Here is a problem I almost forgot: I have a 1993 SBC with the small HEI Disruptor, it has been upgraded to a MSI performance Disruptor with the Hoped for but NOT fixed module burn out problem.

I have gone through a bunch of these modules, it will start to misfire, and I would replace it and on I would go. On a trip from Phoenix to El Paso, I used three of them, one by Caste Grandy, then at El Paso and the third after getting back to Phoenix.

Seems MSI use OEM Modules with still fail. Cleaned to mounting area and applied the thermo grease.

I had had a 74 G20 Van with a 350 that on trips to LA needed a set of spark plugs from leaking valve sleeves and oil fowling on one side…and by the return trip they would be fowled again…I had my own sand blaster plug cleaner and carried 4 sets.

I have tried nearly every idea I can, I added pure ground wires from the Disruptor to the battery, I added a 30 AMP relay from the Positive term so it gets pure 12volts and I added a pair of Didoes and a old fashion cap/condenser to block and EMI.

It seemed to cure the problem but I am not 100% sure.

Anyone run into the damn modules failing and any cure/fix??

Rich

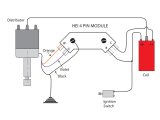

This module:

I have gone through a bunch of these modules, it will start to misfire, and I would replace it and on I would go. On a trip from Phoenix to El Paso, I used three of them, one by Caste Grandy, then at El Paso and the third after getting back to Phoenix.

Seems MSI use OEM Modules with still fail. Cleaned to mounting area and applied the thermo grease.

I had had a 74 G20 Van with a 350 that on trips to LA needed a set of spark plugs from leaking valve sleeves and oil fowling on one side…and by the return trip they would be fowled again…I had my own sand blaster plug cleaner and carried 4 sets.

I have tried nearly every idea I can, I added pure ground wires from the Disruptor to the battery, I added a 30 AMP relay from the Positive term so it gets pure 12volts and I added a pair of Didoes and a old fashion cap/condenser to block and EMI.

It seemed to cure the problem but I am not 100% sure.

Anyone run into the damn modules failing and any cure/fix??

Rich

This module: