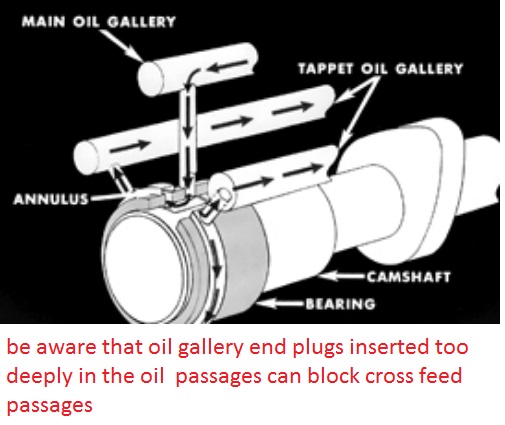

’65-’66 Big-Block Lifter Gallery Oiling: In order to feed pressurized oil to the galleries that feed the lifters, the ’65-’66 big-blocks used a combination of a groove in the rear cam journal and a rear cam bearing with a matching groove on its inside diameter. Oil entered the bearing through a hole at the bottom, traveled around the journal through the groove in the bearing and the journal, and exited the bearing through two holes at the top that aligned with two holes in the block; those two holes fed the oil galleries on each side that fed the lifters. Both the cam journal and the cam bearing MUST have the groove in order to provide adequate oil flow to the lifters, and the bearing must have the two exit holes at the top.

’67-Up Big-Block Lifter Gallery Oiling: Starting in 1967, Chevrolet redesigned the oiling path to the lifter galleries. The groove was removed from both the rear cam journal AND from the I.D. of the rear cam bearing, and an annular groove was machined into the rear cam bearing bore in the block instead. With the smooth rear journal and cam bearing surfaces, oil entered the bearing through the same hole in the bottom, but part of it flowed around the outside diameter of the cam bearing, through the groove machined in the bearing bore, and exited through the same two holes in the block at the top that fed the lifter galleries. The cam bearing now had only one hole, at the bottom.

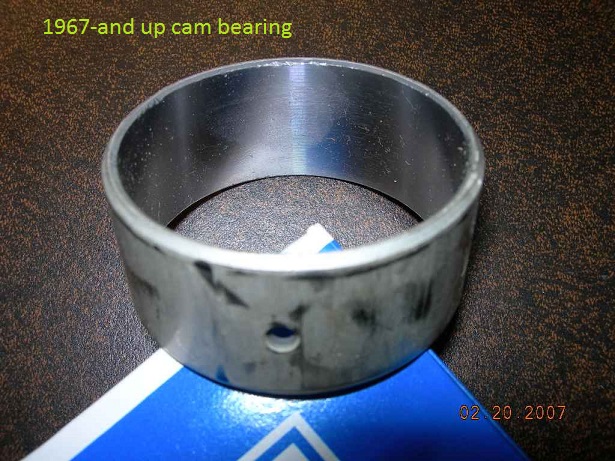

What This Means To You: Your block dictates what you can use. The 1967 non-grooved cam and non-grooved one-hole rear bearing will NOT work in a ’65-’66 block, period; you need the cam with the grooved rear journal and the rear cam bearing with the three holes and the groove on its I.D. The cam isn’t a big problem – any competent machine shop can cut the required groove in the rear journal of the camshaft, and all you need then is the correct rear cam bearing, which will be included with a ’65-’66-only big-block cam bearing set.

Photo below is the '67-up rear cam bearing, with only one (inlet) hole at the bottom and no groove; the rest of the oil goes around the OUTSIDE of the bearing shell (through the annular groove machined in the bearing bore in the block), to feed the two lifter gallery holes at the top of the bearing bore. '65-'66 3-hole grooved bearing also shown for comparison.

on the early big blocks oil from the oil pump enters the rear cam bearing at 6 0,clock travels around both sides of the rear cam journal and exits into both lifter oil feed gallery passages at about 10 o,clock and 2 o,clock to feed the lifters

on the later big blocks oil from the oil pump enters the rear cam bearing at about 2 0,clock travels around both sides of the rear cam journal and exits slowly thru bearing clearances but the vast majority of the oil flow from the pump travels around the outside of the bearing thru the groove in the block the routes oil directly to the lifter gallerys on both banks into both lifter oil feed gallery passages at about 10 o,clock and 2 o,clock to feed the lifters

trash in the oil passages, and improved oil flow mods

while your engines running theres several gallons of oil per minutes circulating thru your blocks oil pump and the blocks internal oil passages, if you have any crud suspended in that oil like particles of sealant or micro bits of bearing or cam lobe etc, its pumped, thru the oil system along...

garage.grumpysperformance.com

Oil Pan Damage !

I made some studs so I could see better just how far I was from getting the pan to fit. The clearance I needed was really very small , maybe 1/16". So I ground as much as I thought prudent from that corner of the oil pump. With the studs and some longer hex head bolts I was able to bolt the...

garage.grumpysperformance.com

trash in the oil passages, and improved oil flow mods

while your engines running theres several gallons of oil per minutes circulating thru your blocks oil pump and the blocks internal oil passages, if you have any crud suspended in that oil like particles of sealant or micro bits of bearing or cam lobe etc, its pumped, thru the oil system along...

garage.grumpysperformance.com

Last edited by a moderator: