GRUMPY??

I'm rebuilding a 265 V8 engine to stick in my 1955 chevy, and while the oil pressure gauge shows good oil pressure I'm getting very little oil flow at the rockers, I read a few of your threads about cam bearings and wonder if you would comment?

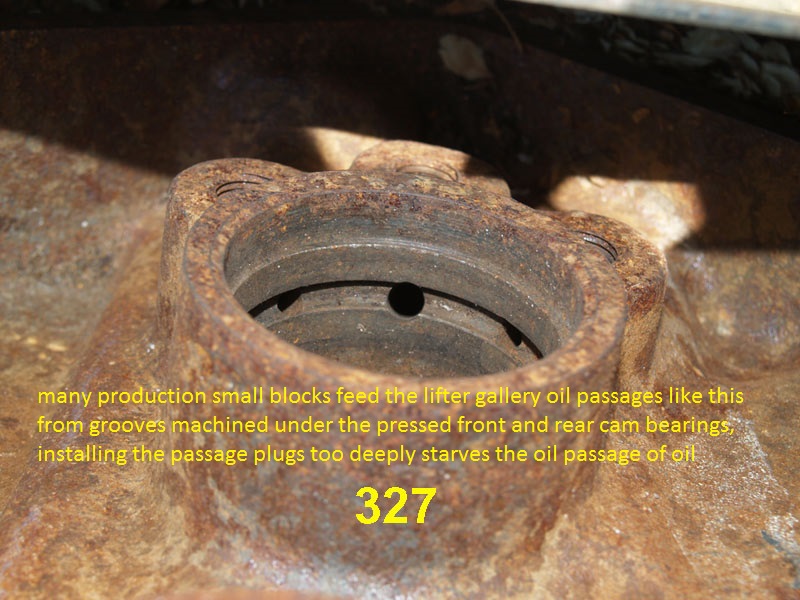

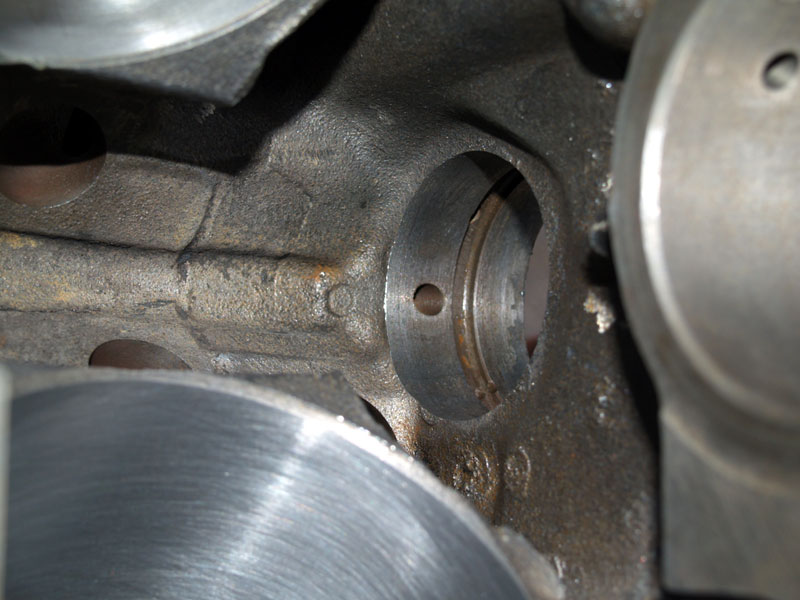

When I got my 265 back from the machine shop the camshaft would not go all the way in. The machine shop installed a common 2 inch freeze plug instead of the correct 2 1/64” shallow rear cam plug. The back of the camshaft was hitting the freeze plug! The thrust surface on the cam sprocket is supposed to ride against the machined surface at the front of the block to correctly position the camshaft. I knocked out the incorrect freeze plug and test fit the camshaft with the sprocket installed. It’s a good thing I checked because I found that they had also installed the cam bearing almost ¼ inch too far back. The back oil hole in the cam bearing was completely blocked of by the camshaft. If I had installed the engine as the machine shop had built it there would have been zero oil supply to the lifters.

ID ALSO POINT OUT 1965-1967 BBC ENGINES HAD SIMILAR REAR CAM BEARING OIL FLOW DESIGN ISSUES

WOW! don,t remember seeing many 265 SBC engines over the last 30 years that are being rebuilt, but I certainly remember they require a bit different rear cam bearing and cam, soJust lining up the rear cam bearing holes to the block is not good enough on a 265. The bearing must also line up with the rear journal of the camshaft to ensure that both holes line up with the machined slot in the camshaft. The best way to check the position of the rear cam bearing is to test fit the bearing on the camshaft before you install it in the block. After you install the cam bearings, bolt the cam sprocket on the camshaft and test fit the camshaft into the block. The back edge of the camshaft should be flush with the back edge of the rear cam bearing. The point here is don’t trust the machine shop to correctly install the rear cam bearing in your 265. Have the machine shop leave the cam plug out so you can check the rear cam bearing position yourself.

After you are sure the rear cam bearing is installed correctly it’s time to install the rear cam plug. Do not use a 2 inch freeze plug! The 265 uses a rear cam plug which is slightly smaller in diameter than the cam plug used in a 1958 and up engines. 265 V8’s use a 2 1/64 inch shallow cam plug, while 1958 and up engines use a 2 3/32 inch cam plug. There is a machined step in the newer engines that prevent driving the plug to deep. There is no step machined into the block on a 55-57 engine, so care must be taken not to drive the plug to deep. The 1956 Shop Manual says the cam plug should be “installed flush to 1/32” deep to maintain a level surface on the rear of the cylinder block”. Here is my original cam plug and the correct replacement.

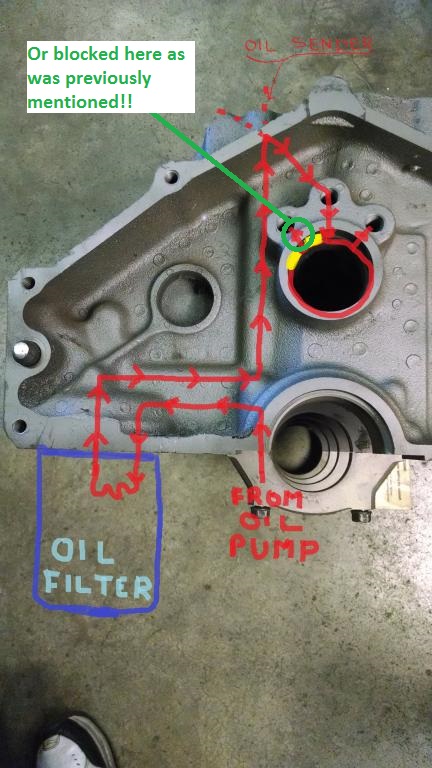

All small block Chevy engines were produced with an annular groove under the rear cam bearing regardless of what year they are. This groove supplies oil to the two lifter galleries. The difference in the 55-56 engines is in how the oil is supplied to the groove. On 1955 and 1956 265’s full oil pressure from the main oil galley passed through a drilled passage to feed a small hole in the rear cam bearing. As the camshaft rotated the machined slot in the rear cam journal would uncover the hole allowing oil to flow (via the machined slot) out a second hole in the cam bearing that was located over the annular groove. This setup supplied "pulsed" oil to the annular groove which supplies reduced pressure to the lifter galleries.

Starting in 1957 the drilled passage from the main oil gallery was redesigned to connect directly to the annular groove. With this change the annular groove and the lifter galleries have full oil pressure. The rear cam bearing on 57 and up engines only needs one oil hole to lubricate the rear cam journal from high pressure oil in the annular groove, and there is no longer a need for the machined slot on the rear cam journal.

A popular modification on 55-56 265 blocks is to grind an oil passage in the block connecting the drilled oil feed passage to the annular groove. This way the 265’s will oil just like the other SBC’s, and there is no longer a need to use a camshaft with a machined slot. If you do this modification you should use a 1957 and up "window" distributor because the higher oil pressure in the lifter galleries may be too much for the 1955-56 distributor which may cause it to leak oil.

Here is a 265 and a newer 327 with the rear cam bearings removed. Note the different location of the drilled oil supply passage from the main oil gallery on these two engines.

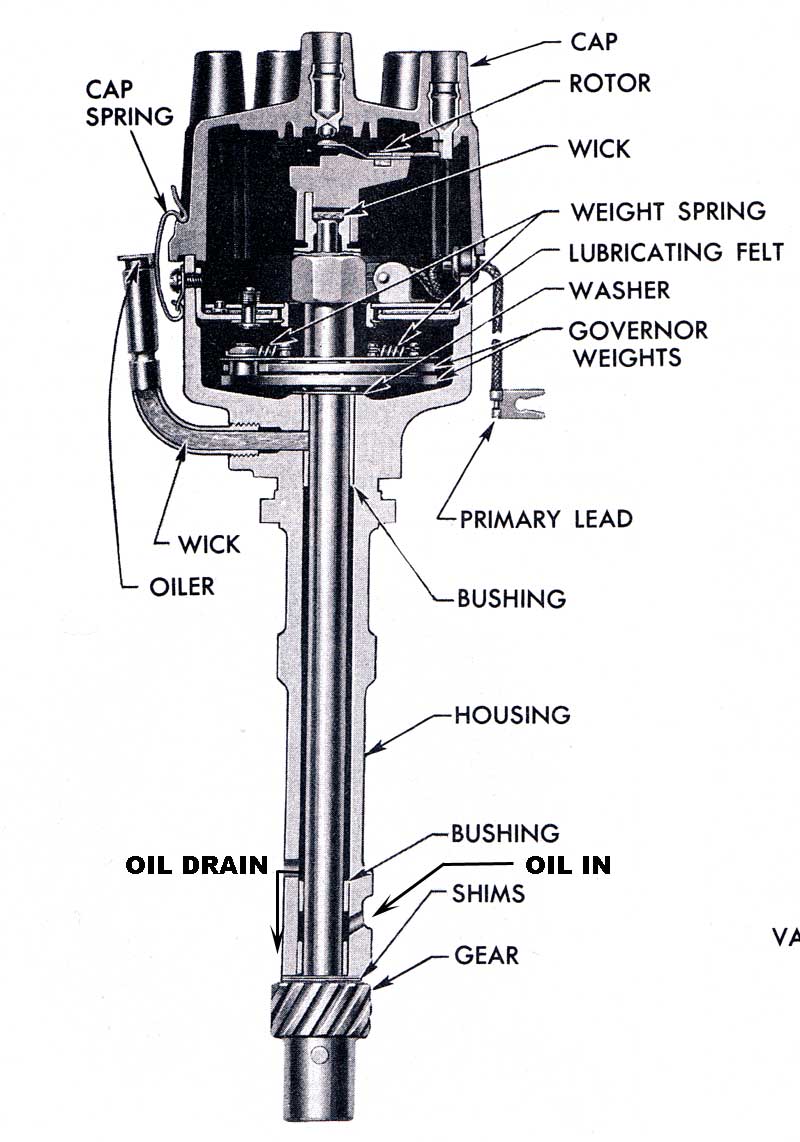

If you convert the 265 to full pressure oiling you may have problems with your 55-56 distributor filling with oil. The lower bushing on these early distributors was fed low pressure "pulsed" oil from the RH lifter gallery. After the oil lubricates the lower distributor bushing it drains out via a hole above the bushing and then spills down the flat on the side of the distributor housing. That is what the "flat" on a 55-56 distributor is for, to let the oil from the distributor drain out. If you convert to full pressure oiling you could overcome the capacity of the drain hole, sending oil up the shaft, past the upper bushing, into the top of the distributor where it will cause all kinds of problems. A worn lower distributor bushing, combined with a high pressure-high volume oil pump, will make the problem worse. In 1957 Chevrolet redesigned the distributor to splash oiling from the drive gear so oil pressure in the lifter galley won’t have any affect on the distributor.

1957 and up distributors will work just fine in any 265. Even an HEI distributor will work in both stock and modified 265’s. If you are going to use the early 265 distributor you should not modify the block for full pressure oiling.

Steve

.

