bytor

Well-Known Member

Planning a 383 build for a street, weekend car. 78 vette with a 4 speed and 3.73 rear end. I would like some feedback on my cam selection.

383 Build components I’m considering,

- Dart SHP 200cc Aluminum heads http://www.jegs.com/i/Dart/301/127322/10002/-1

- Weiand 8150 dual plane intake?

- ~9.7:1 compression

- 1 5/8 long tube headers

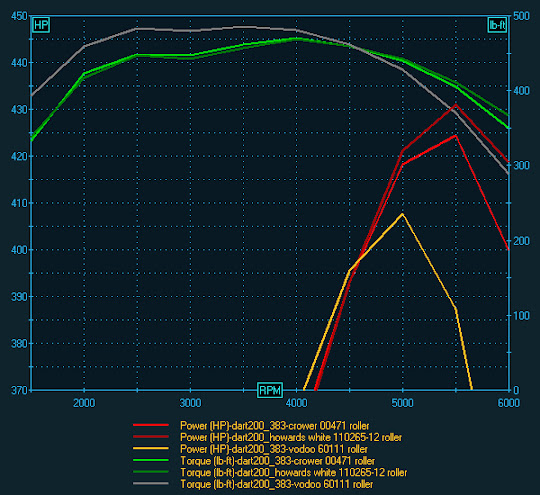

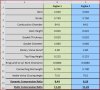

Playing around with DynoSim5, I have narrowed it down to two cams. Both provide around 410hp at 5500RPM. Are these too small for my setup?

The first one is a flat tapped Comp Cams XE-274 http://www.summitracing.com/parts/CCA-12-246-3/

The second one is Lunati barebones 10020 roller. http://www.summitracing.com/parts/LUN-10020LK/

383 Build components I’m considering,

- Dart SHP 200cc Aluminum heads http://www.jegs.com/i/Dart/301/127322/10002/-1

- Weiand 8150 dual plane intake?

- ~9.7:1 compression

- 1 5/8 long tube headers

Playing around with DynoSim5, I have narrowed it down to two cams. Both provide around 410hp at 5500RPM. Are these too small for my setup?

The first one is a flat tapped Comp Cams XE-274 http://www.summitracing.com/parts/CCA-12-246-3/

The second one is Lunati barebones 10020 roller. http://www.summitracing.com/parts/LUN-10020LK/