Ill post these related quotes that may be helpful and a few related links to read through,

as always, when your not 100% sure, what your doing is correct,

(and even when you think you are!) it sure helps to stop and do some basic research to verify your proceeding with the correct parts,clearances etc. yes you might have a problem, if your local machine shop forgot the early SBC engines had a slightly different rear block oil flow set up from the more current versions. BTW verify that your push rods are completely free of oil sludge build-up with a good 24 hour solvent soak and blow them out with high pressure air, and if they are really crappy pipe cleaners run through each one.

http://www.speedwaymotors.com/Speedway-Small-Block-Chevy-Pushrods-5-16-Inch,3214.html

yeah you might even need new ones and verify the rocker geometry

as always a logical series of tests should isolate the cause but Id be thinking the wrong cam bearings were installed or installed incorrectly here

if the oil flow came through the push rods as you primed the engine, in that order your rear cam bearing may not be correctly indexed/installed incorrectly, BOTH the front and rear cam bearings feed oil across to the other lifter gallery when the front and rear cam bearings are correctly indexed to the lifter gallery oil feeds

http://garage.grumpysperformance.co...all-tools-install-info.1479/page-2#post-35245

THE REAR CAM BEARING AND MAIN OIL FEED CENTER OIL PASSAGE AND BOTH LIFTER GALLERY'S ARE FED FROM THE REAR MAIN BEARING AND OIL PUMP THRU THE GROOVE UNDER THE REAR CAM BEARING AND HOLES INDEXED IN IT, ALONG WITH THE READ MAIN CRANK BEARING FED FROM THE CAM BEARING DIRECTLY ABOVE AS ARE ALL THE MAIN BEARINGs

THE FRONT CAM BEARING ALLOWS OIL FLOW TO CROSS OVER ANND FEED BACK DOWN THE OTHER LIFTER GALLERY

NOTICE THE FRONT BEARING FEEDS OIL FROM BOTH SIDES

notice the cam bearing groove feeds both lifter gallerys

LATER SBC ENGINES MODIFIED THE OIL FEED

as these gentlemen do a great job explaining your issue WITH THE EARLY SBC OILING with pictures

"Farm boy" The slot in the original camshaft in out of my 265 is .510” X 1.2” and centered in the middle of the rear journal. A local machine shop had no trouble cutting a slot in a replacement cam.

While you have the cam out you should check the position of the rear cam bearing. You can check it with a tape measure. The front edge of the bearing should be 20¼ inches from the cam sprocket thrust surface on the front of the block. The rear edge of the cam bearing should be 21¼ inches. If the cam bearing is less than 1 inch long it not the correct bearing with two oil holes. If the bearing is the correct 1 inch bearing, but is installed too shallow or too deep, the oil holes in the bearing won’t line up with the machined slot in the camshaft and the lifters won’t get any oil. Hopefully your cam bearing is the right one and is installed at the correct depth.

"

"f.i.57chevynut"]In your original post you didn't mention if the 283 style camshaft was a hydraulic or a solid. The factory notches that are shown in all the previous posts are for hydraulic cams. If the cam was an original solid lifter 55-56 the notch was very small.

The cam on the left is a factory 210-225 HP solid lifter cam. Since solids didn't need oil to operate, the notch allowed enough oil to lube the tip of the pushrod, rocker ball socket and tip of the valve. Since the oil delivery is impulse rather than full time flow, the 55-56 lifters didn't restrict the flow from the lifter. In 57 the lifter was redesigned to restrict the flow because the oil flow was constant. So if you have original 55-56 lifters you don't want to make the cam bearing a full time flow as it will flood the top end with oil. The full time internal oiling with the later lifters never changed after 57

( on small blocks. 65-66 big blocks had a full grooved camshaft. Go figure.).

The easiest way to install your rear cam bearing is to line up the holes in the block with the holes in the bearing checking the alignment with a nail or wire. That will put it at the correct depth to align with the notch in the cam."

"Farm boy" "f.i.57chevynut" The easiest way to install your rear cam bearing is to line up the holes in the block with the holes in the bearing checking the alignment with a nail or wire. That will put it at the correct depth to align with the notch in the cam.[/quote]

Driving the rear cam bearing in until the holes in the bearing are lined up with the holes in the block won’t guarantee the cam bearing is installed at the correct depth. Notice that the oil holes in the block are much bigger than the holes in the bearing. It is possible to have the cam bearing holes aligned with the large holes in the block but not be fully exposed to the slot in the cam. In fact if the rear cam bearing in a 265 is installed as little as 1/8 inch off the oil supply to the lifters will be cut off. For proper oiling the rear cam bearing must be aligned with the slot in the rear cam journal.

"

\\ RELATED INFO THAT YOU PROBABLY NEED TO READ

http://garage.grumpysperformance.co...er-lifter-install-direction.11398/#post-52227

http://garage.grumpysperformance.com/index.php?threads/should-you-buy-bare-or-assembled-heads.534/

http://garage.grumpysperformance.co...ed-holes-in-bearings-shells.10750/#post-46966

http://garage.grumpysperformance.co...all-tools-install-info.1479/page-2#post-35245

http://garage.grumpysperformance.com/index.php?threads/1965-66-396-engines.10360/#post-42658

http://garage.grumpysperformance.com/index.php?threads/sbc-spacer-bearings.3058/

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-51146

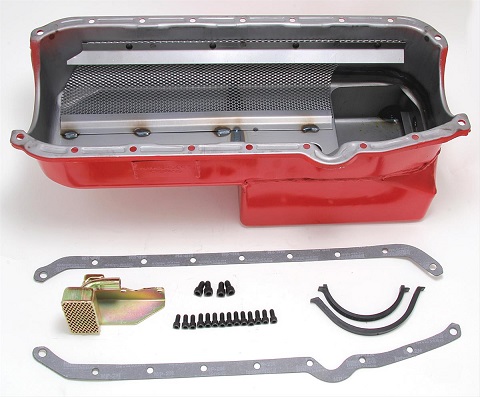

I think the hamburger oil pan is a better value At $242 than most of the common mid priced oil pans

notice the better oil control features

https://www.summitracing.com/parts/ham-1088/overview/

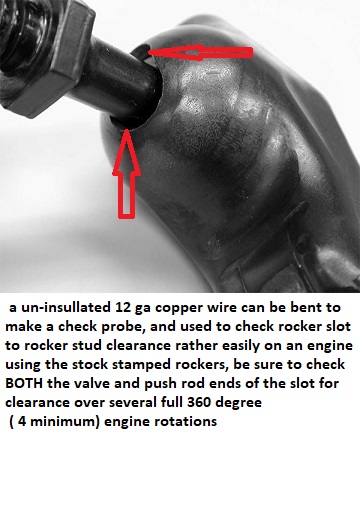

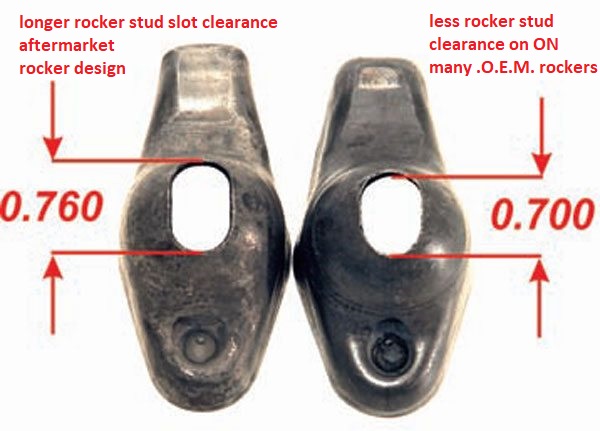

the grooved rocker pivot ball design was an effort by G.M. engineering to economically solve the issue of marginal oil flow causing rocker ball galling, and resulting noisy, or broken valve trains

check all valve train geometry and clearance on any engine you assemble or modify the valve train on.

http://www.milodon.com/oil-pans/street-oil-pans-sbchevy.asp

http://www.jegs.com/p/Moroso/Moroso-Street-Strip-Oil-Pans/763991/10002/-1

https://www.summitracing.com/search/brand/hamburgers-performance/part-type/oil-pans

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?search=action&category=1301

http://www.stefsperformance.net/ste...oil-pans/aluminum-oil-pans-pumps#!prettyPhoto

Last edited: